Single Use Bioreactors Market Report

Published Date: 31 January 2026 | Report Code: single-use-bioreactors

Single Use Bioreactors Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Single Use Bioreactors market, focusing on market dynamics, segmentation, regional insights, and player contributions. It forecasts the market growth from 2023 to 2033, offering key data for stakeholders in the industry.

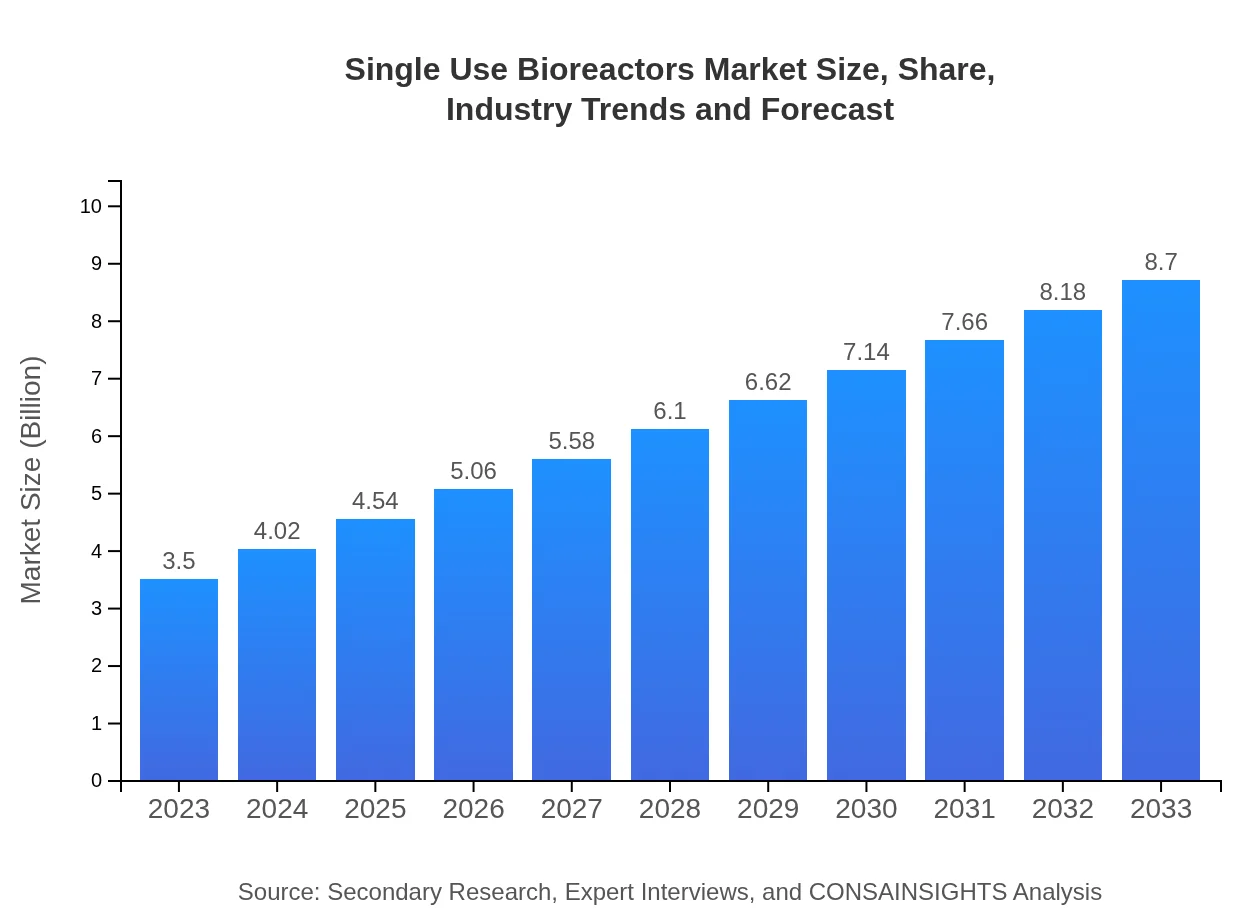

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 9.2% |

| 2033 Market Size | $8.70 Billion |

| Top Companies | Thermo Fisher Scientific, Sartorius AG, Merck KGaA, GE Healthcare |

| Last Modified Date | 31 January 2026 |

Single Use Bioreactors Market Overview

Customize Single Use Bioreactors Market Report market research report

- ✔ Get in-depth analysis of Single Use Bioreactors market size, growth, and forecasts.

- ✔ Understand Single Use Bioreactors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Single Use Bioreactors

What is the Market Size & CAGR of Single Use Bioreactors market in 2023?

Single Use Bioreactors Industry Analysis

Single Use Bioreactors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Single Use Bioreactors Market Analysis Report by Region

Europe Single Use Bioreactors Market Report:

In Europe, the market is expected to grow from $1.08 billion in 2023 to $2.69 billion in 2033. Factors such as stringent regulatory frameworks, an emphasis on safety and sustainability, and robust biopharmaceutical manufacturing capabilities are driving growth in this region.Asia Pacific Single Use Bioreactors Market Report:

The Asia Pacific region is projected to grow significantly, with the market size expected to expand from $0.67 billion in 2023 to $1.66 billion by 2033. This growth is attributed to increasing investments in biotechnology, rising healthcare expenditure, and the presence of emerging manufacturing hubs that are capitalizing on the outsourcing trend in biopharma production.North America Single Use Bioreactors Market Report:

North America remains the largest market for single-use bioreactors, with an estimated size of $1.20 billion in 2023, projected to reach $2.99 billion by 2033. This growth can be attributed to advanced healthcare systems, significant R&D expenditure, and a strong presence of leading biopharmaceutical companies focusing on innovative drug development processes.South America Single Use Bioreactors Market Report:

The South American single-use bioreactor market is expected to grow from $0.26 billion in 2023 to $0.64 billion by 2033. The rising focus on modernizing healthcare infrastructure and the increasing prevalence of chronic diseases will boost market growth in this region, coupled with an expanding biopharmaceutical industry.Middle East & Africa Single Use Bioreactors Market Report:

The Middle Eastern and African single-use bioreactor market is anticipated to increase from $0.28 billion in 2023 to $0.71 billion by 2033. The growth is fueled by rising investment in healthcare and pharmaceutical infrastructure, along with a growing demand for biopharmaceutical production.Tell us your focus area and get a customized research report.

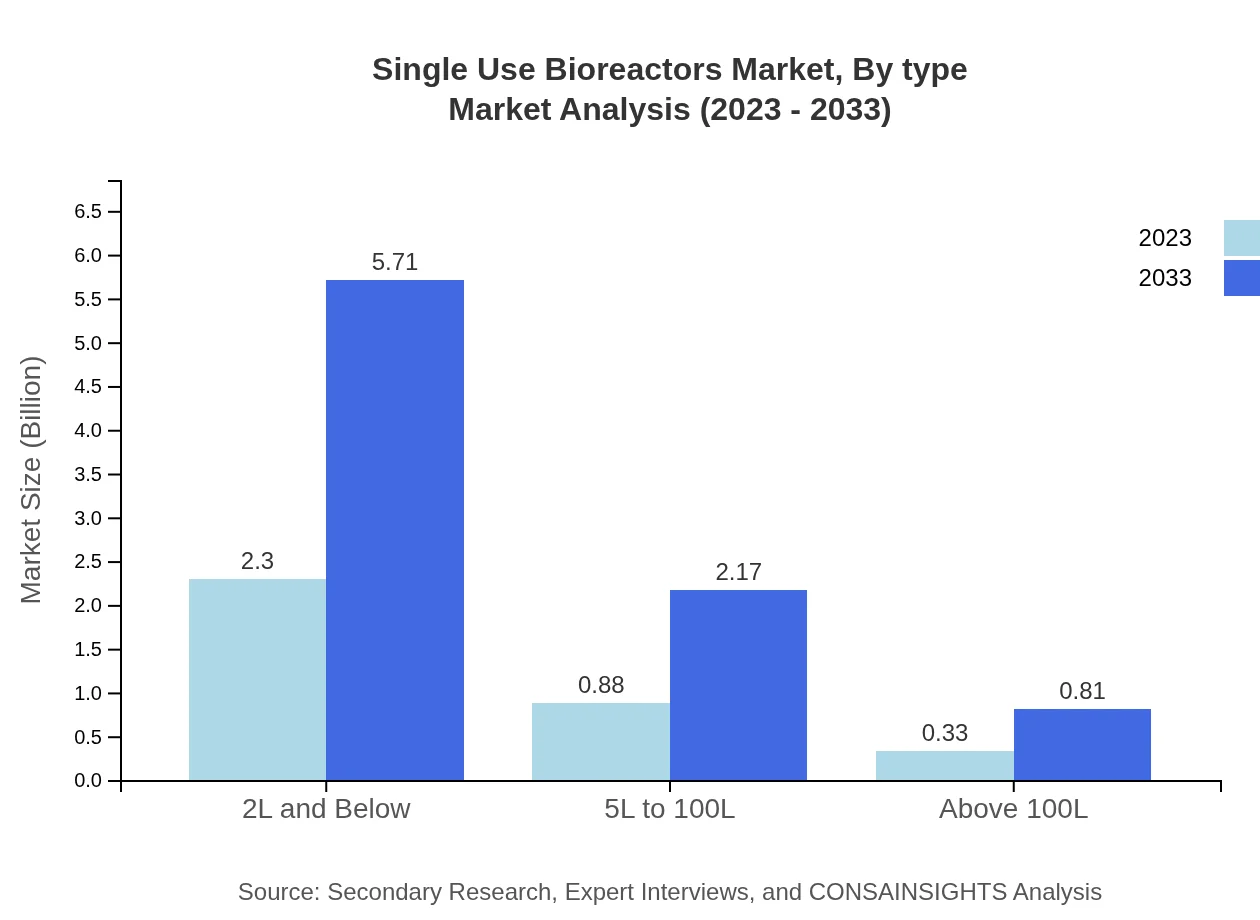

Single Use Bioreactors Market Analysis By Type

The market is segmented by volume capacity: - 2L and Below: The dominant segment, valued at $2.30 billion in 2023 and expected to hit $5.71 billion by 2033, capturing a 65.67% market share. - 5L to 100L: Projected to grow from $0.88 billion to $2.17 billion, with a consistent 25% share over the forecast period. - Above 100L: Slightly smaller in scale, this segment is anticipated to rise from $0.33 billion in 2023 to $0.81 billion by 2033, keeping a 9.33% share.

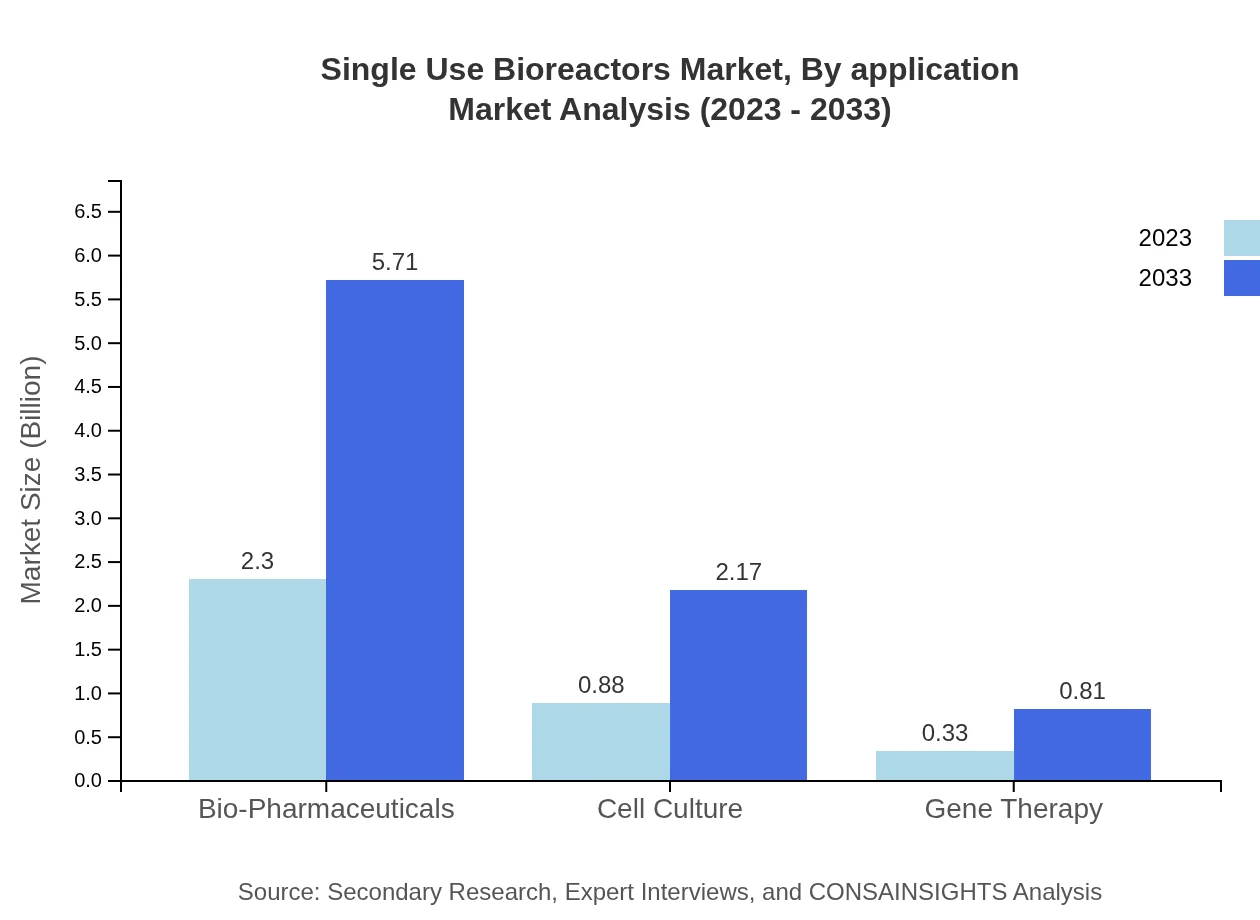

Single Use Bioreactors Market Analysis By Application

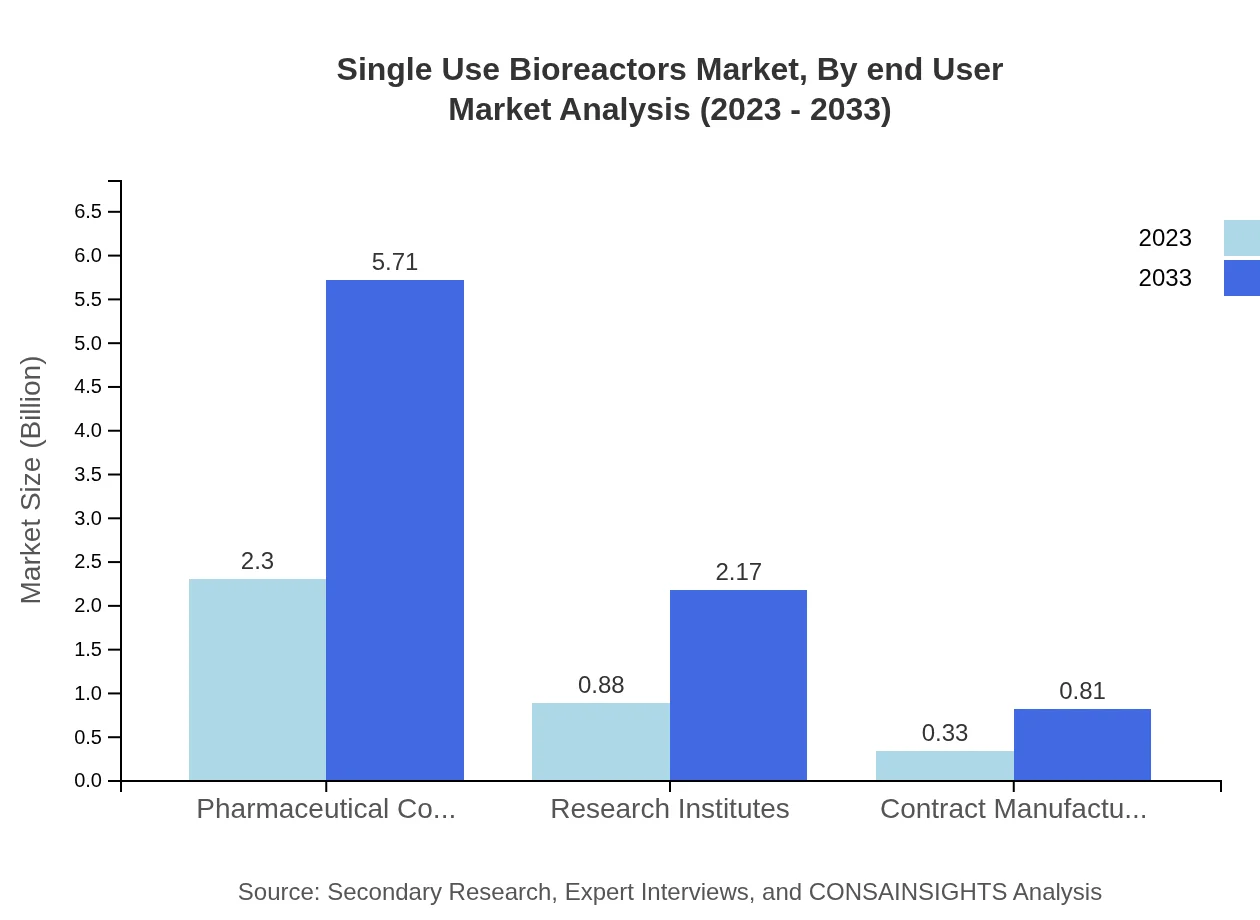

The Single Use Bioreactor market segmentation by application shows: - Pharmaceutical Companies dominate with a segment size of $2.30 billion in 2023, expected to rise to $5.71 billion by 2033, maintaining a 65.67% share. - Research Institutes grow from $0.88 billion to $2.17 billion, representing a 25% market share. - Contract Manufacturers grow from $0.33 billion to $0.81 billion, keeping a steady 9.33%.

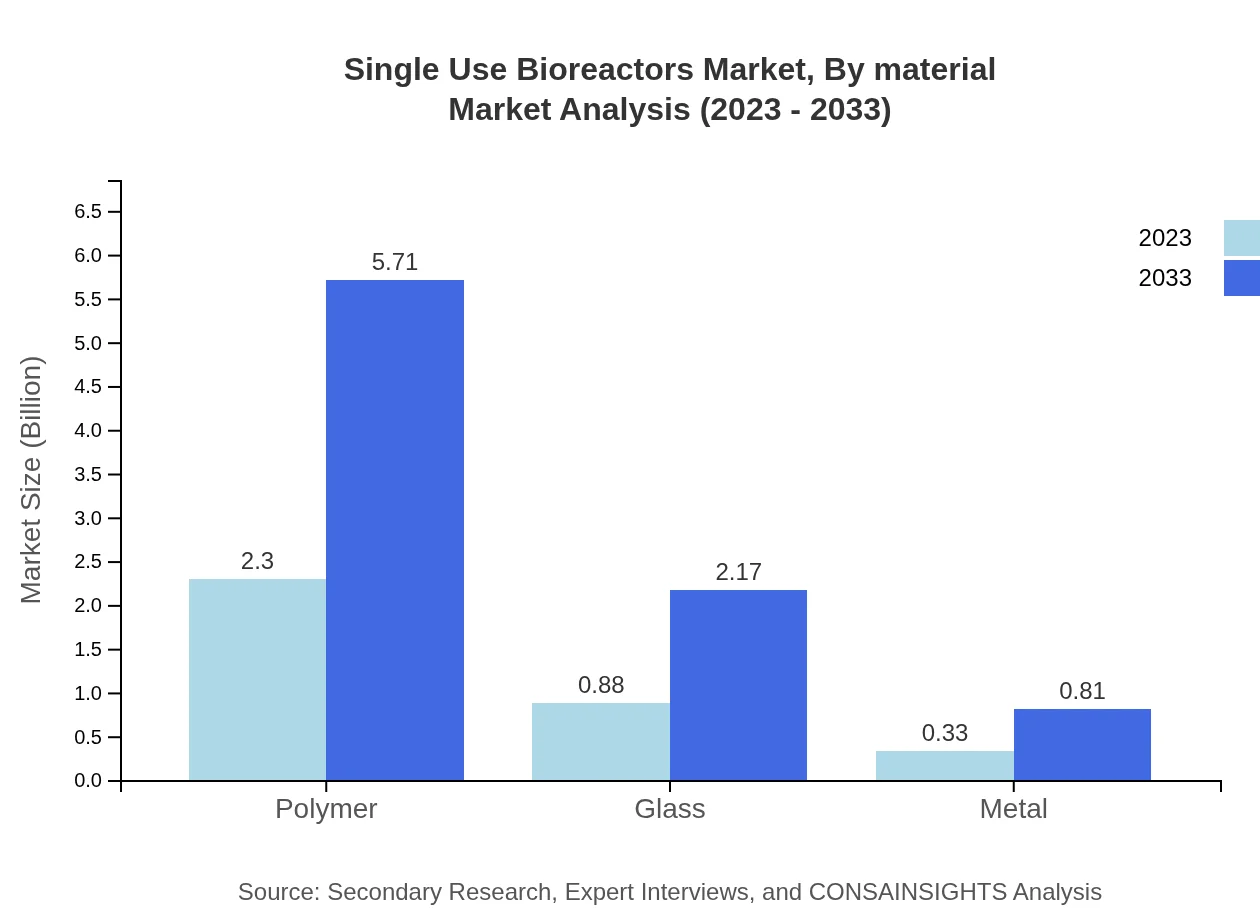

Single Use Bioreactors Market Analysis By Material

This market is categorized based on materials used: - Polymer: Accounts for the largest share, starting at $2.30 billion in 2023, growing to $5.71 billion with a 65.67% share. - Glass is set to increase from $0.88 billion to $2.17 billion, making up 25%. - Metal contributes modestly, rising from $0.33 billion to $0.81 billion, reflecting a 9.33% share.

Single Use Bioreactors Market Analysis By End User

Segmented by end-users: - Bio-Pharmaceuticals: Leading with $2.30 billion in 2023, expected to rise to $5.71 billion, holding strong at 65.67%. - Cell Culture: Expected growth from $0.88 billion to $2.17 billion, with a 25% market share. - Gene Therapy: It grows slowly, moving from $0.33 billion to $0.81 billion, equating to 9.33%.

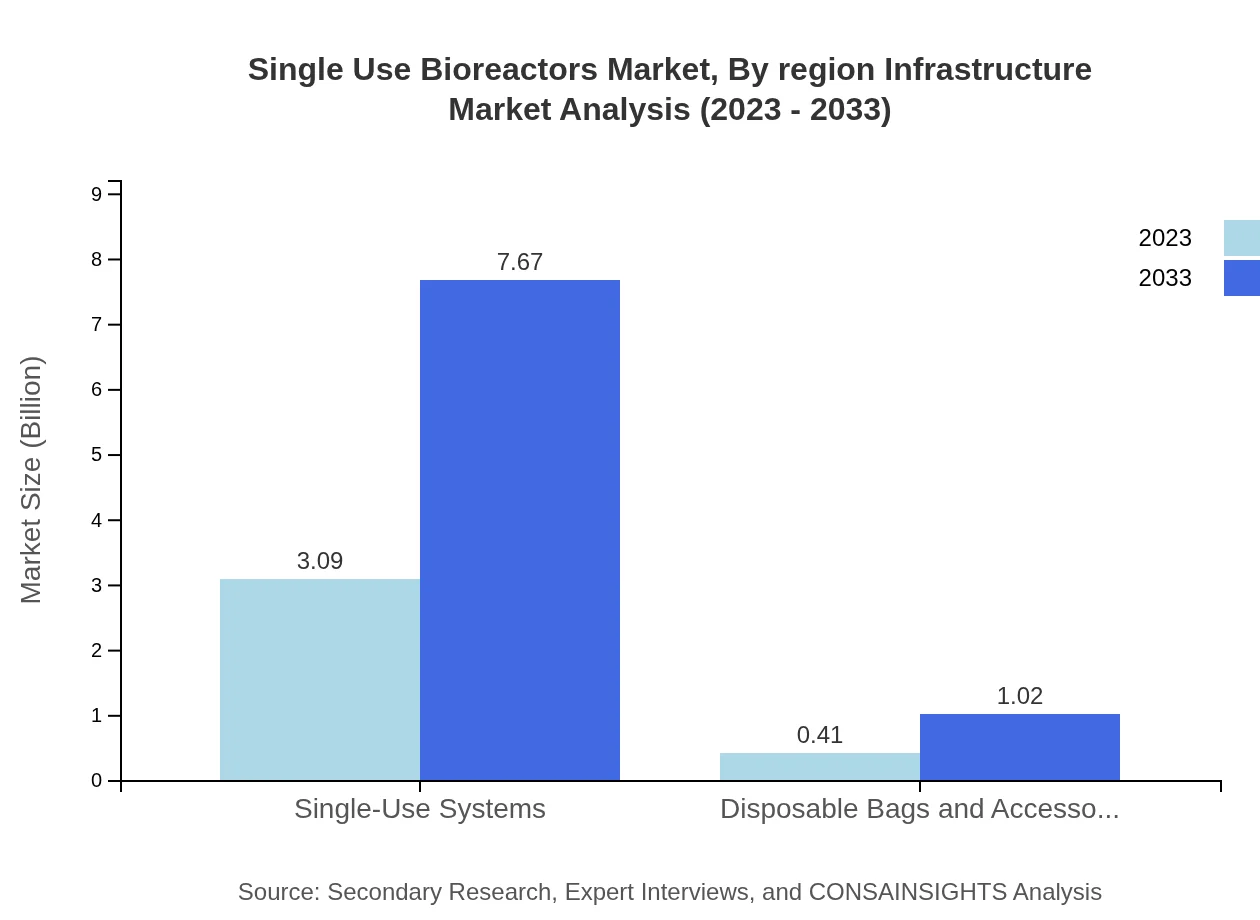

Single Use Bioreactors Market Analysis By Region Infrastructure

Infrastructure in terms of market dynamics aligns with regional insights. North America has established the most advanced single-use systems infrastructure, fostering innovation and robust growth. Europe follows closely with stringent regulatory standards. Asia Pacific captures attention for rapid adoption in manufacturing, while emerging economies in South America and Africa are improving their bioprocessing infrastructures to enhance regional market growth.

Single Use Bioreactors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Single Use Bioreactors Industry

Thermo Fisher Scientific:

A global leader in scientific services, Thermo Fisher provides bioprocessing solutions that streamline single-use technology into end-to-end biomanufacturing workflows.Sartorius AG:

Sartorius specializes in high-quality biopharmaceutical solutions, and its single-use bioreactors offer flexibility and efficiency for pharmaceutical production.Merck KGaA:

Merck is a leading science and technology company known for its extensive range of single-use solutions that enhance productivity and scalability in biopharma operations.GE Healthcare:

With a significant presence in the bioprocessing sector, GE Healthcare focuses on providing innovative solutions to boost efficiency in single-use bioreactor systems.We're grateful to work with incredible clients.

FAQs

What is the market size of Single-Use Bioreactors?

The global Single-Use Bioreactors market is currently valued at approximately $3.5 billion in 2023, with an expected CAGR of 9.2% through 2033, indicating robust growth driven by increased demand across pharmaceutical applications.

What are the key market players or companies in the Single-Use Bioreactors industry?

Key players in the Single-Use Bioreactors market include major biotechnology and pharmaceutical companies, leading equipment manufacturers, and innovative startups specializing in bioprocessing technologies, creating strong competition and driving technological advancements.

What are the primary factors driving the growth in the Single-Use Bioreactors industry?

Growth drivers in the Single-Use Bioreactors market include the increasing demand for biologics, advancements in biomanufacturing technologies, cost efficiency, and flexibility provided by single-use systems for sterile applications.

Which region is the fastest Growing in the Single-Use Bioreactors market?

The fastest-growing region for Single-Use Bioreactors is Europe, projected to grow from $1.08 billion in 2023 to $2.69 billion by 2033, followed closely by Asia Pacific and North America, reflecting robust biopharmaceutical development efforts.

Does ConsaInsights provide customized market report data for the Single-Use Bioreactors industry?

Yes, ConsaInsights offers customized market report data tailored to specific segments of the Single-Use Bioreactors industry, catering to unique client needs and driving data-informed decision-making.

What deliverables can I expect from this Single-Use Bioreactors market research project?

Expect comprehensive deliverables from the research project, including detailed market size reports, segmentation analysis, competitive landscape evaluations, growth forecasts, and strategic recommendations tailored for industry stakeholders.

What are the market trends of Single-Use Bioreactors?

Current trends in the Single-Use Bioreactors market include rising adoption of disposable technologies, increasing focus on upscaling production, and an emphasis on automation, indicating an evolution towards more efficient bioprocessing methods.