Scadabased Industrial Control Systems Market Report

Published Date: 31 January 2026 | Report Code: scadabased-industrial-control-systems

Scadabased Industrial Control Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Scadabased Industrial Control Systems market, covering critical insights, market size, growth forecasts, and key trends from 2023 to 2033.

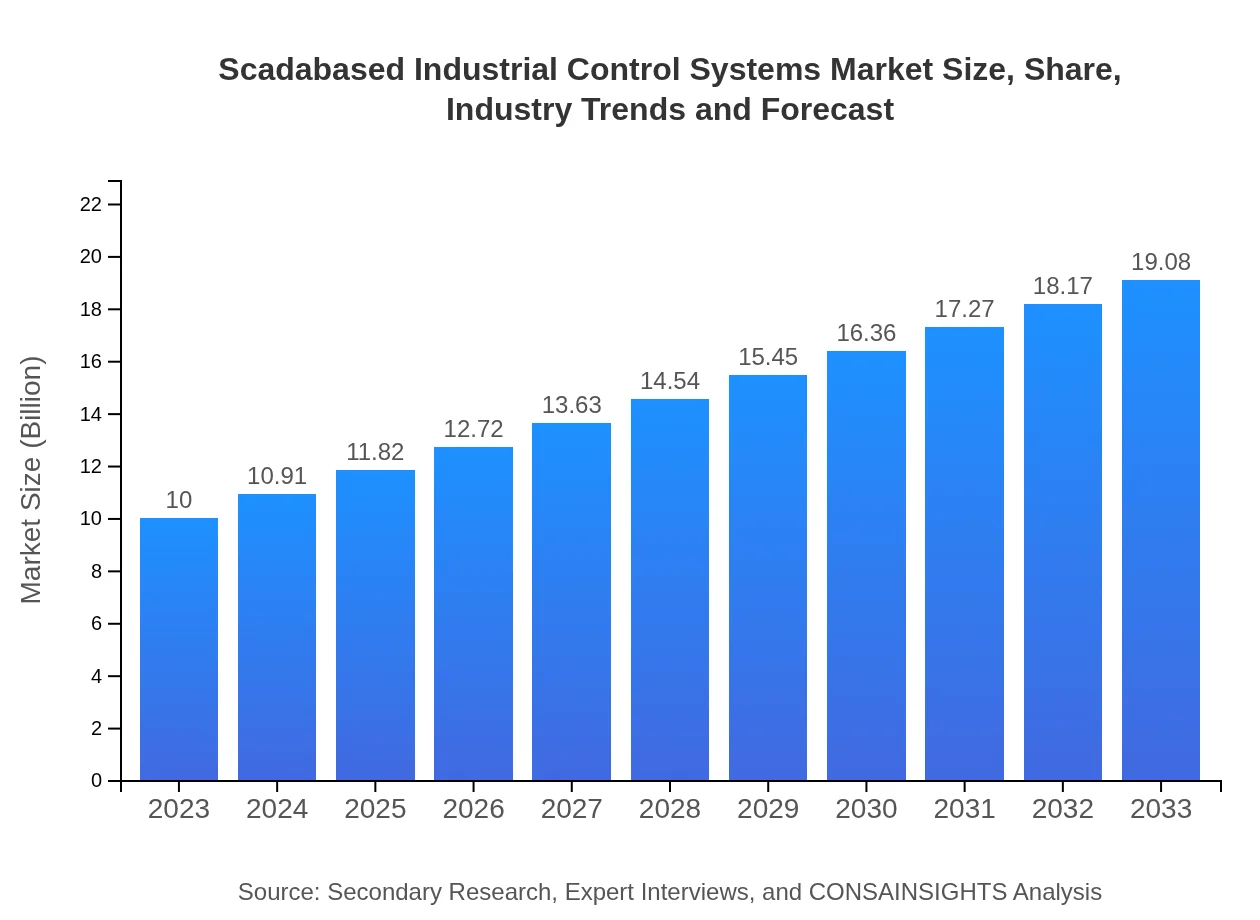

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 6.5% |

| 2033 Market Size | $19.08 Billion |

| Top Companies | Siemens AG, Schneider Electric, Rockwell Automation, Honeywell International Inc., Emerson Electric Co. |

| Last Modified Date | 31 January 2026 |

Scadabased Industrial Control Systems Market Overview

Customize Scadabased Industrial Control Systems Market Report market research report

- ✔ Get in-depth analysis of Scadabased Industrial Control Systems market size, growth, and forecasts.

- ✔ Understand Scadabased Industrial Control Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Scadabased Industrial Control Systems

What is the Market Size & CAGR of Scadabased Industrial Control Systems market in 2023?

Scadabased Industrial Control Systems Industry Analysis

Scadabased Industrial Control Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Scadabased Industrial Control Systems Market Analysis Report by Region

Europe Scadabased Industrial Control Systems Market Report:

Europe's market is expected to expand from $2.52 billion in 2023 to $4.82 billion by 2033, fueled by stringent regulations on energy consumption and sustainability that drive investments in more efficient systems.Asia Pacific Scadabased Industrial Control Systems Market Report:

The Asia-Pacific region shows promising growth potential with a market size of $2.18 billion in 2023, projected to reach $4.16 billion by 2033. This growth is driven by rapid industrialization, increased adoption of automation solutions, and significant government initiatives aimed at digital transformation in sectors like manufacturing and utilities.North America Scadabased Industrial Control Systems Market Report:

North America dominates the market with a valuation of $3.71 billion in 2023, anticipated to double to $7.08 billion by 2033. The robust growth stems from a mature industrial landscape, high-level investment in R&D, and a strong inclination towards smart manufacturing and digital integration.South America Scadabased Industrial Control Systems Market Report:

In South America, the market size for Scadabased Industrial Control Systems is relatively small at $0.41 billion in 2023, expected to grow to $0.79 billion by 2033. The growth is supported by increasing energy demands and improvements in infrastructure.Middle East & Africa Scadabased Industrial Control Systems Market Report:

The Middle East and Africa market stands at $1.17 billion in 2023, aiming for $2.24 billion by 2033. This increase is attributed to the booming oil and gas sector, coupled with increasing investments in industrial automation and control systems.Tell us your focus area and get a customized research report.

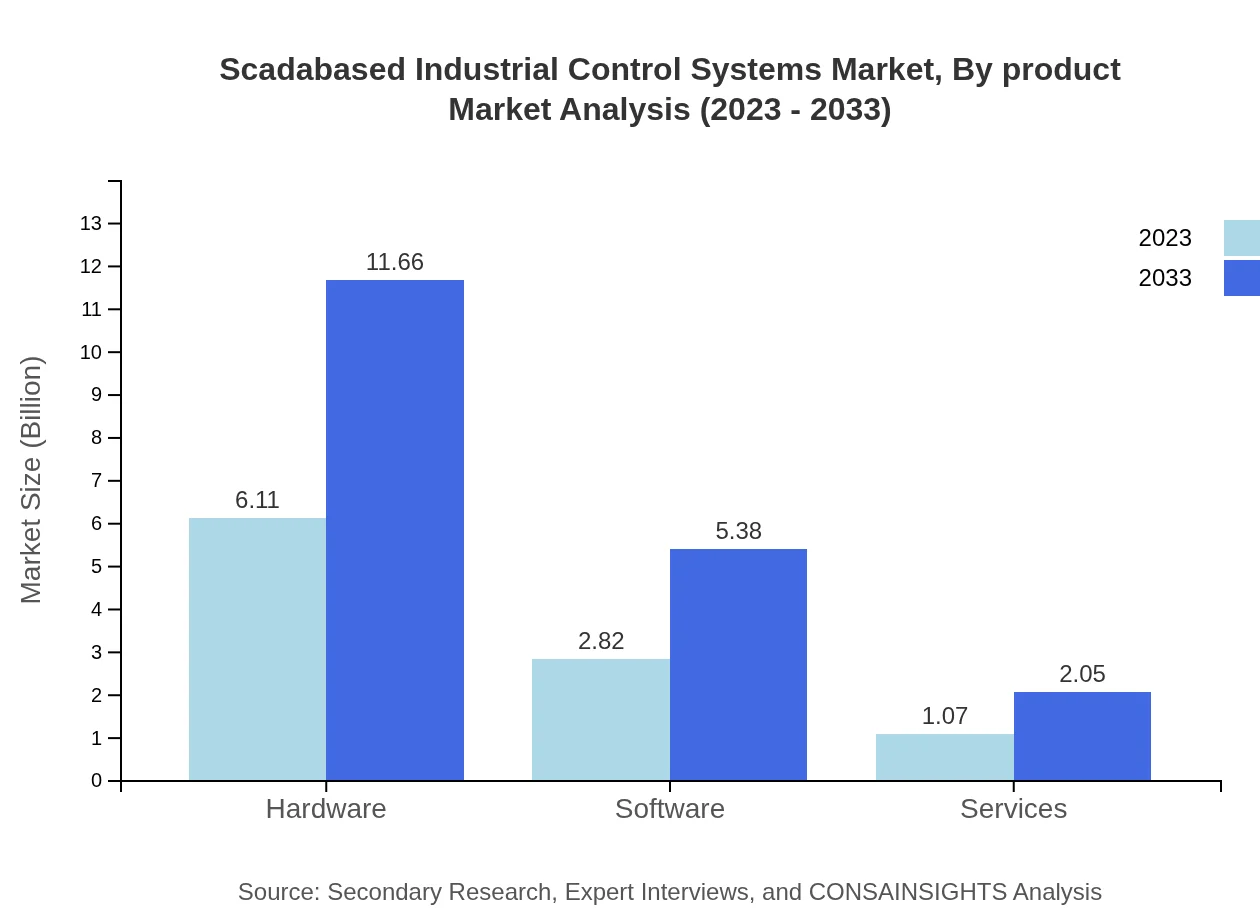

Scadabased Industrial Control Systems Market Analysis By Product

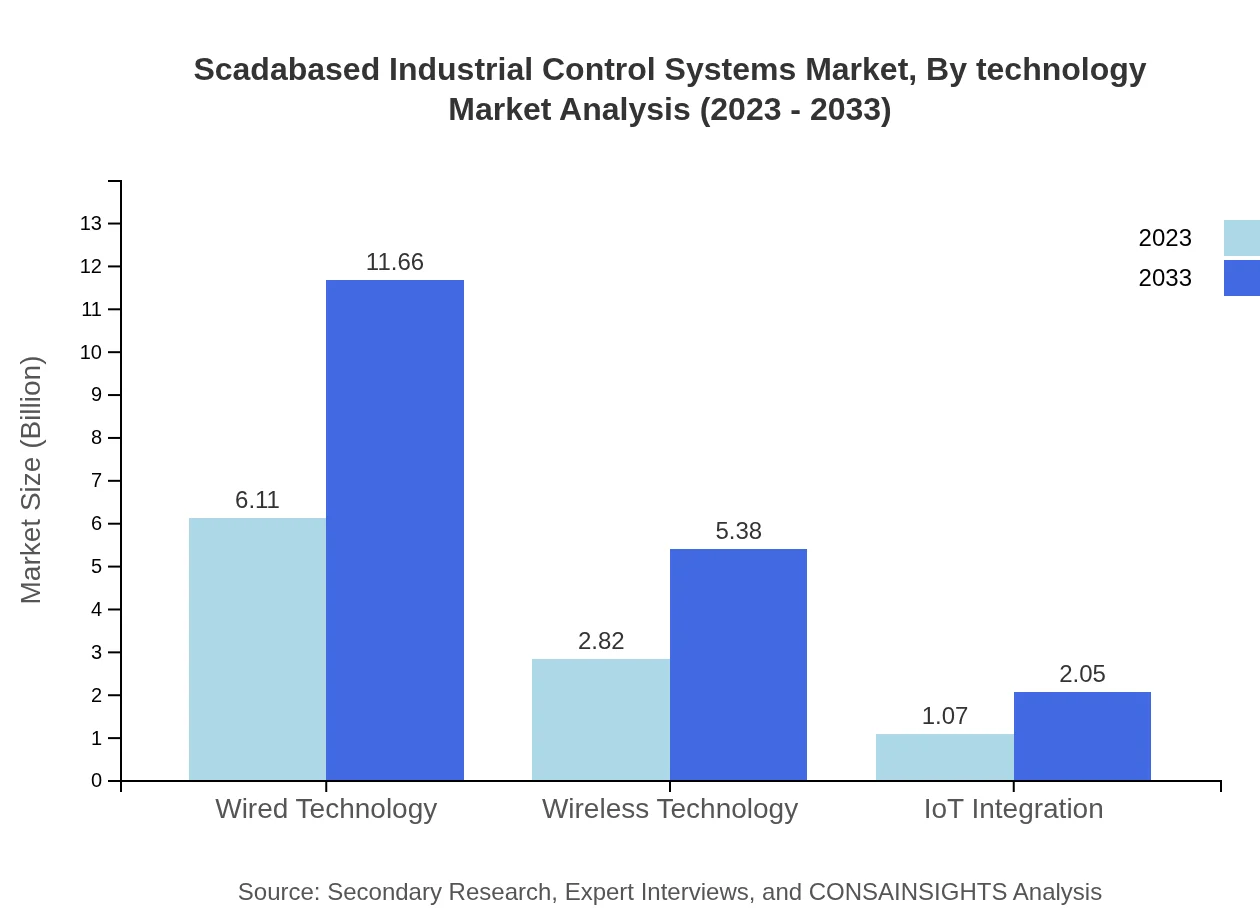

The hardware segment leads the market with a size of $6.11 billion in 2023, expected to grow to $11.66 billion by 2033. Notable for its share of 61.08%, hardware encompasses critical components like sensors, actuators, and controllers, fundamental for system efficiency. The software segment, valued at $2.82 billion in 2023 and projected to reach $5.38 billion by 2033 (28.19% share), underpins data analytics and system integration. Lastly, the services sector, accounting for $1.07 billion in 2023 with a forecast of $2.05 billion by 2033 (10.73% share), provides essential maintenance and support to optimize system performance.

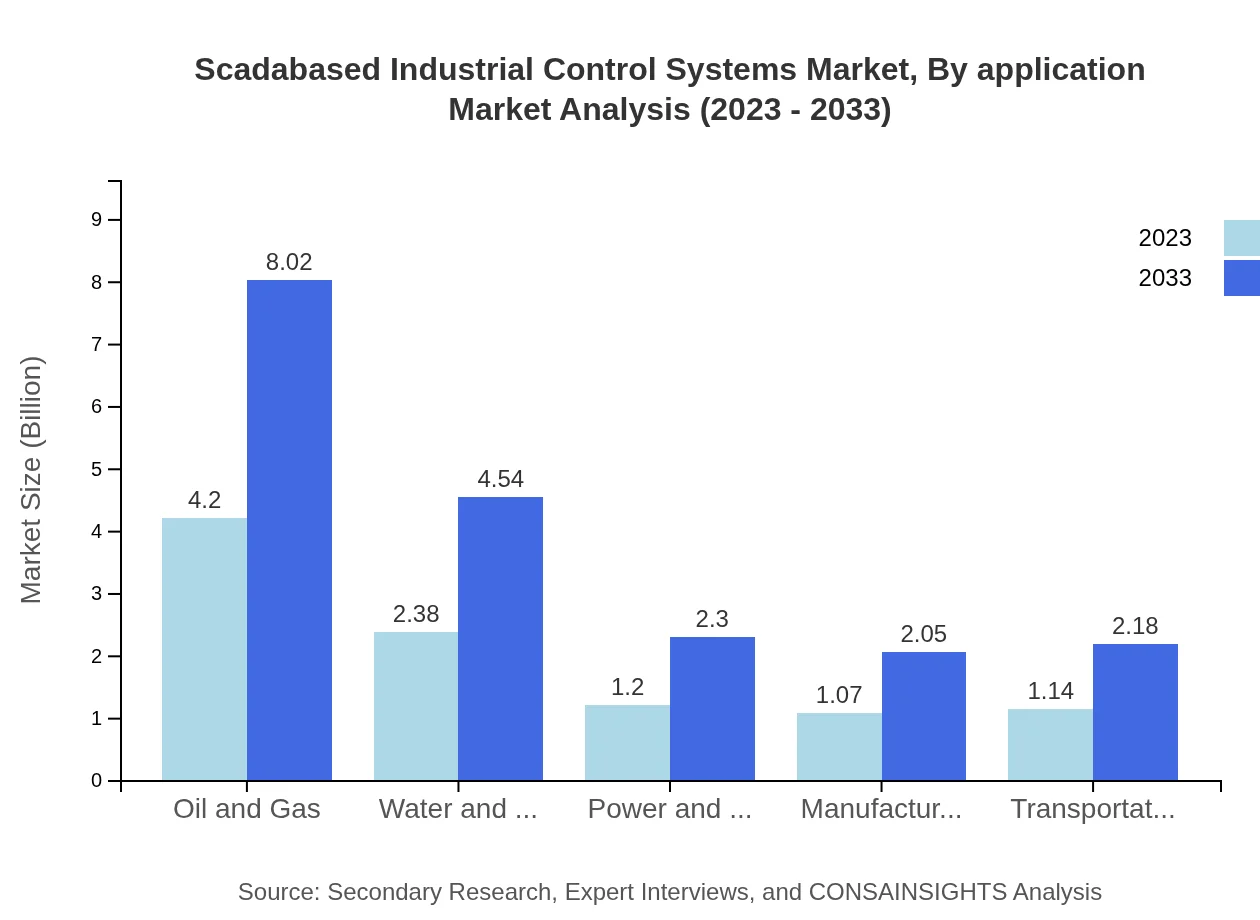

Scadabased Industrial Control Systems Market Analysis By Application

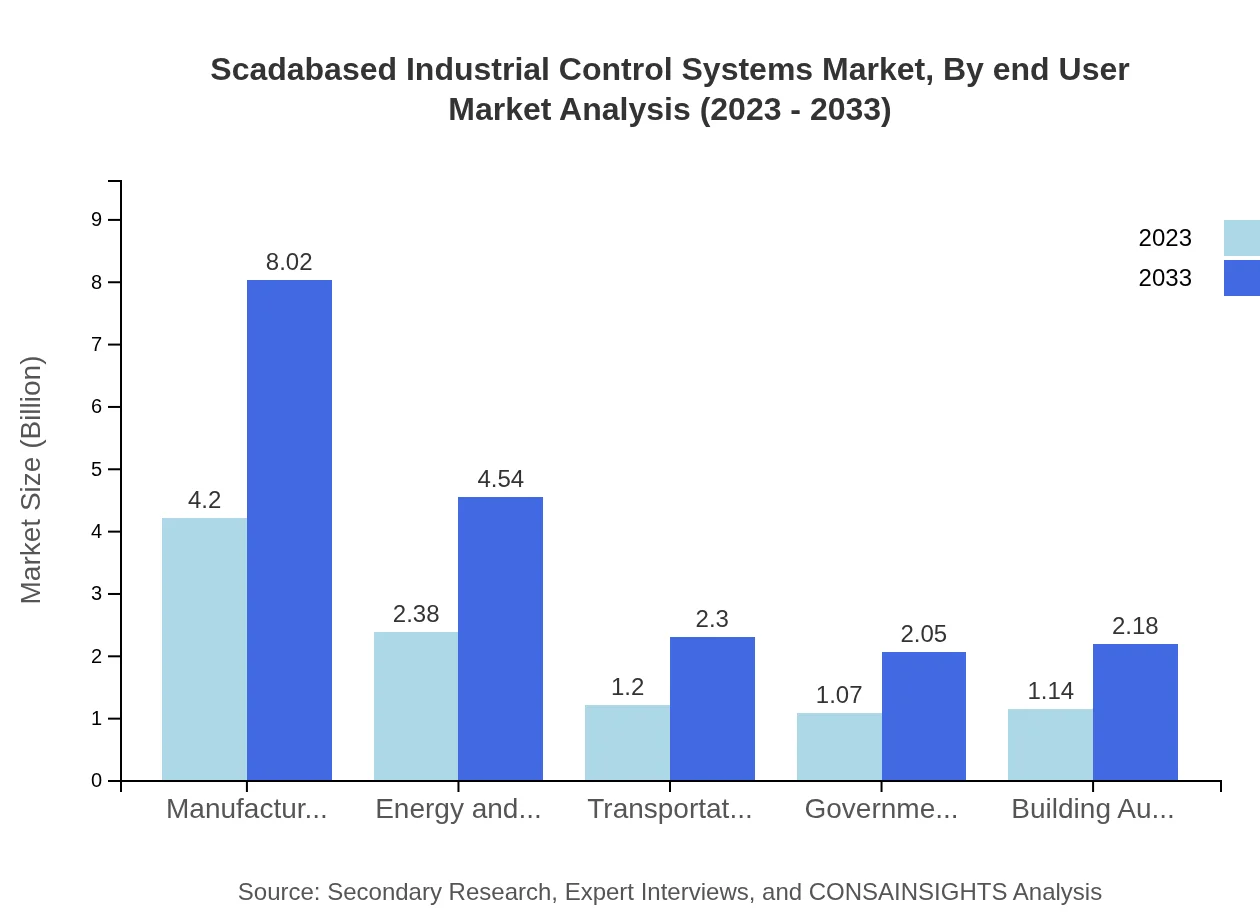

The manufacturing sector commands a significant share, expected to grow from $4.20 billion in 2023 to $8.02 billion by 2033, reflecting 42.01% of the market. Additionally, energy and utilities applications have a significant footprint, valued at $2.38 billion in 2023 and anticipated to hit $4.54 billion by 2033 (23.81% share). Transportation and logistics follow, with expected growth from $1.20 billion to $2.30 billion (12.04% share), while government and defense applications are projected to maintain 10.72% share, growing from $1.07 billion to $2.05 billion.

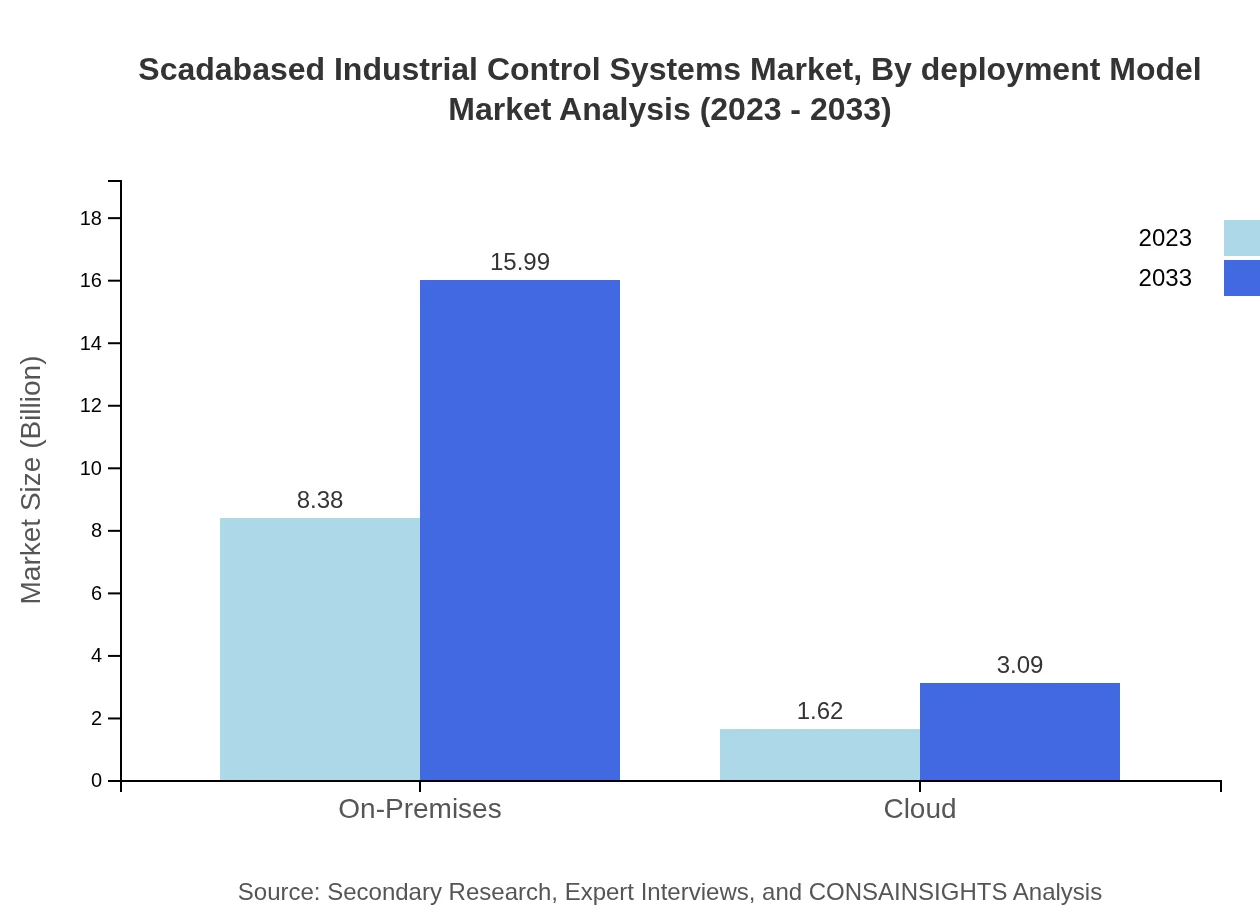

Scadabased Industrial Control Systems Market Analysis By Deployment Model

The on-premises model retains the largest market share, currently valued at $8.38 billion and expected to grow to $15.99 billion by 2033 (83.8% share), favored for its security and control. In contrast, the cloud model, with $1.62 billion in 2023, is anticipated to rise to $3.09 billion by 2033 (16.2% share), driven by its flexibility and scalability, particularly among smaller enterprises seeking cost-effective solutions.

Scadabased Industrial Control Systems Market Analysis By End User

Key sectors utilizing SCADA-based systems include oil and gas, manufacturing, and water and wastewater management. The oil and gas sector shows significant potential, with a market size of $4.20 billion in 2023, projected to grow to $8.02 billion by 2033 (42.01% share). The manufacturing sector and water management are also vital end-users, anticipating considerable growth reflected in their respective market sizes.

Scadabased Industrial Control Systems Market Analysis By Technology

The wired technology segment presently leads the market with a size of $6.11 billion in 2023, which is expected to reach $11.66 billion by 2033, having a 61.08% market share. Meanwhile, the wireless technology segment earns a considerable share of 28.19%, growing from $2.82 billion to $5.38 billion, likely benefiting from the demand for mobility and remote monitoring capabilities. IoT integration is emerging, valued at $1.07 billion in 2023 and anticipated to expand to $2.05 billion by 2033 (10.73% share), focusing on smart technology and connectivity.

Scadabased Industrial Control Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Scadabased Industrial Control Systems Industry

Siemens AG:

A leader in automation and digitalization, Siemens offers comprehensive Scada solutions and hardware that enhance operational efficiency across various industries.Schneider Electric:

Known for innovative electricity management and automation solutions, Schneider Electric provides robust SCADA systems that are integral to energy management and utilities.Rockwell Automation:

Specializing in industrial automation and information technology, Rockwell delivers comprehensive SCADA solutions, ensuring operational excellence and system integration.Honeywell International Inc.:

Honeywell is recognized for its full-spectrum ICS solutions that enable effective monitoring and control across manufacturing processes and critical infrastructure.Emerson Electric Co.:

With a strong focus on automation solutions, Emerson provides advanced SCADA systems that enhance performance and reliability in industrial processes.We're grateful to work with incredible clients.

FAQs

What is the market size of scadabased Industrial Control Systems?

The SCADA-based Industrial Control Systems market size is projected to reach approximately $10 billion in 2023, with an expected CAGR of 6.5% through 2033, indicating robust growth and increasing demand for automation.

What are the key market players or companies in this scadabased Industrial Control Systems industry?

Key players include major companies providing SCADA solutions, automation hardware manufacturers, and software providers. These key players leverage innovative technology and strategic partnerships to enhance their market presence in the industrial control systems sector.

What are the primary factors driving the growth in the scadabased Industrial Control Systems industry?

Growth drivers include the increasing demand for automation across industries, the need for operational efficiency, advancements in IoT technology, and heightened focus on real-time data analytics, all contributing to a flourishing SCADA market.

Which region is the fastest Growing in the scadabased Industrial Control Systems?

North America emerges as the fastest-growing region in the SCADA market, expected to expand from $3.71 billion in 2023 to $7.08 billion by 2033, driven by robust manufacturing and infrastructure sectors.

Does ConsaInsights provide customized market report data for the scadabased Industrial Control Systems industry?

Yes, ConsaInsights offers tailored market report data for the SCADA-based industrial control systems industry, enabling clients to access specific insights that meet their unique business needs.

What deliverables can I expect from this scadabased Industrial Control Systems market research project?

Expect detailed market analysis reports, segmentation insights, growth forecasts, competitive landscape evaluations, and region-specific insights that cater to decision-making in the SCADA market.

What are the market trends of scadabased Industrial Control Systems?

Current trends include increased adoption of cloud-based solutions, integration of IoT in SCADA systems, and a shift towards enhanced cybersecurity measures, reflecting the evolving technological landscape in the industry.