Rubber Conveyor Belt Market Report

Published Date: 22 January 2026 | Report Code: rubber-conveyor-belt

Rubber Conveyor Belt Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Rubber Conveyor Belt market, covering key insights from 2023 to 2033, including market size, growth forecasts, segment performance, regional insights, and emerging trends.

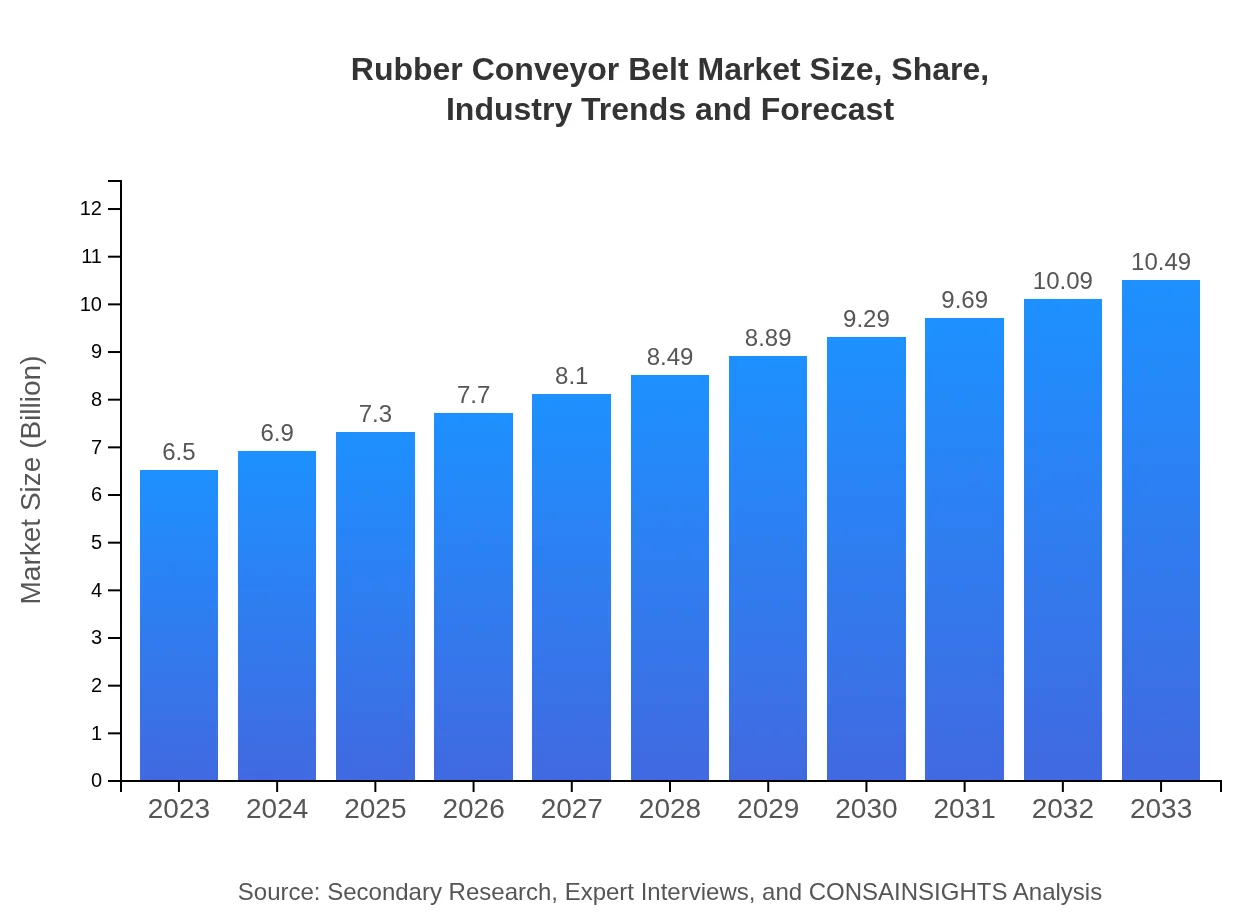

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.50 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $10.49 Billion |

| Top Companies | ContiTech AG, Fenner Dunlop, Goodyear Engineered Products, Bridgestone Corporation |

| Last Modified Date | 22 January 2026 |

Rubber Conveyor Belt Market Overview

Customize Rubber Conveyor Belt Market Report market research report

- ✔ Get in-depth analysis of Rubber Conveyor Belt market size, growth, and forecasts.

- ✔ Understand Rubber Conveyor Belt's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rubber Conveyor Belt

What is the Market Size & CAGR of Rubber Conveyor Belt market in 2023?

Rubber Conveyor Belt Industry Analysis

Rubber Conveyor Belt Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rubber Conveyor Belt Market Analysis Report by Region

Europe Rubber Conveyor Belt Market Report:

Europe's market is projected to grow from $1.97 billion in 2023 to $3.18 billion by 2033, spurred by stringent regulations promoting eco-friendly conveyor solutions and advances in recycling practices.Asia Pacific Rubber Conveyor Belt Market Report:

In the Asia Pacific region, the Rubber Conveyor Belt market is poised to grow from $1.23 billion in 2023 to $1.98 billion by 2033. This growth is fueled by industrial expansion and infrastructure development projects.North America Rubber Conveyor Belt Market Report:

In North America, the market size will expand from $2.36 billion in 2023 to $3.81 billion by 2033, driven by technological advancements and a shift toward automation in industries.South America Rubber Conveyor Belt Market Report:

The South American market is small but growing, with revenues expected to increase from $0.04 billion in 2023 to $0.07 billion in 2033. The rise in mining and construction activities is a significant contributor.Middle East & Africa Rubber Conveyor Belt Market Report:

In the Middle East and Africa, the market will increase from $0.89 billion in 2023 to $1.44 billion by 2033, as significant investments in oil and gas projects drive demand for durable conveyor systems.Tell us your focus area and get a customized research report.

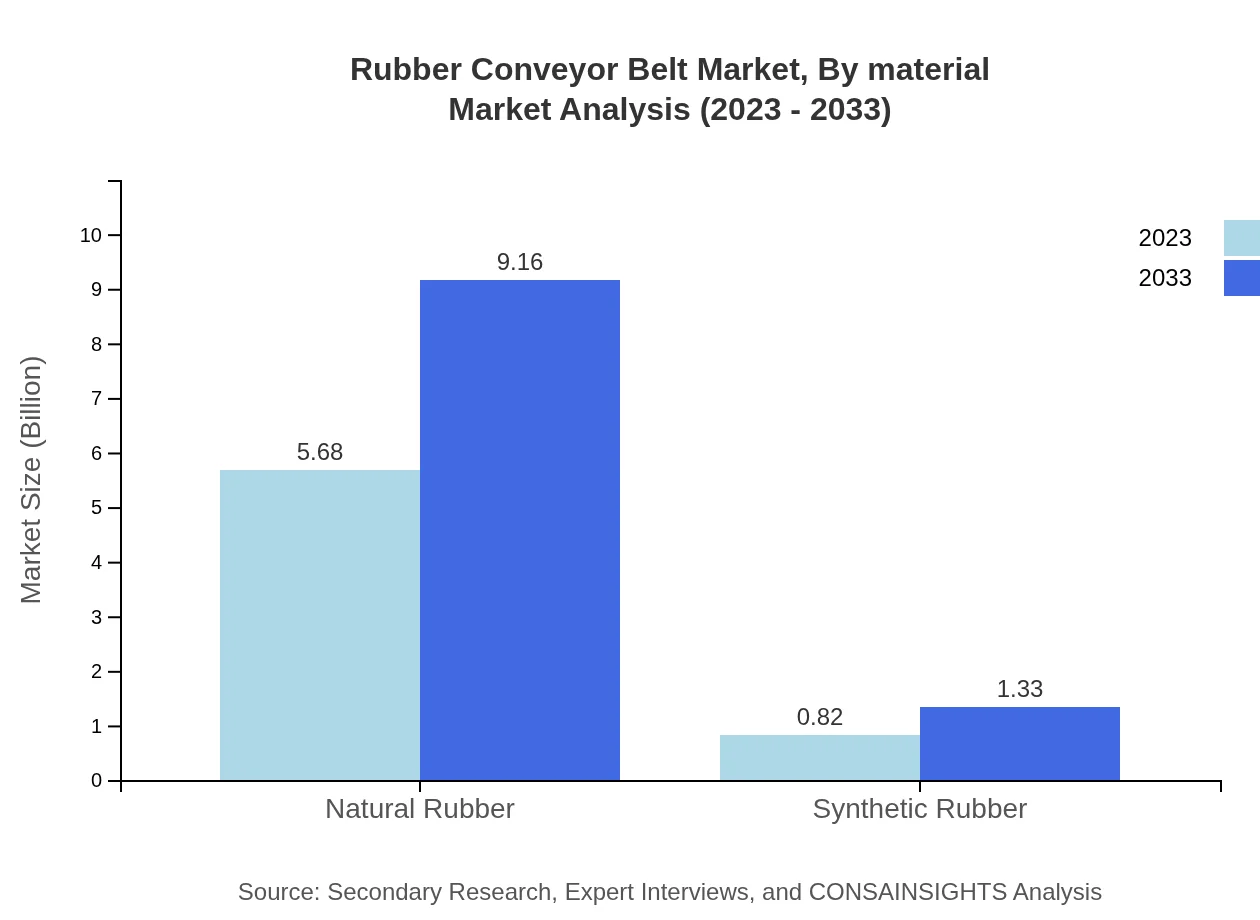

Rubber Conveyor Belt Market Analysis By Material

The market comprises natural rubber and synthetic rubber segments. In 2023, natural rubber holds a market share of 87.33%, equating to a size of $5.68 billion. By 2033, it is expected to reach $9.16 billion, indicating strong demand. Synthetic rubber, while lower in share at 12.67%, is anticipated to see growth due to its versatility in harsh environments.

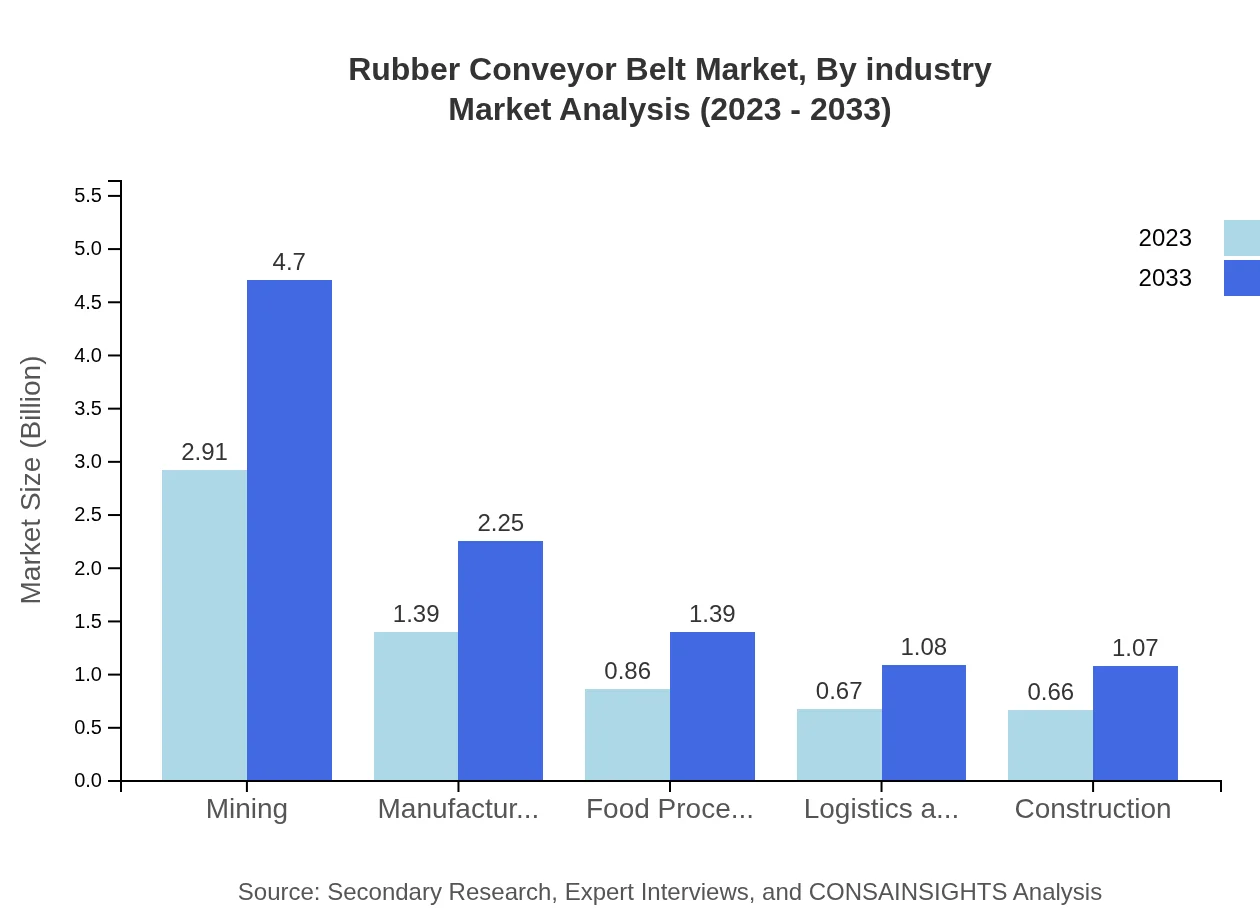

Rubber Conveyor Belt Market Analysis By Industry

The mining industry remains the largest segment, with a market share of 44.83% in 2023, accounting for $2.91 billion. This is expected to grow to $4.70 billion by 2033. Other sectors such as manufacturing and food processing also form significant portions, reflecting diverse applications.

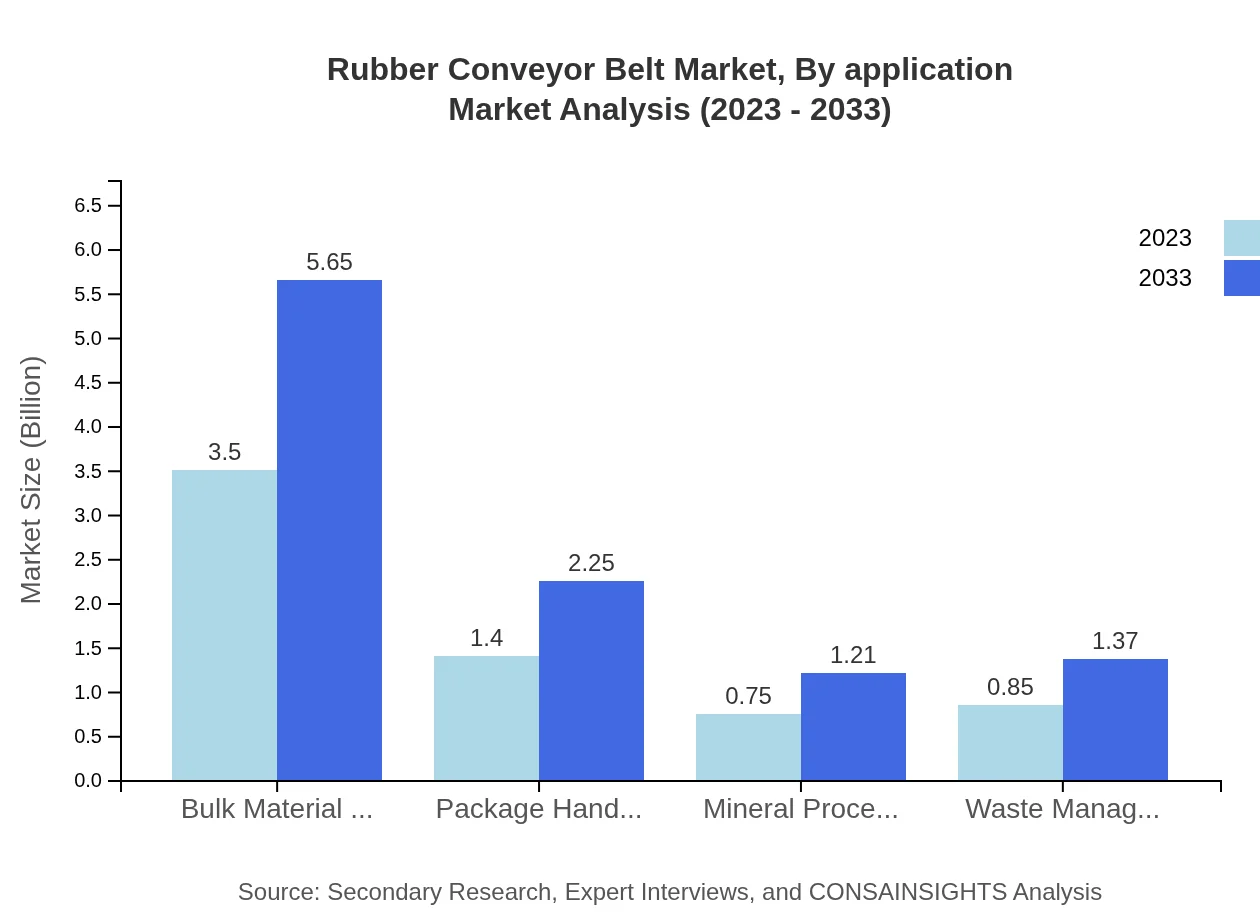

Rubber Conveyor Belt Market Analysis By Application

Segmented by application, bulk material handling, logistics, and waste management dominate the market. Each application serves crucial roles within various industries, influencing demand for specific belt types.

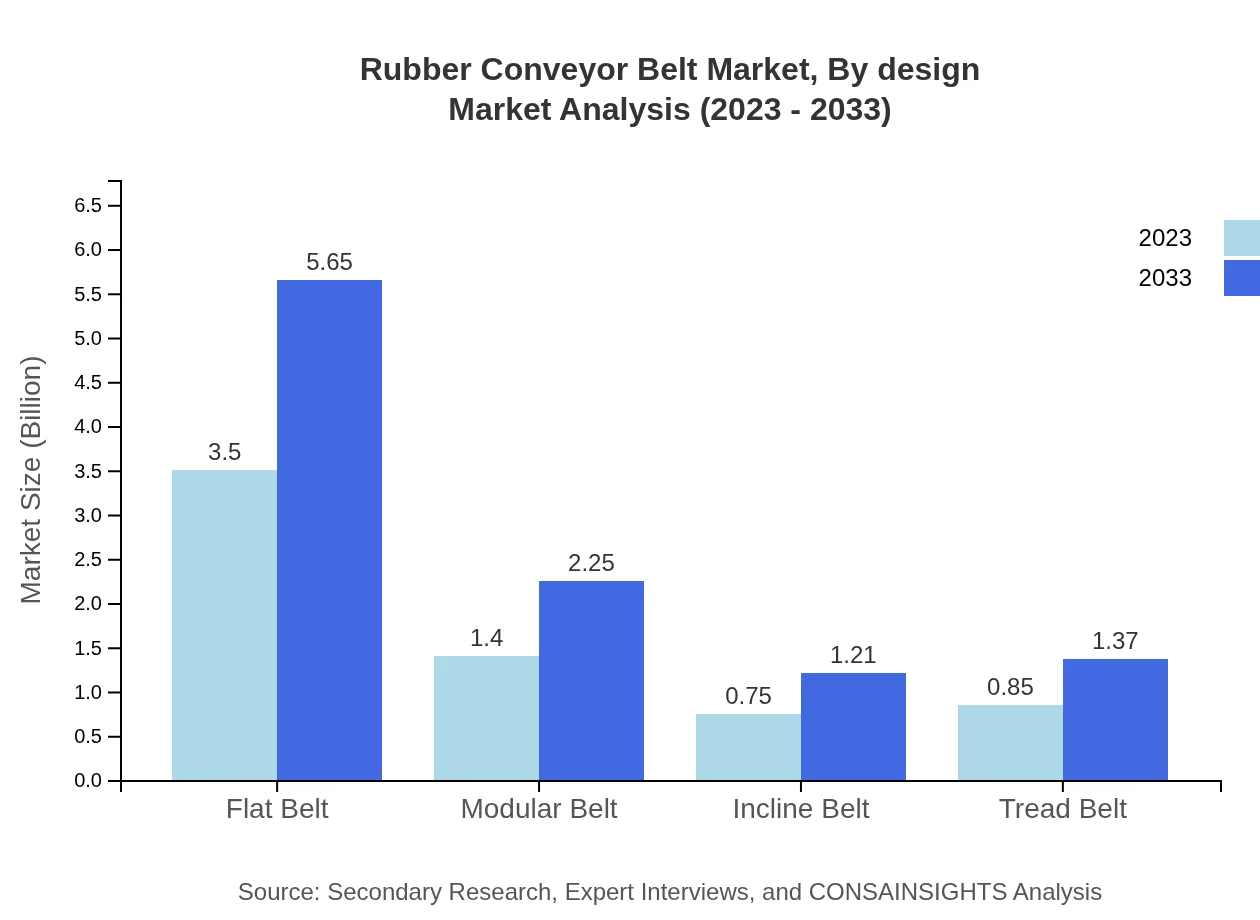

Rubber Conveyor Belt Market Analysis By Design

Various design types such as flat belts, modular belts, and incline belts are prevalent, with flat belts leading the market. In 2023, flat belts represent 53.92% of the market share, with a size of $3.50 billion.

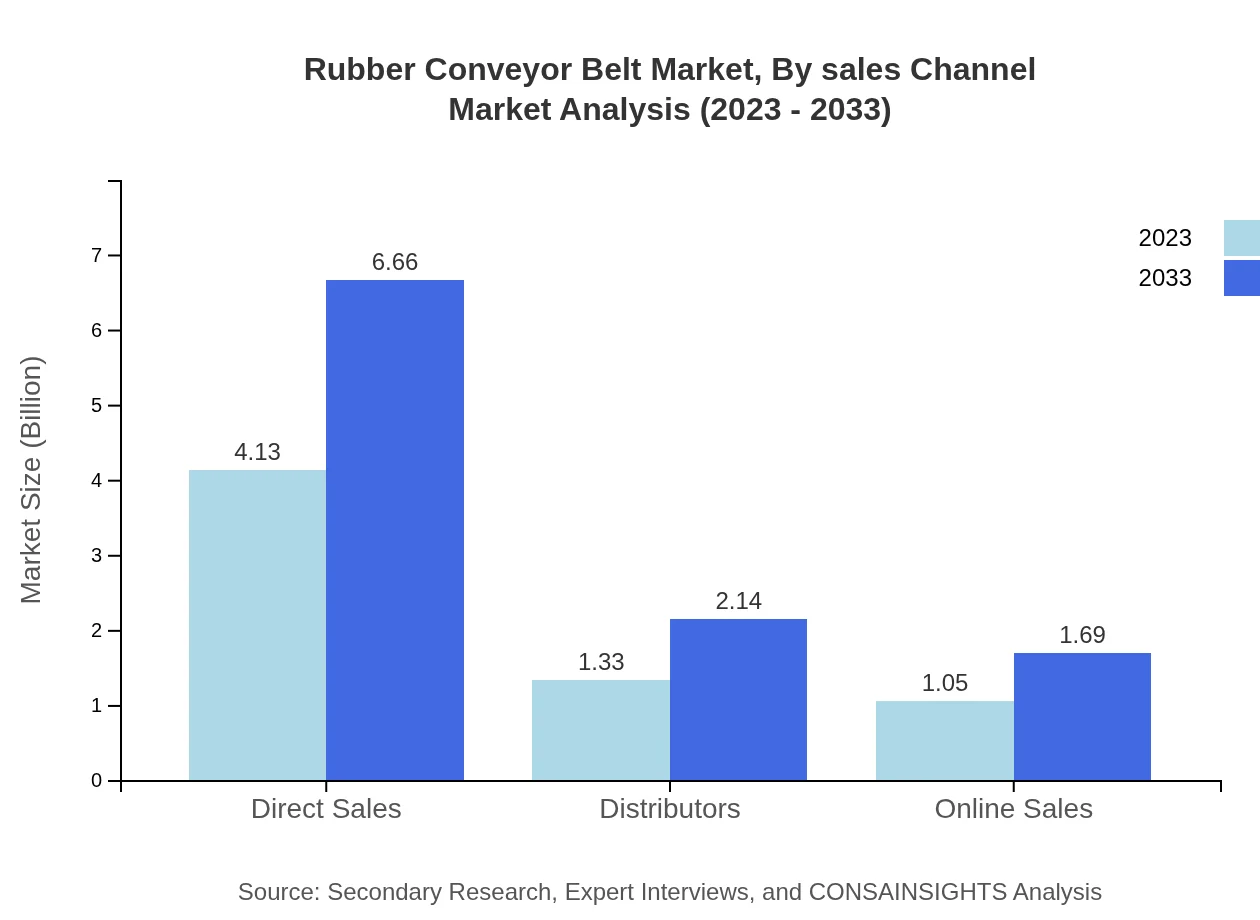

Rubber Conveyor Belt Market Analysis By Sales Channel

The sales channels include direct sales, distributors, and online sales. Direct sales dominate with a share of 63.51% in 2023. This channel continues to be vital due to the complexity of product specifications required by industrial consumers.

Rubber Conveyor Belt Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rubber Conveyor Belt Industry

ContiTech AG:

A leading manufacturer specializing in the production of high-performance conveyor belts and related systems tailored for various industries.Fenner Dunlop:

Known for its extensive range of conveyor belts and offering high-quality products to mining and industrial sectors worldwide.Goodyear Engineered Products:

A significant player in developing innovative conveyor solutions, with a focus on custom configurations for unique applications.Bridgestone Corporation:

Renowned for integrating advanced technology into their products, Bridgestone provides durable conveyor belts suitable for high-demand environments.We're grateful to work with incredible clients.

FAQs

What is the market size of rubber Conveyor Belt?

The global rubber conveyor belt market is valued at approximately $6.5 billion in 2023, with a projected CAGR of 4.8% from 2023 to 2033, indicating steady growth and increasing demand across various sectors.

What are the key market players or companies in the rubber Conveyor Belt industry?

Key players in the rubber conveyor belt market include established manufacturers such as Continental AG, Bridgestone Corporation, and Fenner PLC, along with regional players who contribute to diverse industry applications.

What are the primary factors driving the growth in the rubber Conveyor Belt industry?

Growth in the rubber conveyor belt industry is driven by rising industrial automation, increased demand in mining and logistics sectors, and advancements in rubber technology that enhance durability and performance.

Which region is the fastest Growing in the rubber Conveyor Belt?

Asia Pacific is the fastest-growing region for the rubber conveyor belt market, expected to rise from $1.23 billion in 2023 to $1.98 billion by 2033, fueled by expanding industrial activities and infrastructure projects.

Does ConsaInsights provide customized market report data for the rubber Conveyor Belt industry?

Yes, ConsaInsights offers customized market report data tailored to client specifications within the rubber conveyor belt industry, ensuring relevant insights and analyses to meet specific business needs.

What deliverables can I expect from this rubber Conveyor Belt market research project?

Clients can expect comprehensive deliverables including detailed market analysis reports, growth projections, competitive landscape assessments, and tailored recommendations based on the latest market trends.

What are the market trends of rubber Conveyor Belt?

Market trends in the rubber conveyor belt industry include increasing adoption of eco-friendly materials, enhanced modular belt designs, growth in e-commerce logistics, and the demand for automation solutions in manufacturing and processing sectors.