Solid Control Equipment Market Report

Published Date: 22 January 2026 | Report Code: solid-control-equipment

Solid Control Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Solid Control Equipment market, covering market size, trends, and forecasts from 2023 to 2033, along with insights into segmentation and regional dynamics, industry leaders, and technological advancements impacting the sector.

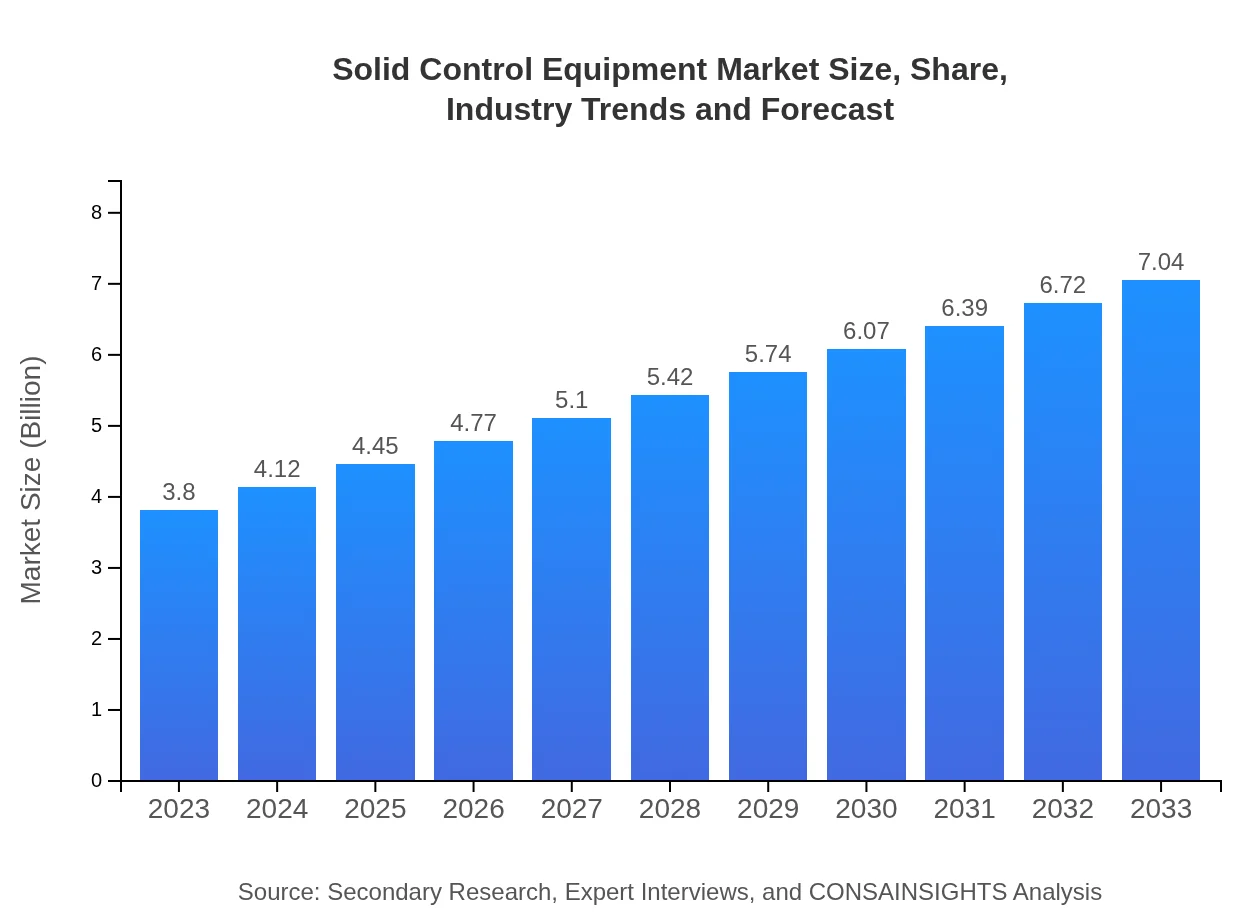

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $7.04 Billion |

| Top Companies | Schlumberger Limited, Halliburton, Baker Hughes, Weir Group |

| Last Modified Date | 22 January 2026 |

Solid Control Equipment Market Overview

Customize Solid Control Equipment Market Report market research report

- ✔ Get in-depth analysis of Solid Control Equipment market size, growth, and forecasts.

- ✔ Understand Solid Control Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Solid Control Equipment

What is the Market Size & CAGR of Solid Control Equipment market in 2023?

Solid Control Equipment Industry Analysis

Solid Control Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Solid Control Equipment Market Analysis Report by Region

Europe Solid Control Equipment Market Report:

The European market is anticipated to rise from $0.91 billion in 2023 to $1.69 billion by 2033. The growth is influenced by the shift towards sustainable solutions and stringent regulations enforcing waste disposal standards across the oil and gas sector.Asia Pacific Solid Control Equipment Market Report:

In the Asia Pacific region, the market is expected to grow from $0.79 billion in 2023 to $1.46 billion in 2033, driven by increasing mining activities and oil exploration in countries like China and India. Investments in infrastructure and advanced technology adoption are further expected to bolster market growth.North America Solid Control Equipment Market Report:

The North American market is forecasted to escalate from $1.23 billion in 2023 to $2.29 billion in 2033. The U.S. and Canada are key players, benefiting from substantial investments in drilling and exploration operations, alongside robust regulatory frameworks mandating effective waste management practices.South America Solid Control Equipment Market Report:

The South American market is projected to increase from $0.34 billion in 2023 to $0.63 billion by 2033. This growth is largely attributed to rising oil extraction efforts and regulatory pressures to manage waste effectively in countries like Brazil and Argentina.Middle East & Africa Solid Control Equipment Market Report:

In the Middle East and Africa, the market is expected to grow from $0.52 billion in 2023 to $0.97 billion by 2033, fueled by ongoing oil recovery projects and investments in modern waste management technologies.Tell us your focus area and get a customized research report.

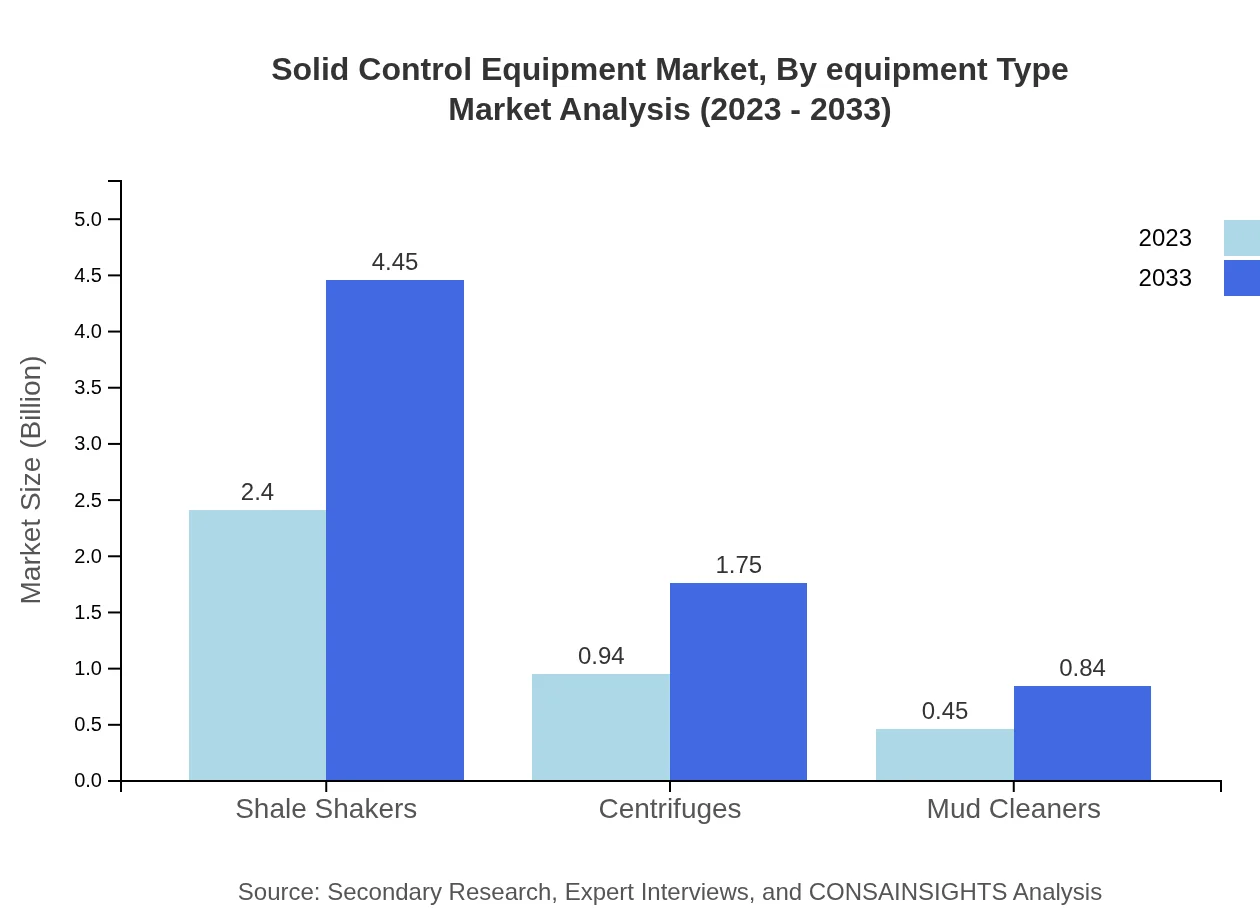

Solid Control Equipment Market Analysis By Equipment Type

The market by equipment type shows a strong preference for Mechanical Technology, which accounted for $2.40 billion in 2023 and is expected to rise to $4.45 billion by 2033, representing 63.24% of market share. This growth is driven by robust demand for Shale Shakers and Centrifuges, crucial for effective solid control processes in various drilling campaigns.

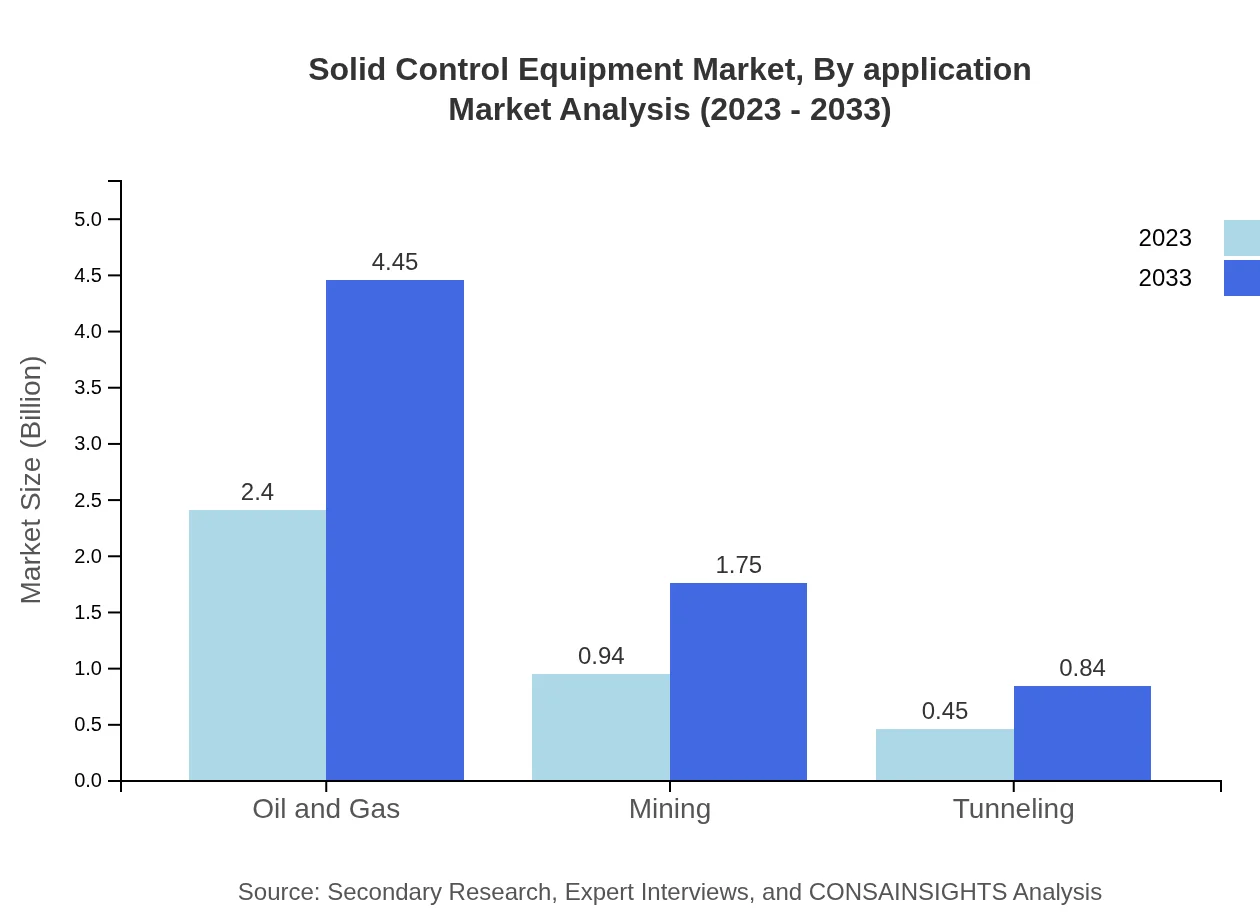

Solid Control Equipment Market Analysis By Application

Among applications, the Oil and Gas sector retains the largest share, projected at $2.40 billion in 2023 and anticipated to reach $4.45 billion by 2033, with 63.24% market share. Mining follows with $0.94 billion expected to grow to $1.75 billion, representing a 24.8% share as demand for advanced solid control systems escalates in mining operations.

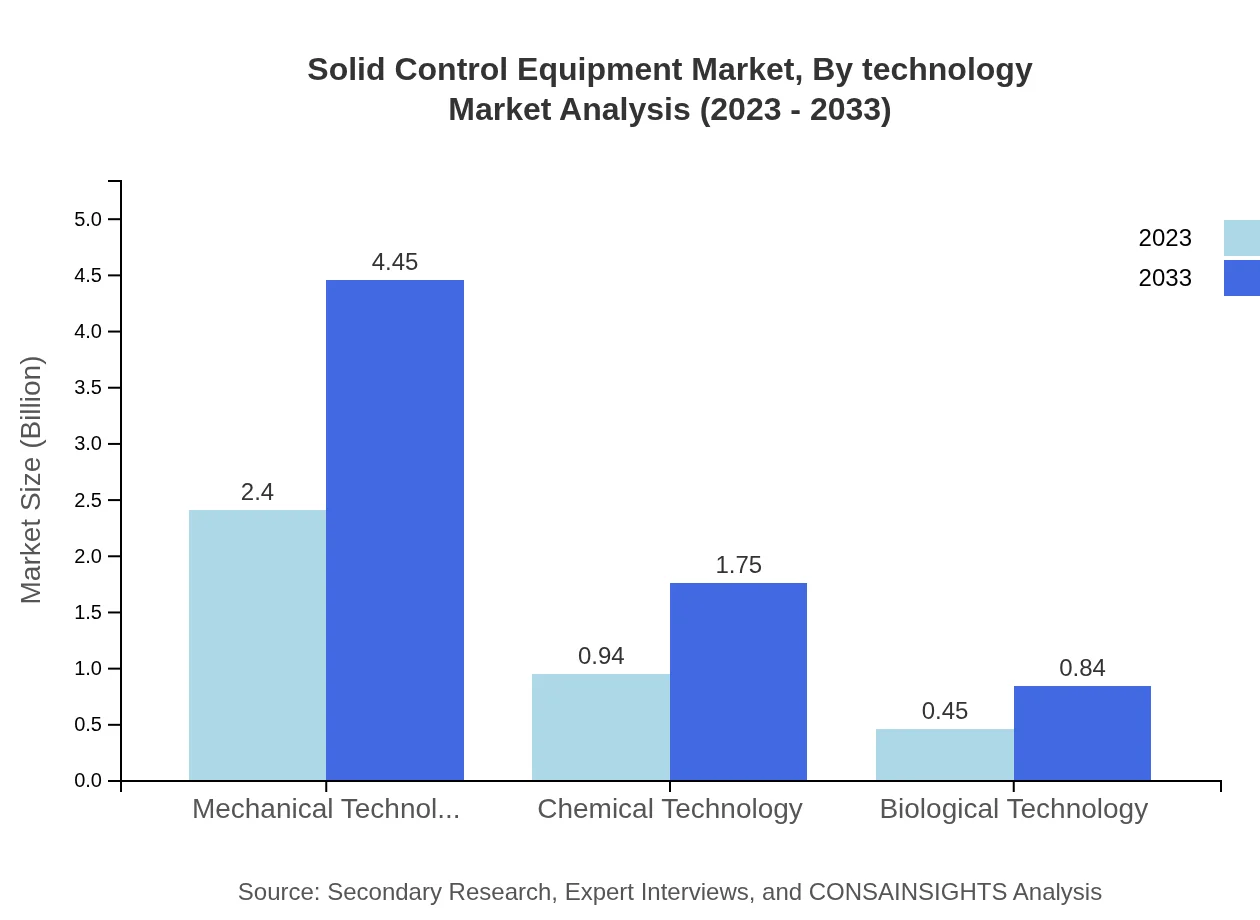

Solid Control Equipment Market Analysis By Technology

Mechanical Technology leads the segment with significant market presence valued at $2.40 billion in 2023, while Chemical Technology and Biological Technology account for $0.94 billion and $0.45 billion, respectively. Each of these technological segments plays a pivotal role, with advancements in automation and environmental compliance shaping their growth by 2033.

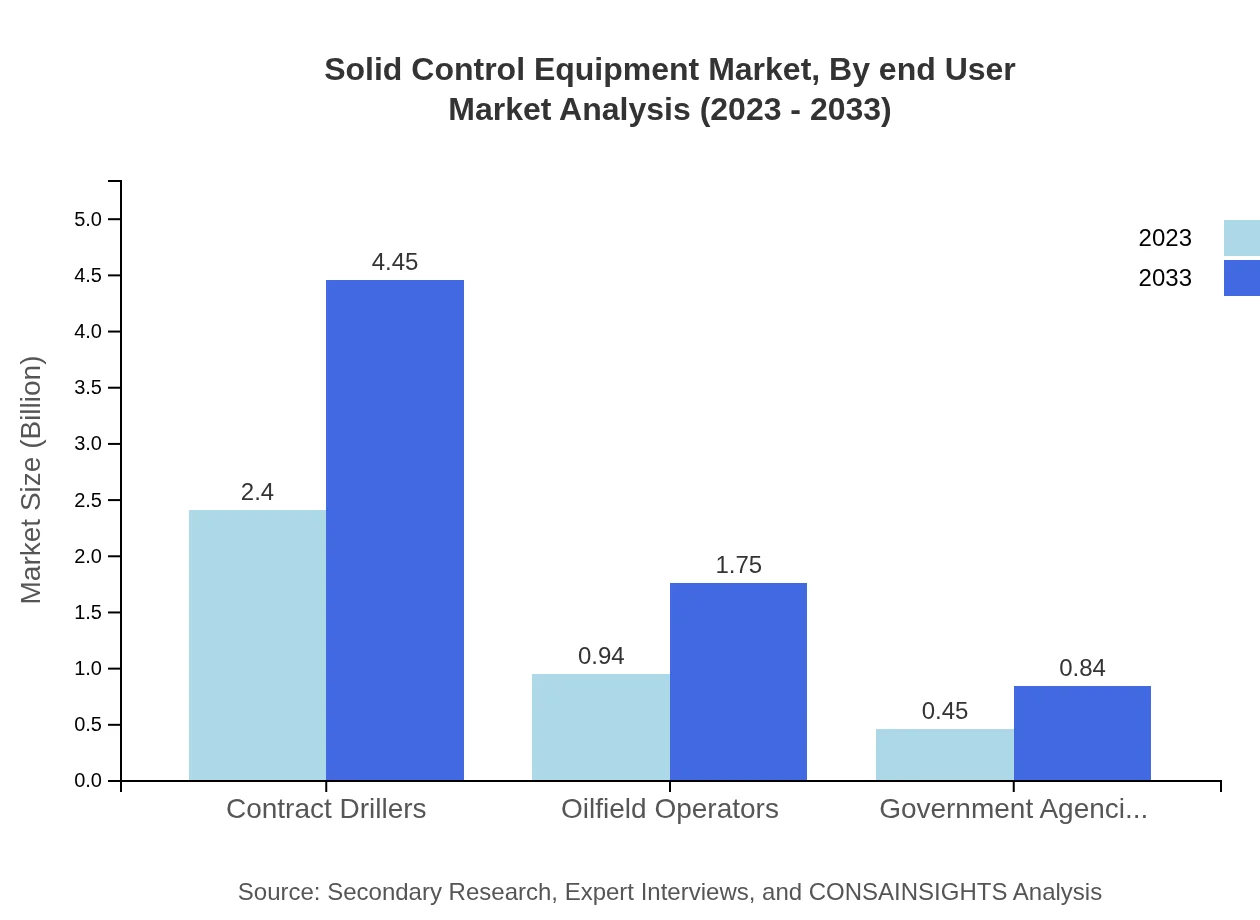

Solid Control Equipment Market Analysis By End User

The major end-users of Solid Control Equipment are Contract Drillers, Oilfield Operators, and Government Agencies, with Contract Drillers commanding a noteworthy market share of 63.24% in 2023. The focus on efficiency and regulatory compliance continues to drive advancements tailored towards these user specifications leading to market expansion.

Solid Control Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Solid Control Equipment Industry

Schlumberger Limited:

A leading technology provider for the oil and gas industry, offering a wide range of solid control equipment along with drilling services.Halliburton:

A major player in oilfield services, providing comprehensive solid control solutions to enhance operational efficiency.Baker Hughes:

Known for engineering solutions, Baker Hughes integrates advanced solid control solutions in its service offerings.Weir Group:

Specializes in solids control equipment and offers innovative products to cater to mining and energy sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of solid Control Equipment?

The global solid control equipment market is valued at approximately $3.8 billion as of 2023, with a compound annual growth rate (CAGR) of 6.2% projected through 2033.

What are the key market players or companies in this solid Control Equipment industry?

Key players in the solid control equipment market include major firms like Halliburton, Schlumberger, and Baker Hughes, which dominate segments through advanced technology offerings and extensive service networks.

What are the primary factors driving the growth in the solid Control Equipment industry?

Growth drivers in this sector include increased oil & gas exploration activities, technological advancements in solid control technology, and rising environmental regulations necessitating efficient waste management solutions.

Which region is the fastest Growing in the solid Control Equipment?

The fastest-growing region in the solid control equipment market is North America, projected to grow from $1.23 billion in 2023 to $2.29 billion by 2033, driven by heightened drilling activities.

Does ConsaInsights provide customized market report data for the solid Control Equipment industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs in the solid control equipment industry, including segment-focused analyses and regional insights.

What deliverables can I expect from this solid Control Equipment market research project?

Deliverables typically include a comprehensive market analysis report, regional market breakdowns, competitive landscape insights, and forecasts covering trends, growth opportunities, and strategic recommendations.

What are the market trends of solid Control Equipment?

Current trends in the solid control equipment sector include a shift toward automation, increased emphasis on sustainability, and integration of IoT technologies to optimize drilling operations.