Sensor Bearing Market Report

Published Date: 22 January 2026 | Report Code: sensor-bearing

Sensor Bearing Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the sensor bearing market from 2023 to 2033, analyzing market size, growth trends, segmentation, and leading players. It offers comprehensive insights on current dynamics and provides projections to support strategic decision-making.

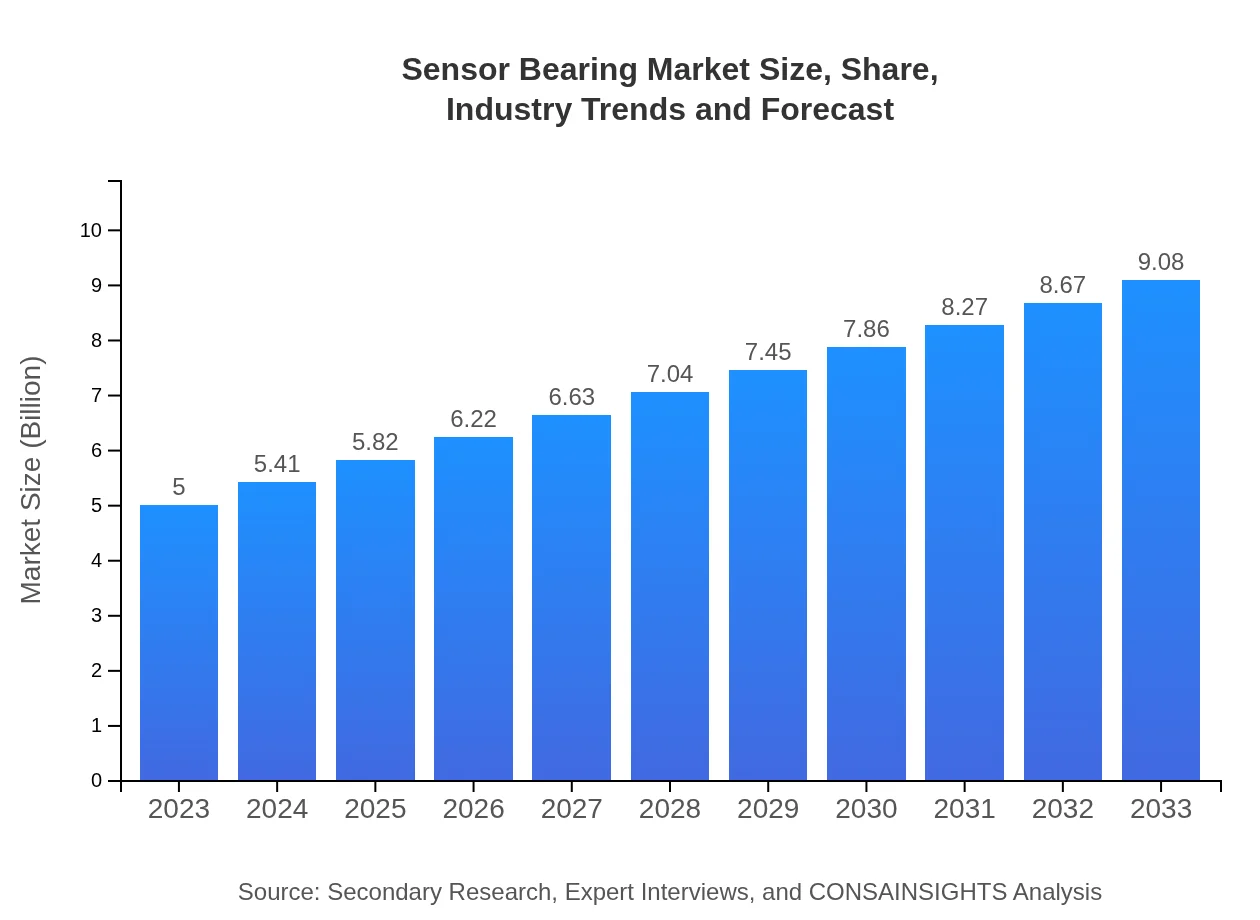

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 6% |

| 2033 Market Size | $9.08 Billion |

| Top Companies | SKF, Honeywell International Inc., NTN Corporation, Thrustmaster |

| Last Modified Date | 22 January 2026 |

Sensor Bearing Market Overview

Customize Sensor Bearing Market Report market research report

- ✔ Get in-depth analysis of Sensor Bearing market size, growth, and forecasts.

- ✔ Understand Sensor Bearing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Sensor Bearing

What is the Market Size & CAGR of Sensor Bearing market in 2023?

Sensor Bearing Industry Analysis

Sensor Bearing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Sensor Bearing Market Analysis Report by Region

Europe Sensor Bearing Market Report:

The European market for sensor bearings is anticipated to grow from $1.78 billion in 2023 to $3.23 billion by 2033. This growth can be attributed to stringent regulations regarding machinery safety, alongside a strong automotive industry focused on innovation, leading to greater adoption of sophisticated sensor technologies in vehicular systems.Asia Pacific Sensor Bearing Market Report:

The Asia Pacific region holds a significant share of the sensor bearing market, valued at approximately $0.93 billion in 2023, projected to reach $1.69 billion by 2033. The growth is fueled by rising manufacturing activities, increased investments in automation technologies, and the expansion of automotive production in countries like China and India, contributing substantially to the overall demand for sensor bearings.North America Sensor Bearing Market Report:

North America is a notable player in the sensor bearing market, valued at $1.61 billion in 2023 and projected to grow to $2.93 billion by 2033. The region benefits from a robust industrial sector, advancements in smart technologies, and significant research and development initiatives aimed at enhancing automation and reliability in manufacturing processes.South America Sensor Bearing Market Report:

In South America, the sensor bearing market is relatively smaller, valued at $0.40 billion in 2023, expected to reach $0.73 billion by 2033. While the market is currently hampered by economic challenges, the increasing focus on improving fleet management and efficiency in mining and agricultural sectors is paving the way for gradual growth.Middle East & Africa Sensor Bearing Market Report:

In the Middle East and Africa, the sensor bearing market is relatively nascent, valued at $0.27 billion in 2023, expected to grow to $0.49 billion by 2033. Growth is driven by increasing investments in infrastructure development and a burgeoning oil and gas sector, prompting a demand for more advanced monitoring solutions.Tell us your focus area and get a customized research report.

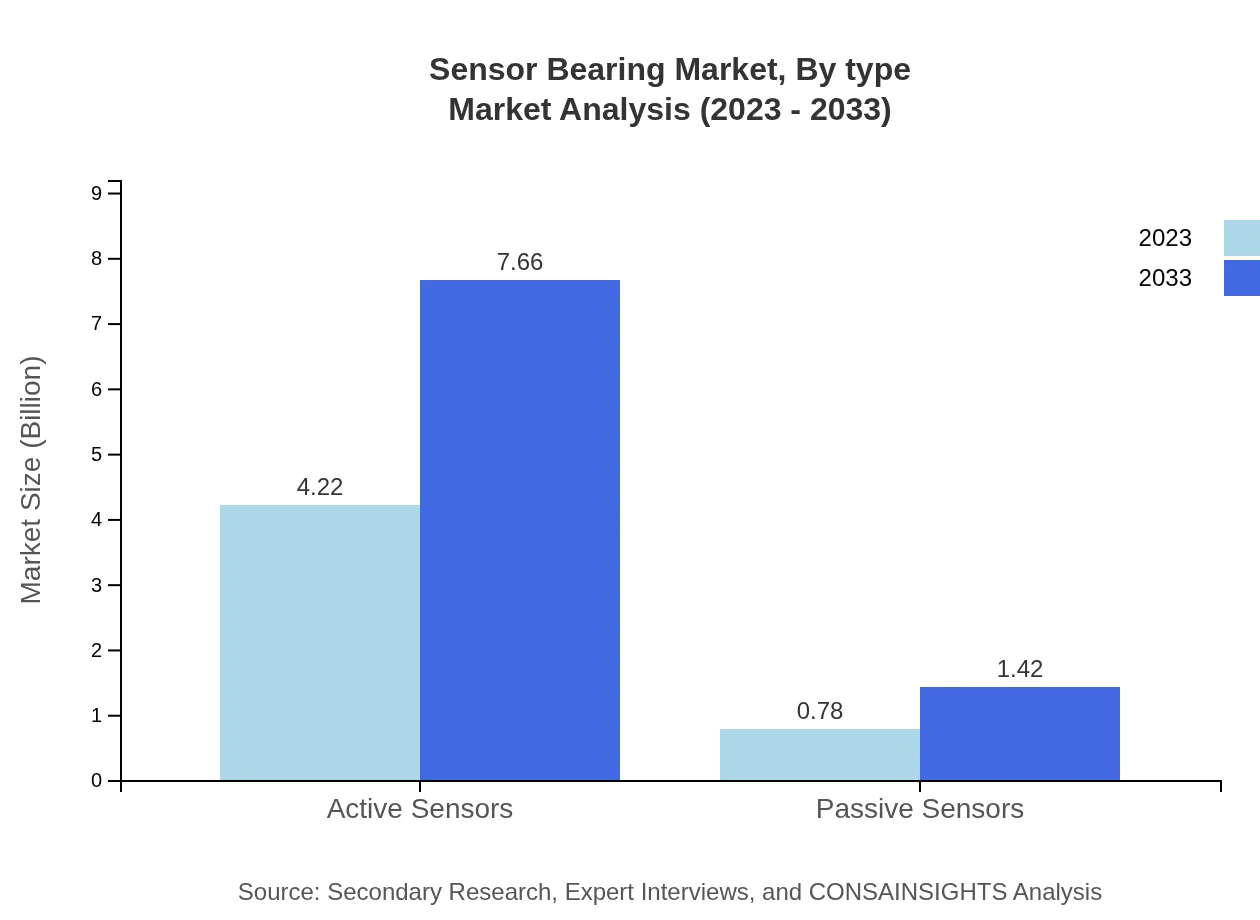

Sensor Bearing Market Analysis By Type

The sensor-bearing market segment is predominantly divided into active and passive sensors. Active sensors accounted for approximately $4.22 billion in 2023, maintaining an 84.38% share, with expectations to rise to $7.66 billion by 2033. Conversely, passive sensors represent a smaller segment valued at $0.78 billion in 2023, with a projected growth to $1.42 billion by 2033 and a 15.62% market share.

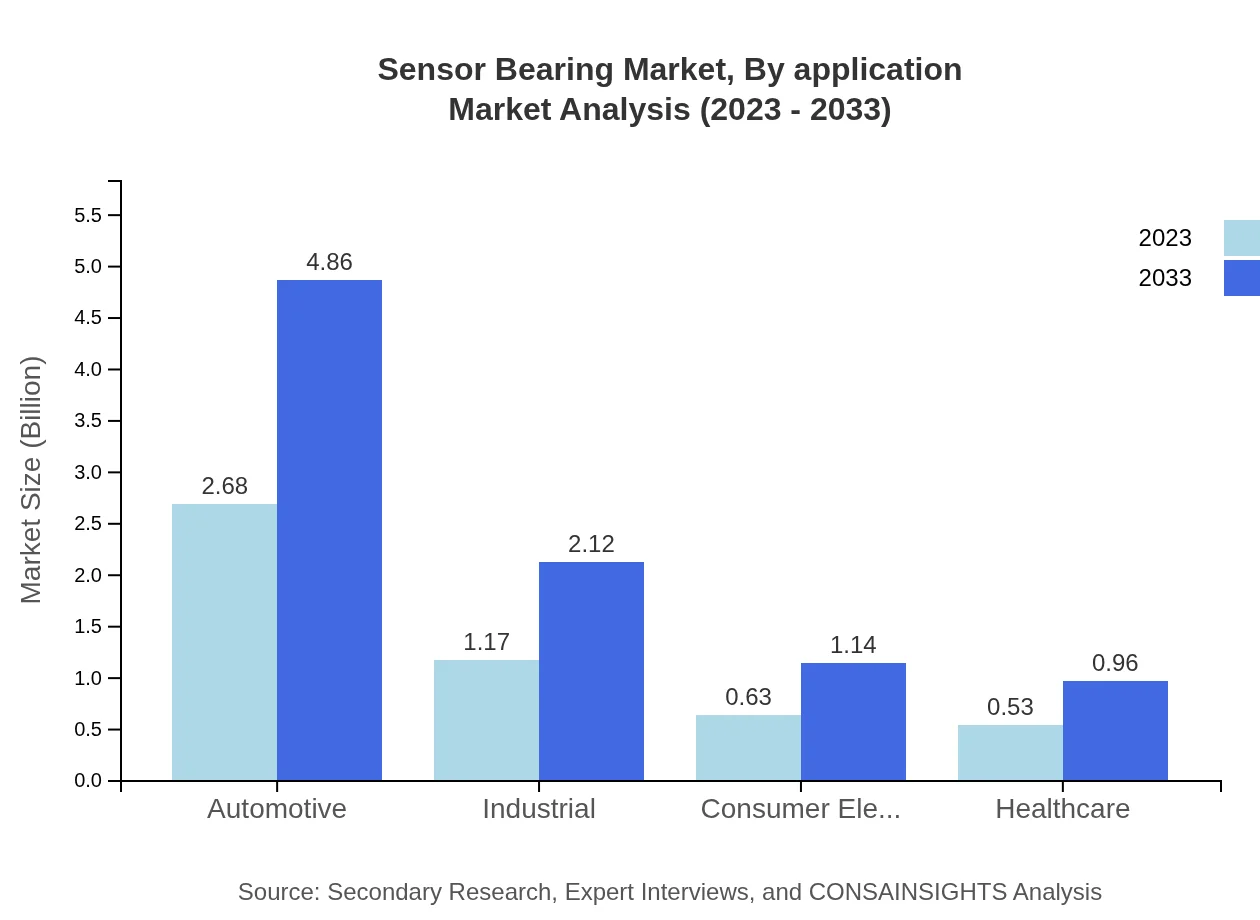

Sensor Bearing Market Analysis By Application

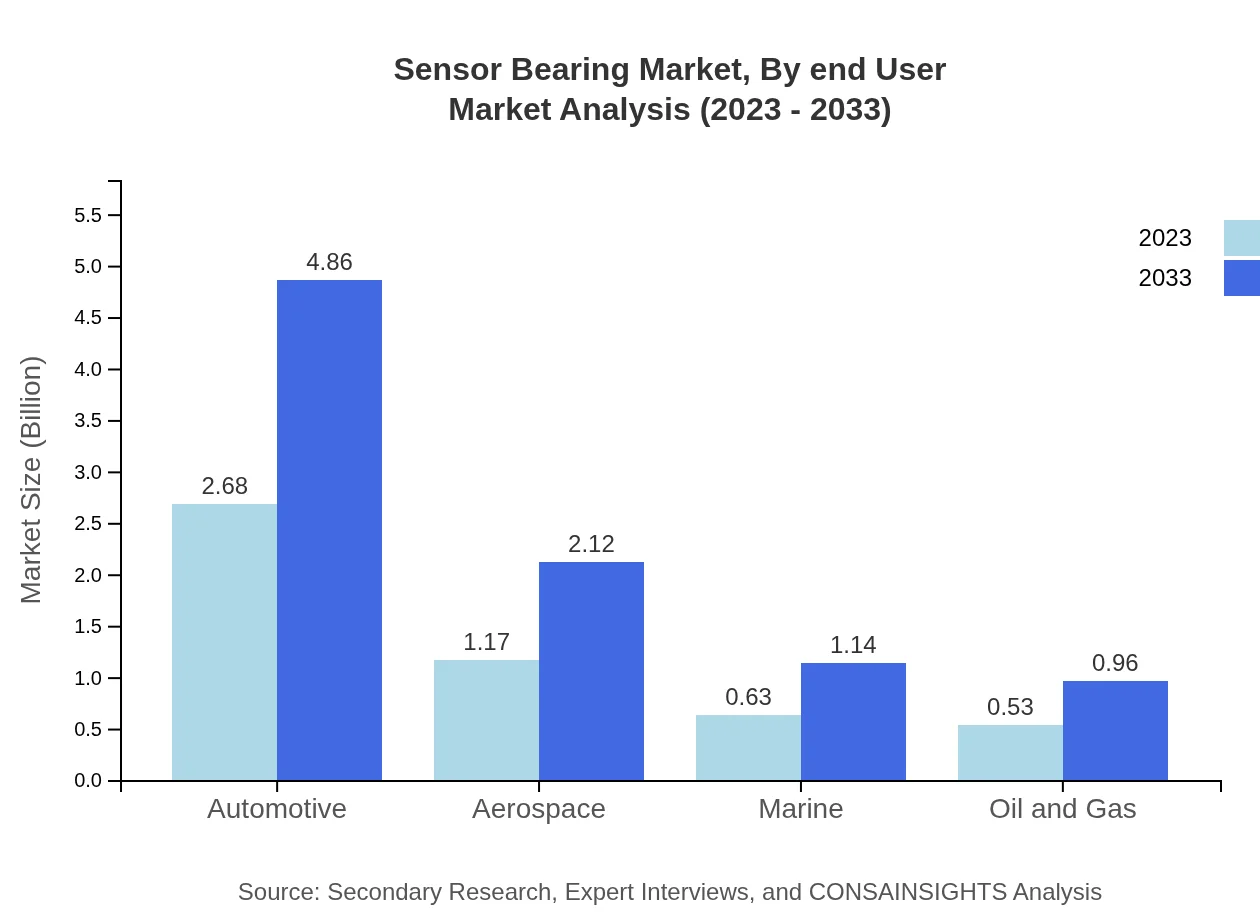

Applications of sensor bearings are extensive, with the automotive sector capturing the largest share at $2.68 billion in 2023, anticipated to grow to $4.86 billion by 2033, indicating a 53.55% market share. Aerospace and industrial applications also play significant roles, valued at $1.17 billion and projected at $2.12 billion from 2023 to 2033. Other sectors like marine, oil and gas, healthcare, and consumer electronics are similarly contributing to the market expansion.

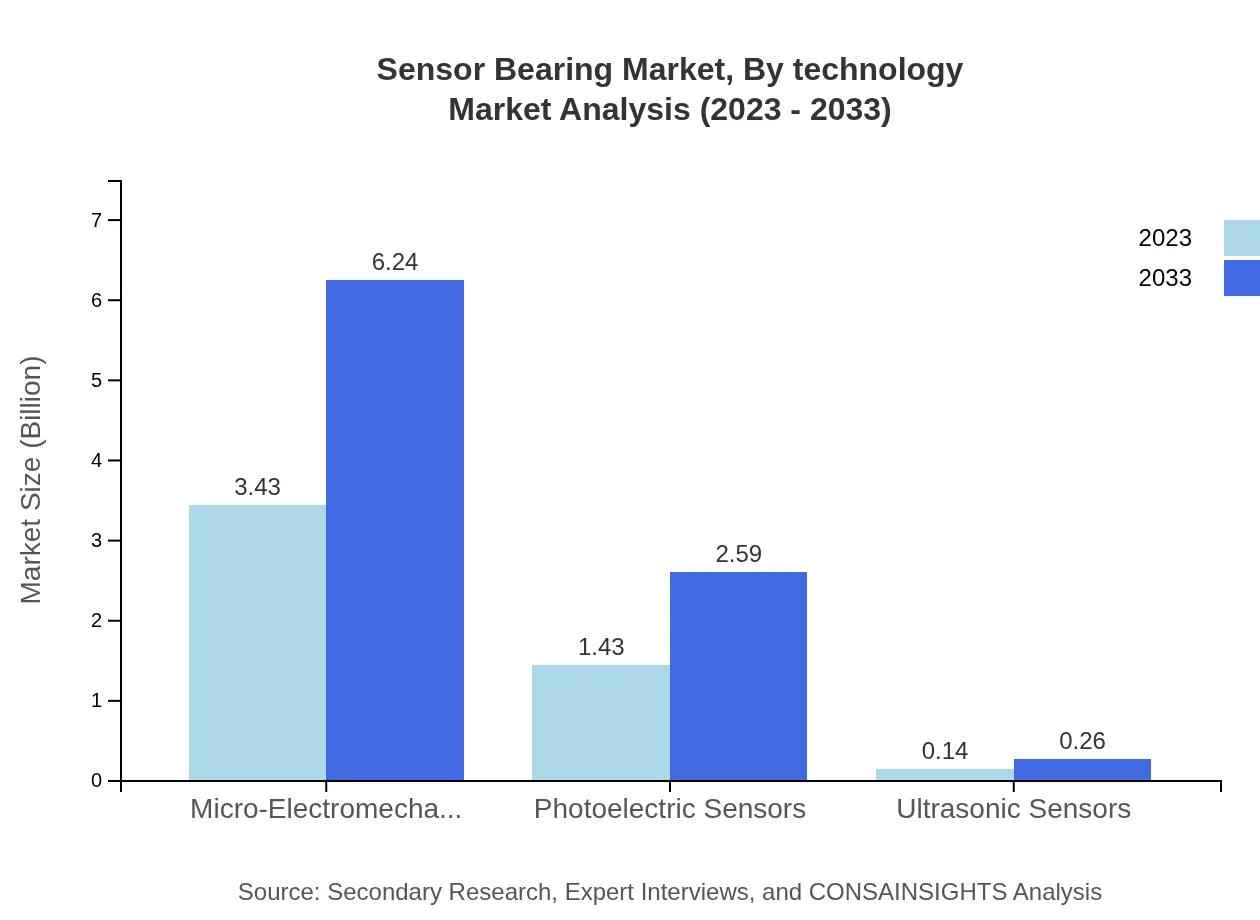

Sensor Bearing Market Analysis By Technology

Technological advancements are central to the sensor bearing market. Micro-Electromechanical Systems (MEMS) currently dominate the technology segment, valued at $3.43 billion in 2023 with projections to grow to $6.24 billion by 2033. This segment encompasses a significant market share of 68.67%. Other technologies include photoelectric sensors and ultrasonic sensors, valued at $1.43 billion and $0.14 billion respectively in 2023, demonstrating robust growth prospects.

Sensor Bearing Market Analysis By End User

In the sensor-bearing market, the end-user industry segmentation entails automotive, aerospace, marine, oil and gas, industrial, consumer electronics, and healthcare. Each sector plays a critical role in driving adoption and innovation within the market, with automotive and industrial sectors leading in market share and size. The increasing need for smart and efficient solutions will continue to catalyze the growth of sensor bearings across these industries.

Sensor Bearing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Sensor Bearing Industry

SKF:

A global leader in bearing technology, SKF develops and manufactures high-quality sensor bearings which are critical for various applications, particularly in automotive and aerospace sectors, known for their strong performance and reliability.Honeywell International Inc.:

Honeywell is a leading manufacturer of advanced sensing technology, including sensor bearings. Their commitment to innovation and quality has positioned them as a preferred partner in providing tailored solutions across diverse industries.NTN Corporation:

NTN Corporation specializes in the manufacturing of precision bearings and sensor technologies, focusing on cutting-edge research and development to enhance performance in automotive and industrial applications.Thrustmaster:

Renowned for its advanced torque measurement technology, Thrustmaster produces high-performance sensor bearings for the marine and aerospace sectors, upholding a reputation for premium product quality and reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of the sensor Bearing?

The global sensor-bearing market size was estimated at $5 billion in 2023, with a projected CAGR of 6% from 2023 to 2033. This growth indicates a robust demand for sensor-bearing solutions across various industries.

What are the key market players or companies in the sensor Bearing industry?

Key players in the sensor-bearing market include major manufacturers like SKF Group, Schaeffler Group, and Timken Company, all of which play significant roles in advancing sensor technology and engineering solutions.

What are the primary factors driving the growth in the sensor Bearing industry?

Growth is driven by increasing automation in manufacturing, advancements in IoT technology, demand for smart devices, and the need for enhanced efficiency in various sectors like automotive and aerospace.

Which region is the fastest Growing in the sensor Bearing?

Asia Pacific is the fastest-growing region, projected to grow from $0.93 billion in 2023 to $1.69 billion by 2033, driven by booming manufacturing sectors and increasing technology adoption across industries.

Does ConsaInsights provide customized market report data for the sensor Bearing industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs within the sensor-bearing industry, providing detailed insights and analytics to suit various business objectives.

What deliverables can I expect from this sensor Bearing market research project?

Deliverables include comprehensive market analysis reports, trend forecasts, competitive landscape assessments, and actionable insights tailored to specific industry segments and regional markets.

What are the market trends of sensor Bearing?

Current trends include growing demand for energy-efficient solutions, increased integration of AI and IoT technologies, and enhanced focus on predictive maintenance across industries, indicating a dynamic and evolving market.