Shape Memory Alloys Market Report

Published Date: 02 February 2026 | Report Code: shape-memory-alloys

Shape Memory Alloys Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Shape Memory Alloys market, focusing on key insights from 2023 to 2033, including market trends, forecasts, segmentation, and leading players in the industry.

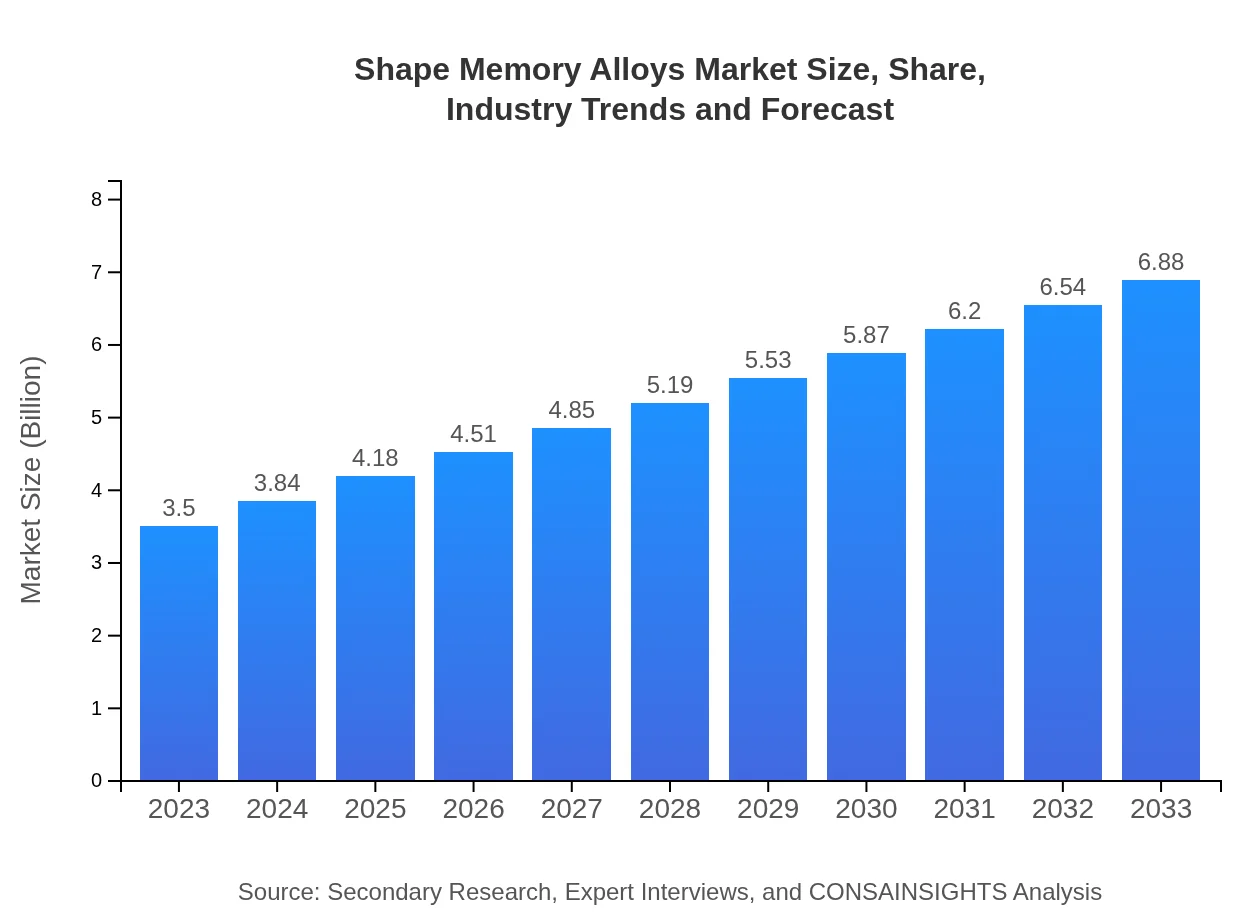

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Johnson Matthey Plc, SAES Getters S.p.A., Mitsubishi Materials Corporation, Alcoa Corporation, Nitinol Devices & Components |

| Last Modified Date | 02 February 2026 |

Shape Memory Alloys Market Overview

Customize Shape Memory Alloys Market Report market research report

- ✔ Get in-depth analysis of Shape Memory Alloys market size, growth, and forecasts.

- ✔ Understand Shape Memory Alloys's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Shape Memory Alloys

What is the Market Size & CAGR of Shape Memory Alloys market in 2033?

Shape Memory Alloys Industry Analysis

Shape Memory Alloys Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Shape Memory Alloys Market Analysis Report by Region

Europe Shape Memory Alloys Market Report:

Europe's Shape Memory Alloys market is projected to expand from $0.87 billion in 2023 to $1.71 billion by 2033. The region is characterized by strong automotive and aerospace industries which are increasingly leveraging SMAs for manufacturing components to improve efficiency and reduce weight.Asia Pacific Shape Memory Alloys Market Report:

The Asia Pacific region is expected to see substantial growth in the Shape Memory Alloys market, projected to increase from $0.72 billion in 2023 to $1.41 billion by 2033. The rapid industrial growth, particularly in countries like China and Japan, and increasing investments in R&D for advanced materials significantly contribute to market expansion.North America Shape Memory Alloys Market Report:

North America is anticipated to dominate the Shape Memory Alloys market, with growth from $1.17 billion in 2023 to $2.30 billion by 2033. The high adoption rate of advanced technologies in medical and aerospace applications fuels this growth. Major companies in the region are investing heavily in innovation and production capabilities.South America Shape Memory Alloys Market Report:

In South America, the market for Shape Memory Alloys is expected to grow from $0.32 billion in 2023 to $0.62 billion by 2033. The growth is driven by increasing applications in the healthcare sector, along with evolving automotive and aerospace industries in countries like Brazil and Argentina.Middle East & Africa Shape Memory Alloys Market Report:

The Middle East and Africa market for Shape Memory Alloys is expected to increase from $0.43 billion in 2023 to $0.84 billion by 2033, primarily due to rising investment in industrial applications and growing healthcare infrastructure in GCC countries.Tell us your focus area and get a customized research report.

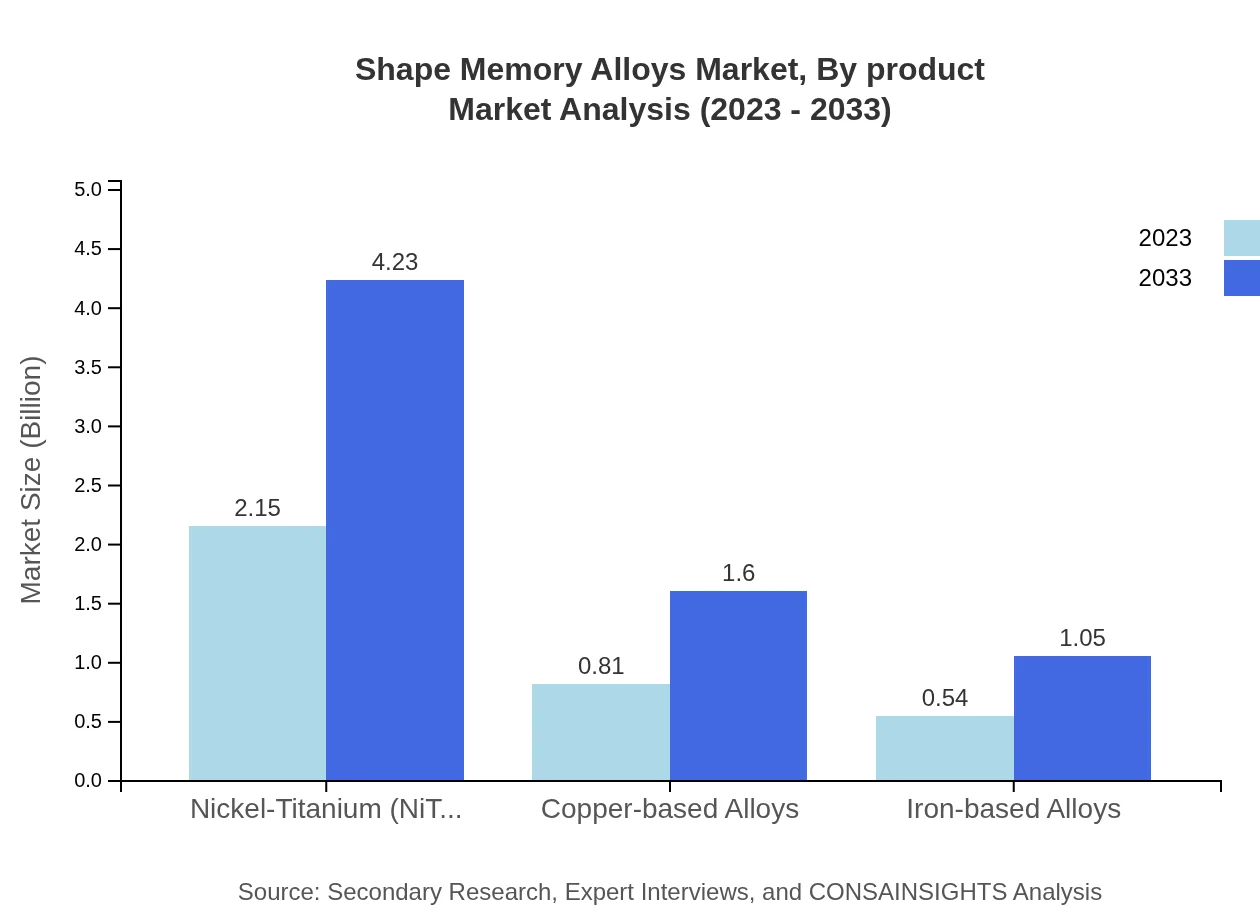

Shape Memory Alloys Market Analysis By Product

Nickel-Titanium (NiTi) Alloys dominate the market, projected to increase from $2.15 billion in 2023 to $4.23 billion by 2033, holding 61.44% market share. Copper-based Alloys are also significant, with growth from $0.81 billion to $1.60 billion (23.23% share), while Iron-based Alloys will expand from $0.54 billion to $1.05 billion (15.33% share) over the same period.

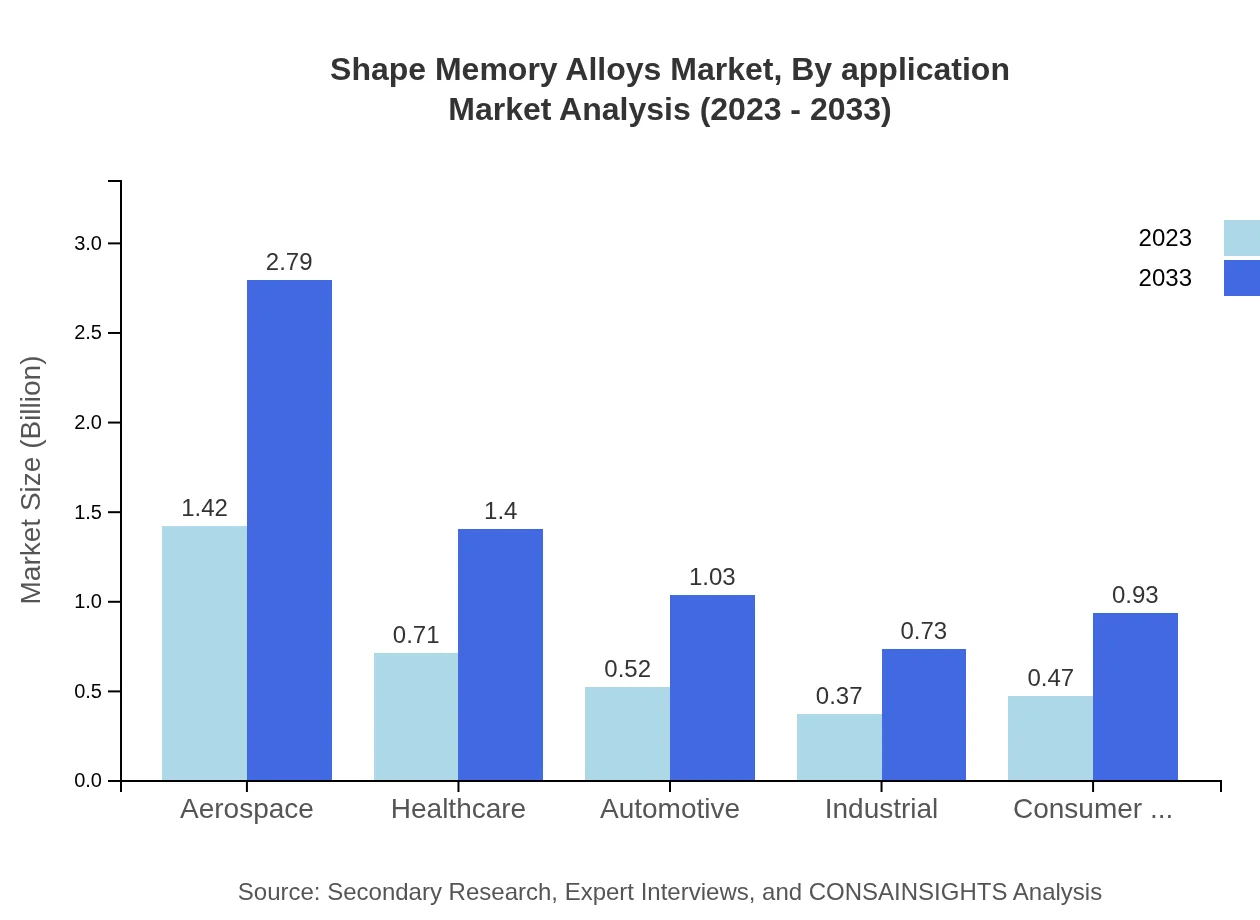

Shape Memory Alloys Market Analysis By Application

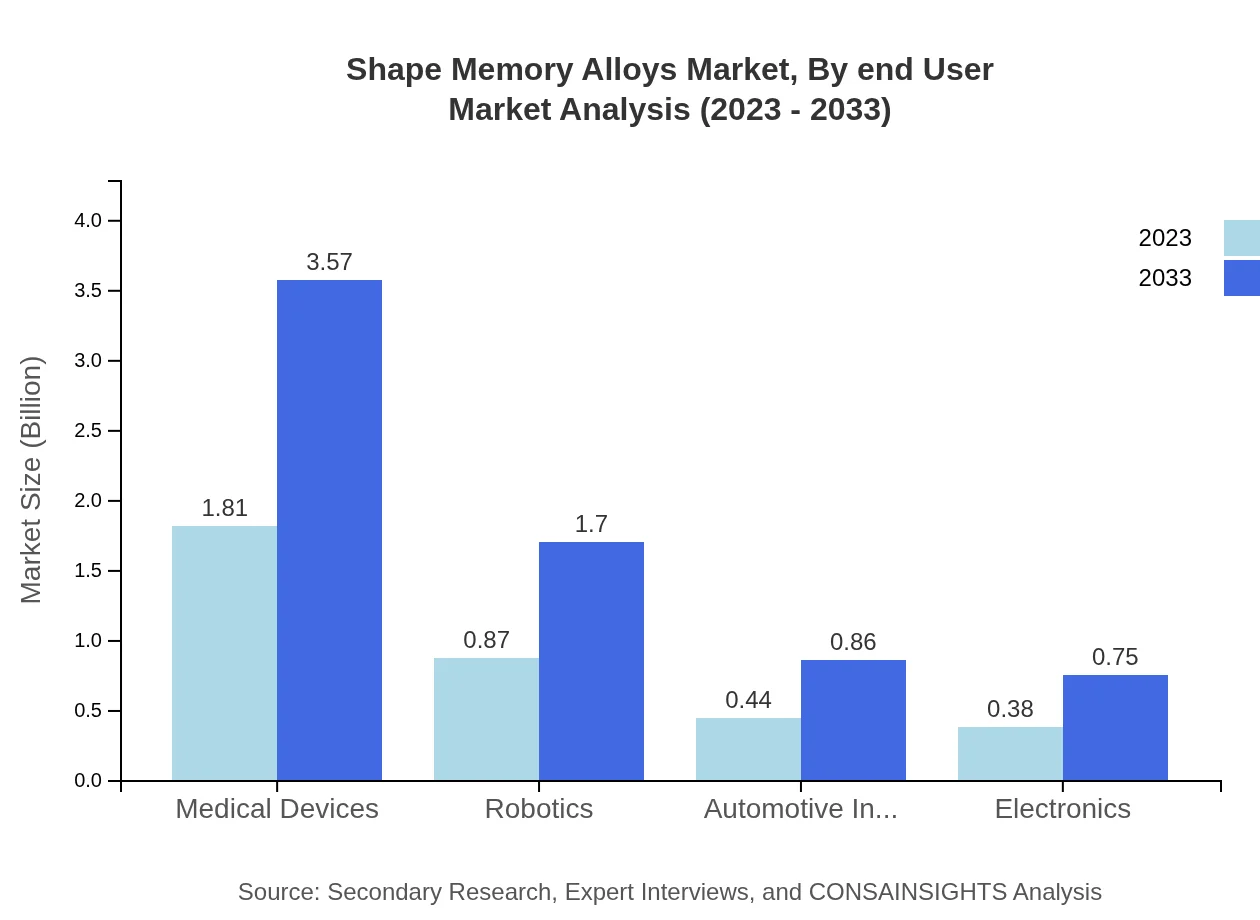

The medical devices sector is leading, anticipated to grow from $1.81 billion in 2023 to $3.57 billion by 2033, taking 51.83% of the market. Aerospace applications will see growth from $1.42 billion to $2.79 billion (40.61% share), followed by robotics applications with a growth potential from $0.87 billion to $1.70 billion (24.78% share). Other segments include automotive, electronics, and consumer products.

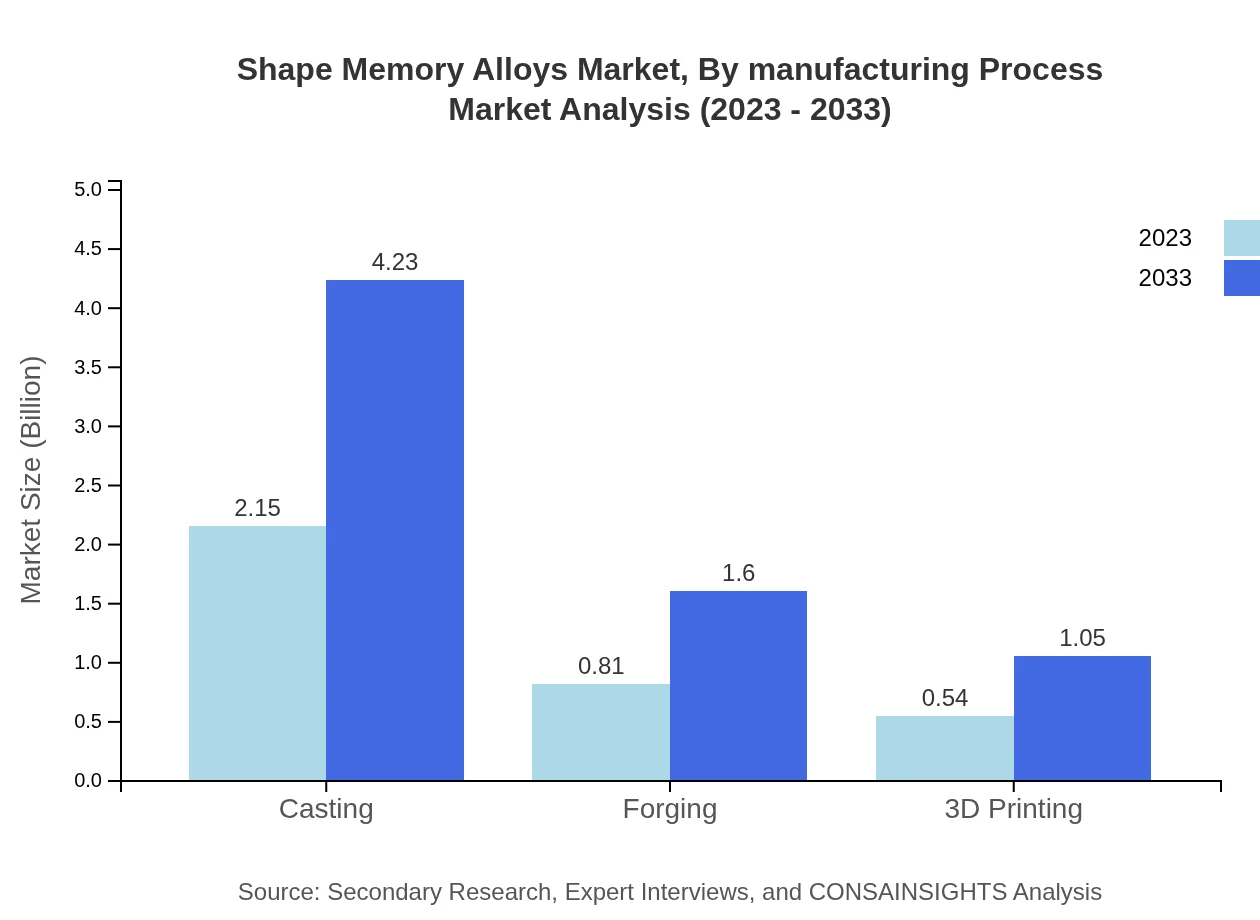

Shape Memory Alloys Market Analysis By Manufacturing Process

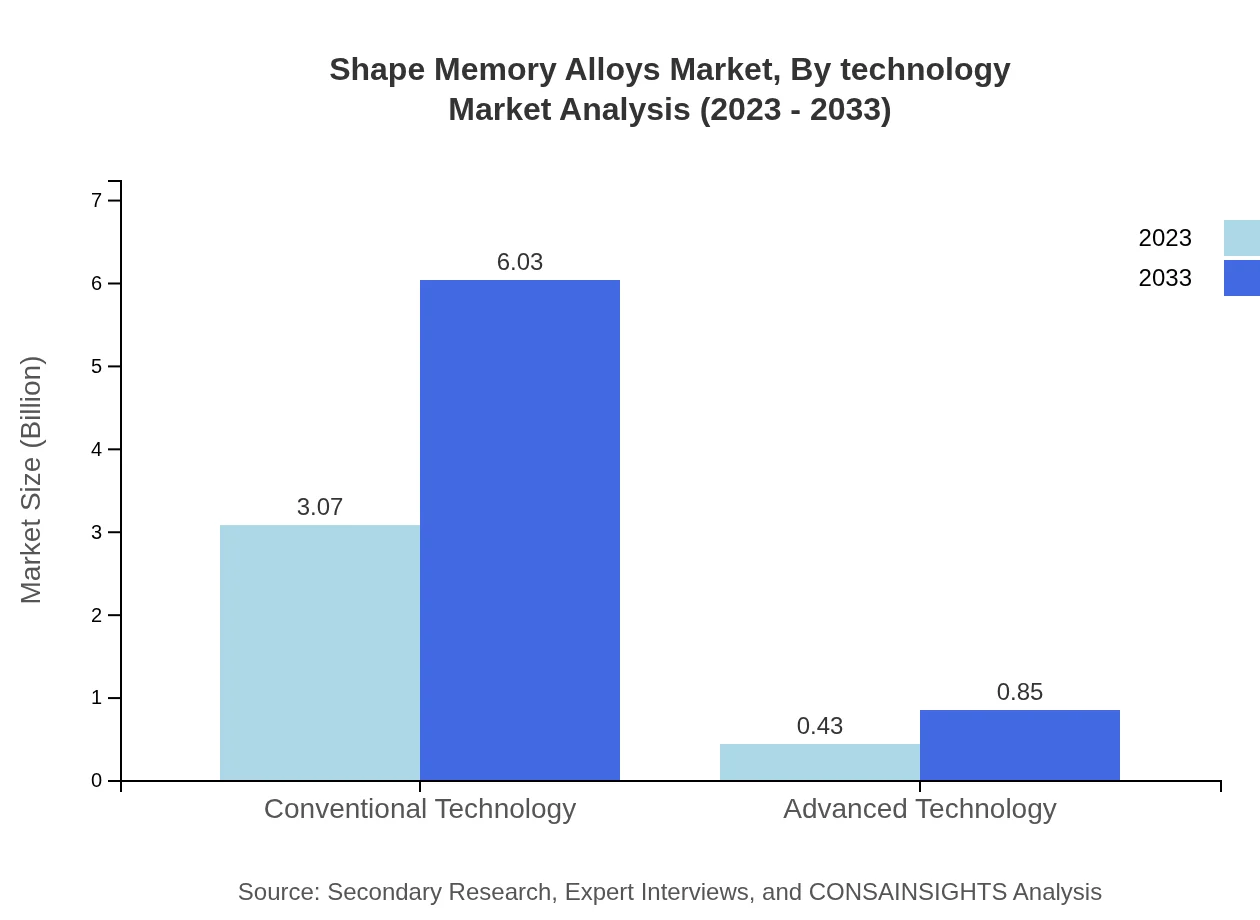

The conventional manufacturing process holds a considerable share of 87.64%, with the value projected to expand from $3.07 billion in 2023 to $6.03 billion by 2033. Advanced technology processes, while smaller in scale, are expected to grow from $0.43 billion to $0.85 billion, capturing 12.36% share, owing to their increasing adoption in high-tech applications.

Shape Memory Alloys Market Analysis By Technology

Conventional technology dominates the market with a size of $3.07 billion in 2023 and projected to reach $6.03 billion by 2033. Advanced technology, although smaller, shows potential for growth, increasing from $0.43 billion in 2023 to $0.85 billion by 2033, driven by innovative applications in industrial sectors.

Shape Memory Alloys Market Analysis By End User

Key end-users include medical devices, automotive, and aerospace. The medical devices market is projected to grow significantly from $1.81 billion to $3.57 billion (51.83% share). The aerospace sector follows closely, set to increase from $1.42 billion to $2.79 billion (40.61% share), showing the pivotal role of SMAs in lightweight and efficient component production.

Shape Memory Alloys Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Shape Memory Alloys Industry

Johnson Matthey Plc:

A leading global player in the SMAs market, Johnson Matthey focuses on sustainable technologies and provides high-performance alloys for various industrial applications.SAES Getters S.p.A.:

SAES Getters specializes in advanced material technologies, including SMAs, and offers innovative solutions primarily for the aerospace and healthcare industries.Mitsubishi Materials Corporation:

Mitsubishi Materials is a prominent manufacturer producing a range of SMAs, notably for automotive and electronics applications, emphasizing R&D for new alloy compositions.Alcoa Corporation:

A well-known leader in the aerospace sector, Alcoa develops advanced material solutions including SMAs, enhancing performance and reducing weight in aircraft designs.Nitinol Devices & Components:

This company focuses on manufacturing Nitinol-based devices, playing a vital role in the medical devices sector with a strong position in SMA applications.We're grateful to work with incredible clients.

FAQs

What is the market size of Shape Memory Alloys?

The global shape memory alloys market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 6.8% leading to significant growth towards 2033.

What are the key market players or companies in this Shape Memory Alloys industry?

Key players in the shape memory alloys market include companies like SAES Getters S.p.A., Johnson & Johnson, and Nitinol Devices & Components, among others, who drive innovation.

What are the primary factors driving the growth in the Shape Memory Alloys industry?

Growth is primarily driven by advancements in medical devices, increasing demand in aerospace applications, and innovations in robotics and automation, alongside a strong automotive sector.

Which region is the fastest Growing in the Shape Memory Alloys?

The fastest-growing region is Europe, projected to expand from $0.87 billion in 2023 to $1.71 billion by 2033, followed closely by Asia Pacific with significant expansion as well.

Does ConsaInsights provide customized market report data for the Shape Memory Alloys industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs, ensuring detailed insights on various segments and regional developments within the shape memory alloys industry.

What deliverables can I expect from this Shape Memory Alloys market research project?

Deliverables include comprehensive reports featuring market size estimates, growth forecasts, competitive analysis, and detailed insights into key segments and trends over the projected period.

What are the market trends of Shape Memory Alloys?

Trends indicate increasing usage in medical devices, advancements in casting and forging techniques, and a growing focus on sustainable manufacturing practices in the shape memory alloys sector.