Rubber Testing Equipment Market Report

Published Date: 31 January 2026 | Report Code: rubber-testing-equipment

Rubber Testing Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report presents a comprehensive analysis of the Rubber Testing Equipment market, covering key insights, size forecasts, industry trends, and regional performance from 2023 to 2033.

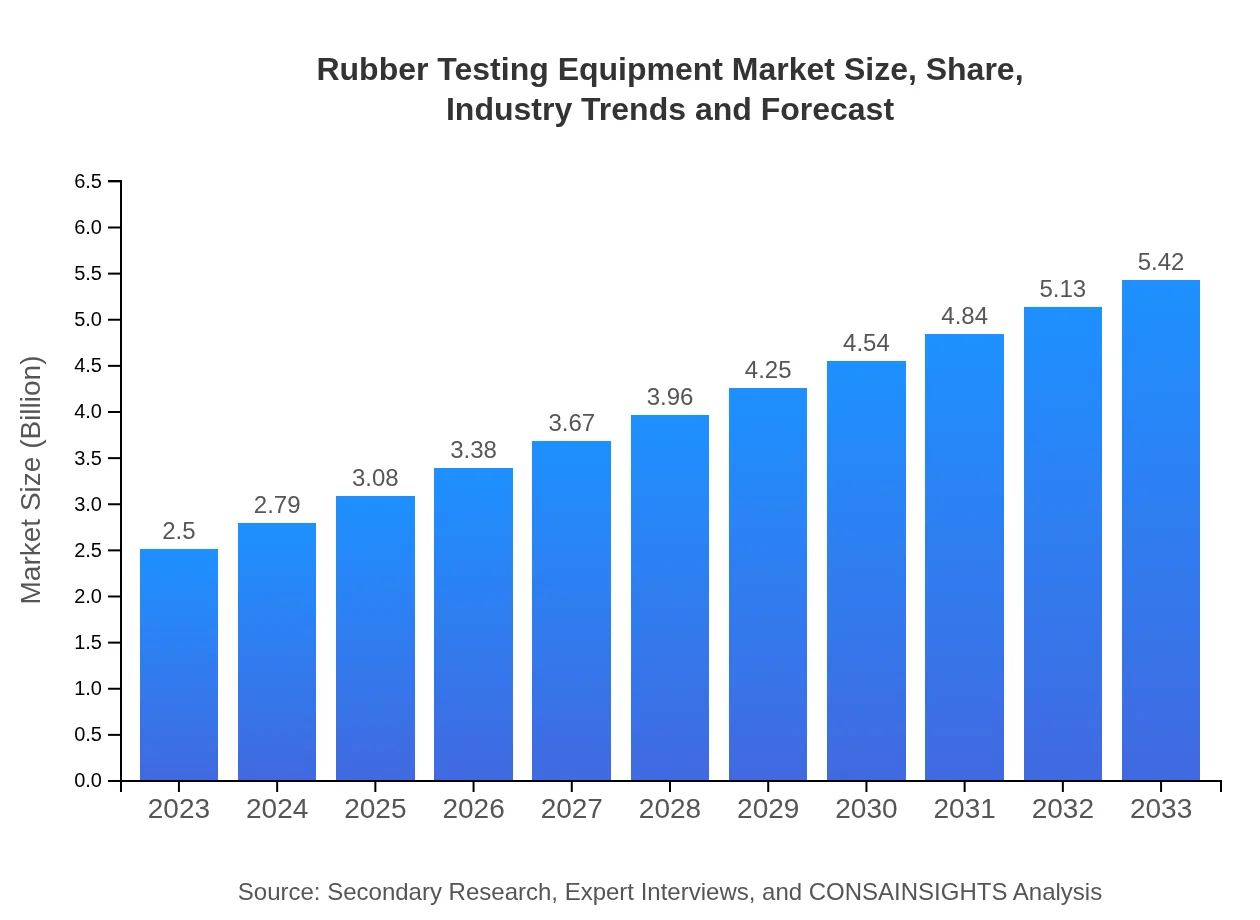

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $5.42 Billion |

| Top Companies | Instron, MTS Systems Corporation, ZwickRoell, Tensile Testing Machines (TTM) |

| Last Modified Date | 31 January 2026 |

Rubber Testing Equipment Market Overview

Customize Rubber Testing Equipment Market Report market research report

- ✔ Get in-depth analysis of Rubber Testing Equipment market size, growth, and forecasts.

- ✔ Understand Rubber Testing Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rubber Testing Equipment

What is the Market Size & CAGR of Rubber Testing Equipment market in 2023?

Rubber Testing Equipment Industry Analysis

Rubber Testing Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rubber Testing Equipment Market Analysis Report by Region

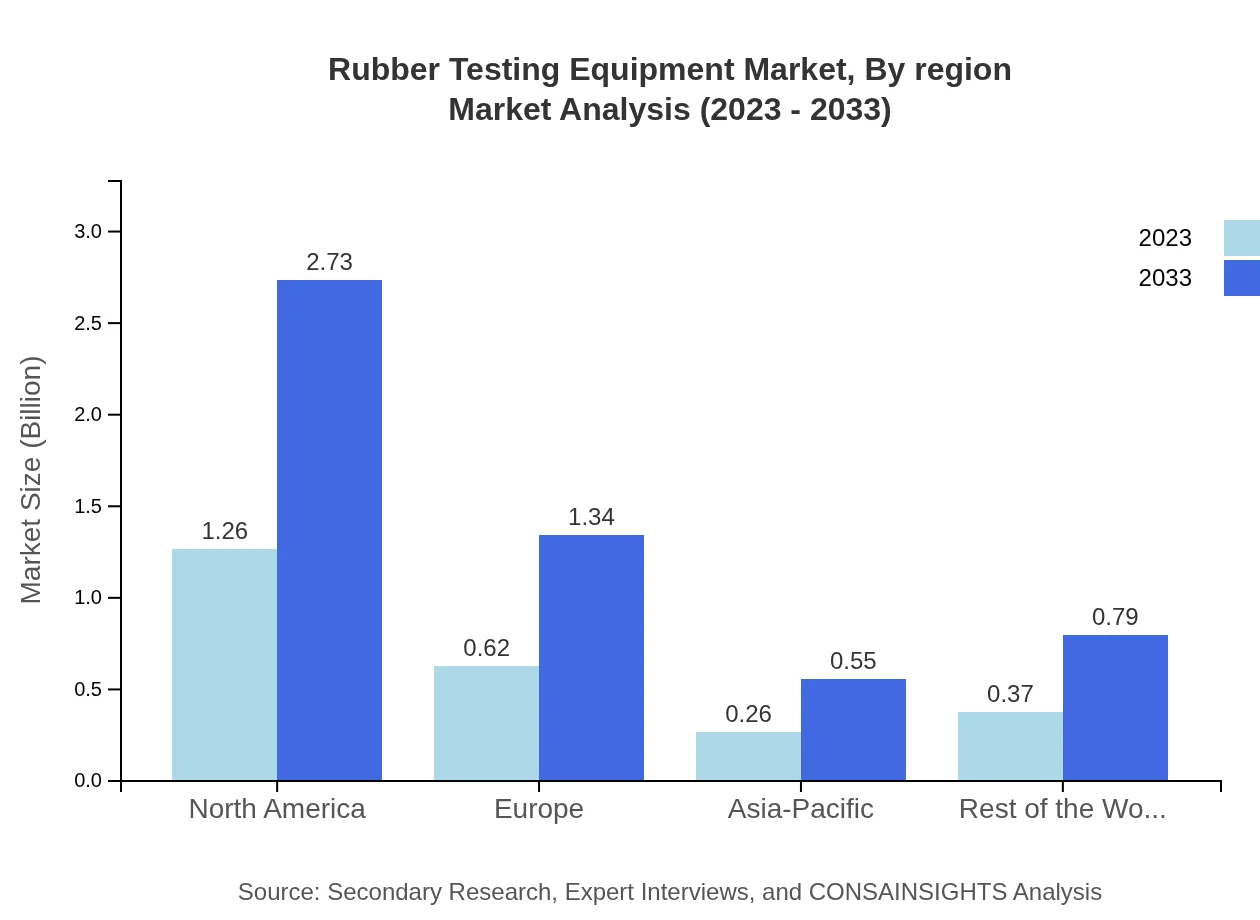

Europe Rubber Testing Equipment Market Report:

Europe's Rubber Testing Equipment market is estimated at $0.76 billion in 2023 and is expected to grow to $1.64 billion by 2033. The region's focus on automotive and aerospace sectors, coupled with strict compliance and quality standards, drives the demand for sophisticated testing equipment.Asia Pacific Rubber Testing Equipment Market Report:

The Asia Pacific region is witnessing significant growth, characterized by an increasing industrial base and strong demand for high-quality rubber components. The market size in 2023 is $0.49 billion, projected to grow to $1.06 billion by 2033, driven by advancements in testing methods and a booming automotive industry in countries like China and India.North America Rubber Testing Equipment Market Report:

North America, dominating the sector, has a market size of $0.87 billion in 2023, forecasted to reach $1.89 billion in 2033. Growth in this region is fueled by stringent regulations in the automotive sector, along with a high prevalence of advanced testing facilities, positioning it as a leader in innovations and quality assurance.South America Rubber Testing Equipment Market Report:

In South America, the Rubber Testing Equipment market, valued at $0.11 billion in 2023, is expected to grow to $0.24 billion by 2033. This growth correlates with industrial advancements and increasing attention towards quality control in manufacturing processes across various sectors.Middle East & Africa Rubber Testing Equipment Market Report:

In the Middle East and Africa, the market size for Rubber Testing Equipment is projected to grow from $0.27 billion in 2023 to $0.59 billion by 2033. The development of local manufacturing facilities and increased investment in quality assurance contribute to this growth, alongside rising automotive and industrial activities in the region.Tell us your focus area and get a customized research report.

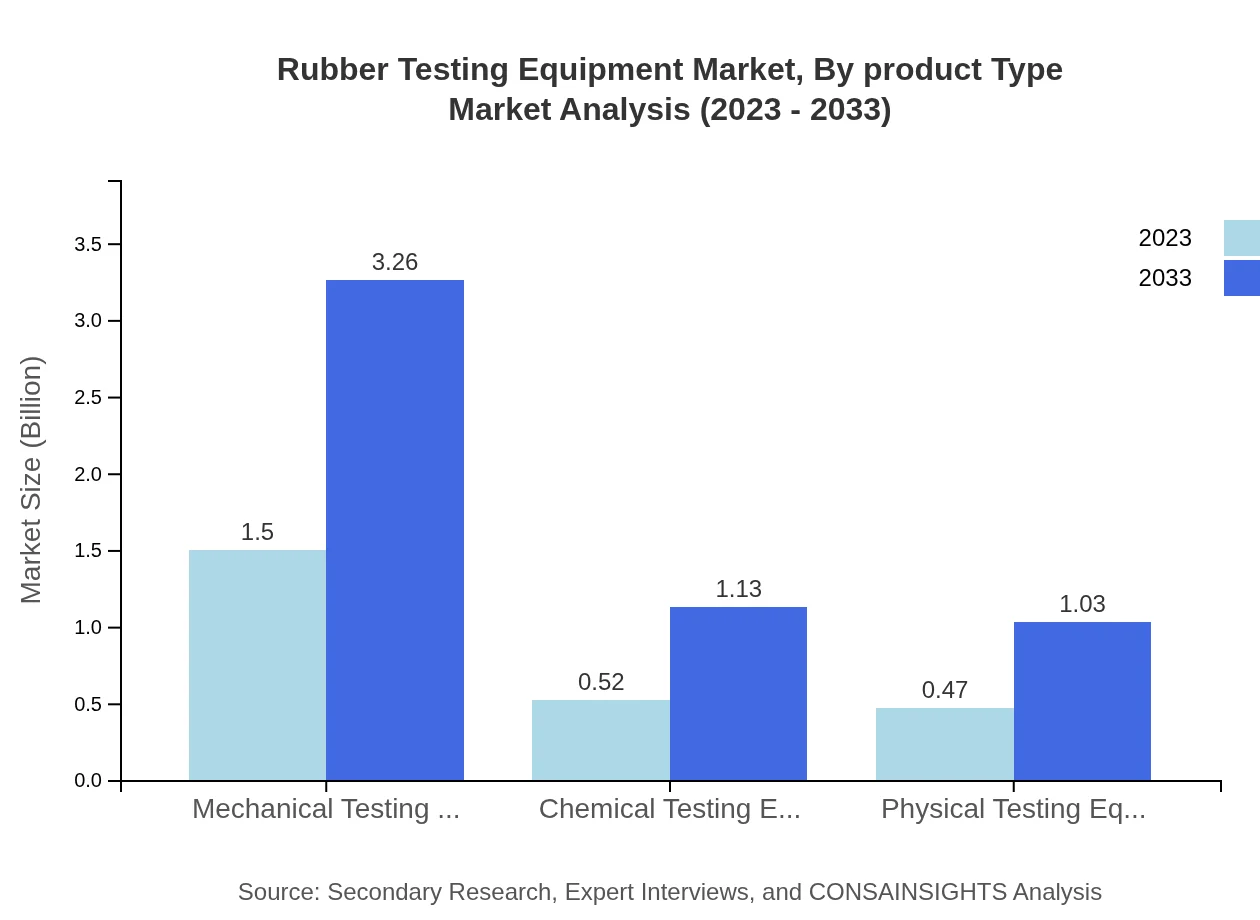

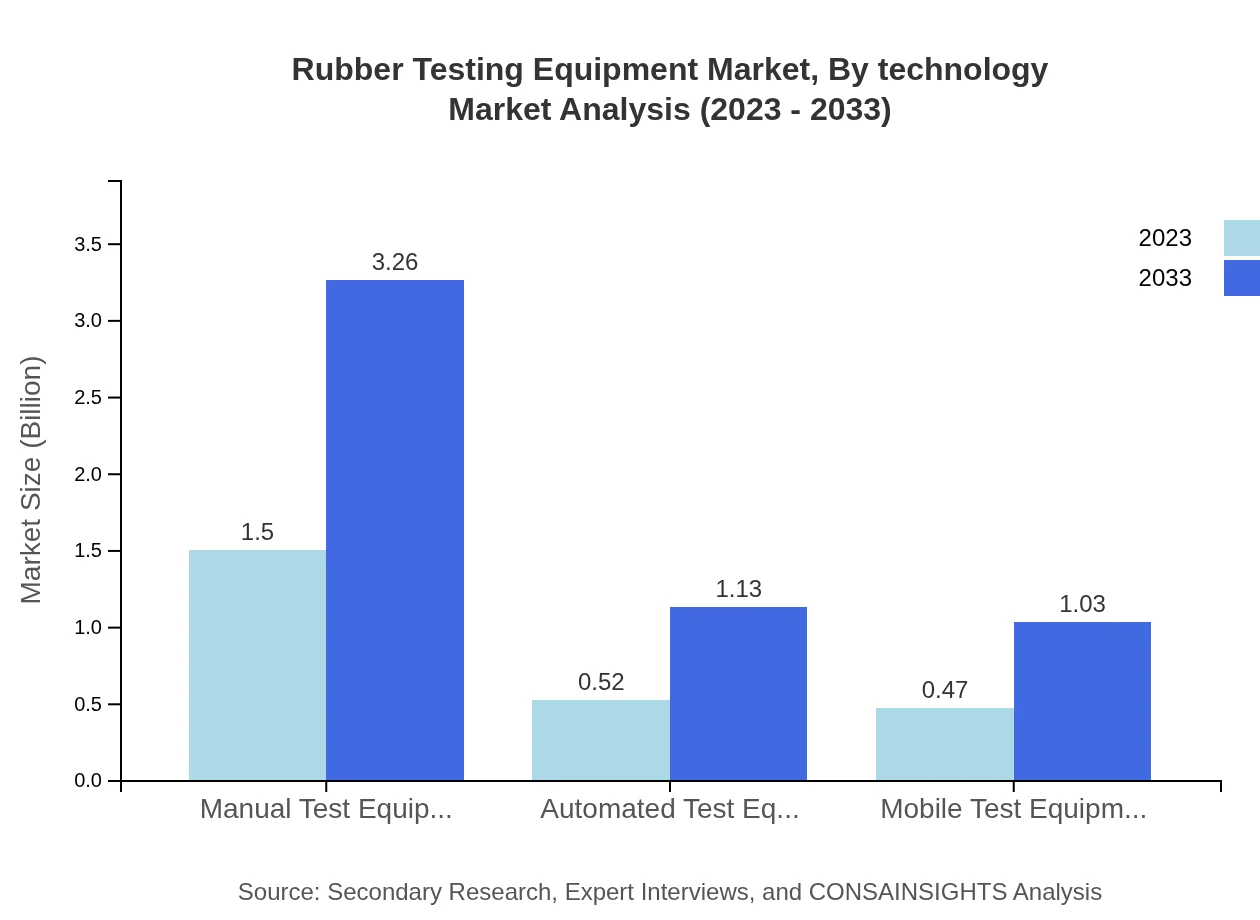

Rubber Testing Equipment Market Analysis By Product Type

The Rubber Testing Equipment market can be segmented into manual, automated, and mobile testing equipment. In 2023, manual testing equipment is valued at $1.50 billion, with a projected increase to $3.26 billion by 2033, holding a significant market share of 60.14%. Automated equipment, valued at $0.52 billion in 2023, is expected to grow to $1.13 billion by 2033, catering to the demand for efficiency and accuracy in testing processes. Mobile testing equipment, valued at $0.47 billion in 2023, is anticipated to reach $1.03 billion by 2033, reflecting the trend towards flexibility in testing solutions.

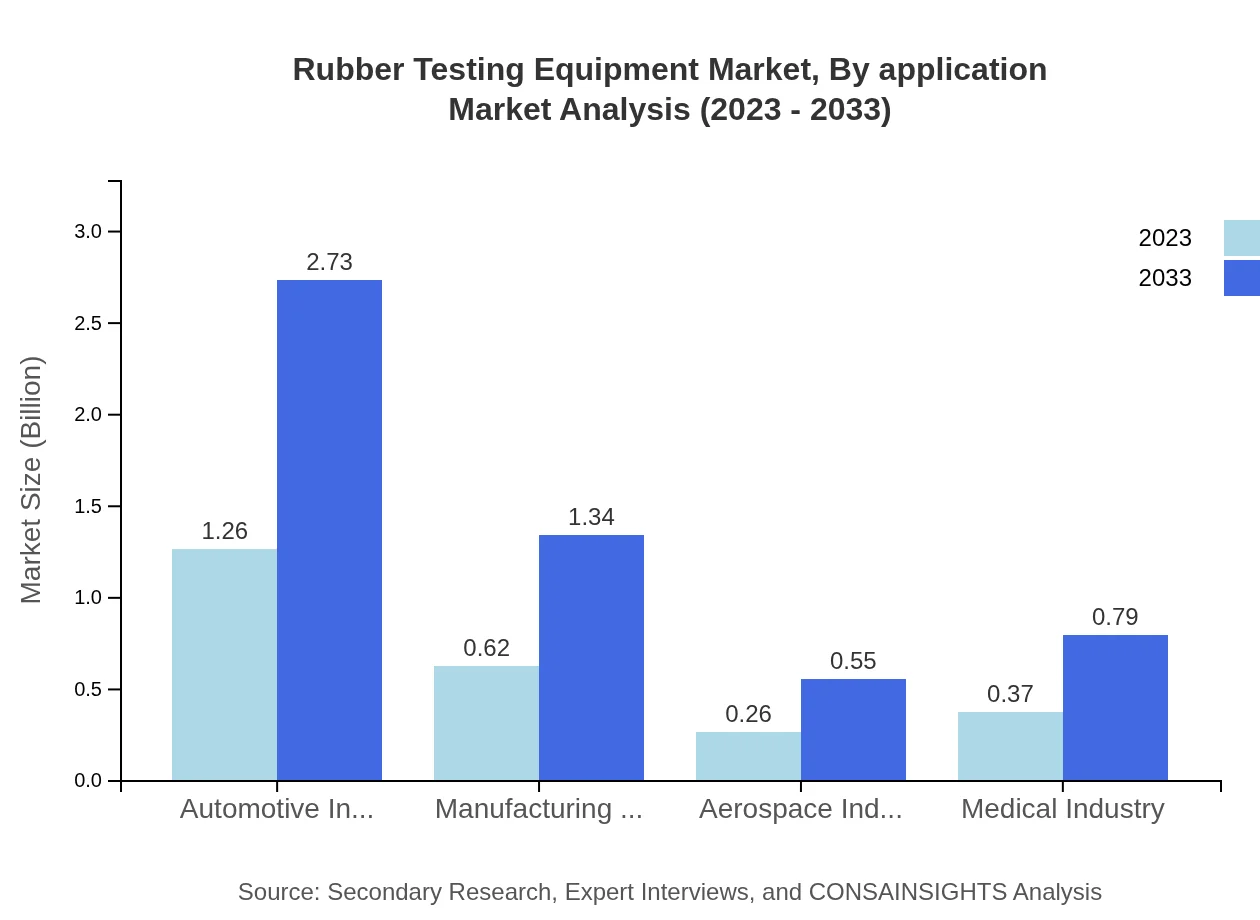

Rubber Testing Equipment Market Analysis By Application

The applications of Rubber Testing Equipment span across various industries, predominantly in automotive (50.44% market share), manufacturing (24.68%), aerospace (10.23%), and medical (14.65%). The automotive sector holds a substantial part of the market, projected to grow from $1.26 billion in 2023 to $2.73 billion by 2033. The need for stringent quality testing ensures that manufacturers comply with international standards, thus boosting the overall market.

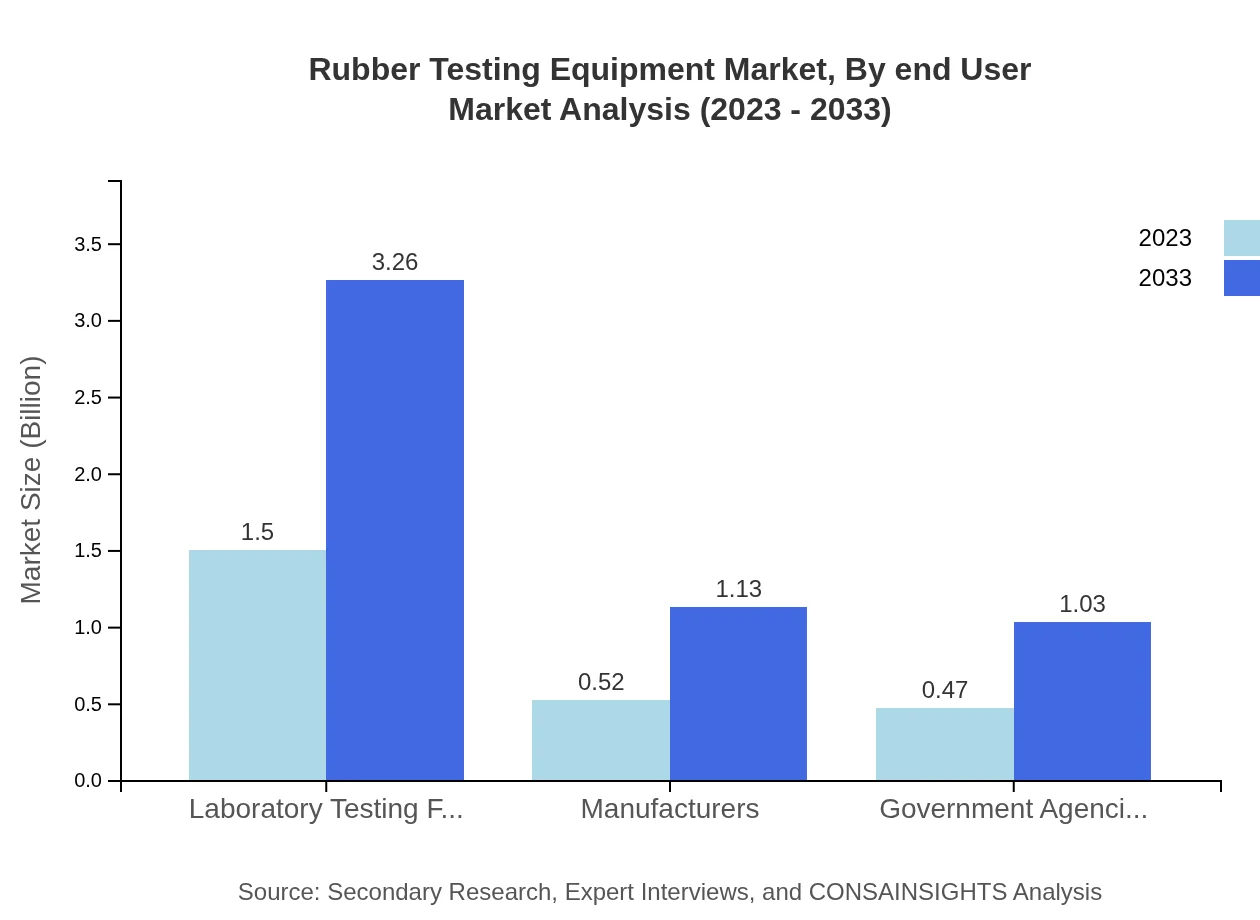

Rubber Testing Equipment Market Analysis By End User

The key end-users of Rubber Testing Equipment include manufacturers, government agencies, and laboratories. Manufacturers hold a share of 20.89%, with an expected growth from $0.52 billion to $1.13 billion by 2033. Government agencies (18.97% market share) will also see significant growth, projected to increase from $0.47 billion to $1.03 billion over the forecast period, underscoring the need for regulatory compliance and public safety.

Rubber Testing Equipment Market Analysis By Technology

The adoption of innovative technologies is pivotal in the Rubber Testing Equipment market, expanding focus towards automated and IoT-enabled solutions. This segment is increasingly becoming significant due to the high efficiency and accuracy in testing results. Automated testing equipment is projected to grow substantially, with a growth forecast from $0.52 billion in 2023 to $1.13 billion by 2033, reflecting a trend toward modernization and integration with manufacturing processes.

Rubber Testing Equipment Market Analysis By Region

The regional analysis reveals that North America remains the largest market holder, with a significant market share of 50.44%, and is set for growth. Europe follows, driving demand due to regulatory standards. Asia-Pacific is poised for considerable growth, emphasizing the demand for quality assurance and efficient testing solutions in rapidly growing markets.

Rubber Testing Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rubber Testing Equipment Industry

Instron:

Instron is a leading manufacturer and supplier of mechanical testing equipment, known for its high-quality materials testing solutions tailored for various industries.MTS Systems Corporation:

MTS specializes in test systems and an array of sensors and software for rubber testing, providing services across automotive, aerospace, and energy sectors.ZwickRoell:

ZwickRoell offers a comprehensive range of rubber testing equipment, committed to advancing material testing technology and quality assurance in various applications.Tensile Testing Machines (TTM):

TTM focuses on designing and manufacturing sophisticated testing machines and custom solutions for rubber material testing applications.We're grateful to work with incredible clients.

FAQs

What is the market size of rubber Testing Equipment?

The global rubber testing equipment market is valued at approximately $2.5 billion in 2023, with a projected compound annual growth rate (CAGR) of 7.8%. By 2033, the market is expected to expand significantly, reflecting the rising demand for rubber products across various industries.

What are the key market players or companies in this rubber Testing Equipment industry?

The rubber testing equipment industry is dominated by key players including Instron Corporation, ZwickRoell GmbH, and MTS Systems Corporation. These companies have established themselves in the market through innovation and a comprehensive product portfolio aimed at diverse testing needs.

What are the primary factors driving the growth in the rubber testing equipment industry?

Growth in the rubber testing equipment market is primarily driven by increased demand from end-user industries, stringent quality control regulations, and technological advancements. The expanding automotive sector, coupled with the rising need for durable rubber products, also significantly contributes to market expansion.

Which region is the fastest Growing in the rubber testing equipment industry?

The Asia-Pacific region is expected to be the fastest-growing market for rubber testing equipment from 2023 to 2033, driven by rapid industrialization, especially in countries like China and India, and an increasing focus on quality in manufacturing processes.

Does ConsaInsights provide customized market report data for the rubber testing equipment industry?

Yes, ConsaInsights offers tailored market report data for the rubber testing equipment industry. Clients can request specific insights based on geographical areas, application segments, and emerging trends to better understand their market landscape.

What deliverables can I expect from this rubber Testing Equipment market research project?

The deliverables from the rubber testing equipment market research project include comprehensive market analysis reports, trend assessments, competitive landscape evaluations, and segmented market forecasts, providing clients with crucial insights for strategic decision-making.

What are the market trends of rubber testing equipment?

Current market trends in rubber testing equipment include advancements in automated testing technologies, increasing adoption of eco-friendly materials and adhesives in production, and a growing trend towards integrating IoT in testing equipment to enhance monitoring and data analysis.