Seamless Pipes Market Report

Published Date: 22 January 2026 | Report Code: seamless-pipes

Seamless Pipes Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Seamless Pipes market, covering key trends, market size, and forecasts from 2023 to 2033. Valuable insights into regional dynamics and industry challenges are also discussed.

| Metric | Value |

|---|---|

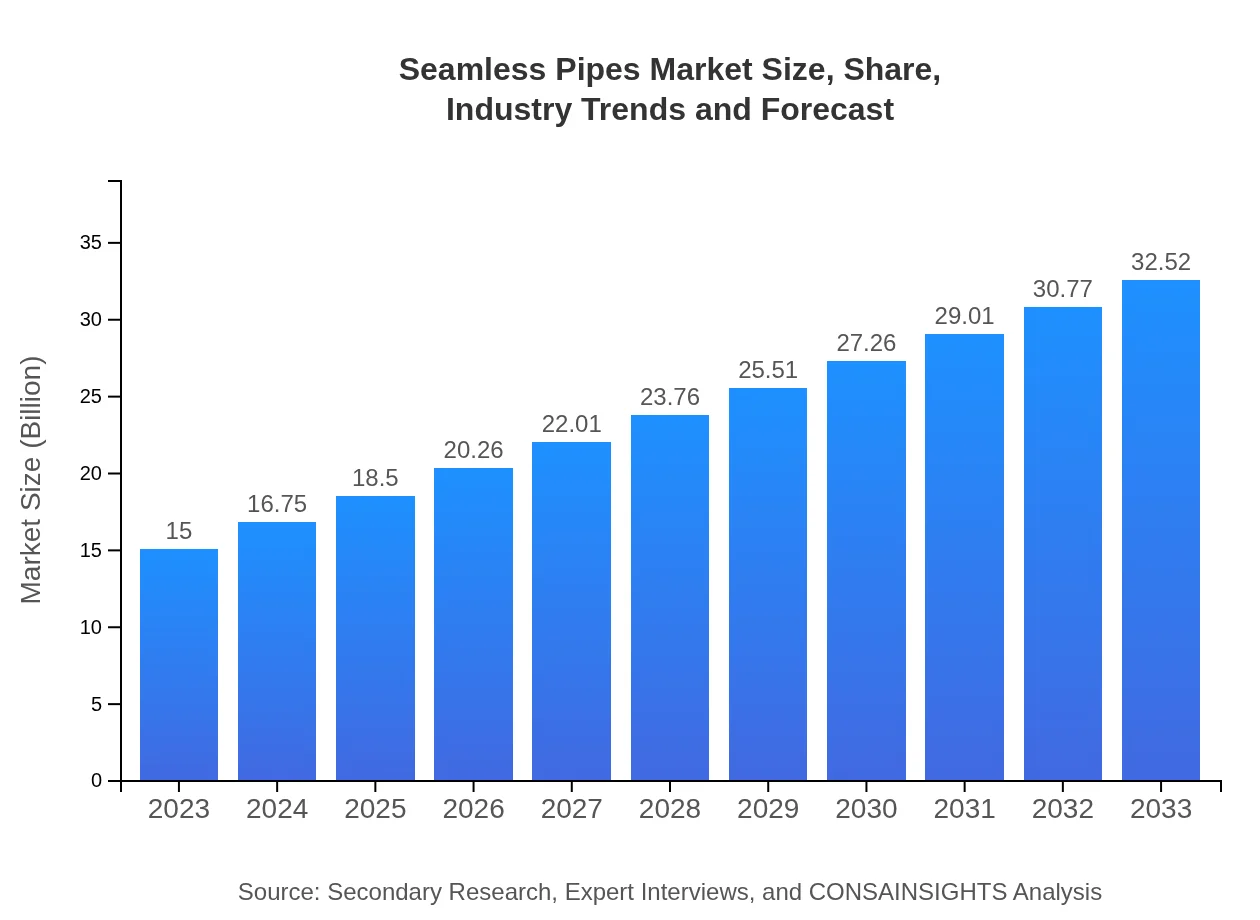

| Study Period | 2023 - 2033 |

| 2023 Market Size | $15.00 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $32.52 Billion |

| Top Companies | Tenaris, Vallourec, Salzgitter AG, JFE Steel Corporation, Tata Steel |

| Last Modified Date | 22 January 2026 |

Seamless Pipes Market Overview

Customize Seamless Pipes Market Report market research report

- ✔ Get in-depth analysis of Seamless Pipes market size, growth, and forecasts.

- ✔ Understand Seamless Pipes's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Seamless Pipes

What is the Market Size & CAGR of the Seamless Pipes Market in 2023?

Seamless Pipes Industry Analysis

Seamless Pipes Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Seamless Pipes Market Analysis Report by Region

Europe Seamless Pipes Market Report:

The European region is forecasted to have a market of 4.99 billion USD in 2023, with an increase to 10.82 billion USD by 2033. The region is focusing on advanced manufacturing techniques and sustainability initiatives in pipeline production.Asia Pacific Seamless Pipes Market Report:

In 2023, the Asia Pacific region is estimated to have a market size of 2.62 billion USD, projected to grow to 5.68 billion USD by 2033. The growth is fueled by rapid industrialization, urbanization, and substantial investments in infrastructure development.North America Seamless Pipes Market Report:

In North America, the market size for seamless pipes is projected at 5.26 billion USD in 2023 and is expected to increase to 11.40 billion USD by 2033. This growth is driven by a robust oil and gas sector and increasing construction projects.South America Seamless Pipes Market Report:

The South American market for seamless pipes is relatively small, valued at 0.04 billion USD in 2023 and expected to reach 0.09 billion USD by 2033. Limited growth prospects are influenced by economic factors and infrastructural deficits.Middle East & Africa Seamless Pipes Market Report:

In the Middle East and Africa, the seamless pipes market is expected to grow from 2.08 billion USD in 2023 to 4.52 billion USD by 2033, largely driven by the expanding oil and gas industry and new energy projects.Tell us your focus area and get a customized research report.

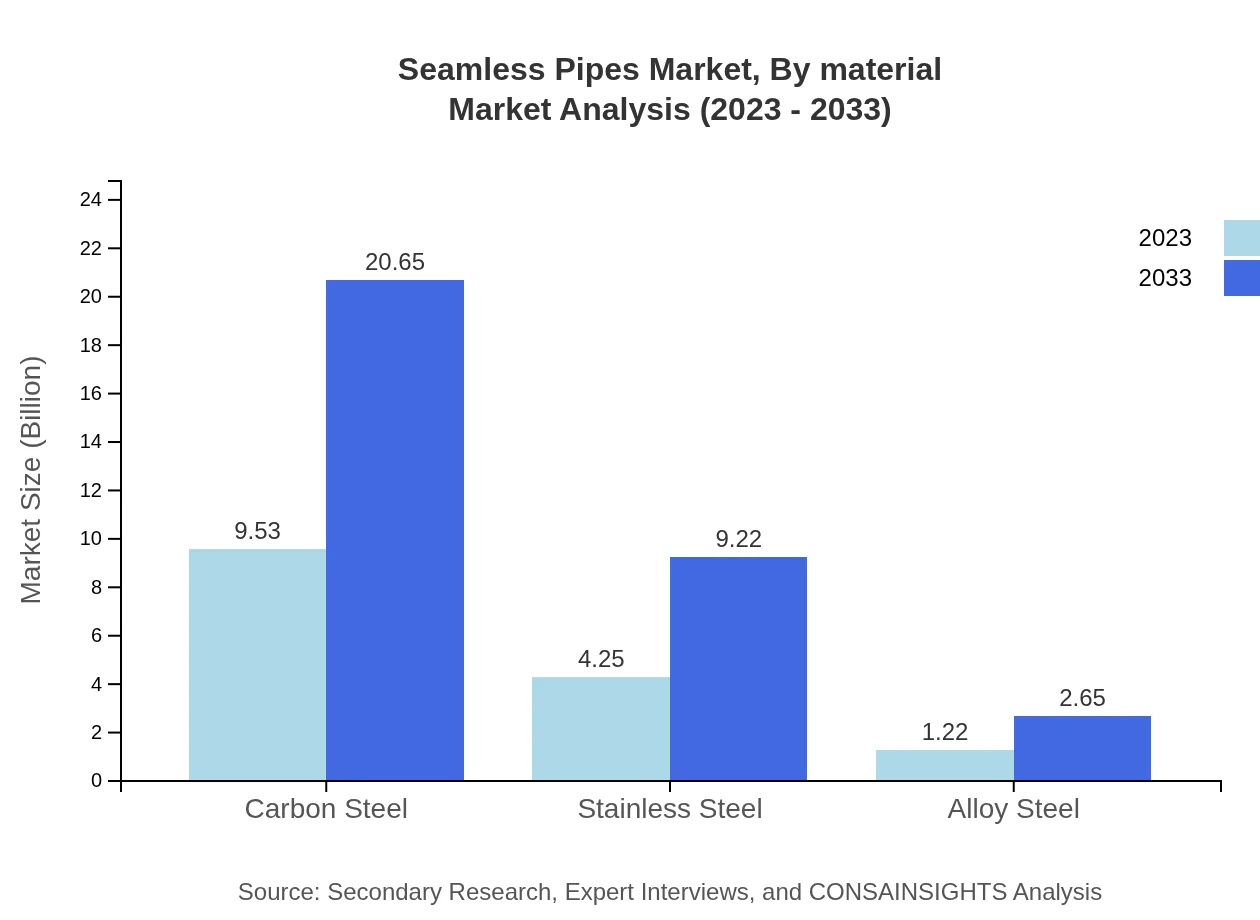

Seamless Pipes Market Analysis By Material

In the segmented analysis by material, carbon steel accounts for about 63.51% of the market share, reflecting its utilization in various industries for durability and cost-effectiveness. The stainless steel segment represents about 28.35% of the market, predominantly used in chemical processing and food applications due to its corrosion resistance. Alloy steel, while smaller, is expected to see a growth in demand from specialized industries.

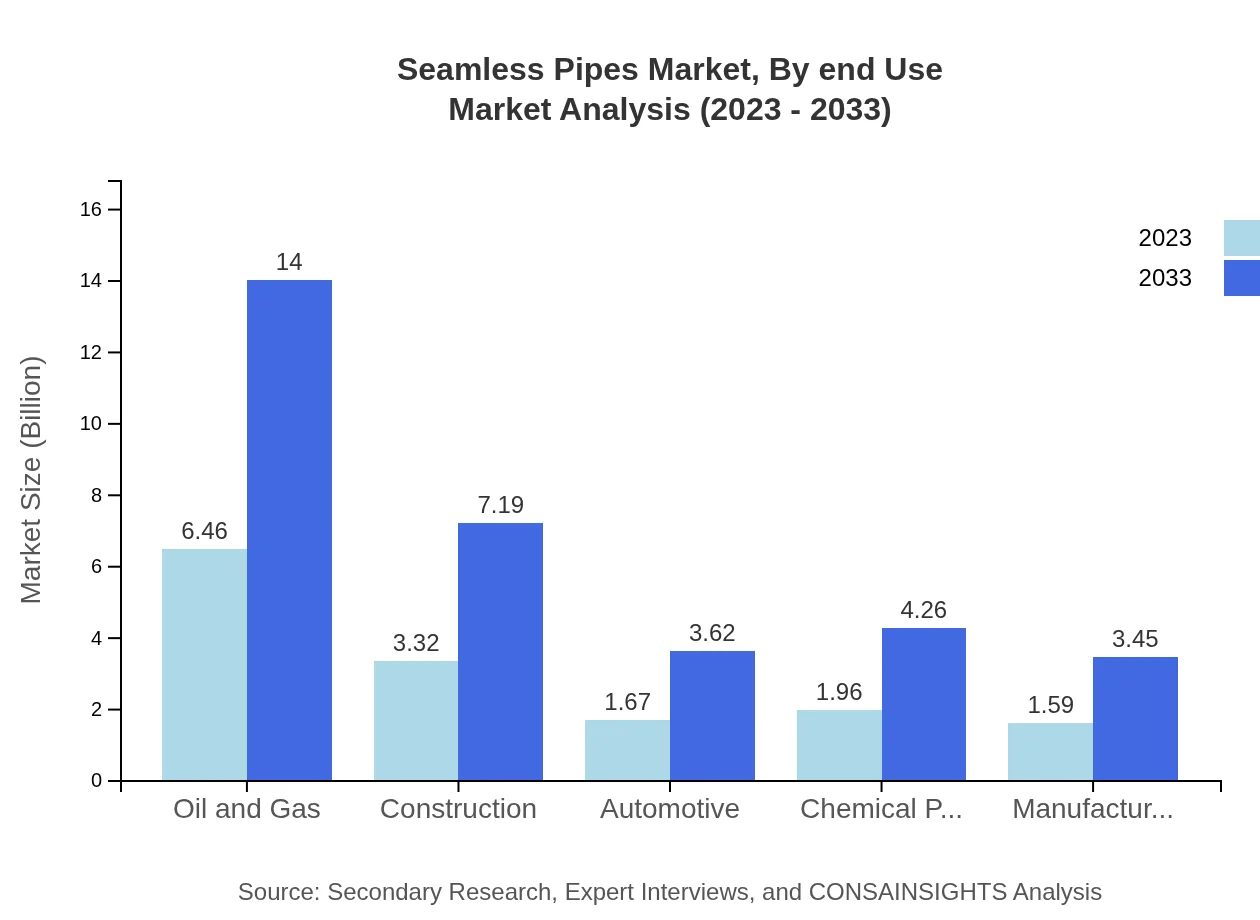

Seamless Pipes Market Analysis By End Use

The oil and gas sector is the largest end-use segment, commanding a market size of 6.46 billion USD in 2023, projected to grow to 14.00 billion USD by 2033. The construction segment follows with a market size of 3.32 billion USD, reinforced by ongoing infrastructure projects, while the automotive industry continues to contribute significantly with an expected rise from 1.67 billion in 2023 to 3.62 billion by 2033.

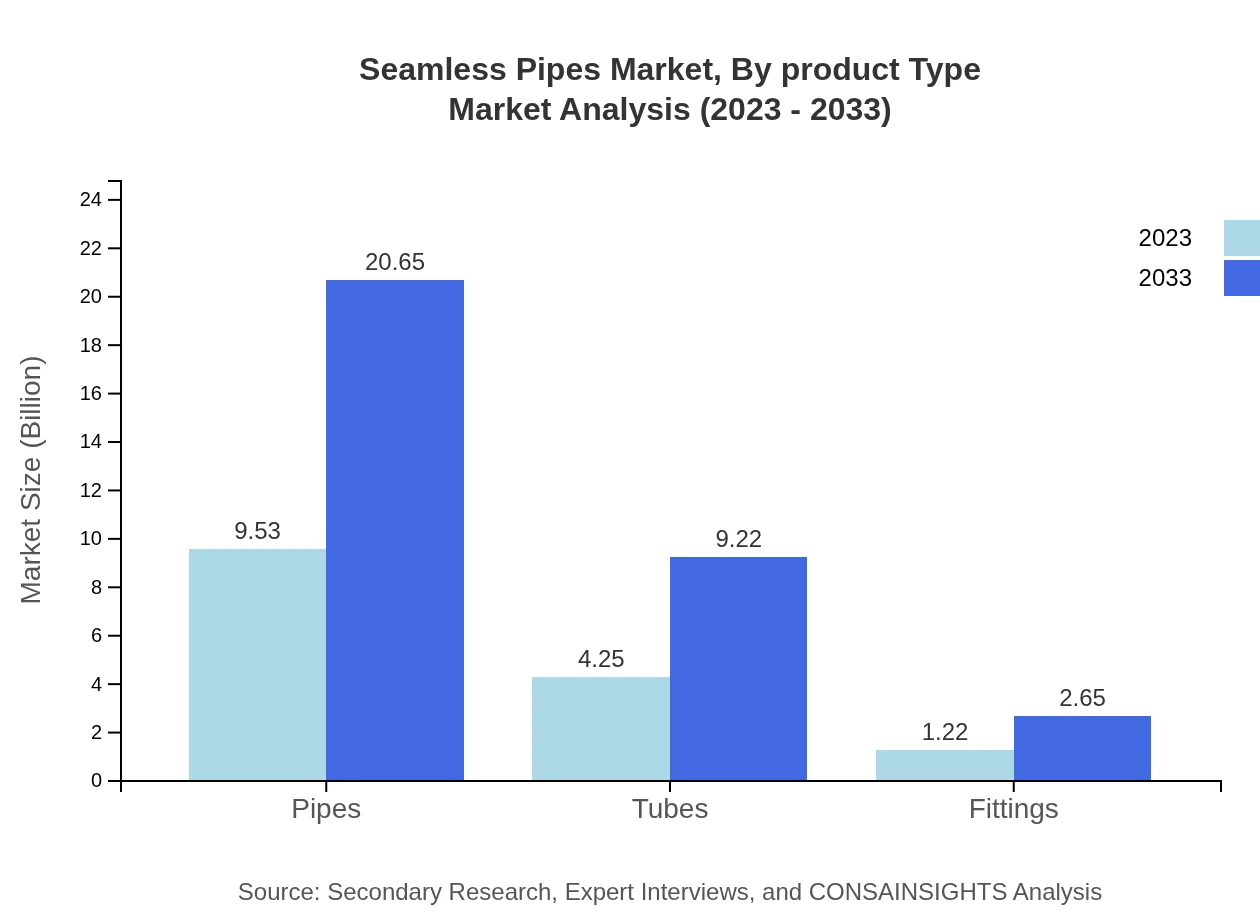

Seamless Pipes Market Analysis By Product Type

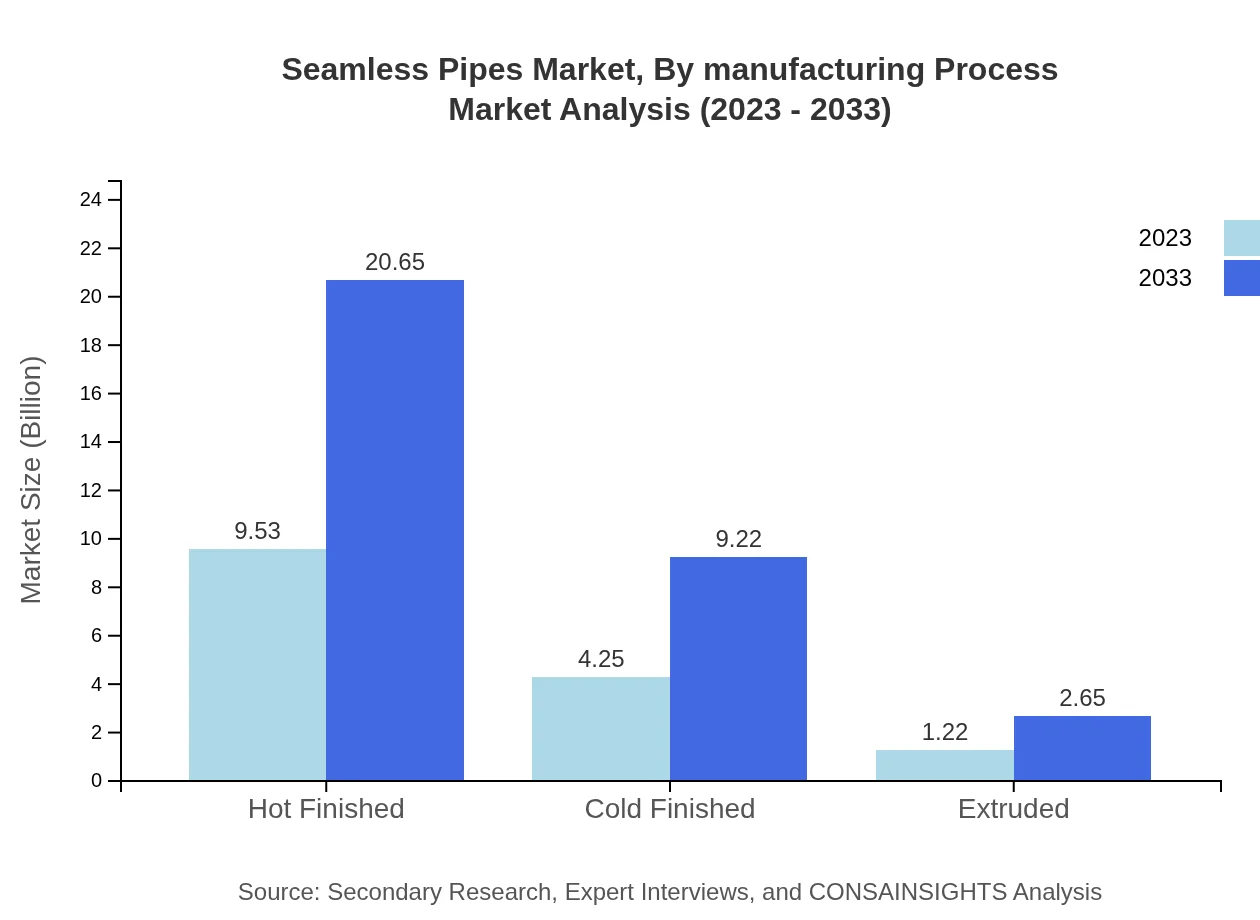

Seamless pipes and tubes make up the bulk of the market, with expected growth from 9.53 billion USD to 20.65 billion USD by 2033. Tubes also hold a significant share, projected to grow from 4.25 billion USD to 9.22 billion USD due to demand in precision applications across various sectors.

Seamless Pipes Market Analysis By Manufacturing Process

Hot finished methods dominate the production processes, accounting for significant market share at 63.51%, while cold finished processes are crucial for high-precision requirements, representing 28.35%. Emerging extrusion techniques are carving a niche market as manufacturers focus on producing innovative product designs.

Seamless Pipes Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in the Seamless Pipes Industry

Tenaris:

Tenaris is a leading global manufacturer of steel pipes, providing a wide range of products for the energy sector, notably oil and gas, with significant R&D investment to innovate their seamless pipe offerings.Vallourec:

Vallourec specializes in seamless pipes for various applications, focusing on sustainable practices and advanced technology in their production methods to cater to the energy and construction sectors.Salzgitter AG:

Salzgitter is a major player in the steel industry with a broad portfolio of seamless pipes utilized in various industries, emphasizing the use of high-quality materials and sustainability in their operations.JFE Steel Corporation:

JFE Steel is known for its advanced steel manufacturing technologies, producing seamless pipes for the oil and gas industry, with a strong emphasis on quality and innovation.Tata Steel:

Tata Steel operates in the global market with a substantial focus on seamless pipes production for diverse applications, championing sustainability and technological advancement.We're grateful to work with incredible clients.

FAQs

What is the market size of seamless pipes?

The global seamless pipes market is projected to reach approximately $15 billion by 2033, growing at a compound annual growth rate (CAGR) of 7.8%. The increasing demand from various sectors is a key growth factor.

What are the key market players or companies in the seamless pipes industry?

Key players in the seamless pipes industry include established manufacturers and suppliers known for quality and innovation. These companies continuously invest in product development to meet diverse industry needs.

What are the primary factors driving the growth in the seamless pipe industry?

Primary growth factors in the seamless pipe industry include increasing demand from the oil and gas, construction, and automotive sectors, as well as advancements in manufacturing technologies that enhance product quality and efficiency.

Which region is the fastest Growing in the seamless pipe market?

The fastest-growing region in the seamless pipe market is Europe, expected to rise from $4.99 billion in 2023 to $10.82 billion by 2033, driven by substantial industrial activities and infrastructure projects.

Does ConsaInsights provide customized market report data for the seamless pipes industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the seamless pipes industry, enabling clients to gain deeper insights based on unique market challenges.

What deliverables can I expect from this seamless pipes market research project?

Deliverables for seamless pipes market research include comprehensive reports featuring market trends, forecasts, competitive analysis, and regional insights to support strategic decision-making for stakeholders.

What are the market trends of seamless pipes?

Market trends for seamless pipes indicate a growing preference for carbon steel due to its strength and durability, along with significant expansions in the oil and gas and construction sectors, emphasizing infrastructure development.