Sand Blasting Machines Market Report

Published Date: 22 January 2026 | Report Code: sand-blasting-machines

Sand Blasting Machines Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the Sand Blasting Machines market, covering trends, sizes, segment analysis, and growth forecasts for the period 2023 to 2033.

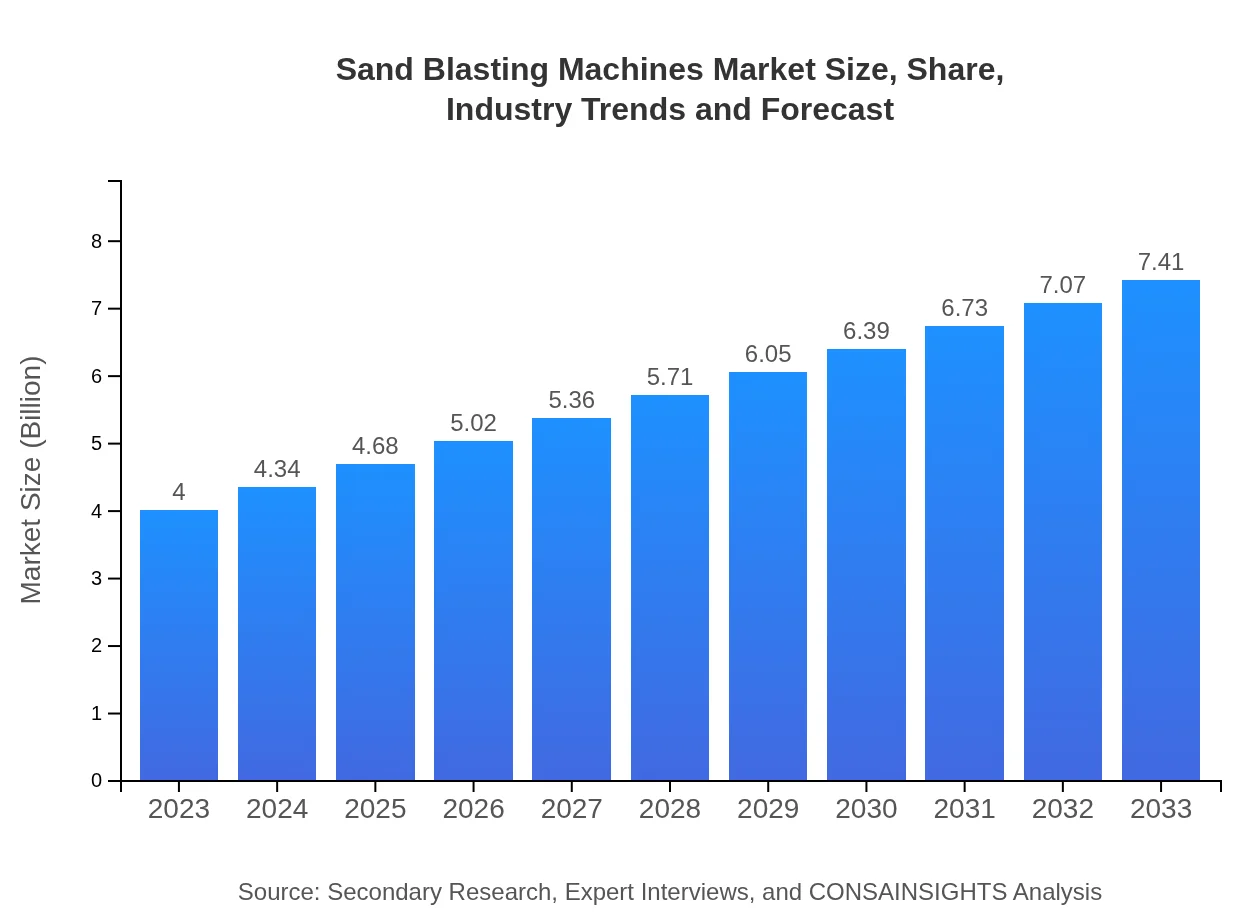

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.00 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $7.41 Billion |

| Top Companies | Graco Inc., Clemco Industries Corp., ABSHERON |

| Last Modified Date | 22 January 2026 |

Sand Blasting Machines Market Overview

Customize Sand Blasting Machines Market Report market research report

- ✔ Get in-depth analysis of Sand Blasting Machines market size, growth, and forecasts.

- ✔ Understand Sand Blasting Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Sand Blasting Machines

What is the Market Size & CAGR of Sand Blasting Machines market in 2023?

Sand Blasting Machines Industry Analysis

Sand Blasting Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Sand Blasting Machines Market Analysis Report by Region

Europe Sand Blasting Machines Market Report:

Europe's market size for Sand Blasting Machines in 2023 is projected at $1.15 billion, growing to $2.12 billion by 2033. Rising environmental regulations and demand for high-quality surface finishing processes in automotive and industrial applications significantly influence market dynamics in this region.Asia Pacific Sand Blasting Machines Market Report:

The Asia Pacific region accounted for a significant market share in 2023, estimated at $0.80 billion. By 2033, it is projected to grow to $1.48 billion. The growth is driven by rapid industrialization in countries like China and India and a booming automotive sector. The increasing manufacturing capabilities affirm the region as a key player in the Sand Blasting Machines market.North America Sand Blasting Machines Market Report:

North America is expected to see robust growth in the Sand Blasting Machines market, from $1.41 billion in 2023 to approximately $2.61 billion by 2033. The region is home to advanced manufacturing industries, particularly in aerospace and heavy machinery, propelling demand for precision surface treatment technologies.South America Sand Blasting Machines Market Report:

In South America, the Sand Blasting Machines market is valued at $0.24 billion in 2023, with expectations to rise to $0.44 billion by 2033. The region is focusing on infrastructure development and steel production, creating opportunities for sand blasting technologies necessary for various applications.Middle East & Africa Sand Blasting Machines Market Report:

The Middle East and Africa market is estimated at $0.41 billion in 2023, with a growth forecast of reaching $0.75 billion by 2033. The demand stems from various sectors, including oil and gas and construction, needing effective surface treatment solutions.Tell us your focus area and get a customized research report.

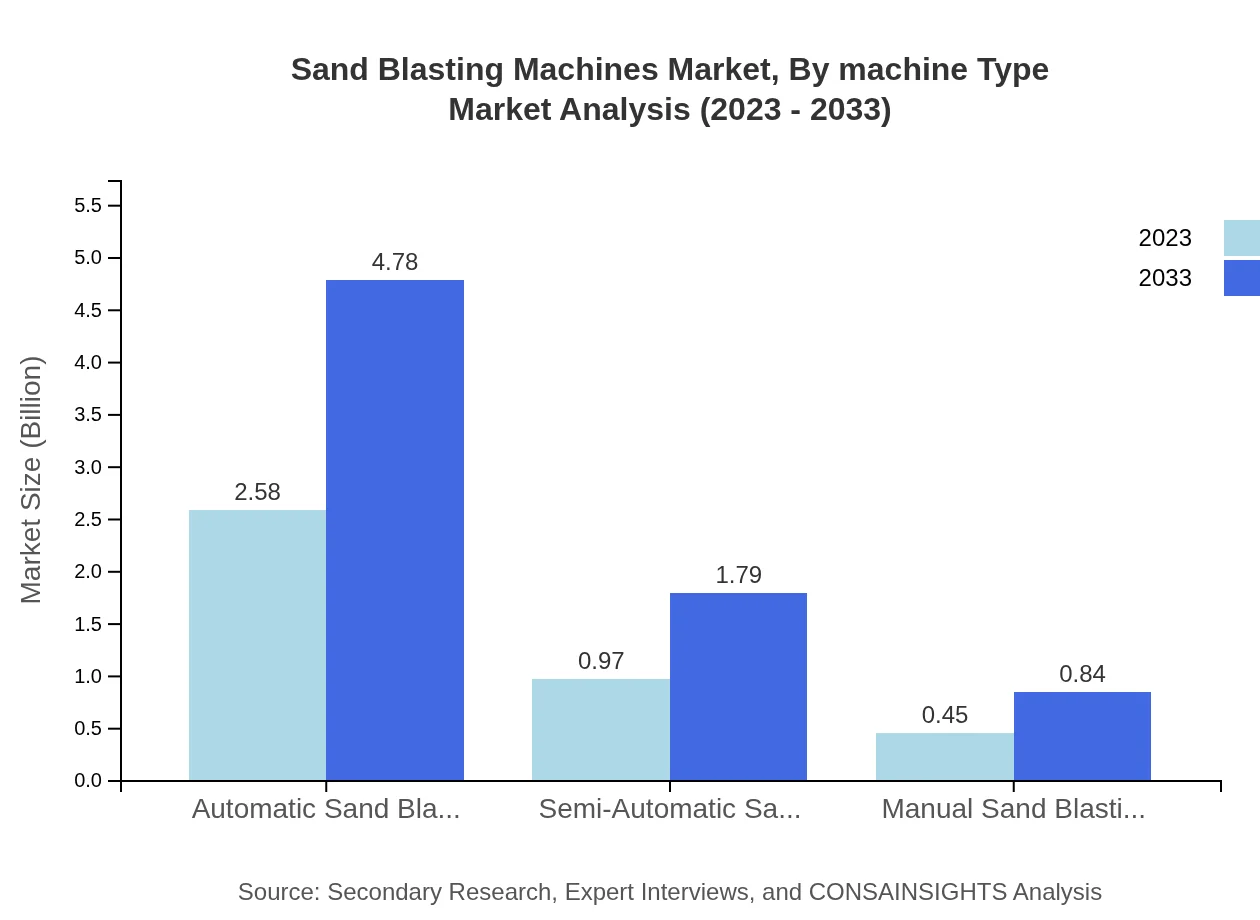

Sand Blasting Machines Market Analysis By Machine Type

The market is predominantly driven by automatic sand blasting machines, which represent a significant segment with a market value of $2.58 billion in 2023, expected to grow to $4.78 billion by 2033. Their adoption is fueled by the increasing emphasis on efficiency and productivity. Semi-automatic and manual machines also hold a share but are comparatively lower, valued at $0.97 billion and $0.45 billion respectively in 2023.

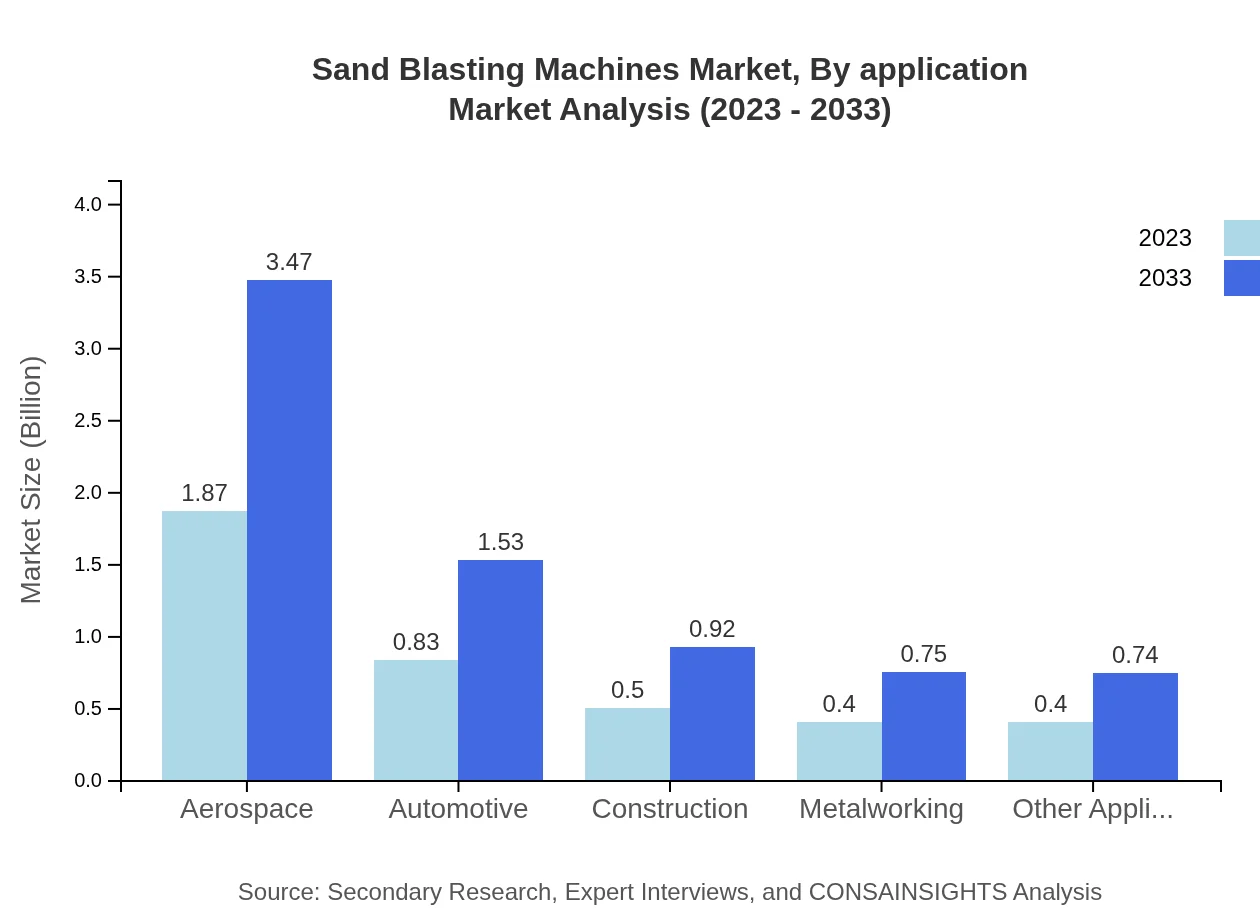

Sand Blasting Machines Market Analysis By Application

Aerospace is the leading application segment, with a market size of $1.87 billion in 2023, projected to grow to $3.47 billion by 2033, maintaining a 46.83% market share. The automotive sector follows closely with $0.83 billion, expanding to $1.53 billion. Construction and metalworking applications also contribute significantly, highlighting the diverse demand for sand blasting technologies across industries.

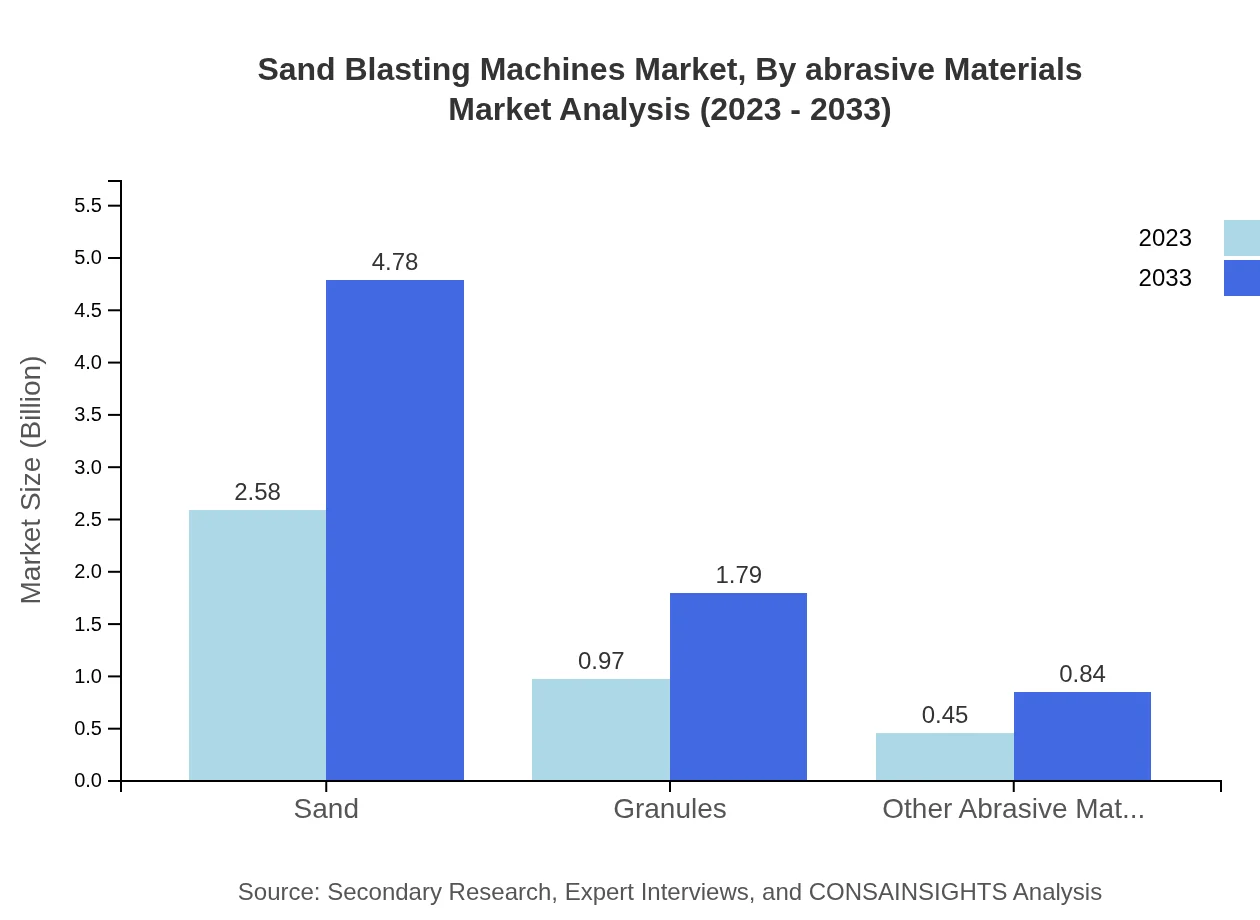

Sand Blasting Machines Market Analysis By Abrasive Materials

The use of Sand as an abrasive material dominates the market with a size of $2.58 billion in 2023 and is expected to grow to $4.78 billion by 2033. Granules represent a crucial segment, valued at $0.97 billion, while other abrasive materials hold a smaller market share, underpinning innovations in material sourcing and application strategies.

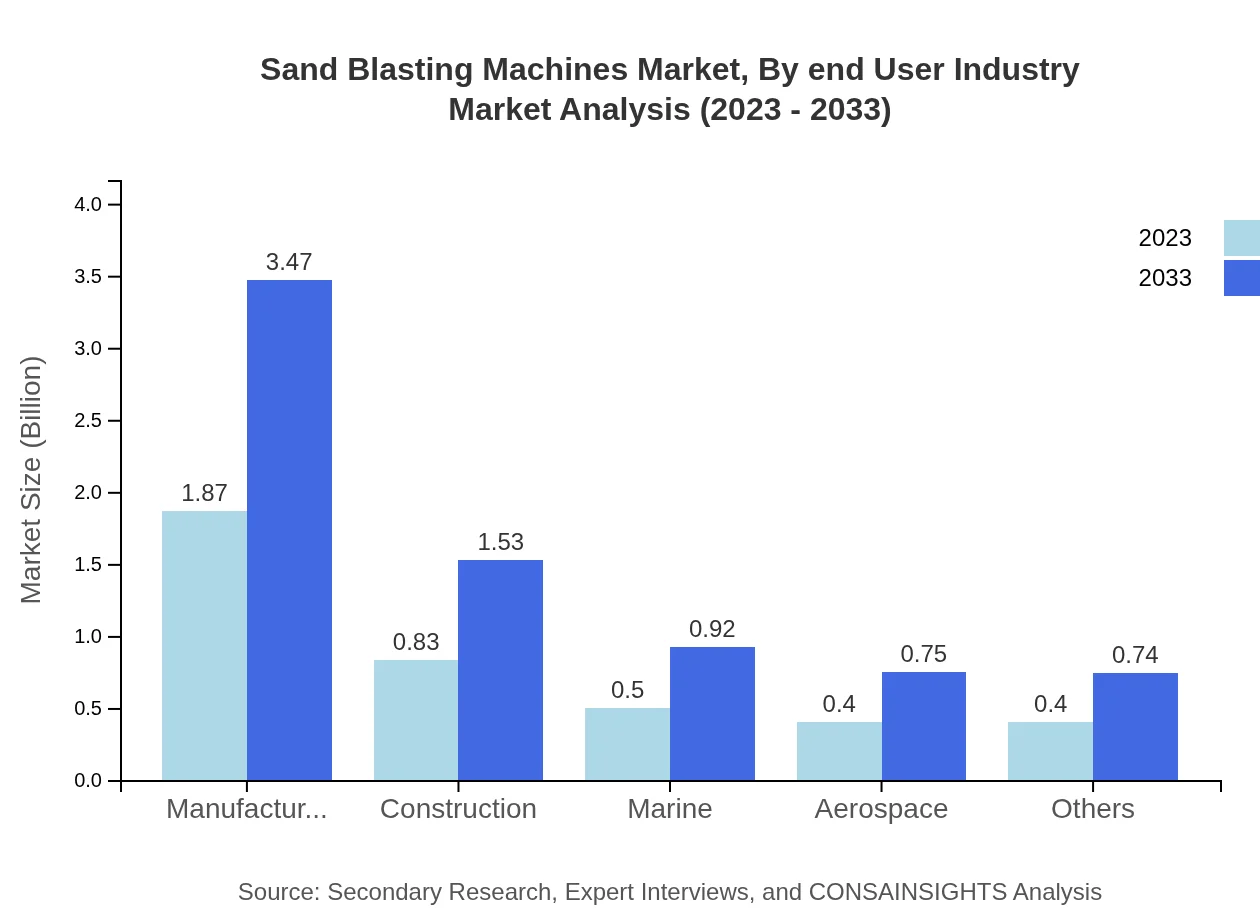

Sand Blasting Machines Market Analysis By End User Industry

The manufacturing sector is the largest end-user, contributing significantly to the market with $1.87 billion in 2023 and an expected growth to $3.47 billion by 2033. Focus industries include automotive, aerospace, and marine, which drive the demand for specialized sand blasting equipment tailored to meet specific standards and operational needs.

Sand Blasting Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Sand Blasting Machines Industry

Graco Inc.:

Graco Inc. is a leading manufacturer of fluid handling systems, including sand blasting technologies, known for innovation in machinery design, improving efficiency and effectiveness in surface preparation.Clemco Industries Corp.:

Clemco Industries Corp. specializes in sand blasting and shot blasting equipment, providing high-quality products that are instrumental in surface preparation across various industries.ABSHERON:

ABSHERON focuses on advanced abrasive technology, supplying an extensive range of sand blasting machines and supplementary equipment, catering to industrial needs globally.We're grateful to work with incredible clients.

FAQs

What is the market size of sand Blasting Machines?

The global sand-blasting machines market is projected to reach approximately $4 billion by 2033, growing at a CAGR of 6.2% from 2023. This growth is driven by increasing industrial applications, particularly in manufacturing processes.

What are the key market players or companies in the sand Blasting Machines industry?

Key players in the sand-blasting machines industry include established manufacturers and innovators that focus on advanced technology and efficiency. Prominent companies often specialize in different categories like automatic and semi-automatic machines, contributing to competitive landscape.

What are the primary factors driving the growth in the sand Blasting Machines industry?

Growth in the sand-blasting machines industry is fueled by increasing demand from sectors such as manufacturing, aerospace, and automotive. Automation trends, a focus on product quality, and advancements in machine efficiency also significantly contribute to market expansion.

Which region is the fastest Growing in the sand Blasting Machines market?

The Asia-Pacific region is experiencing rapid growth in the sand-blasting machines market, expected to rise from $0.80 billion in 2023 to $1.48 billion by 2033. Driving factors include industrial expansions and increased construction activities.

Does ConsaInsights provide customized market report data for the sand Blasting Machines industry?

Yes, ConsaInsights offers tailored market report data for the sand-blasting machines industry. These customized reports cater to specific client needs, providing insights into market trends, competitive analysis, and growth forecasts.

What deliverables can I expect from this sand Blasting Machines market research project?

Deliverables include comprehensive market analysis reports, detailed segment data, competitive landscape insights, and regional outlooks. These provide actionable intelligence beneficial for strategic decision-making and investment.

What are the market trends of sand Blasting Machines?

Market trends indicate a shift toward automation, with automatic sand-blasting machines projected to maintain a 64.46% share. Additionally, sustainable materials and eco-friendly practices are becoming more prevalent in machine design and operation.