Slaughtering Equipment Market Report

Published Date: 22 January 2026 | Report Code: slaughtering-equipment

Slaughtering Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Slaughtering Equipment market from 2023 to 2033, offering insights into market trends, size, industry analysis, and regional performance, along with forecasts and growth opportunities.

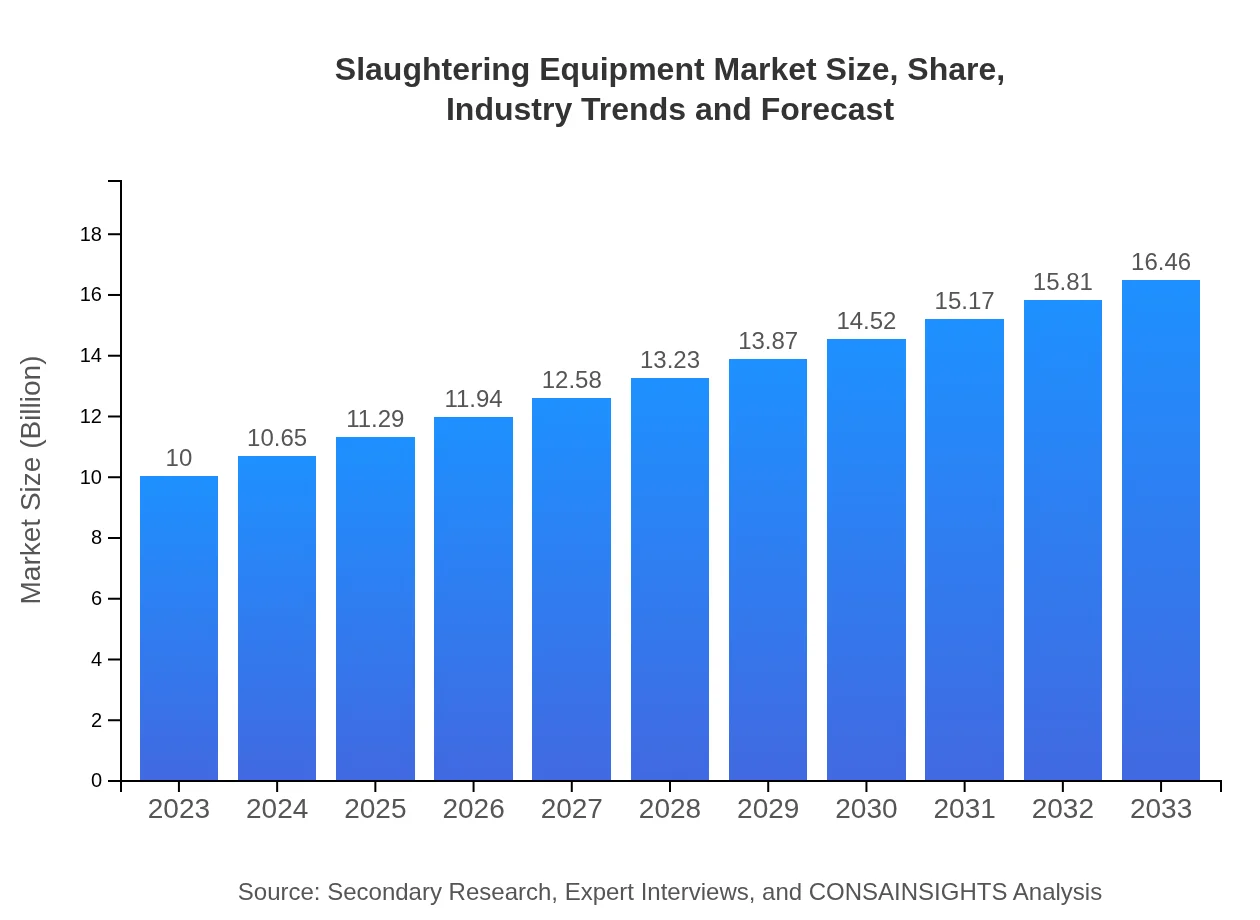

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | JBT Corporation, Marel, BETTCHER Industries, Prime Equipment Group |

| Last Modified Date | 22 January 2026 |

Slaughtering Equipment Market Overview

Customize Slaughtering Equipment Market Report market research report

- ✔ Get in-depth analysis of Slaughtering Equipment market size, growth, and forecasts.

- ✔ Understand Slaughtering Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Slaughtering Equipment

What is the Market Size & CAGR of Slaughtering Equipment market in 2023?

Slaughtering Equipment Industry Analysis

Slaughtering Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Slaughtering Equipment Market Analysis Report by Region

Europe Slaughtering Equipment Market Report:

Europe's Slaughtering Equipment market is expected to grow from $3.65 billion in 2023 to $6.01 billion in 2033. The region has stringent regulations regarding animal welfare and food safety, driving innovation and compliance in slaughtering technologies. Countries such as Germany and France are pivotal players in the European market.Asia Pacific Slaughtering Equipment Market Report:

Asia Pacific is experiencing significant growth in the Slaughtering Equipment market, with a valuation expected to increase from $1.88 billion in 2023 to $3.10 billion in 2033. This region's growth is driven by rising meat consumption, expanding food processing industries, and increasing foreign investment in modern slaughtering technologies, notably in countries like China and India.North America Slaughtering Equipment Market Report:

North America is anticipated to rise from $3.25 billion in 2023 to $5.35 billion in 2033, characterized by technological advancements and high standards of food safety. The U.S is a leader due to its large-scale meat production facilities and emphasis on automation and efficient processing systems.South America Slaughtering Equipment Market Report:

The South American market for slaughtering equipment is projected to grow from $0.94 billion in 2023 to $1.56 billion in 2033, with Brazil leading the region due to its prolific beef and poultry production. Increasing demand for processed meat products is propelling investments in modernization and compliance with international quality standards.Middle East & Africa Slaughtering Equipment Market Report:

The Middle East and Africa region is projected to grow modestly, from $0.27 billion in 2023 to $0.44 billion in 2033. The market growth is fueled by rising meat consumption and investments in modern slaughter facilities to meet the demand for halal meat products and adhere to quality standards.Tell us your focus area and get a customized research report.

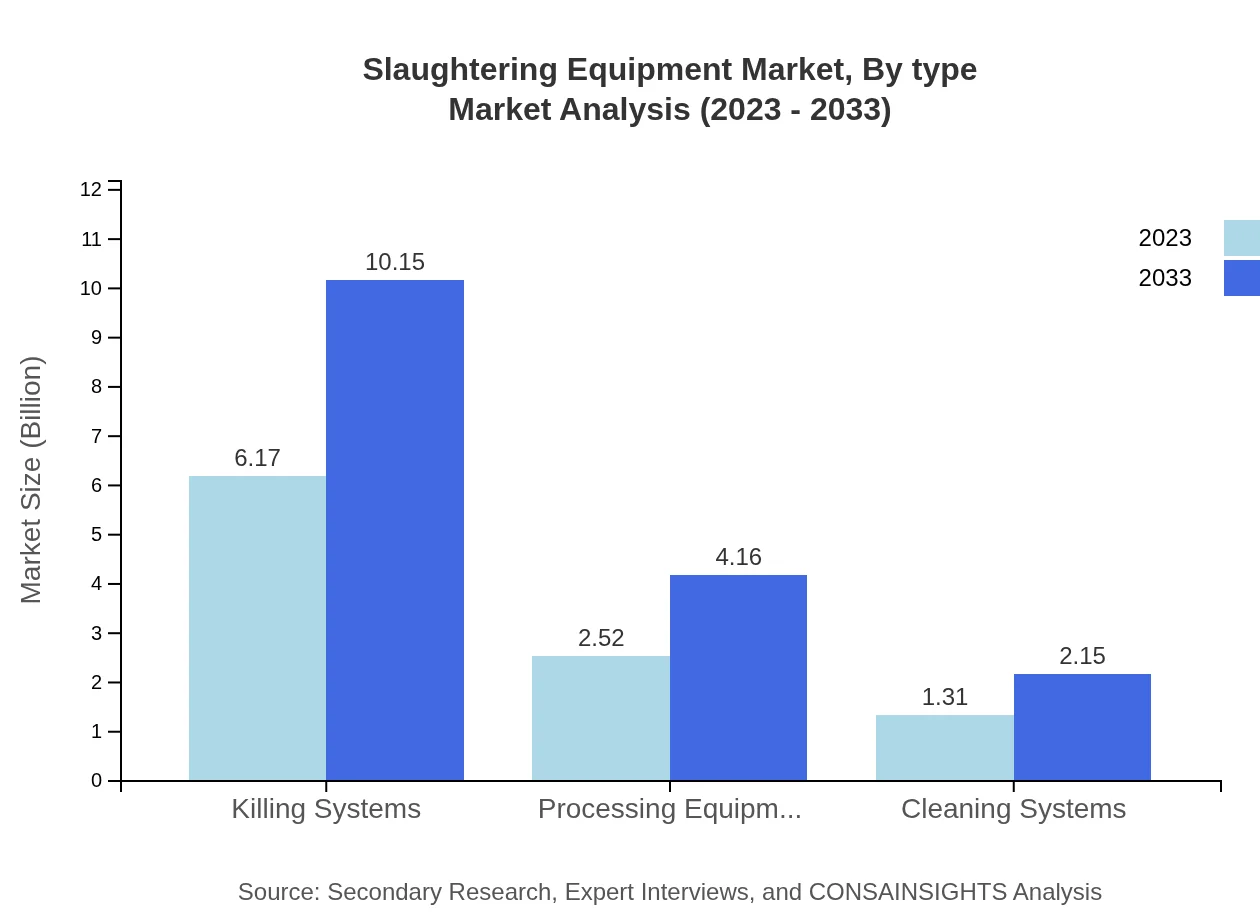

Slaughtering Equipment Market Analysis By Type

The Killing Systems segment dominates the Slaughtering Equipment market, accounting for a market size of $6.17 billion in 2023, projected to increase to $10.15 billion by 2033, holding a 61.67% market share. Processing Equipment follows, with a market value of $2.52 billion in 2023, expected to grow to $4.16 billion by 2033, capturing 25.25% market share. The Cleaning Systems segment plays a crucial role as well, with values expected to increase from $1.31 billion to $2.15 billion over the same period.

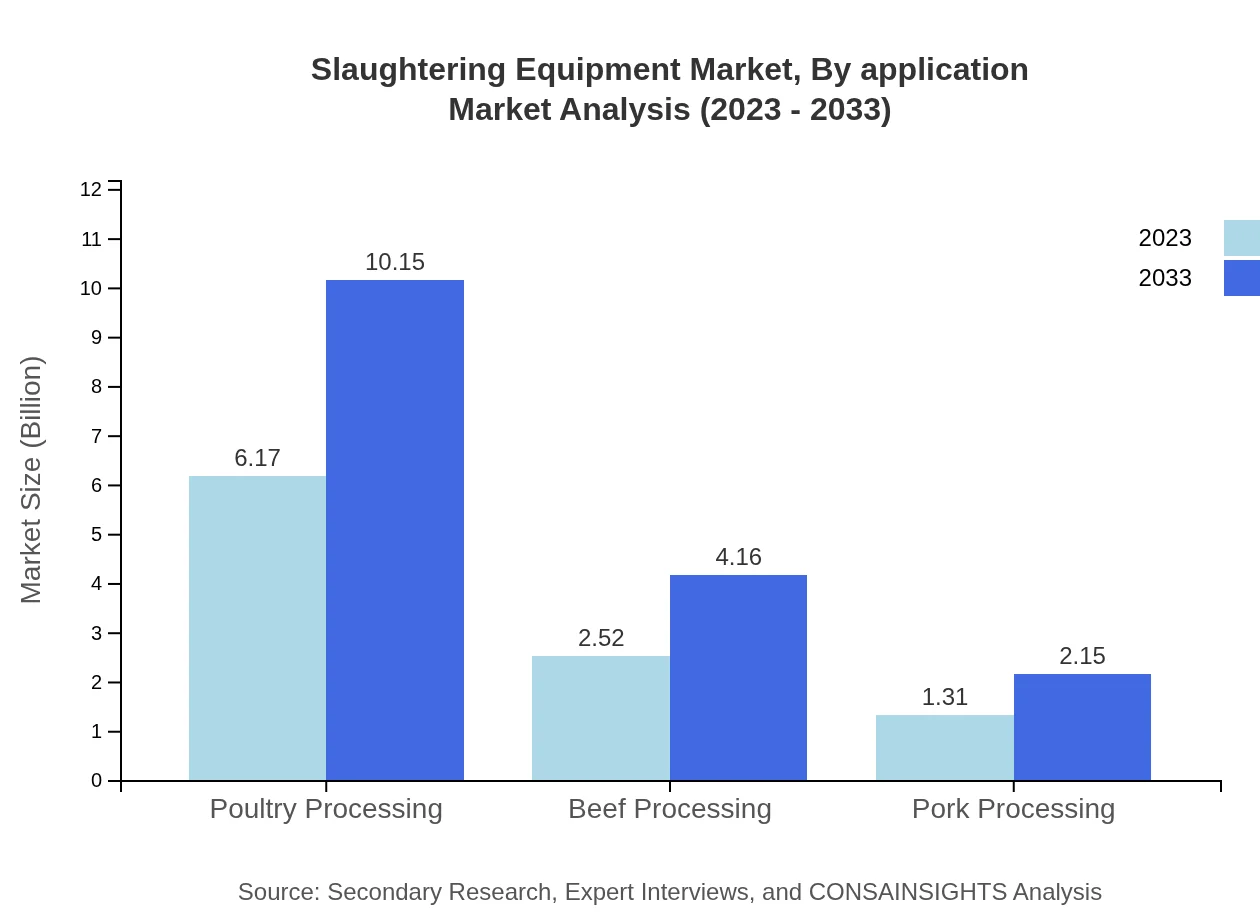

Slaughtering Equipment Market Analysis By Application

In terms of application, the Slaughtering Equipment market is significantly segmented into poultry processing, beef processing, and pork processing. Poultry Processing is expected to hold a substantial market share of 61.67%, with its size climbing from $6.17 billion in 2023 to $10.15 billion by 2033. Beef Processing and Pork Processing are also vital segments, transitioning from $2.52 billion to $4.16 billion and $1.31 billion to $2.15 billion respectively, reflecting the demand for varied meat products.

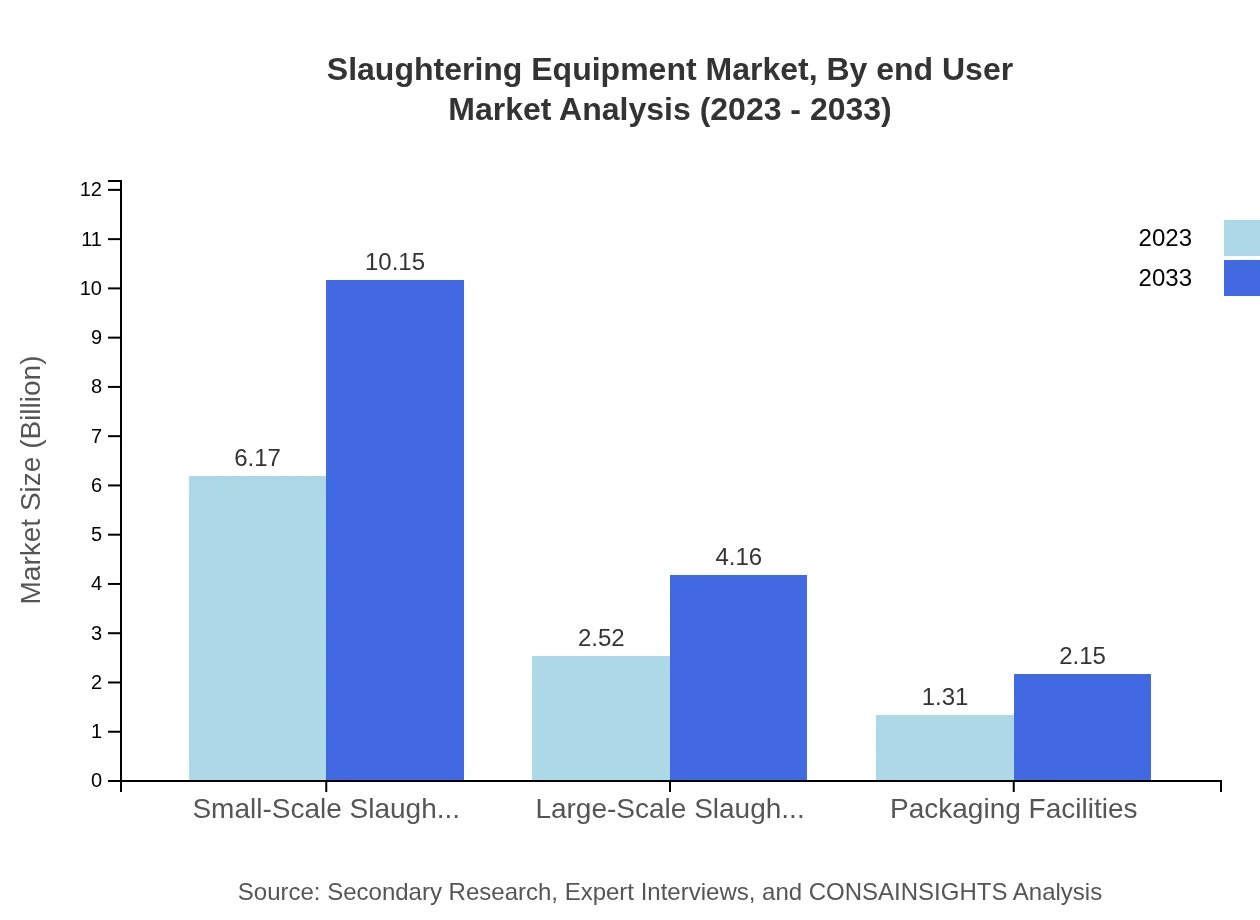

Slaughtering Equipment Market Analysis By End User

The end-user segment illustrates the engagement of small-scale and large-scale slaughterhouses in the Slaughtering Equipment market. Small-Scale Slaughterhouses hold a significant market share at 61.67%, with performance size increasing from $6.17 billion in 2023 to $10.15 billion by 2033. Large-Scale Slaughterhouses are also crucial, with market size expected to transition from $2.52 billion in 2023 to $4.16 billion.

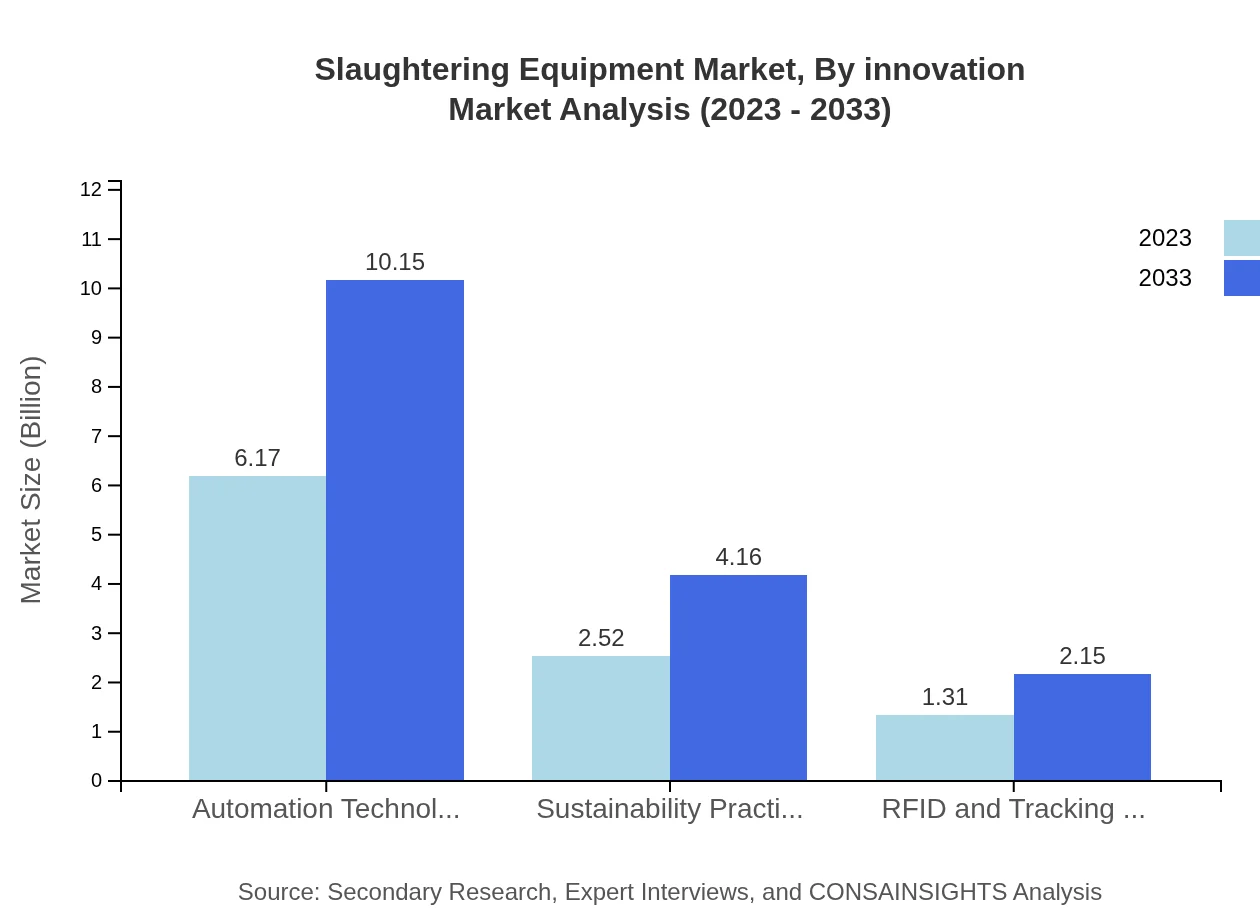

Slaughtering Equipment Market Analysis By Innovation

Innovation in slaughtering processes is marked by the adoption of automation technologies, enhancing efficiency and production capabilities. This segment is projected to grow significantly, contributing to market size expansions and upgrades in existing facilities. Incorporation of practical innovations like RFID and tracking technologies also streamlines operations, improving traceability and compliance.

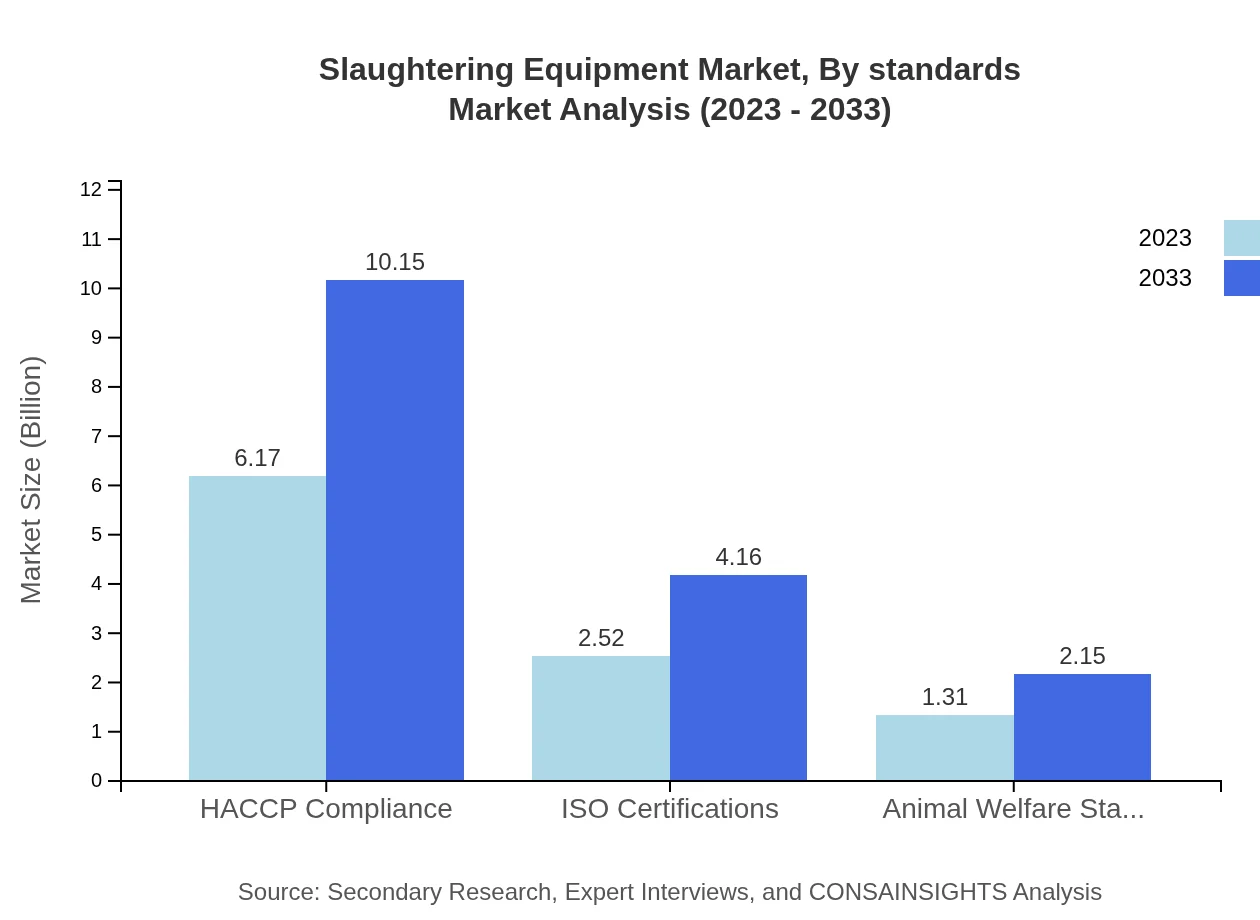

Slaughtering Equipment Market Analysis By Standards

Compliance with standards such as HACCP and ISO certifications is fundamental to the slaughtering equipment market. The HACCP Compliance segment is instrumental, growing from $6.17 billion to $10.15 billion by 2033. ISO Certifications are also critical, indicating quality and safety in processing, expected to rise from $2.52 billion to $4.16 billion.

Slaughtering Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Slaughtering Equipment Industry

JBT Corporation:

JBT Corporation is a leading provider of technology solutions for the food industry, offering a range of slaughtering equipment that ensures efficiency and compliance with food safety standards globally.Marel:

Marel is a prominent player specializing in innovative food processing solutions, focusing on advanced slaughtering technologies aimed at enhancing productivity and product quality.BETTCHER Industries:

BETTCHER Industries produces advanced slaughtering tools and equipment, recognized for their focus on improving processing efficiency and meeting stringent safety regulations.Prime Equipment Group:

The company provides customized slaughtering solutions and equipment, catering to both large-scale and small-scale operations while emphasizing sustainability and biometrics.We're grateful to work with incredible clients.

FAQs

What is the market size of Slaughtering Equipment?

The global slaughtering equipment market is valued at approximately $10 billion in 2023, with a projected compound annual growth rate (CAGR) of 5%, indicating consistent growth in the industry through 2033.

What are the key market players or companies in the Slaughtering Equipment industry?

The primary companies in the slaughtering equipment market include leading manufacturers specializing in meat processing technology and equipment. These players continuously innovate, adapting to regulatory changes and evolving consumer preferences.

What are the primary factors driving the growth in the slaughtering equipment industry?

Key growth drivers for the slaughtering equipment market include rising meat consumption, advancements in processing technologies, and increasing focus on hygienic practices in food processing, all of which enhance operational efficiency and product safety.

Which region is the fastest Growing in the slaughtering equipment market?

The fastest-growing region in the slaughtering equipment market is expected to be Europe, projecting significant growth from $3.65 billion in 2023 to $6.01 billion by 2033, reflecting increasing demand for advanced meat processing solutions.

Does ConsaInsights provide customized market report data for the slaughtering equipment industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the slaughtering equipment industry, providing actionable insights based on unique parameters, customer preferences, and competitive landscapes.

What deliverables can I expect from the slaughtering equipment market research project?

Deliverables from a slaughtering equipment market research project typically include comprehensive reports featuring market trends, competitive analysis, regional data, and forecasts, along with actionable recommendations tailored to client objectives.

What are the market trends of slaughtering equipment?

Current market trends in slaughtering equipment include a shift towards automation technologies, sustainability practices, and adherence to rigorous animal welfare standards, which are increasingly influencing purchasing decisions and operational protocols.