Smart Manufacturing Platform Market Report

Published Date: 22 January 2026 | Report Code: smart-manufacturing-platform

Smart Manufacturing Platform Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Smart Manufacturing Platform market, including current trends, forecast data from 2023 to 2033, and detailed insights into segmentation, regional performances, and key market players.

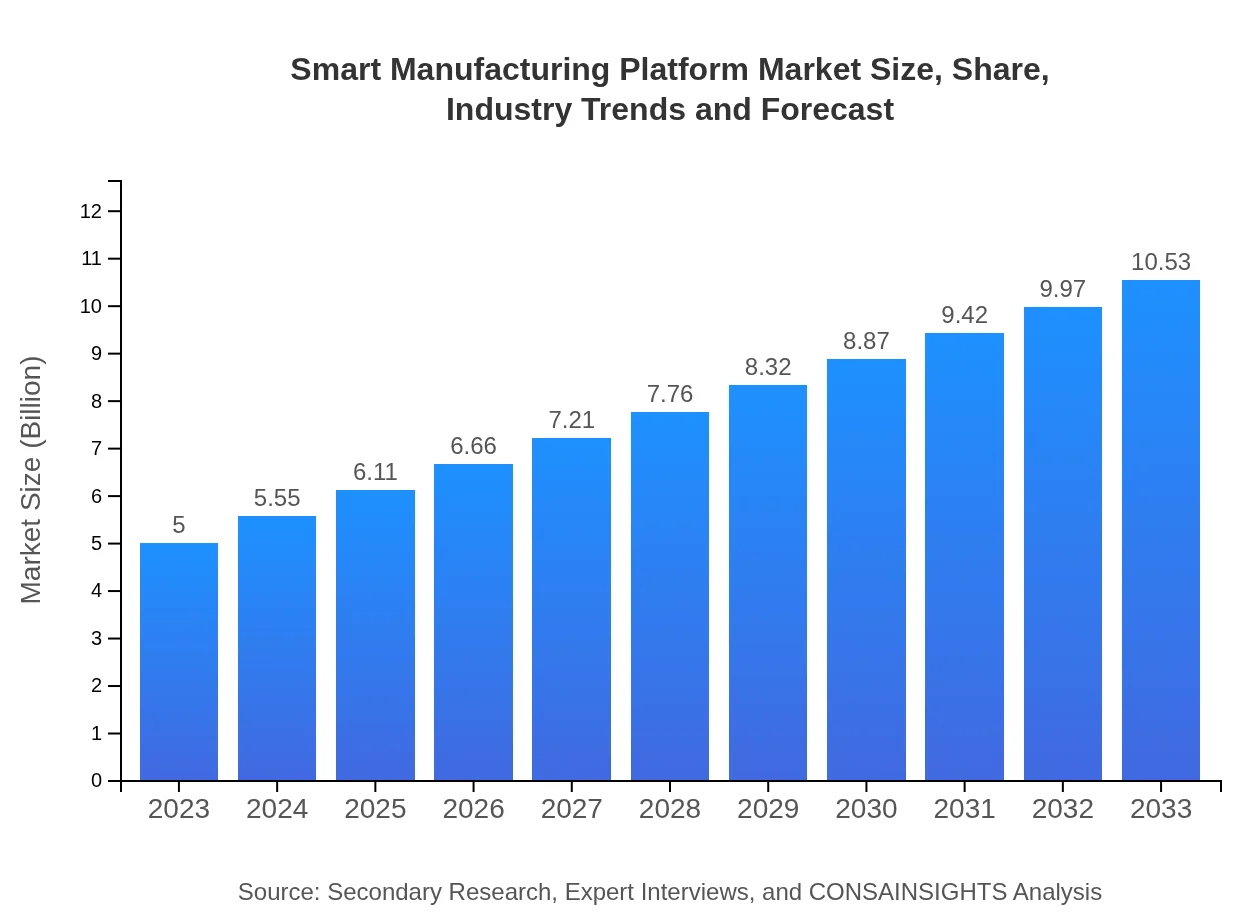

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Inc., Honeywell International Inc., ABB Ltd., Schneider Electric SE |

| Last Modified Date | 22 January 2026 |

Smart Manufacturing Platform Market Overview

Customize Smart Manufacturing Platform Market Report market research report

- ✔ Get in-depth analysis of Smart Manufacturing Platform market size, growth, and forecasts.

- ✔ Understand Smart Manufacturing Platform's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Smart Manufacturing Platform

What is the Market Size & CAGR of Smart Manufacturing Platform market in 2023?

Smart Manufacturing Platform Industry Analysis

Smart Manufacturing Platform Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Smart Manufacturing Platform Market Analysis Report by Region

Europe Smart Manufacturing Platform Market Report:

Europe is witnessing robust growth in the Smart Manufacturing Platform market, with an estimated size of USD 1.71 billion in 2023, likely expanding to USD 3.60 billion by 2033. The region’s focus on sustainability and industry innovation is driving widespread adoption across various manufacturing sectors.Asia Pacific Smart Manufacturing Platform Market Report:

The Asia Pacific region leads the Smart Manufacturing Platform market, driven by rapid industrialization in countries like China and India. The market was valued at USD 0.92 billion in 2023 and is expected to reach USD 1.93 billion by 2033, fueled by increasing investments in smart factories and automation technologies.North America Smart Manufacturing Platform Market Report:

North America is a significant contributor to the Smart Manufacturing Platform market, expected to grow from USD 1.65 billion in 2023 to USD 3.48 billion by 2033. The presence of major technology companies and a high adoption rate of advanced manufacturing technologies support this market growth.South America Smart Manufacturing Platform Market Report:

In South America, the Smart Manufacturing Platform market is gradually growing with a valuation projected at USD 0.41 billion in 2023, increasing to USD 0.87 billion by 2033. Nations like Brazil and Argentina are prioritizing manufacturing modernization, thereby fostering market growth.Middle East & Africa Smart Manufacturing Platform Market Report:

The Middle East and Africa region remains nascent in the Smart Manufacturing Platform market, estimated to reach USD 0.30 billion in 2023 and grow to USD 0.64 billion by 2033. Investment in manufacturing technologies is on the rise as countries aim to diversify their economies and enhance operational efficiencies.Tell us your focus area and get a customized research report.

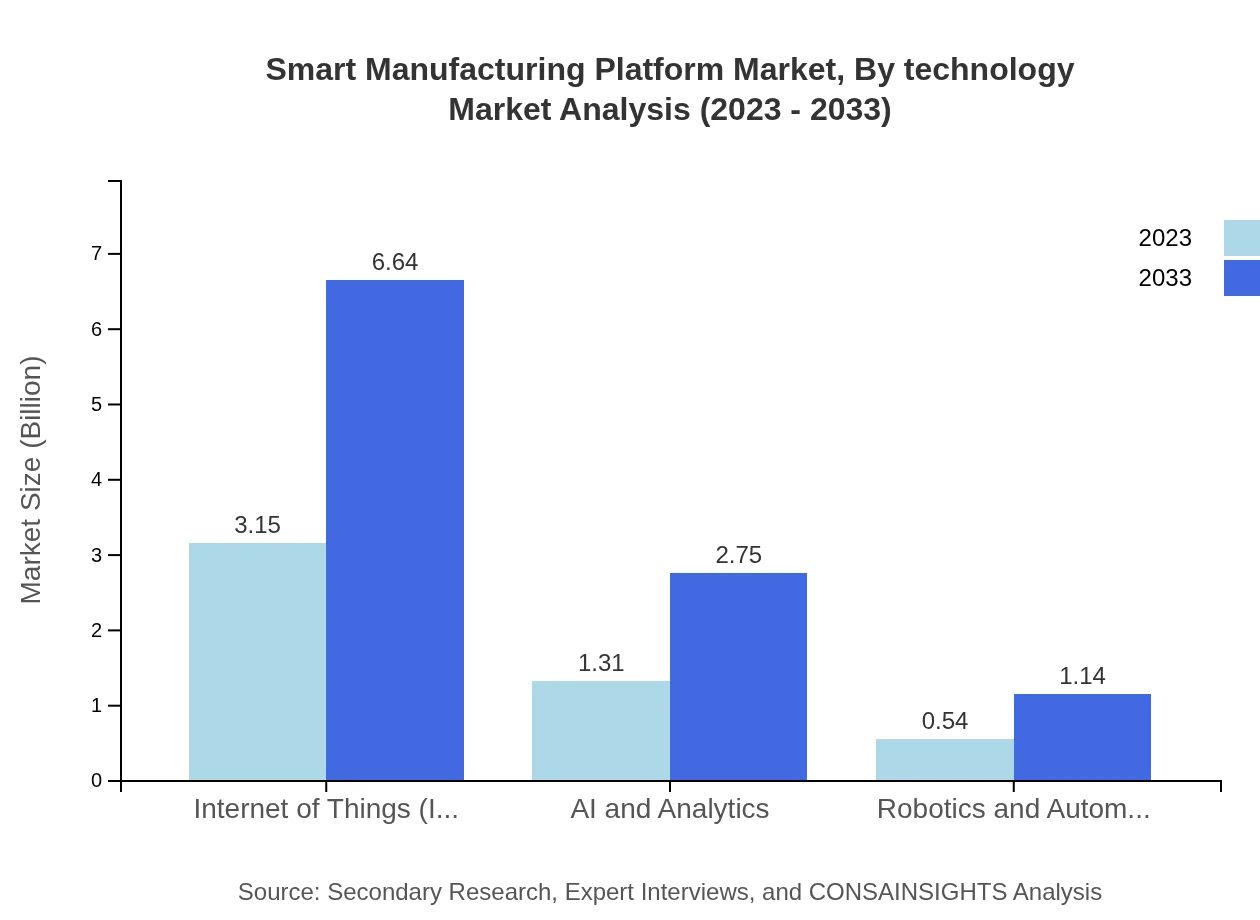

Smart Manufacturing Platform Market Analysis By Technology

Key technologies such as IoT, AI and analytics, and robotics and automation dominate the market landscape. IoT is projected to capture a significant share, reaching USD 3.15 billion in 2023 and expanding to USD 6.64 billion by 2033. AI is also gaining traction, emphasizing data-driven decision-making and automation.

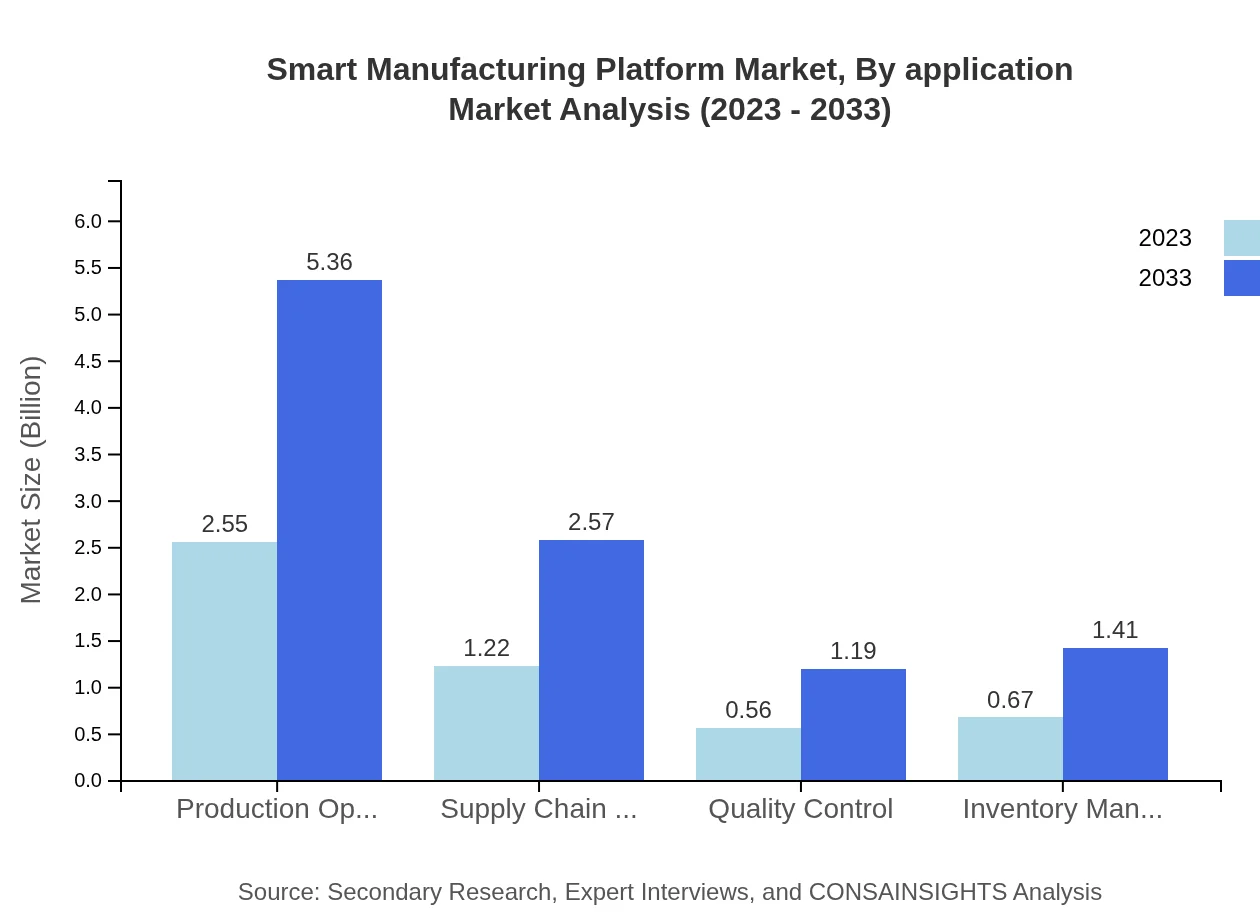

Smart Manufacturing Platform Market Analysis By Application

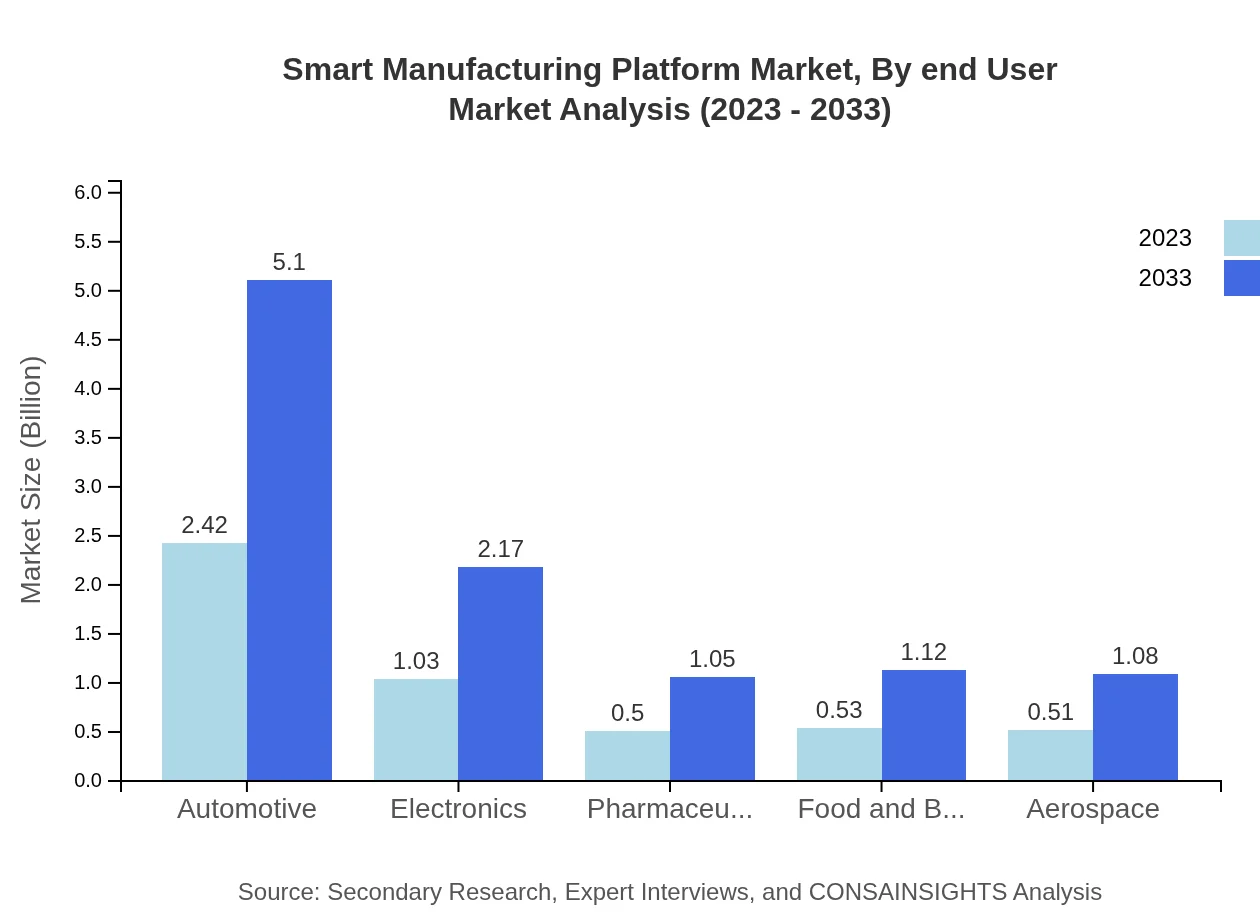

Applications in automotive, electronics, pharmaceuticals, and food and beverage sectors drive demand for Smart Manufacturing platforms. The automotive segment leads, with market sizes projected to reach USD 2.42 billion in 2023, growing to USD 5.10 billion by 2033, highlighting the critical need for enhanced efficiency and reduced operational costs.

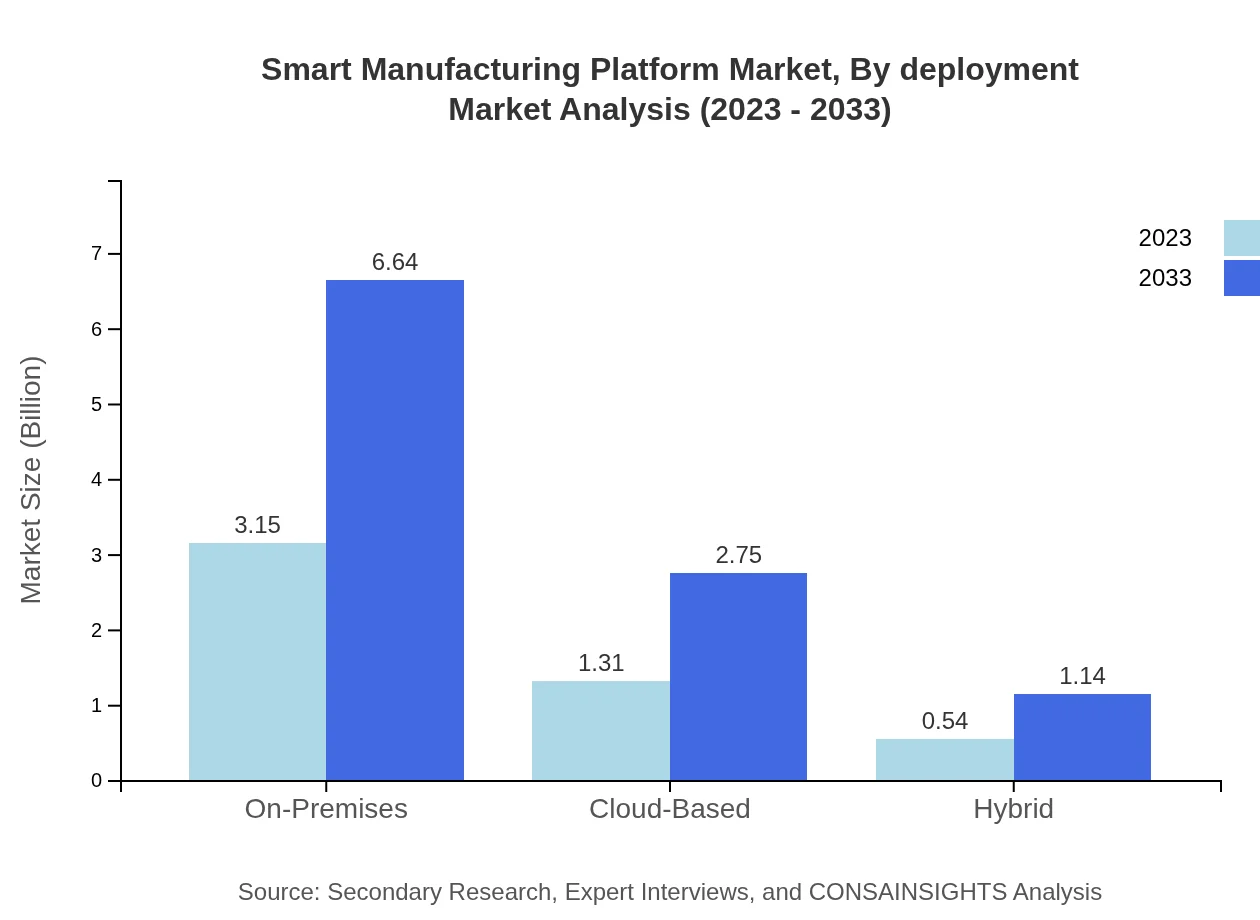

Smart Manufacturing Platform Market Analysis By Deployment

The market is classified into on-premises and cloud-based deployments, with on-premises solutions holding a robust market share. By 2033, on-premises solutions are expected to grow from USD 3.15 billion in 2023 to USD 6.64 billion, as businesses leverage existing infrastructures while embracing new technologies.

Smart Manufacturing Platform Market Analysis By End User

The market serves diverse end-user industries including automotive, aerospace, electronics, and pharmaceuticals. In the automotive sector, the forecast growth from USD 2.42 billion in 2023 to USD 5.10 billion by 2033 underscores the industry's investment in smart technologies and digital transformation.

Smart Manufacturing Platform Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Smart Manufacturing Platform Industry

Siemens AG:

A leader in automation and digitalization, Siemens AG offers a comprehensive portfolio of Smart Manufacturing solutions to enhance operational efficiency and productivity.Rockwell Automation, Inc.:

Rockwell Automation provides advanced manufacturing technology solutions and services, focusing on industrial automation and information for various manufacturing sectors.Honeywell International Inc.:

Honeywell delivers integrated Smart Manufacturing solutions that leverage IoT, analytics, and automation for improved manufacturing efficiency and safety.ABB Ltd.:

ABB is a global leader in industrial technology, supplying automation solutions that enhance productivity and operational excellence in smart manufacturing.Schneider Electric SE:

Schneider Electric offers smart factory solutions that optimize asset performance and energy management for sustainable manufacturing practices.We're grateful to work with incredible clients.

FAQs

What is the market size of smart Manufacturing Platform?

The global smart manufacturing platform market is projected to grow from $5 billion in 2023 to an estimated value reflecting a 7.5% CAGR by 2033. This signifies a robust expansion driven by advanced manufacturing technologies.

What are the key market players or companies in this smart Manufacturing Platform industry?

Key players in the smart manufacturing platform industry typically include major technology firms, industrial automation companies, and software developers focusing on IoT, AI, and analytics, contributing significantly to market innovations and competitive dynamics.

What are the primary factors driving the growth in the smart Manufacturing Platform industry?

The growth in the smart manufacturing platform industry is primarily driven by increased automation, IoT integration, need for production efficiency, data analytics advancements, and the pursuit of sustainable manufacturing practices.

Which region is the fastest Growing in the smart Manufacturing Platform?

The fastest-growing region in the smart manufacturing platform market is Europe, with the market anticipated to grow from approximately $1.71 billion in 2023 to $3.60 billion by 2033, highlighting substantial growth opportunities.

Does ConsaInsights provide customized market report data for the smart Manufacturing Platform industry?

Yes, ConsaInsights offers customized market report data for the smart manufacturing platform sector, tailoring insights and analytics to meet specific client needs and industry challenges.

What deliverables can I expect from this smart Manufacturing Platform market research project?

Expect deliverables such as comprehensive market analysis reports, trend assessments, competitive landscape insights, forecasts, and tailored recommendations that cater to strategic decision-making in the smart manufacturing sector.

What are the market trends of smart Manufacturing Platform?

Key trends in the smart manufacturing platform market include increasing deployment of AI and machine learning technologies, heightened focus on supply chain resilience, and the growing integration of IoT for real-time data utilization.