Spray Drying Equipment Market Report

Published Date: 22 January 2026 | Report Code: spray-drying-equipment

Spray Drying Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Spray Drying Equipment market, detailing insights on market size, segmentation, key players, and future trends from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

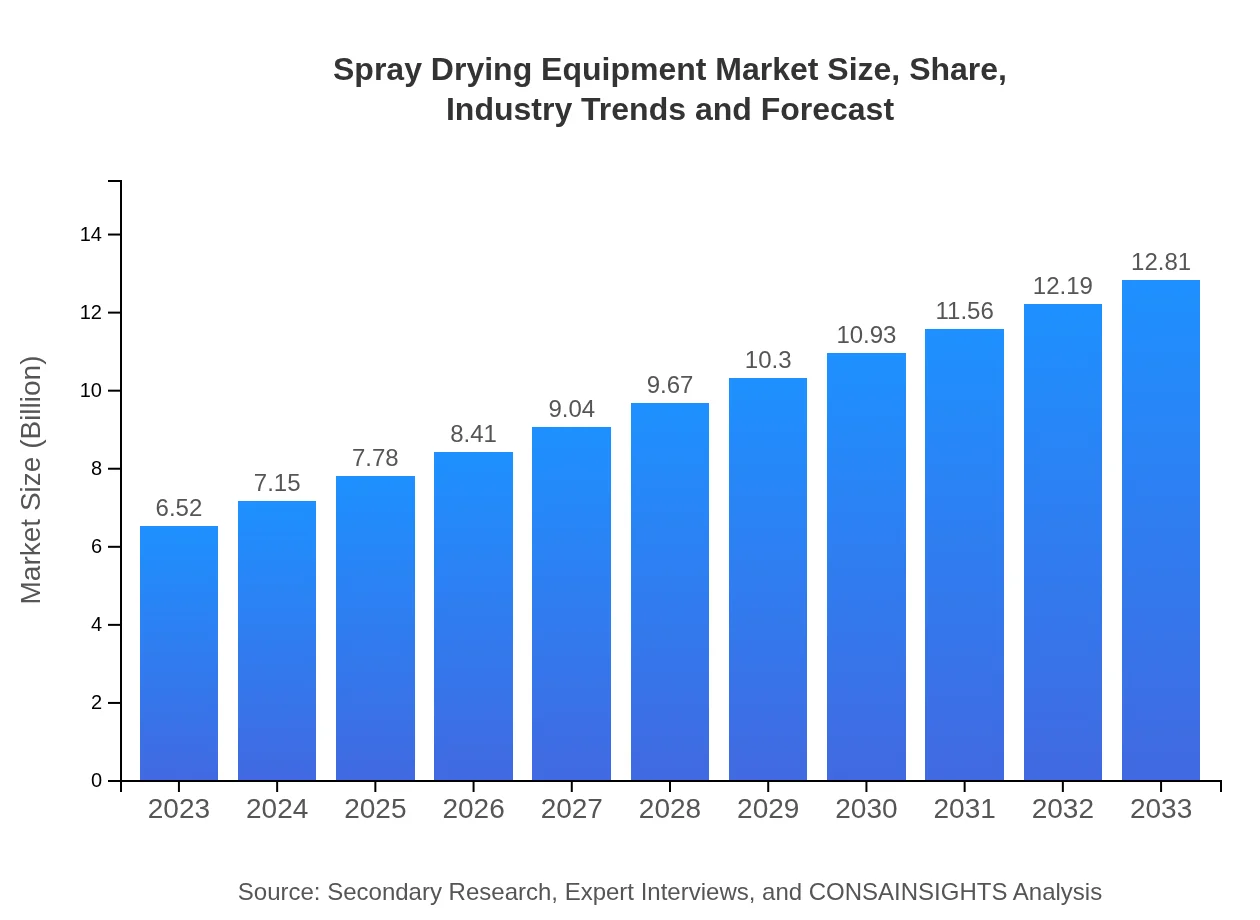

| 2023 Market Size | $6.52 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $12.81 Billion |

| Top Companies | GEA Group AG, SPX FLOW, Inc., Bühler Group, Matsui Mfg. Co., Ltd. |

| Last Modified Date | 22 January 2026 |

Spray Drying Equipment Market Overview

Customize Spray Drying Equipment Market Report market research report

- ✔ Get in-depth analysis of Spray Drying Equipment market size, growth, and forecasts.

- ✔ Understand Spray Drying Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Spray Drying Equipment

What is the Market Size & CAGR of Spray Drying Equipment market in 2023?

Spray Drying Equipment Industry Analysis

Spray Drying Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Spray Drying Equipment Market Analysis Report by Region

Europe Spray Drying Equipment Market Report:

The European market for Spray Drying Equipment reached approximately USD 1.80 billion in 2023, with projections to grow to USD 3.54 billion by 2033. The stringent quality regulations in the food and pharmaceuticals sectors and a growing trend towards energy-efficient and low-emission technologies in drying processes are key factors driving this growth.Asia Pacific Spray Drying Equipment Market Report:

In the Asia Pacific region, the Spray Drying Equipment market is valued at approximately USD 1.34 billion in 2023 and is expected to reach USD 2.64 billion by 2033. The rapid industrialization and growing food processing and pharmaceutical sectors in countries like India and China are driving the market's growth. Additionally, the region's significant investment in research and development activities to sustain high-quality manufacturing processes is a key driver.North America Spray Drying Equipment Market Report:

North America holds a significant share of the Spray Drying Equipment market, with an estimated value of USD 2.40 billion in 2023, expected to rise to USD 4.71 billion by 2033. A robust demand from food, pharmaceuticals, and chemicals industries, coupled with technological innovation and presence of key market players, is contributing to the region's growth.South America Spray Drying Equipment Market Report:

The South American market for Spray Drying Equipment is valued at around USD 0.47 billion in 2023, projected to grow to USD 0.91 billion by 2033. Growth in this region is influenced by increasing agricultural productivity, driving the need for improved processing technology in food products, as well as expansion in local manufacturing capacities.Middle East & Africa Spray Drying Equipment Market Report:

Middle East and Africa showcase modest growth for Spray Drying Equipment, with a market value projected at USD 0.51 billion in 2023, increasing to USD 1.01 billion by 2033. Initiatives to diversify economies and improve infrastructure support the growth of this sector, particularly in nations investing in food processing technology and pharmaceuticals.Tell us your focus area and get a customized research report.

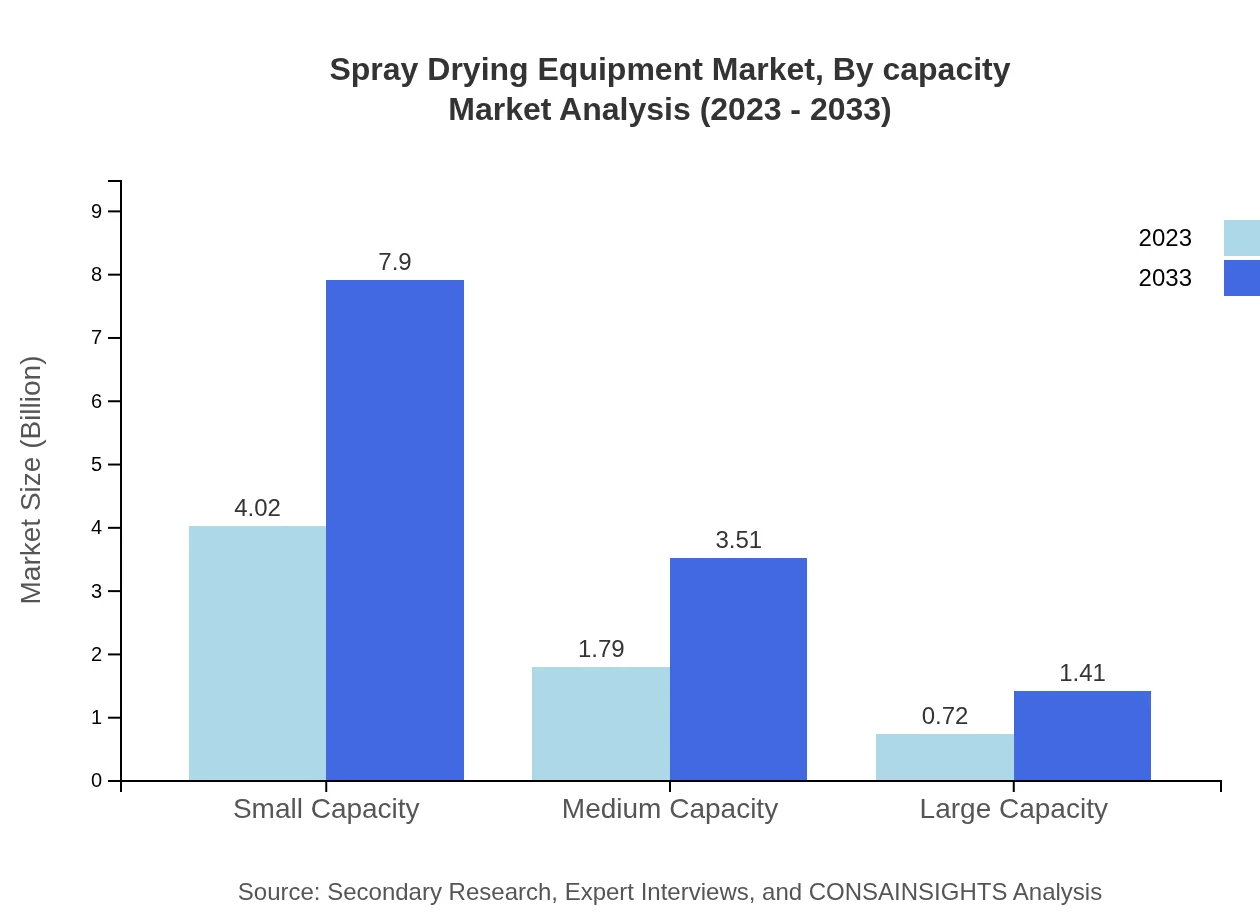

Spray Drying Equipment Market Analysis By Capacity

The Spray Drying Equipment market is categorized into small, medium, and large capacities. Small capacities are expected to dominate with a market size of USD 4.02 billion in 2023, increasing to USD 7.90 billion by 2033, maintaining a market share of 61.65%. Medium and large capacities also display growth, expected to reach USD 3.51 billion and USD 1.41 billion by 2033, respectively, serving niche markets that require specialized drying solutions.

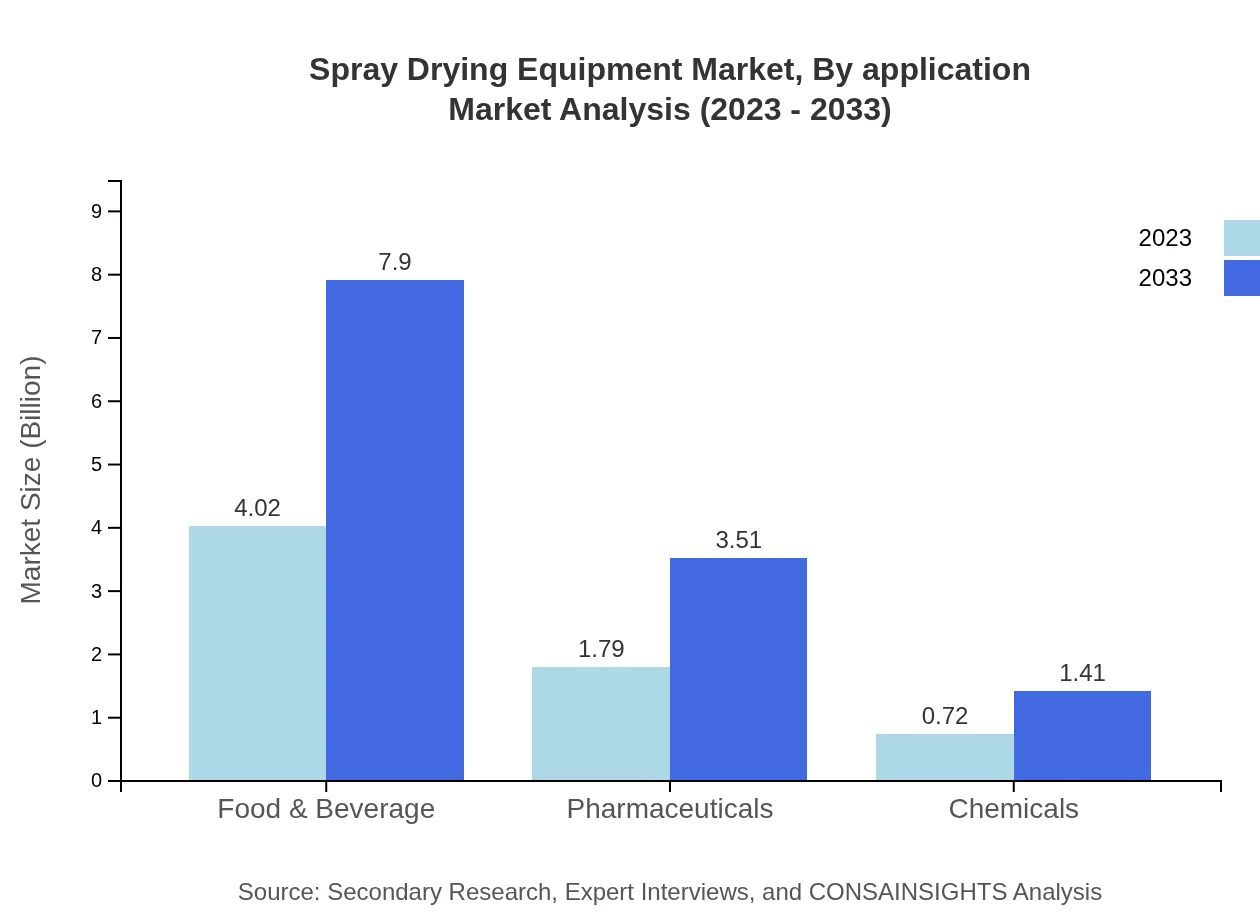

Spray Drying Equipment Market Analysis By Application

The applications of Spray Drying Equipment span food, pharmaceuticals, chemicals, and others. Notably, the food industry leads with a market size of USD 3.56 billion in 2023 and a segment share of 54.65% projected to grow robustly. The pharmaceutical industry is also significant, valued at USD 1.61 billion in 2023, and expected to reflect strong growth due to increased healthcare demands.

Spray Drying Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Spray Drying Equipment Industry

GEA Group AG:

A leading global supplier of process technology, GEA specializes in food processing and pharmaceutical solutions, offering state-of-the-art spray drying equipment for various industrial applications.SPX FLOW, Inc.:

SPX FLOW provides comprehensive and reliable drying solutions, focusing on customization and efficiency, contributing significantly to the food and chemical industries.Bühler Group:

Bühler is a key player in developing advanced spray drying technologies, renowned for its innovation in food and materials processing.Matsui Mfg. Co., Ltd.:

Matsui specializes in spray dryer technologies suitable for various sectors, with a focus on the pharmaceutical and chemical industries.We're grateful to work with incredible clients.

FAQs

What is the market size of spray Drying equipment?

The spray-drying equipment market is valued at approximately $6.52 billion in 2023, with a projected CAGR of 6.8% through 2033. This growth underscores increasing applications in industries like food, pharmaceuticals, and chemicals.

What are the key market players or companies in the spray Drying equipment industry?

Key players in the spray-drying equipment market include GEA Group AG, SPX FLOW, Inc., and Schenck Process Holding GmbH among others. These companies significantly influence market trends and advancements in technology, focusing on efficient drying solutions.

What are the primary factors driving the growth in the spray Drying equipment industry?

Growth drivers for the spray-drying equipment industry include increasing demand for processed food products, rising pharmaceutical production, and technological advancements in drying techniques. These factors contribute to higher efficiency and product quality in industrial processes.

Which region is the fastest Growing in the spray Drying equipment market?

The Asia Pacific region is the fastest-growing market for spray-drying equipment, projected to expand from $1.34 billion in 2023 to approximately $2.64 billion by 2033. This growth is driven by increasing industrialization and demand for processed foods.

Does ConsaInsights provide customized market report data for the spray Drying equipment industry?

Yes, ConsaInsights offers customized market report data, allowing clients to tailor insights based on specific needs and preferences. This ensures access to relevant and actionable market intelligence for informed decision-making.

What deliverables can I expect from this spray Drying equipment market research project?

Deliverables from the spray-drying equipment market research project may include detailed market analysis, segmentation data, trend reports, forecasts, competitive landscape assessment, and actionable insights tailored to specific business needs.

What are the market trends of spray Drying equipment?

Current market trends in the spray-drying equipment sector involve a shift towards eco-friendly technologies, enhanced efficiency, and increased adoption in emerging markets. Notable applications span food processing, pharmaceuticals, and chemical manufacturing.