Safety Programmable Controller Market Report

Published Date: 22 January 2026 | Report Code: safety-programmable-controller

Safety Programmable Controller Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Safety Programmable Controller market, offering detailed insights into market size, growth trends, and forecasts from 2023 to 2033. It covers key drivers, challenges, and competitive dynamics shaping the market landscape.

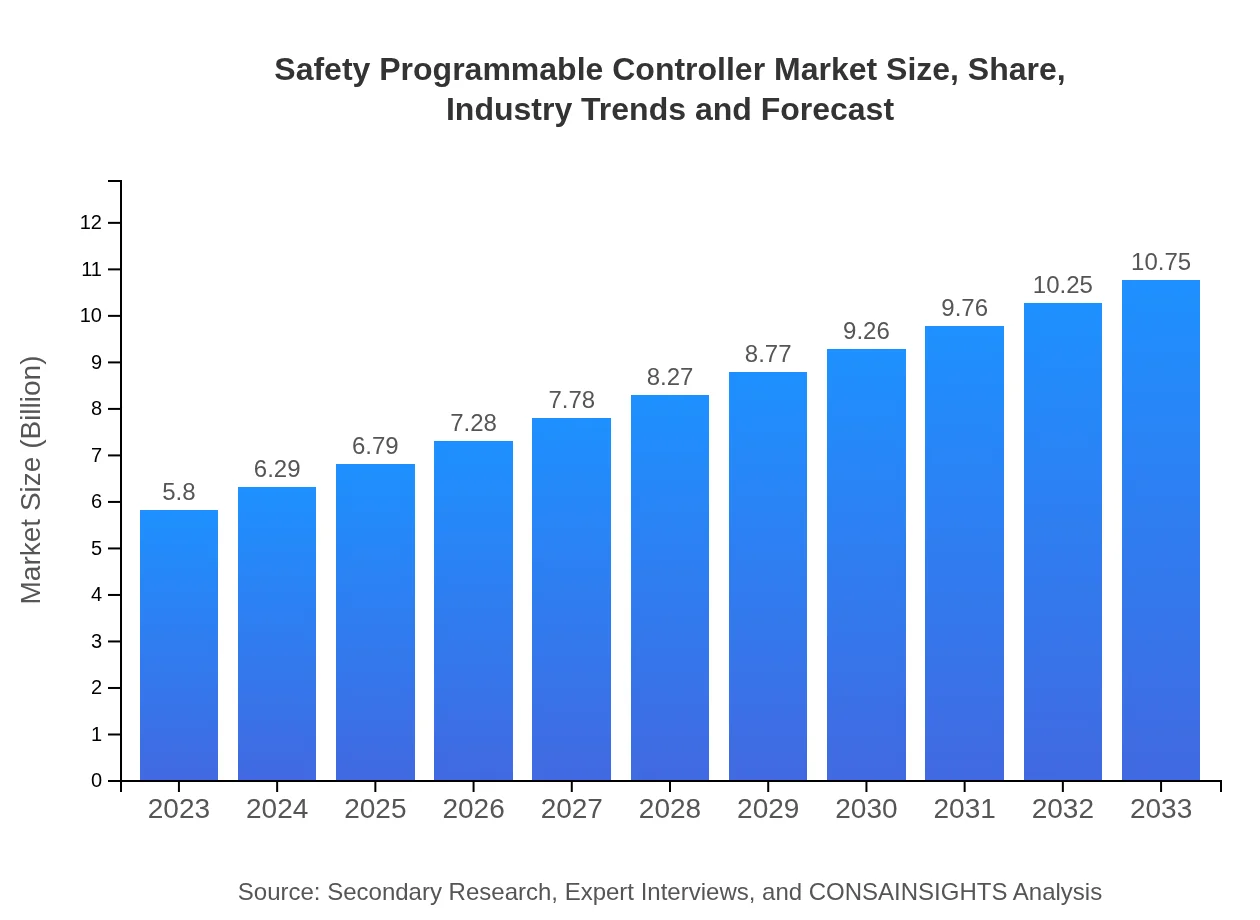

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $10.75 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Schneider Electric, Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Safety Programmable Controller Market Overview

Customize Safety Programmable Controller Market Report market research report

- ✔ Get in-depth analysis of Safety Programmable Controller market size, growth, and forecasts.

- ✔ Understand Safety Programmable Controller's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Safety Programmable Controller

What is the Market Size & CAGR of Safety Programmable Controller market in 2023?

Safety Programmable Controller Industry Analysis

Safety Programmable Controller Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Safety Programmable Controller Market Analysis Report by Region

Europe Safety Programmable Controller Market Report:

The European Safety Programmable Controller market is estimated to expand from $1.51 billion in 2023 to $2.81 billion by 2033. The increase is attributed to stringent safety regulations and the European Union's commitment to improving labor safety conditions across various industries.Asia Pacific Safety Programmable Controller Market Report:

The Asia Pacific region is witnessing significant growth in the Safety Programmable Controller market, with an estimated market size of $1.13 billion in 2023, projected to reach $2.09 billion by 2033. This growth is fueled by increasing industrialization, investments in safety infrastructure, and the adoption of automation technologies across manufacturing sectors.North America Safety Programmable Controller Market Report:

North America currently holds one of the largest markets for Safety Programmable Controllers, valued at approximately $2.26 billion in 2023. It is projected to grow to $4.19 billion by 2033, driven by the region's focus on safety regulations, the early adoption of advanced manufacturing technologies, and a move towards smart factory solutions.South America Safety Programmable Controller Market Report:

In South America, the Safety Programmable Controller market is expected to grow from $0.18 billion in 2023 to $0.32 billion by 2033. This growth is driven by increasing awareness of workplace safety and regulatory compliance in industries such as mining and oil & gas.Middle East & Africa Safety Programmable Controller Market Report:

The Middle East and Africa market for Safety Programmable Controllers is estimated to grow from $0.72 billion in 2023 to $1.34 billion by 2033, driven by rising investments in infrastructure, oil production safety improvements, and a growing emphasis on industrial safety standards.Tell us your focus area and get a customized research report.

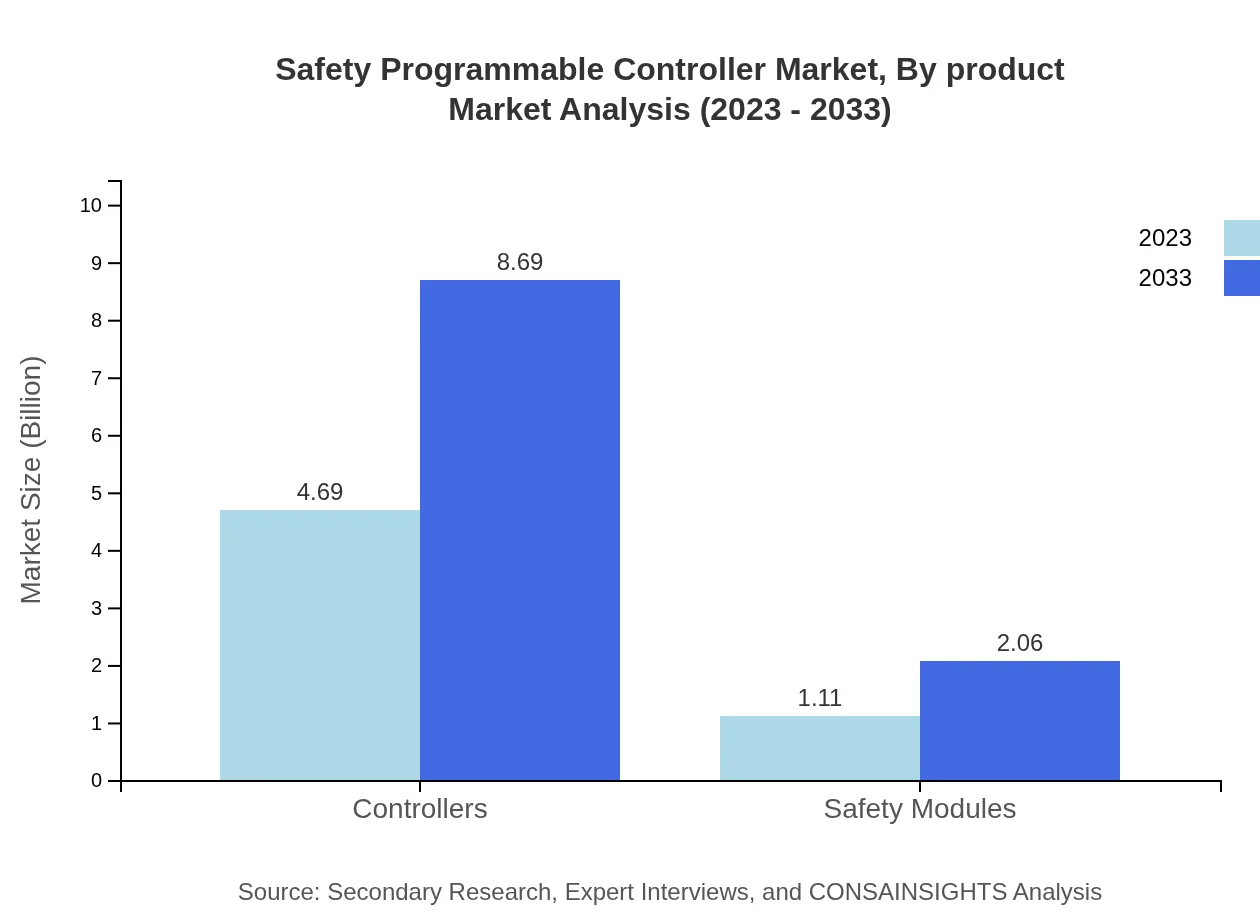

Safety Programmable Controller Market Analysis By Product

The overall Safety Programmable Controller market by product type is projected to grow from $4.69 billion in 2023 to $8.69 billion by 2033. The segment comprises Controllers, Safety Modules, and other safety-related products, ensuring comprehensive market reach across multiple sectors.

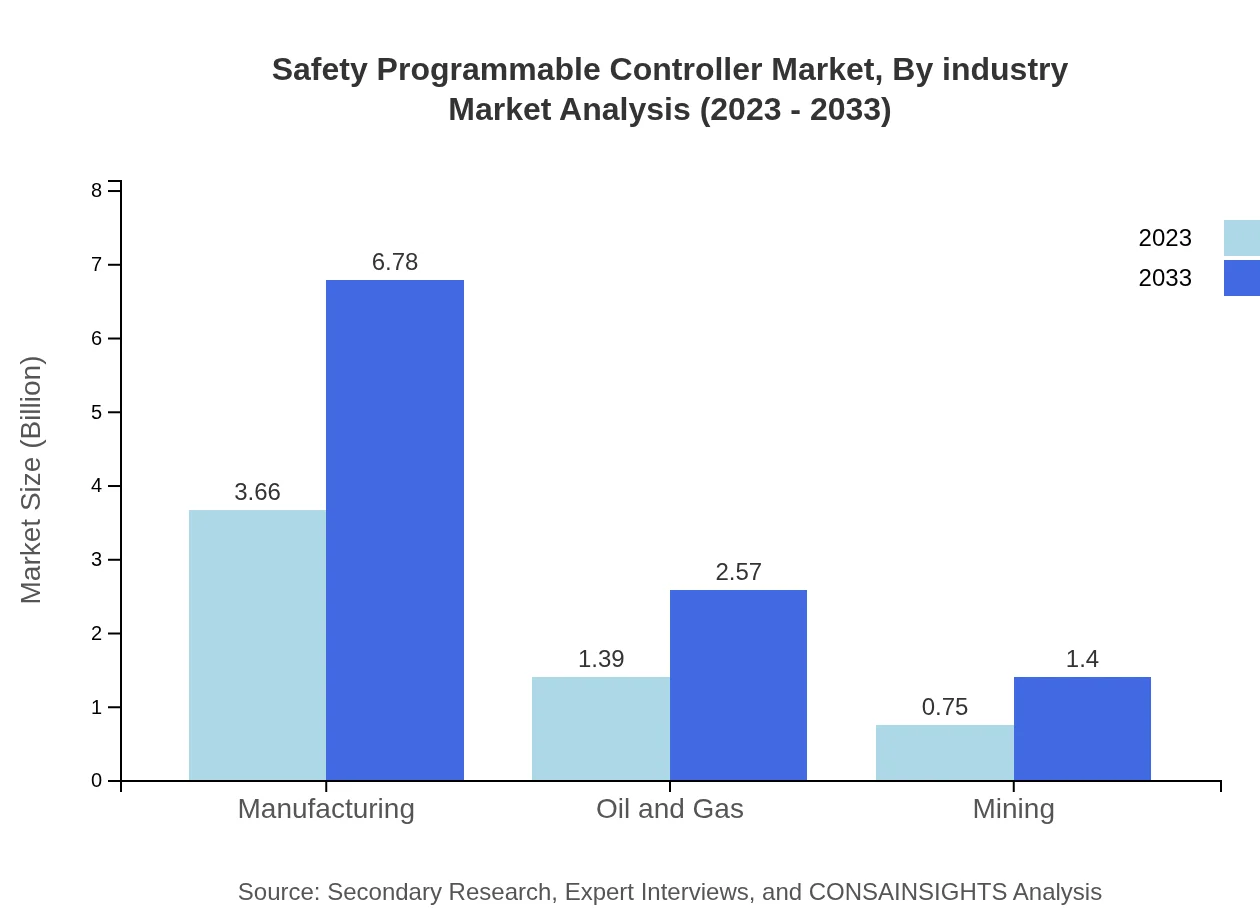

Safety Programmable Controller Market Analysis By Industry

In terms of industry segmentation, the largest contributions come from manufacturing ($3.66 billion in 2023) and oil & gas sectors ($1.39 billion in 2023), reflecting the emphasis on safety and automation within high-risk environments.

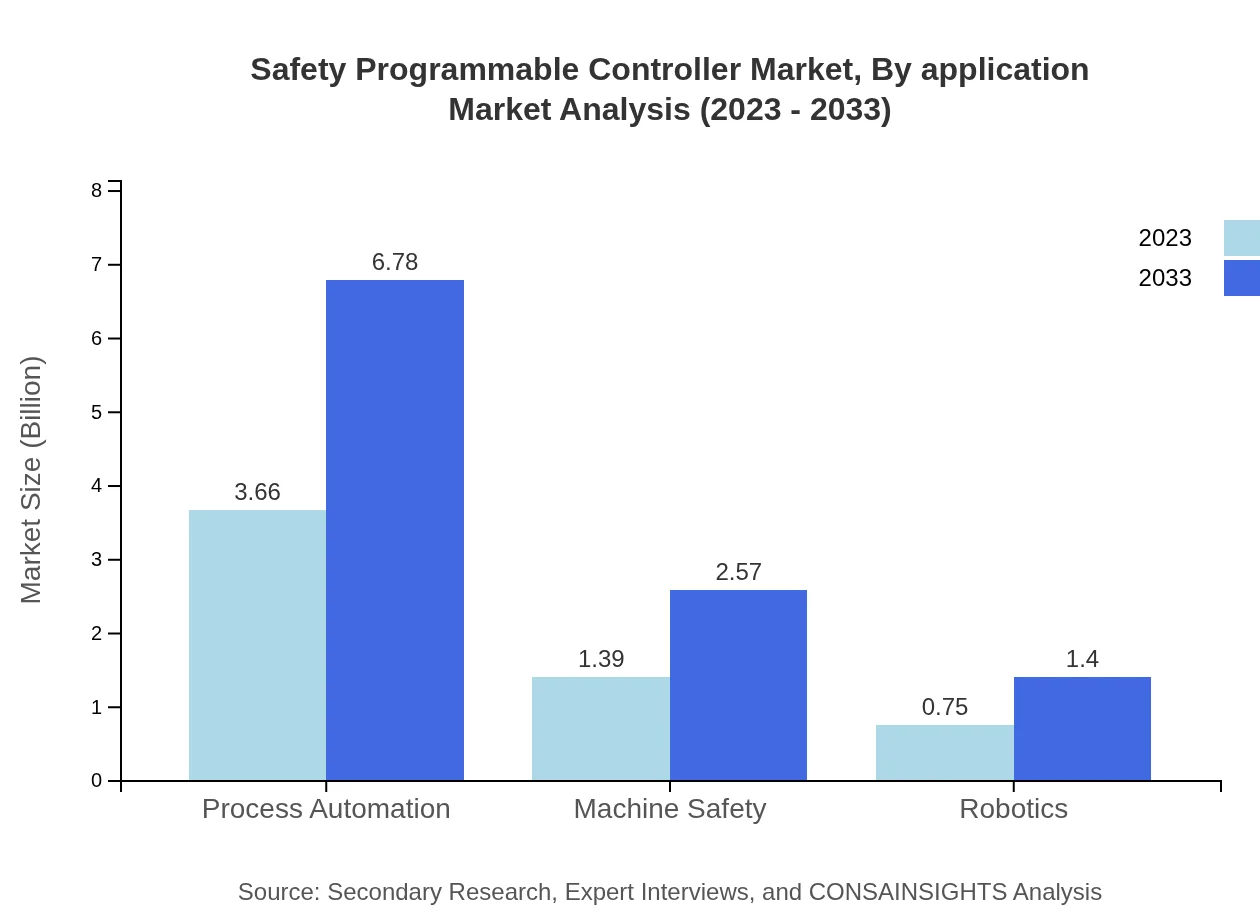

Safety Programmable Controller Market Analysis By Application

The Safety Programmable Controller market is widely applied across various industries, primarily in process automation and machine safety applications. The market for process automation is set to grow significantly due to the need for standardized safety protocols, while machine safety applications ensure operational safety compliance.

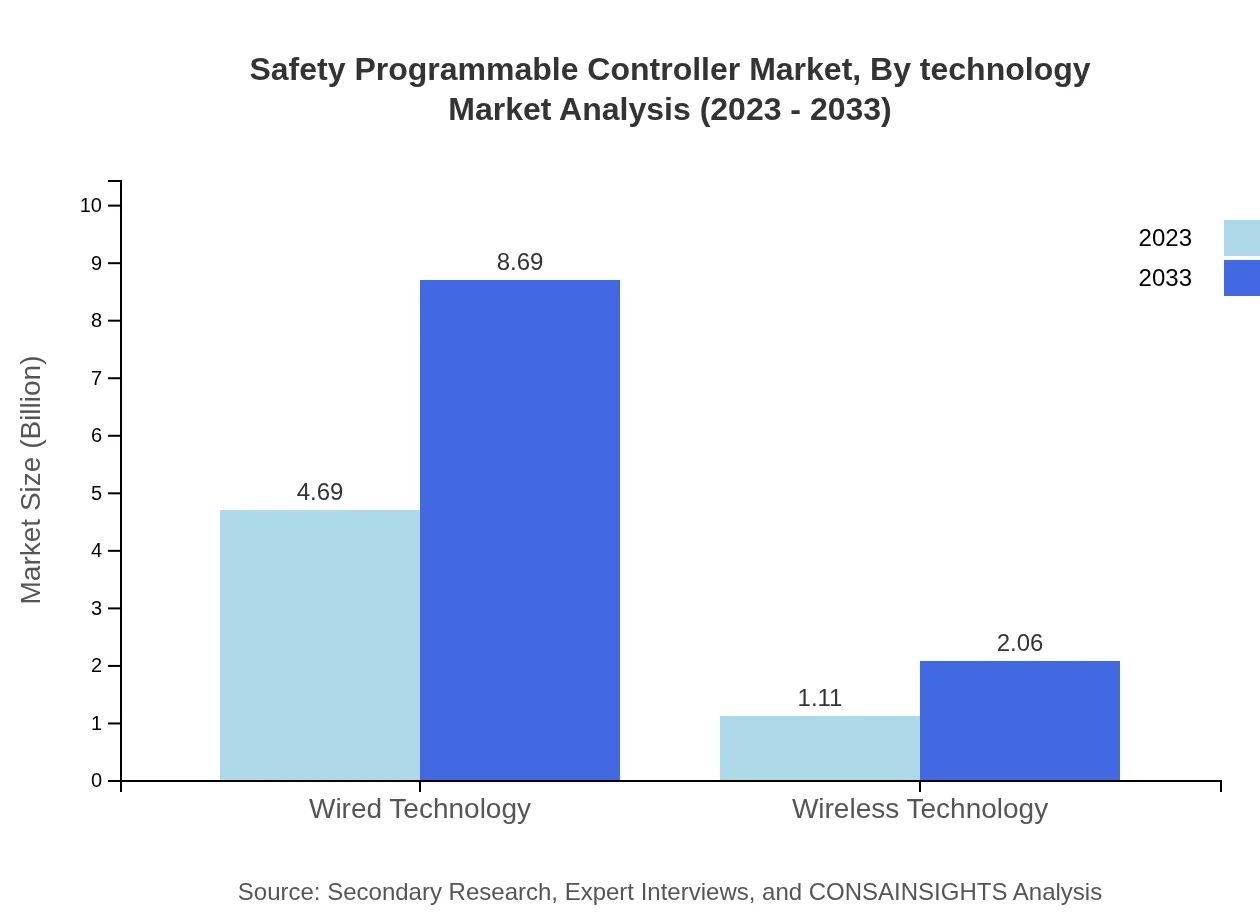

Safety Programmable Controller Market Analysis By Technology

Market technologies, including both wired and wireless systems, are evolving with advancements such as IoT integration and data analytics capabilities. Wired technology continues to dominate with an 80.86% share, while wireless systems are increasingly adopted for flexibility.

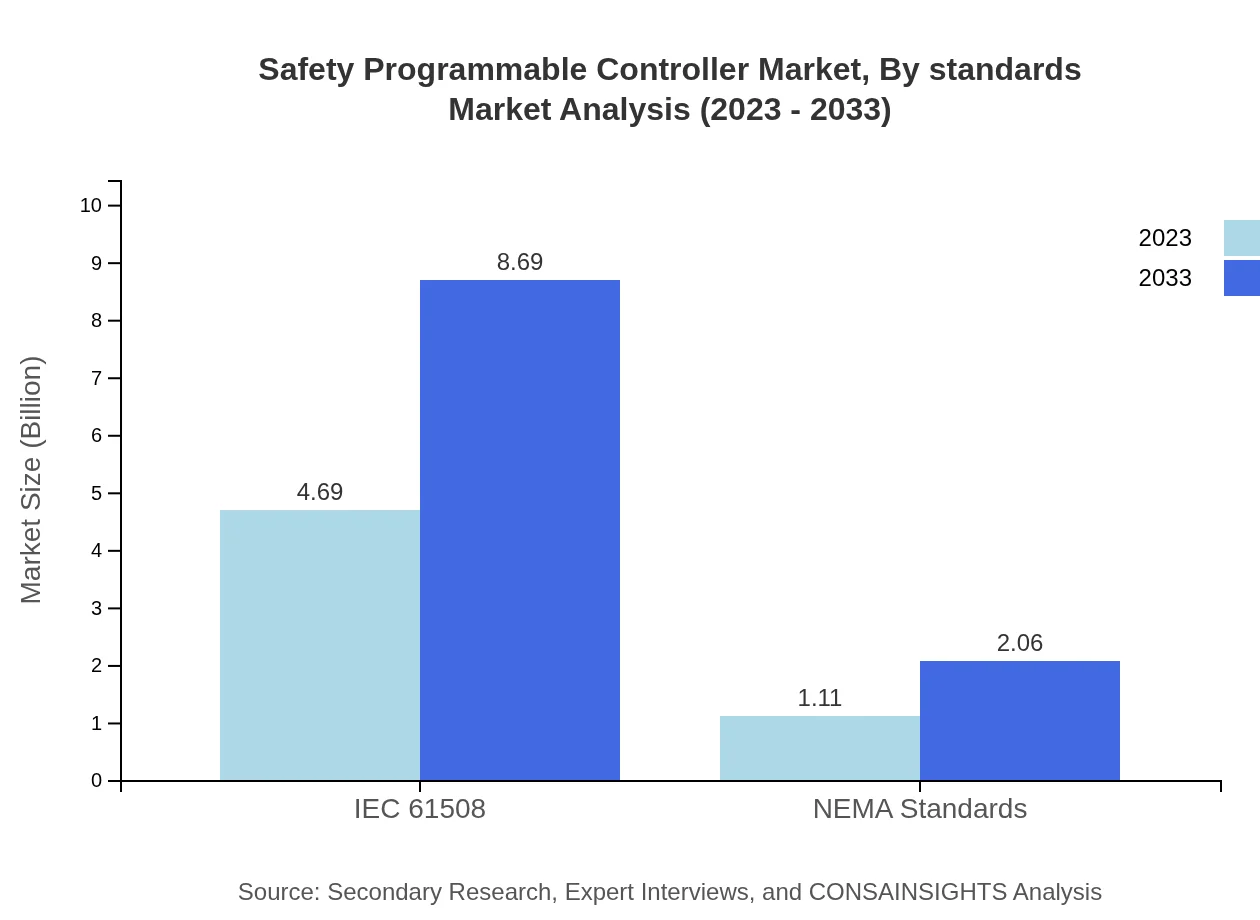

Safety Programmable Controller Market Analysis By Standards

With stringent safety standards like IEC 61508 and NEMA Standards being prevalent, compliance is critical for manufacturers. These standards provide frameworks for ensuring the safety integrity of programmable controllers, guiding product development and innovation.

Safety Programmable Controller Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Safety Programmable Controller Industry

Siemens AG:

A leader in automation and control technology, Siemens AG provides a wide range of safety programmable controllers known for their reliability and compliance with rigorous safety standards.Rockwell Automation:

Rockwell Automation specializes in industrial automation solutions and offers innovative safety programmable controllers aimed at improving operational efficiency and safety in various industries.Schneider Electric:

Renowned for its focus on sustainability and safety, Schneider Electric's safety programmable controllers integrate advanced technologies to meet diverse industrial safety requirements.Honeywell International Inc.:

Honeywell is recognized for its robust safety solutions, including advanced safety programmable controllers that enhance automation and safety across multiple sectors, especially in process industries.We're grateful to work with incredible clients.

FAQs

What is the market size of Safety Programmable Controller?

The global Safety Programmable Controller market is valued at approximately $5.8 billion in 2023, with a projected CAGR of 6.2% through 2033. This growth reflects an increasing demand for advanced safety features in manufacturing and automation sectors.

What are the key market players or companies in the Safety Programmable Controller industry?

Key players in the Safety Programmable Controller market include major firms such as Siemens, Rockwell Automation, Schneider Electric, and Honeywell. These companies lead in terms of technology, market share, and service offerings in safety automation solutions.

What are the primary factors driving the growth in the Safety Programmable Controller industry?

Growth in the Safety Programmable Controller market is primarily driven by increasing industrial automation, rising safety regulations, technological advancements, and the need for improved operational efficiency in various sectors such as manufacturing and oil & gas.

Which region is the fastest Growing in the Safety Programmable Controller market?

North America is the fastest-growing region in the Safety Programmable Controller market, projected to grow from $2.26 billion in 2023 to $4.19 billion by 2033. Following closely are Europe and Asia-Pacific, showcasing significant market potential as well.

Does ConsaInsights provide customized market report data for the Safety Programmable Controller industry?

Yes, ConsaInsights offers customized market report data tailored to the Safety Programmable Controller industry. These reports can address specific inquiries, allowing stakeholders to make informed strategic decisions based on unique requirements and market dynamics.

What deliverables can I expect from this Safety Programmable Controller market research project?

From the Safety Programmable Controller market research project, expect comprehensive deliverables, including a detailed market analysis report, segment insights, regional trends, competitive landscape analysis, and growth forecasts tailored to your specific needs.

What are the market trends of Safety Programmable Controller?

Current market trends in Safety Programmable Controllers include increased integration of IoT technologies, a shift towards wireless communication, and a growing emphasis on machine safety and process automation, which collectively enhance operational reliability and safety.

What segments comprise the Safety Programmable Controller market?

The Safety Programmable Controller market is segmented into controllers, safety modules, and various applications such as manufacturing, oil and gas, and process automation. Each segment shows unique growth characteristics, contributing to the overall market expansion.