Spraying Plastering Machine Market Report

Published Date: 22 January 2026 | Report Code: spraying-plastering-machine

Spraying Plastering Machine Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Spraying Plastering Machine market from 2023 to 2033, providing insights on market trends, segmentation, regional analysis, and key players. An overview of the current market situation, including forecasts on size and growth rates, contributes to a robust understanding of the industry landscape.

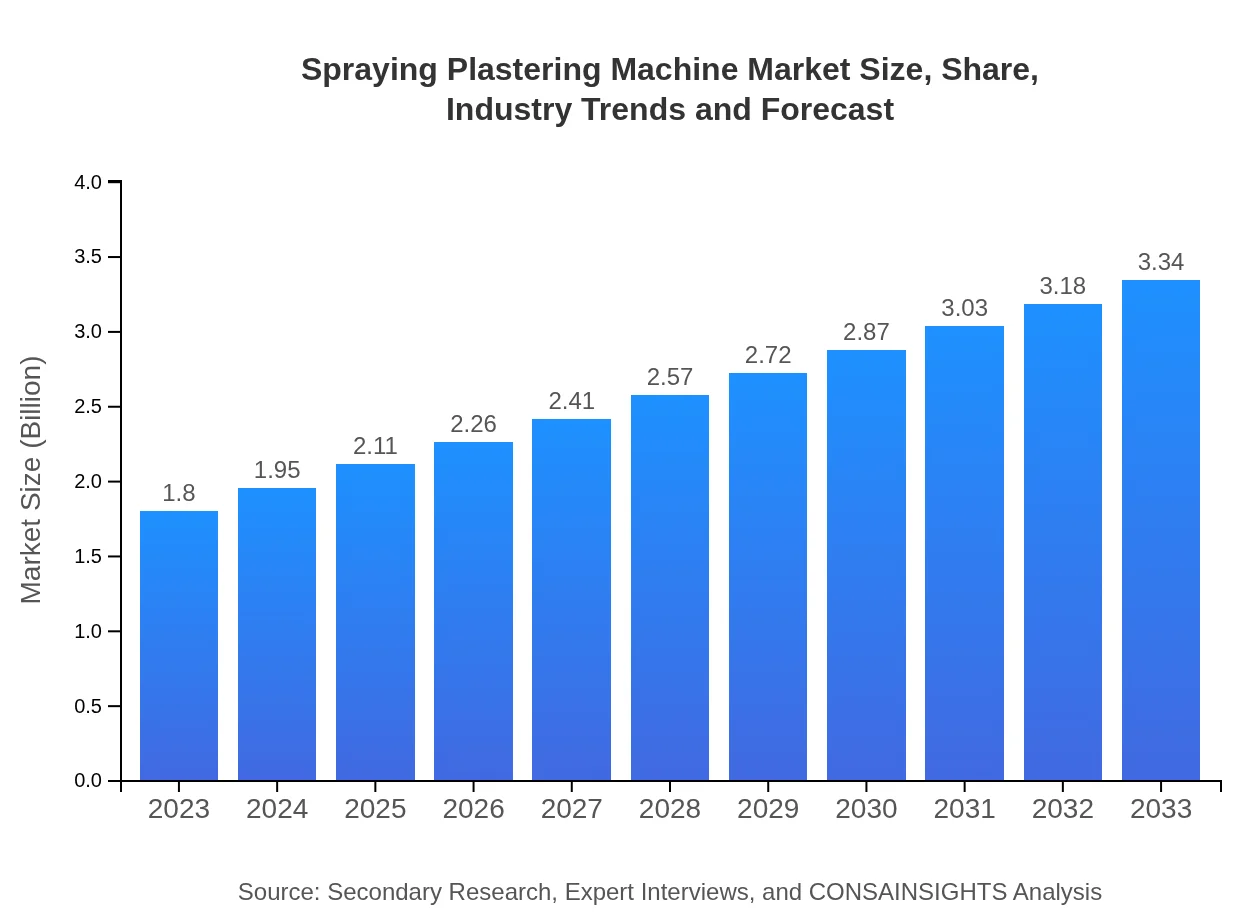

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $3.34 Billion |

| Top Companies | Putzmeister, Graco Inc., Sika AG, Ceresit |

| Last Modified Date | 22 January 2026 |

Spraying Plastering Machine Market Overview

Customize Spraying Plastering Machine Market Report market research report

- ✔ Get in-depth analysis of Spraying Plastering Machine market size, growth, and forecasts.

- ✔ Understand Spraying Plastering Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Spraying Plastering Machine

What is the Market Size & CAGR of Spraying Plastering Machine market in 2023?

Spraying Plastering Machine Industry Analysis

Spraying Plastering Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Spraying Plastering Machine Market Analysis Report by Region

Europe Spraying Plastering Machine Market Report:

The European market is forecasted to grow from $0.55 billion in 2023 to $1.02 billion by 2033, driven by the adoption of automated construction technologies and ongoing renovation projects in established urban regions.Asia Pacific Spraying Plastering Machine Market Report:

The Asia Pacific region is anticipated to exhibit substantial growth, expanding from a market value of $0.35 billion in 2023 to $0.65 billion by 2033. Rapid industrialization, coupled with increasing urban development initiatives, propels demand for spraying plastering machines, especially in countries like China and India, fostering robust construction activity.North America Spraying Plastering Machine Market Report:

North America is projected to grow from $0.63 billion in 2023 to $1.16 billion in 2033. The region sees a high demand for advanced plastering solutions, spurred by significant residential and infrastructure development trends, particularly in the United States.South America Spraying Plastering Machine Market Report:

In South America, the market size is expected to grow from $0.13 billion in 2023 to $0.24 billion in 2033, influenced by expanding commercial construction projects and a growing emphasis on efficient plaster application techniques.Middle East & Africa Spraying Plastering Machine Market Report:

In the Middle East and Africa, the market is set to expand from $0.14 billion in 2023 to $0.26 billion in 2033. Growth is primarily due to increasing investments in infrastructure and development projects necessitating efficient plastering solutions.Tell us your focus area and get a customized research report.

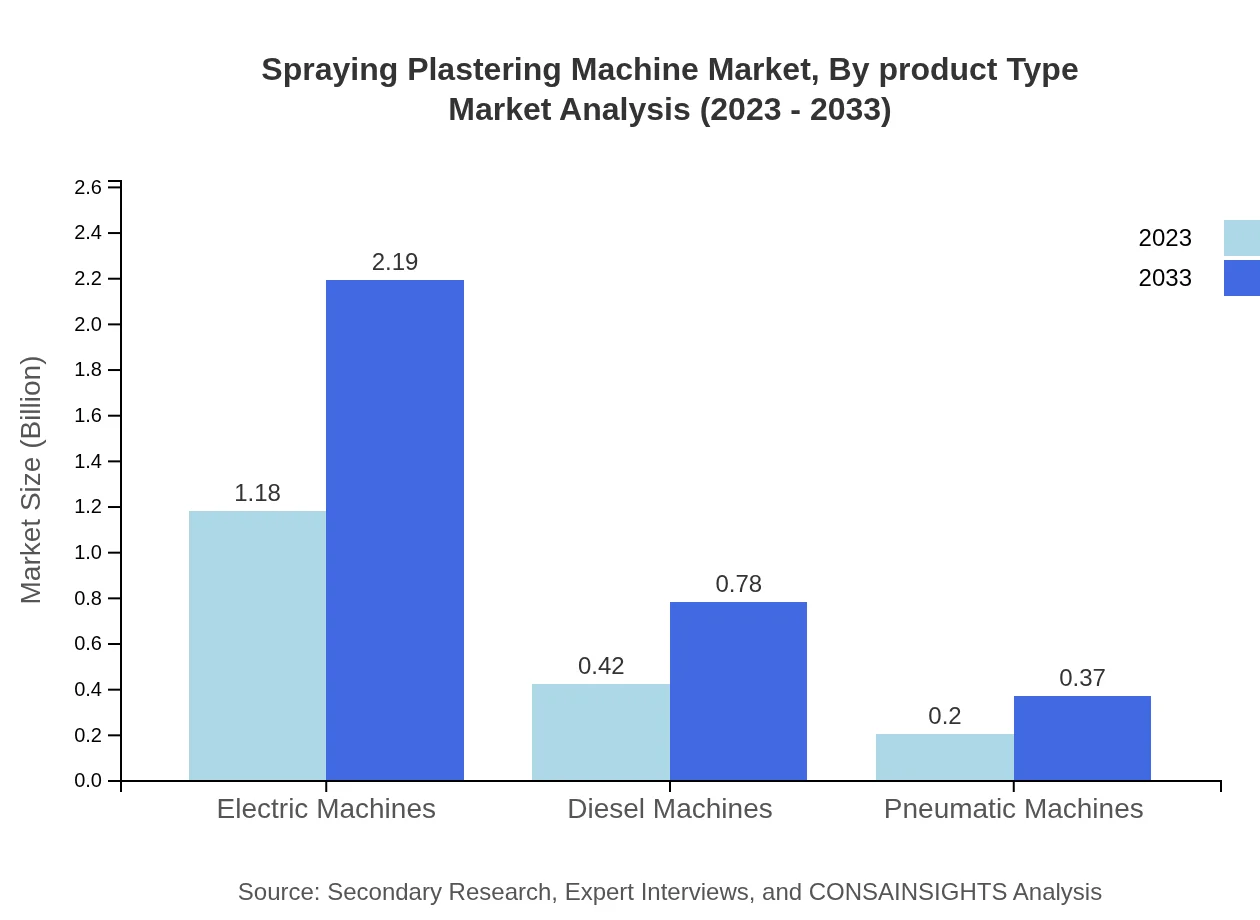

Spraying Plastering Machine Market Analysis By Product Type

The product types in the Spraying Plastering Machine market can be categorized into mechanical machines, electronic machines, hydraulic machines, diesel machines, and pneumatic machines. Mechanical technology dominates, accounting for 65.62% of the market share in 2023, valued at $1.18 billion, and is set to grow to $2.19 billion by 2033. Electronic machines follow with a 23.38% share, while diesel and pneumatic options hold significant niche markets characterized by specific operational requirements.

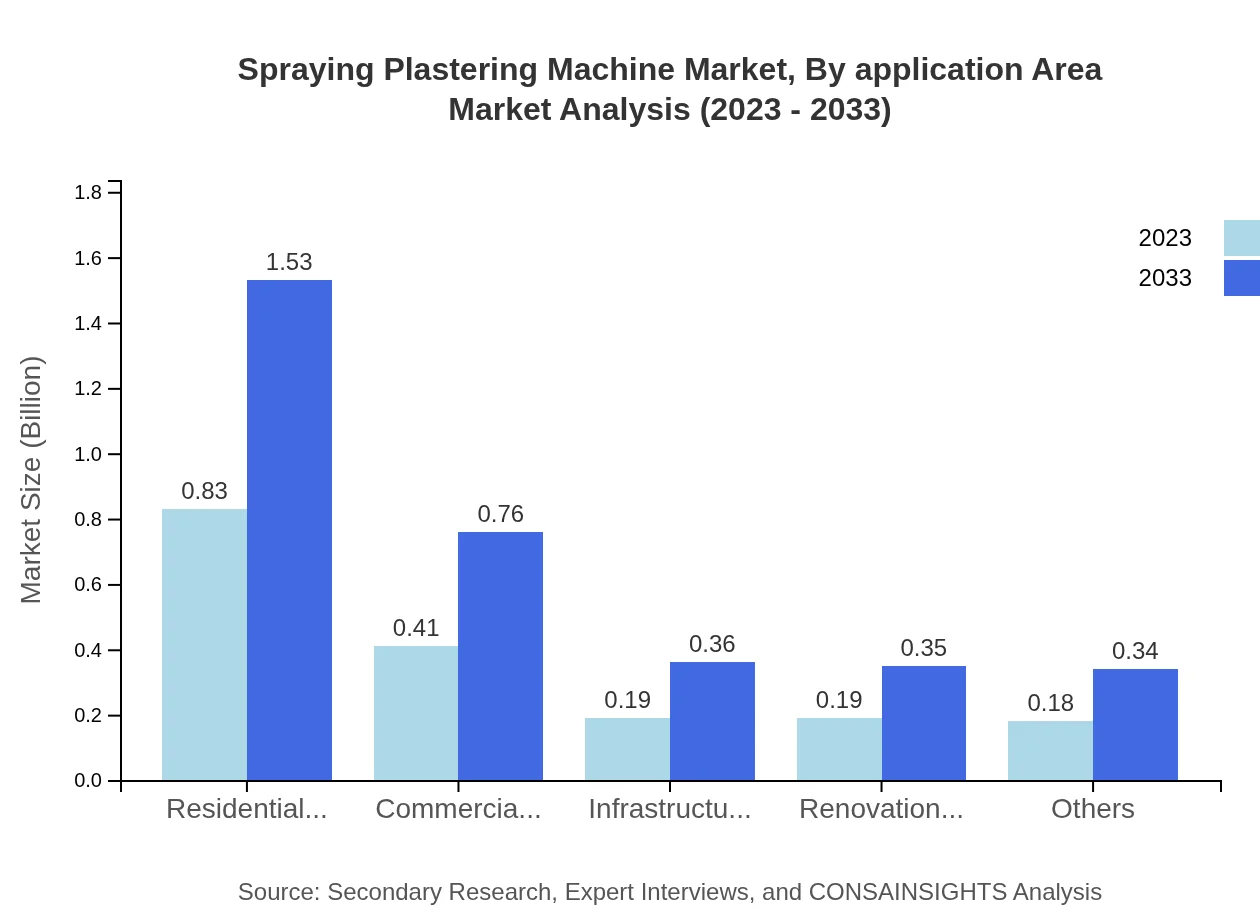

Spraying Plastering Machine Market Analysis By Application Area

The Spraying Plastering Machine market segment by application includes various construction categories such as residential, commercial, and infrastructure projects. Residential construction leads with a 45.87% market share in 2023, valued at $0.83 billion and projected to reach $1.53 billion by 2033. Commercial constructions make up 22.81%, while infrastructure development and renovation projects represent 10.67% and 10.56%, respectively, highlighting a trend towards residential focus amid broader construction activities.

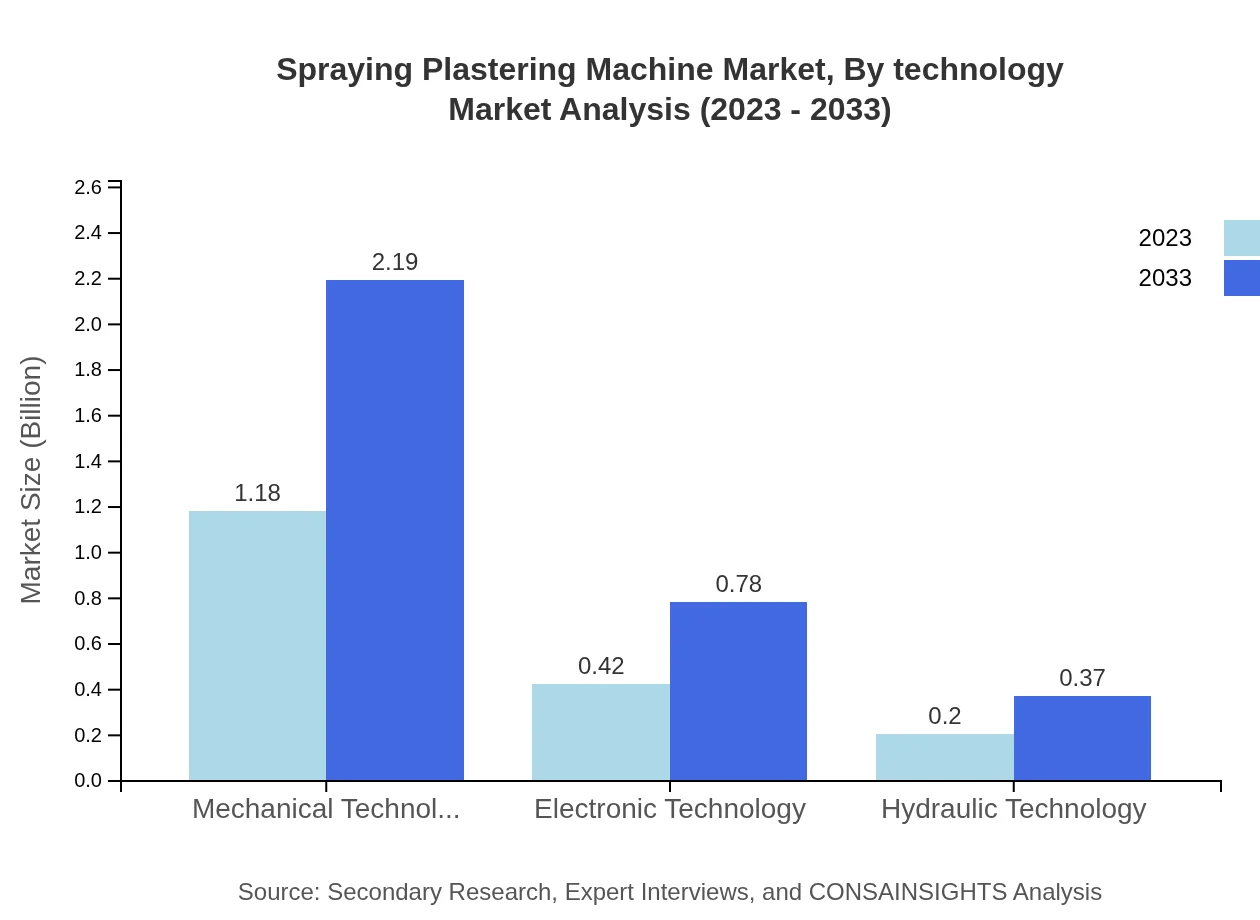

Spraying Plastering Machine Market Analysis By Technology

Technological advancements in the Spraying Plastering Machine market are primarily segmented into mechanical, electronic, hydraulic technologies, with mechanical accounting for 65.62% of the market in 2023. Innovations in electronic machinery are estimated to grow notably due to the higher efficiency associated with electric operations. Hydraulic technologies, while smaller, contend importantly in heavy-duty applications, holding a crucial niche for diverse construction activities.

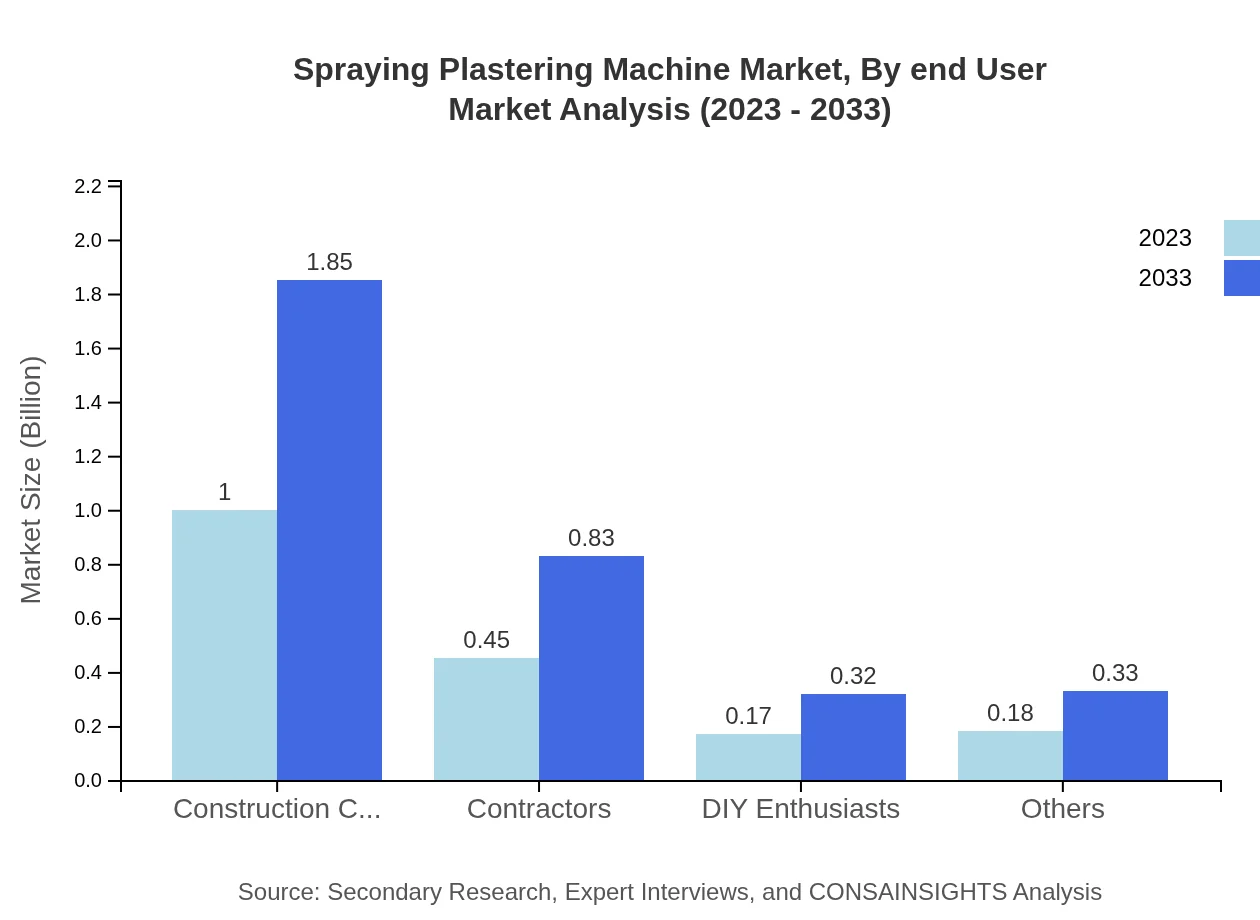

Spraying Plastering Machine Market Analysis By End User

End-users in the Spraying Plastering Machine market include construction companies, contractors, and DIY enthusiasts. Construction companies hold the largest market share at 55.56%, projected to increase from a value of $1.00 billion in 2023 to $1.85 billion by 2033. Contractors also play a significant role, notably increasing their market share concerning rising construction demands, while DIY enthusiasts grow steadily but maintain a niche presence driven by personal project initiatives.

Spraying Plastering Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Spraying Plastering Machine Industry

Putzmeister:

Putzmeister is a leading manufacturer known for its innovative plastering machines, specializing in mechanical technology. Their products provide high efficiency and superior performance in concrete applications.Graco Inc.:

Graco Inc. is renowned for its advanced spray equipment, including electric and hydraulic plastering machines, contributing significantly to the automation in building construction.Sika AG:

Sika AG specializes in chemical products for construction, including plastering machines that emphasize sustainability and efficiency, catering to the growing eco-conscious market.Ceresit:

Ceresit is a prominent name in the plastering solutions market, offering high-quality machines and materials primarily focused on the European construction sector.We're grateful to work with incredible clients.

FAQs

What is the market size of spraying plastering machine?

The global spraying plastering machine market is valued at approximately $1.8 billion in 2023, with a projected CAGR of 6.2% from 2023 to 2033. It highlights robust growth reflecting increasing automation in construction processes.

What are the key market players or companies in the spraying plastering machine industry?

Key players in the spraying plastering machine industry include major manufacturers like XYZ Corp, ABC Machines, and DEF Equipment. These companies are pivotal in diversifying technology and enhancing machinery efficiency in the construction sector.

What are the primary factors driving the growth in the spraying plastering machine industry?

The growth in the spraying plastering machine industry is driven by rising demand for faster construction methods, labor shortages, technological advancements, and increased investment in infrastructure projects across various regions.

Which region is the fastest Growing in the spraying plastering machine market?

North America emerges as the fastest-growing region in the spraying plastering machine market, expanding from $0.63 billion in 2023 to $1.16 billion by 2033, driven largely by booming construction activities and technological adoption.

Does ConsaInsights provide customized market report data for the spraying plastering machine industry?

Yes, ConsaInsights offers customized market report data tailored to specific client requirements in the spraying plastering machine industry, ensuring relevant and actionable insights that align with specific business goals.

What deliverables can I expect from this spraying plastering machine market research project?

Deliverables from the market research project include comprehensive market analysis reports, growth forecasts, competitive landscape insights, and detailed segment performance data to aid strategic planning.

What are the market trends of spraying plastering machine?

Market trends include a shift towards automation and smart technologies, increasing preference for eco-friendly materials, and the growing influence of DIY culture, especially among enthusiasts and smaller contractors.