Safety Valves Market Report

Published Date: 22 January 2026 | Report Code: safety-valves

Safety Valves Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the safety valves market for the forecast period from 2023 to 2033. It covers market size, key segments, regional insights, industry trends, and profiles of leading market players, providing crucial insights for stakeholders.

| Metric | Value |

|---|---|

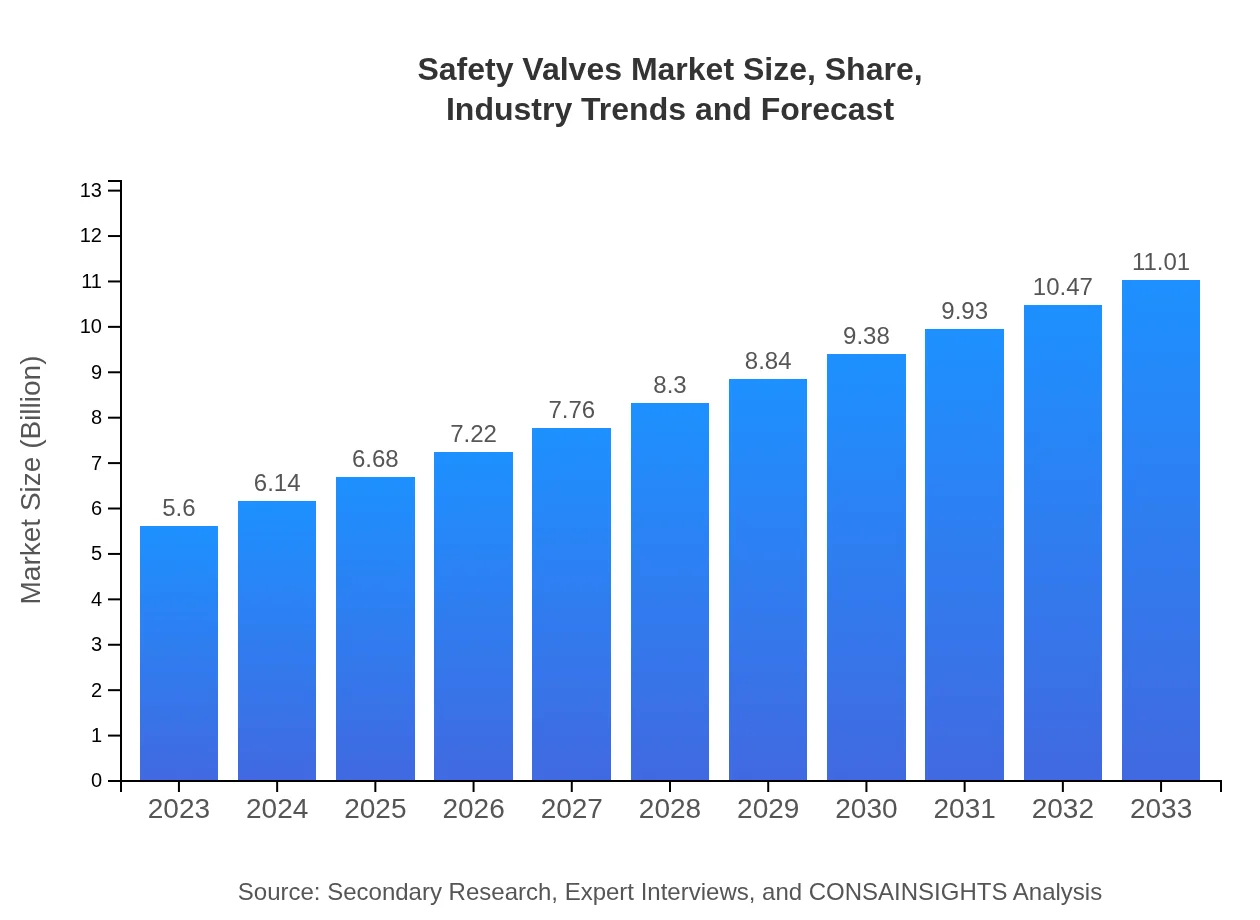

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Emerson Electric Co., Parker Hannifin Corporation, Flowserve Corporation, Valves & Controls |

| Last Modified Date | 22 January 2026 |

Safety Valves Market Overview

Customize Safety Valves Market Report market research report

- ✔ Get in-depth analysis of Safety Valves market size, growth, and forecasts.

- ✔ Understand Safety Valves's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Safety Valves

What is the Market Size & CAGR of Safety Valves market in 2023?

Safety Valves Industry Analysis

Safety Valves Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Safety Valves Market Analysis Report by Region

Europe Safety Valves Market Report:

Europe's safety valves market, estimated at 1.35 billion USD in 2023, may reach 2.66 billion USD by 2033. A focus on environmental sustainability and strict safety regulations will support market growth in this region.Asia Pacific Safety Valves Market Report:

In 2023, the Asia Pacific safety valves market is valued at 1.17 billion USD, projected to reach 2.29 billion USD by 2033. The region's growth is driven by industrial expansion, particularly in manufacturing and energy sectors, alongside increased regulatory emphasis on safety.North America Safety Valves Market Report:

North America leads with a market size of 1.95 billion USD in 2023, likely to expand to 3.83 billion USD by 2033. The robust growth reflects high expenditure on infrastructure and enhanced regulations concerning industrial safety practices.South America Safety Valves Market Report:

The South American market for safety valves, valued at 0.37 billion USD in 2023, is expected to grow to 0.73 billion USD by 2033. Rising investments in oil and gas exploration activities are pivotal in driving demand in this region.Middle East & Africa Safety Valves Market Report:

The Middle East and Africa market stands at 0.76 billion USD in 2023, expected to grow to 1.49 billion USD by 2033, spurred by rising oil and gas sector developments and infrastructural investments.Tell us your focus area and get a customized research report.

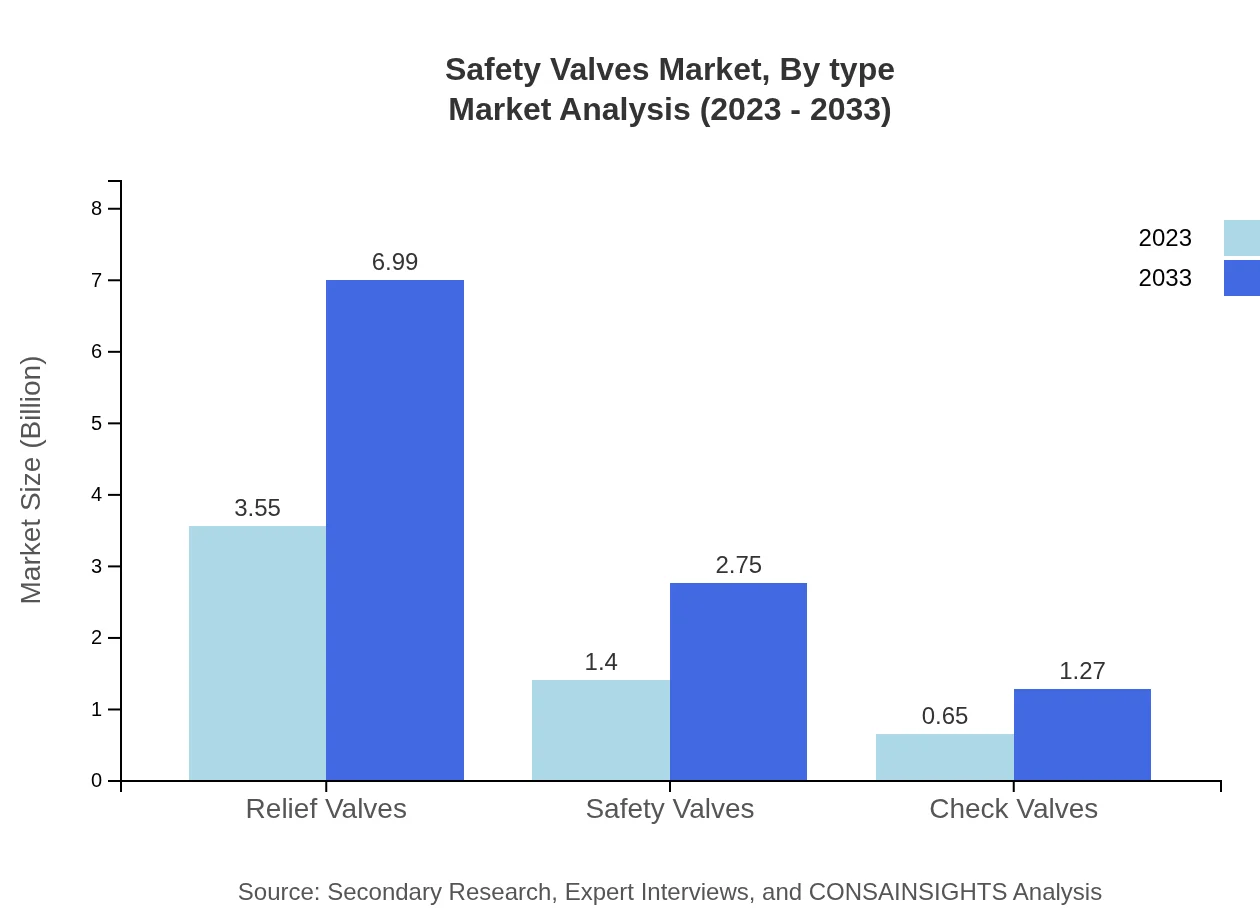

Safety Valves Market Analysis By Type

The Safety Valves market is classified into relief valves, safety valves, and check valves. In 2023, the market size for safety valves stands at 1.40 billion USD, expected to grow to 2.75 billion USD by 2033. Relief valves dominate with a substantial market share of 63.47% in both years due to their imperative safety functions across various industries.

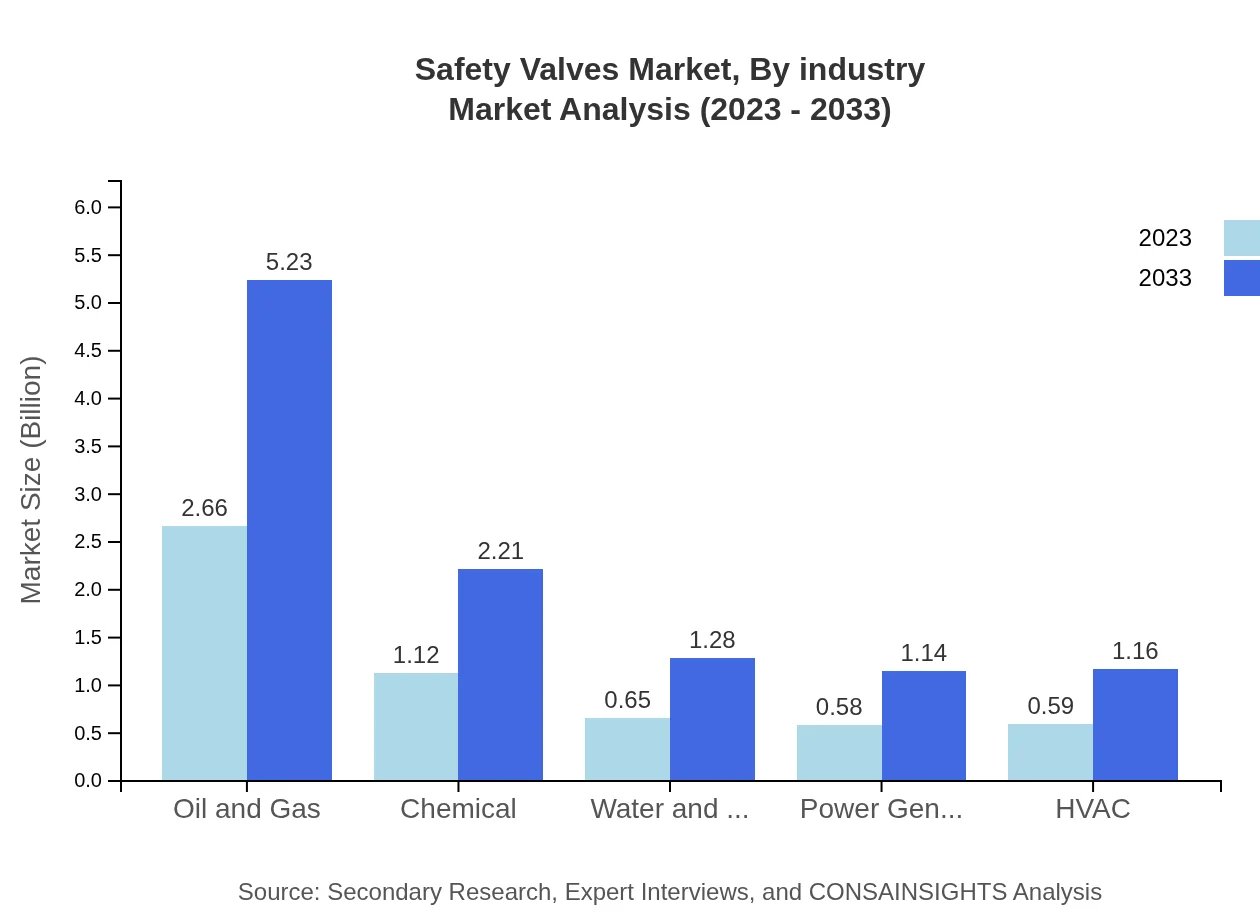

Safety Valves Market Analysis By Industry

The oil and gas industry currently represents 47.48% of the market share, valued at 2.66 billion USD in 2023. It is expected to grow to 5.23 billion USD by 2033, driven by continuous exploration and production activities. Other significant industries include chemicals with a share of 20.05% and a market size of 1.12 billion USD in 2023.

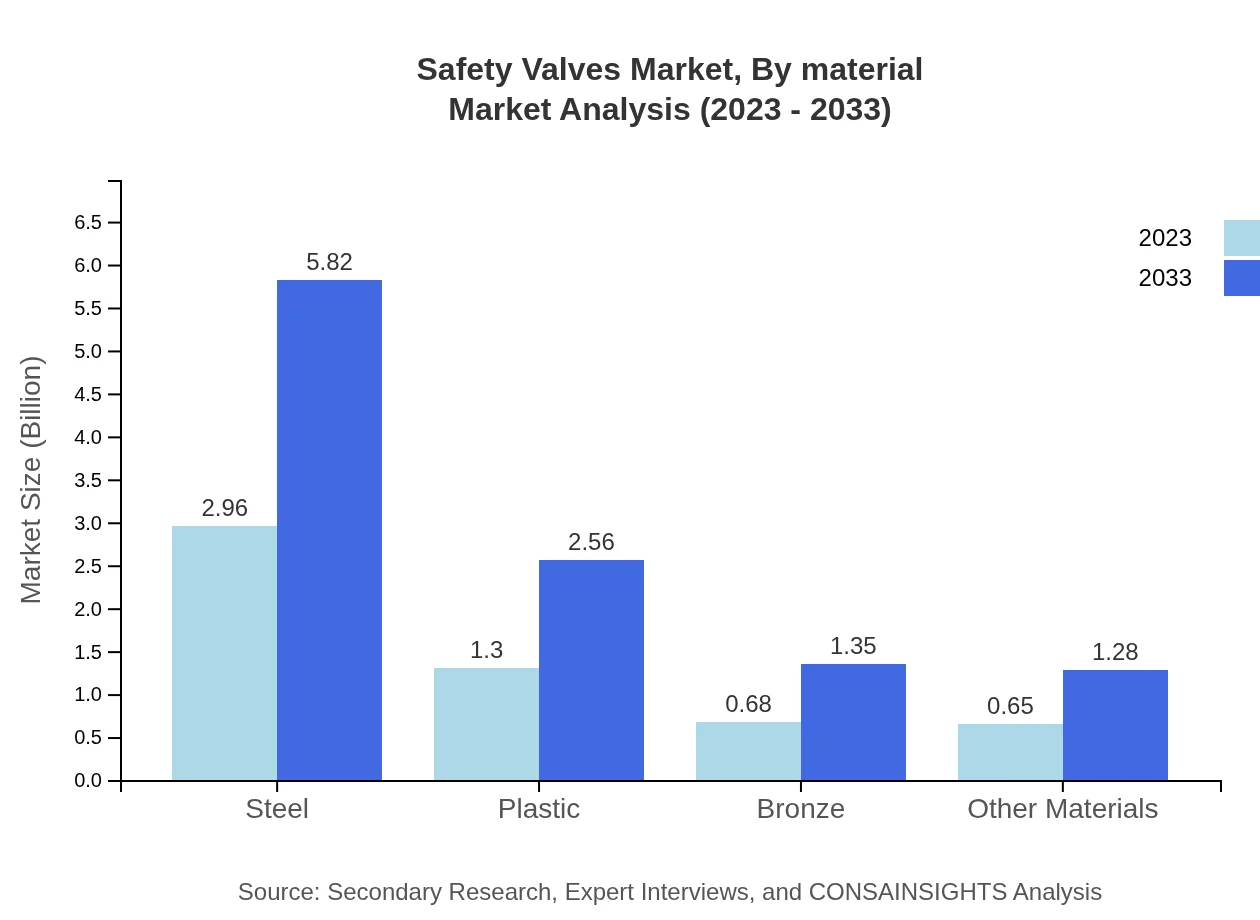

Safety Valves Market Analysis By Material

Steel remains the most utilized material, accounting for 52.86% of the market share, with a size of 2.96 billion USD in 2023. Plastic, bronze, and other materials also feature prominently in the market due to their unique properties and applications.

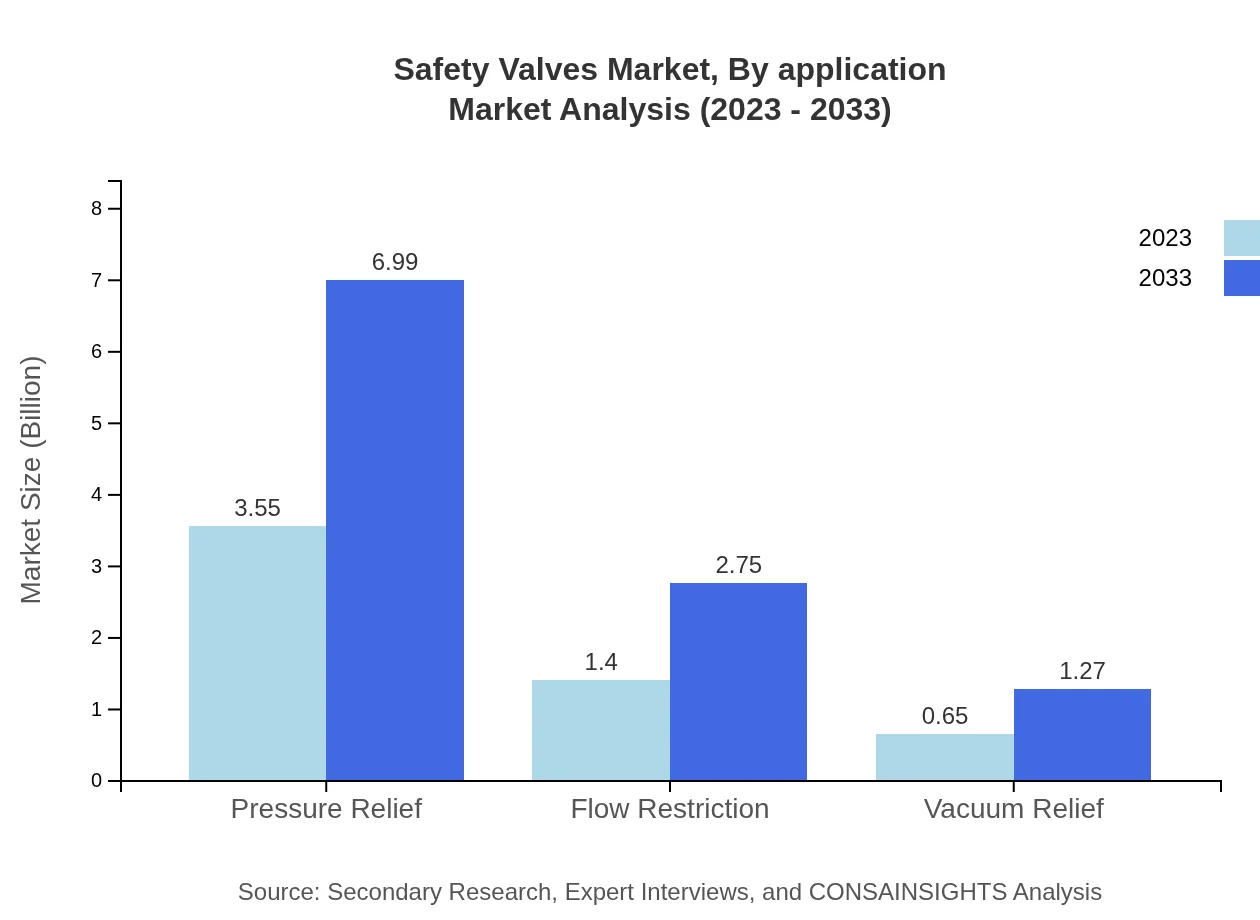

Safety Valves Market Analysis By Application

Pressure relief applications currently command the largest market share of 63.47%. Other applications such as flow restriction and vacuum relief are garnering notice with respective shares of 24.99% and 11.54% due to growing needs for safety protocols in industries.

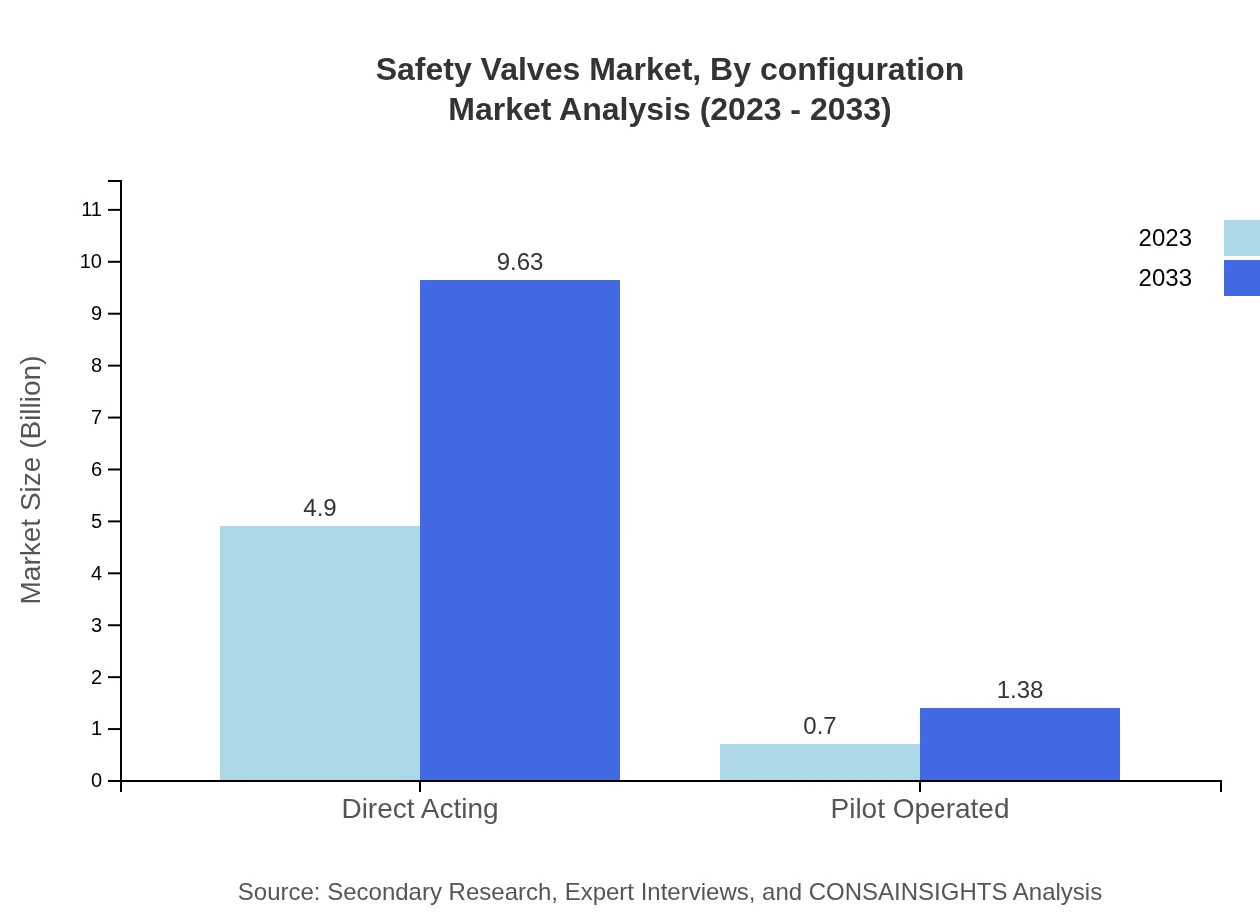

Safety Valves Market Analysis By Configuration

In terms of configuration, direct acting safety valves make up 87.46% of the market due to their reliability and efficiency. The market size for direct acting valves is 4.90 billion USD in 2023, with a steady outlook towards future innovation and material enhancements.

Safety Valves Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Safety Valves Industry

Emerson Electric Co.:

Emerson is a global leader in automation technologies and software, providing advanced safety solutions including a comprehensive range of safety valves for diverse applications.Parker Hannifin Corporation:

Parker Hannifin specializes in motion and control technologies, offering innovative safety valves that ensure reliability and performance in critical applications.Flowserve Corporation:

Flowserve specializes in fluid motion control and provides a wide range of safety valves and related technology globally, focusing on enhancing system safety and efficiency.Valves & Controls:

Valves & Controls focuses on manufacturing and supplying a variety of industrial valves, including safety valves, known for their durable construction and performance standards.We're grateful to work with incredible clients.

FAQs

What is the market size of Safety Valves?

The global safety valves market is valued at approximately $5.6 billion in 2023, and it is projected to grow at a CAGR of 6.8%, potentially reaching significant market size by 2033.

What are the key market players or companies in the Safety Valves industry?

Key players in the safety valves market include Emerson Electric Co., Baker Hughes Company, Honeywell International Inc., and Velan Inc., among others, which significantly contribute to the market through innovation and distribution.

What are the primary factors driving the growth in the Safety Valves industry?

Growth in the safety valves industry is driven by increasing safety regulations, expansion in the oil & gas sector, and advancements in manufacturing technologies, which enhance efficiency and reliability in safety systems.

Which region is the fastest Growing in the Safety Valves market?

The North American region is currently the fastest-growing area in the safety valves market, showing growth from $1.95 billion in 2023 to $3.83 billion by 2033 due to industrial and infrastructural developments.

Does ConsaInsights provide customized market report data for the Safety Valves industry?

Yes, ConsaInsights offers tailored market reports for the safety valves industry, allowing businesses to obtain customized data insights tailored to their specific needs and market segments.

What deliverables can I expect from this Safety Valves market research project?

Expected deliverables from the safety valves market research project include comprehensive reports, market analysis, trend forecasts, competitor analysis, and actionable insights tailored to enhance strategic decision-making.

What are the market trends of Safety Valves?

Current market trends in safety valves include a shift towards digitalization, growing demand in emerging markets, adoption of advanced materials for improved performance, and increased focus on sustainability and compliance.