Strain Gauges Market Report

Published Date: 22 January 2026 | Report Code: strain-gauges

Strain Gauges Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Strain Gauges market, covering critical insights and data related to market trends, size, growth, and forecasts for the period from 2023 to 2033.

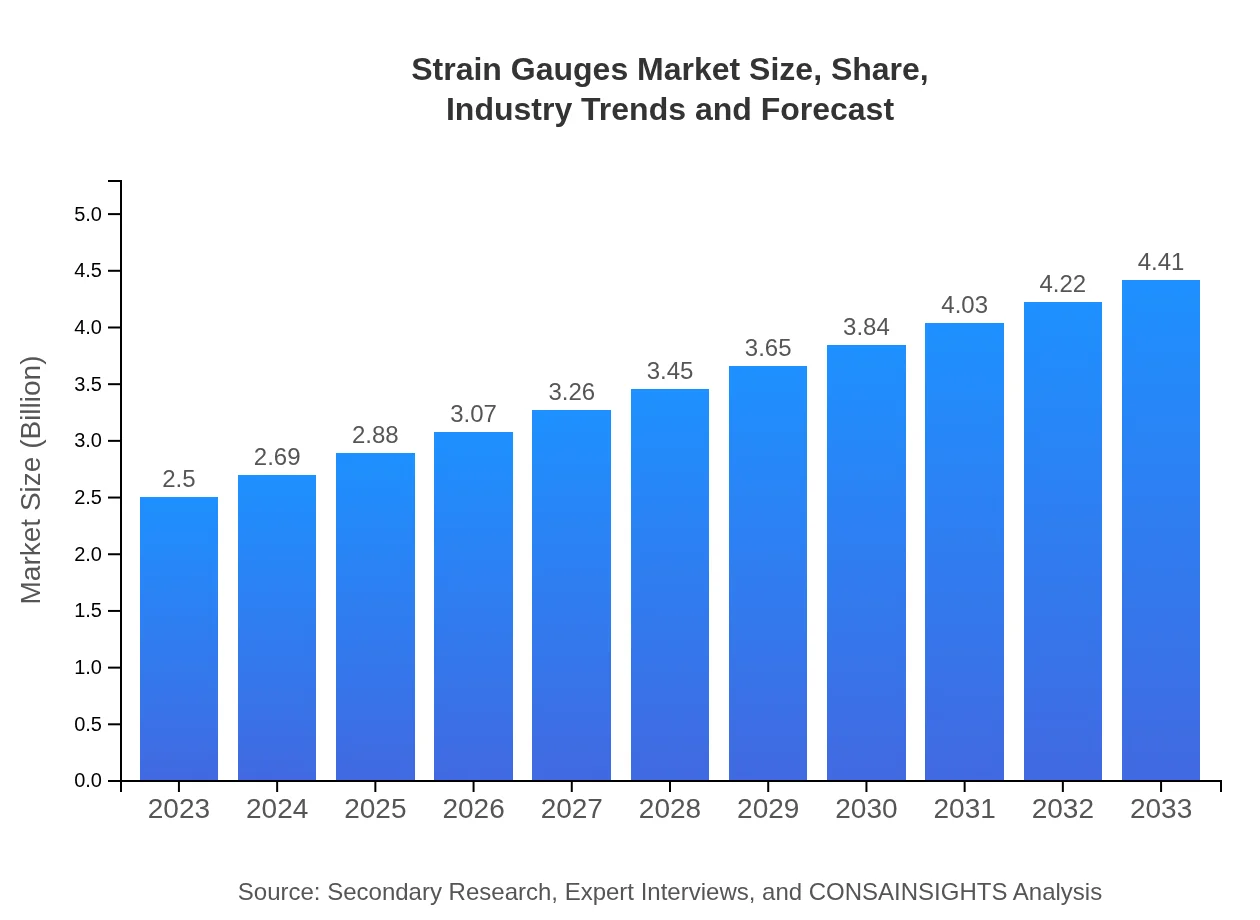

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.7% |

| 2033 Market Size | $4.41 Billion |

| Top Companies | Vishay Precision Group, HBM, Omega Engineering, Micro-Epsilon |

| Last Modified Date | 22 January 2026 |

Strain Gauges Market Overview

Customize Strain Gauges Market Report market research report

- ✔ Get in-depth analysis of Strain Gauges market size, growth, and forecasts.

- ✔ Understand Strain Gauges's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Strain Gauges

What is the Market Size & CAGR of Strain Gauges market in 2023?

Strain Gauges Industry Analysis

Strain Gauges Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Strain Gauges Market Analysis Report by Region

Europe Strain Gauges Market Report:

Europe's Strain Gauges market is projected to grow from USD 0.74 billion in 2023 to USD 1.31 billion by 2033. Significant contributions from the automotive and aerospace sectors, coupled with stringent regulations around safety and monitoring, are central to the market's expansion.Asia Pacific Strain Gauges Market Report:

In the Asia Pacific region, the Strain Gauges market is poised for growth from USD 0.50 billion in 2023 to USD 0.87 billion by 2033. Rapid industrialization and increasing investment in infrastructure contribute to the heightened demand for strain gauges. Countries like China and India are leading this growth due to substantial expenditures in civil engineering and large-scale projects.North America Strain Gauges Market Report:

North America is expected to show strong performance in the Strain Gauges market, estimated at USD 0.88 billion in 2023, growing to USD 1.55 billion by 2033. The advanced technological landscape and regulations for safety in construction and manufacturing sectors are primary drivers of this region's growth.South America Strain Gauges Market Report:

The South American Strain Gauges market, valued at USD 0.11 billion in 2023, is projected to increase to USD 0.19 billion by 2033. The growth is driven by rising investments in mining and energy sectors, necessitating innovations in monitoring and structural integrity, thereby enhancing demand for strain gauges.Middle East & Africa Strain Gauges Market Report:

The Middle East and Africa Strain Gauges market, with an estimated size of USD 0.28 billion in 2023, is expected to reach USD 0.49 billion by 2033. The demand in this region is significantly influenced by the ongoing infrastructure projects and the need for reliable sensor technologies in various applications.Tell us your focus area and get a customized research report.

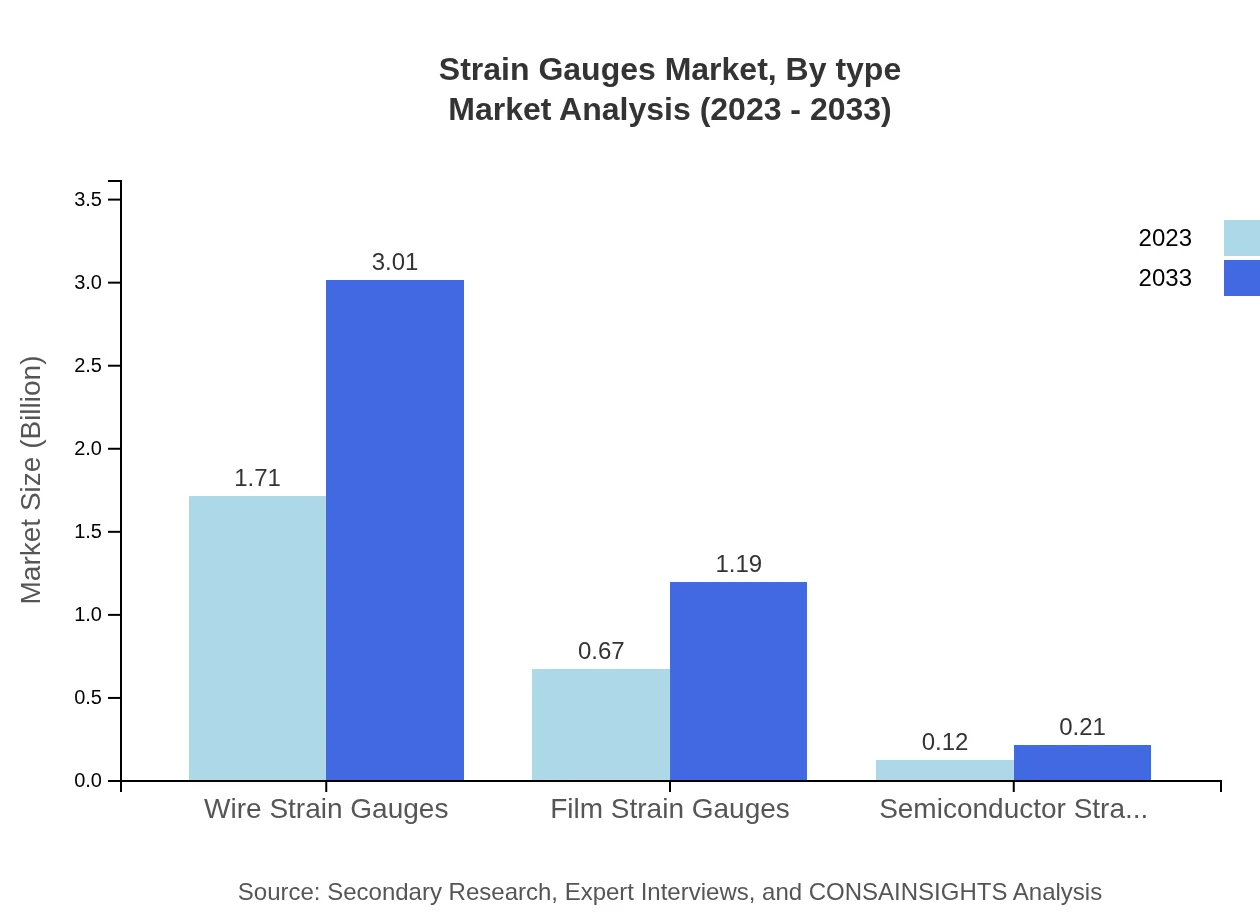

Strain Gauges Market Analysis By Type

The market is segmented by type and includes Wire Strain Gauges, which dominate the market with approximately USD 1.71 billion (68.37% share) in 2023, projected to reach USD 3.01 billion by 2033. Film Strain Gauges account for USD 0.67 billion (26.92% share) in 2023, increasing to USD 1.19 billion in 2033. Semiconductor Strain Gauges, while smaller at USD 0.12 billion (4.71% share), are anticipated to grow to USD 0.21 billion by 2033.

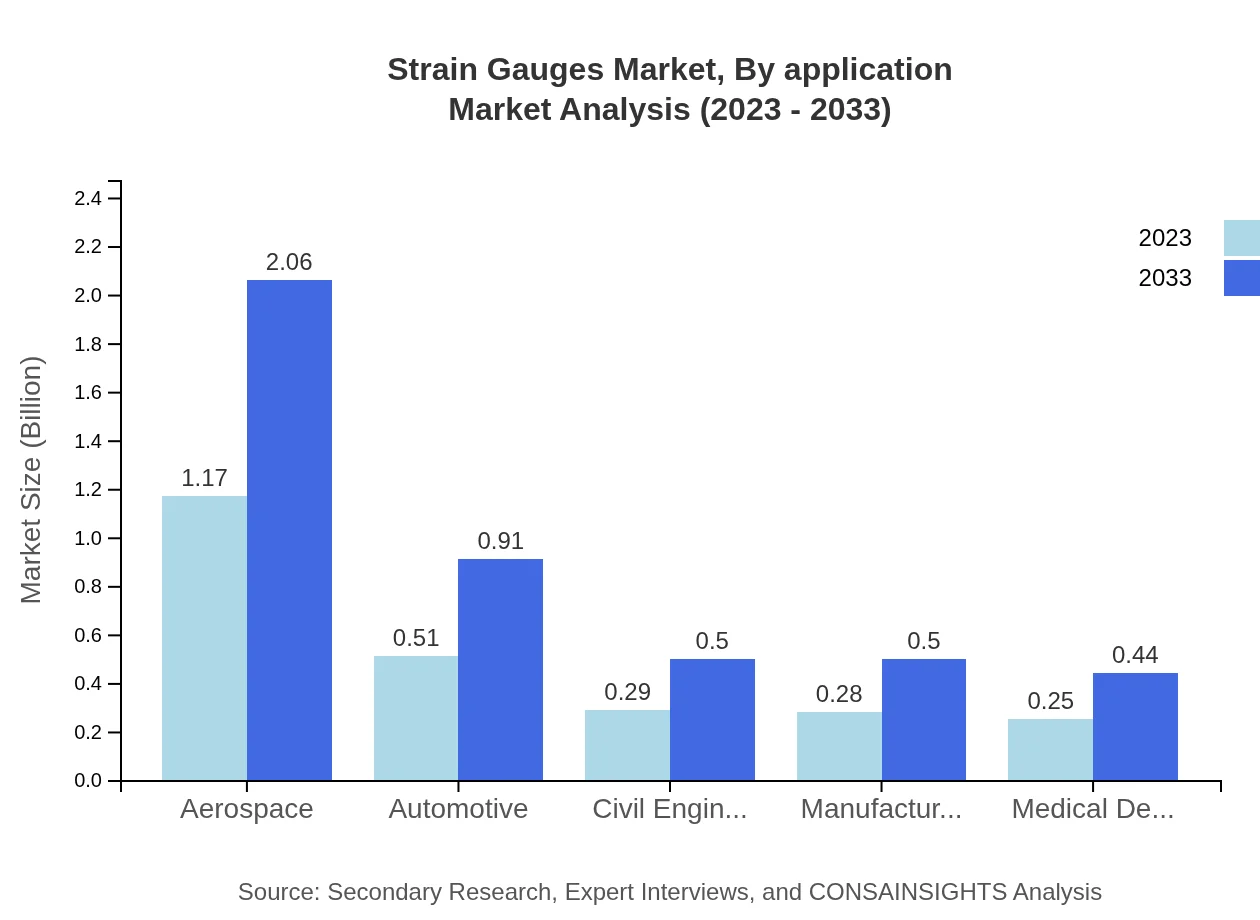

Strain Gauges Market Analysis By Application

In terms of application, the Aerospace sector leads with an estimated size of USD 1.17 billion in 2023 (46.69% share), expected to grow to USD 2.06 billion by 2033, while the Automotive sector represents USD 0.51 billion (20.56% share). Construction and Energy sectors follow closely, highlighting the critical role of strain gauges in structural health monitoring and machinery safety, with respective shares of 46.69% for Construction.

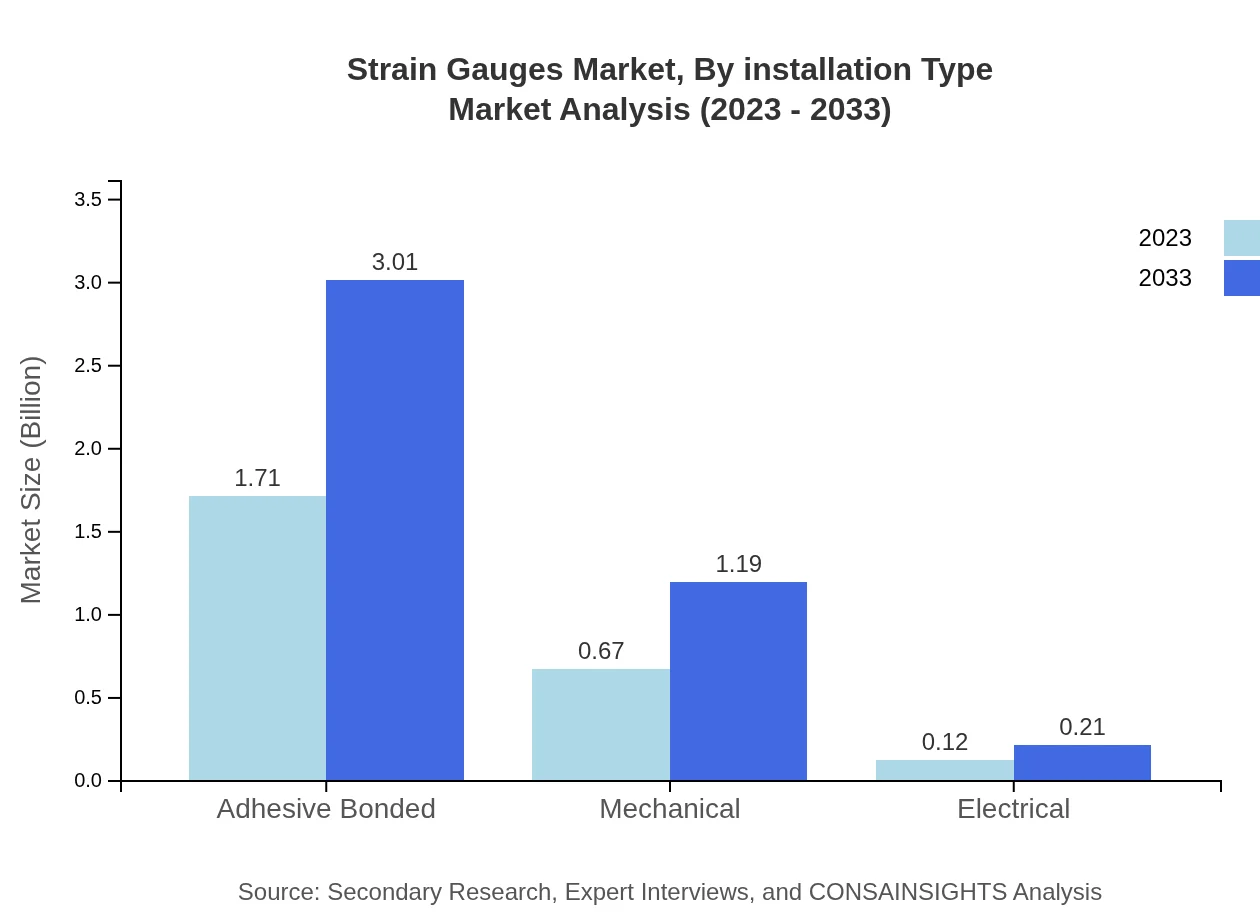

Strain Gauges Market Analysis By Installation Type

Strain gauges are categorized based on installation type into Adhesive Bonded and Mechanical installations. Adhesive Bonded gauges dominate the market share at USD 1.71 billion in 2023 (68.37% share), with expected growth to USD 3.01 billion by 2033. Mechanical installations, while smaller, are significant for specific industrial applications, ensuring stability and accuracy across various platforms.

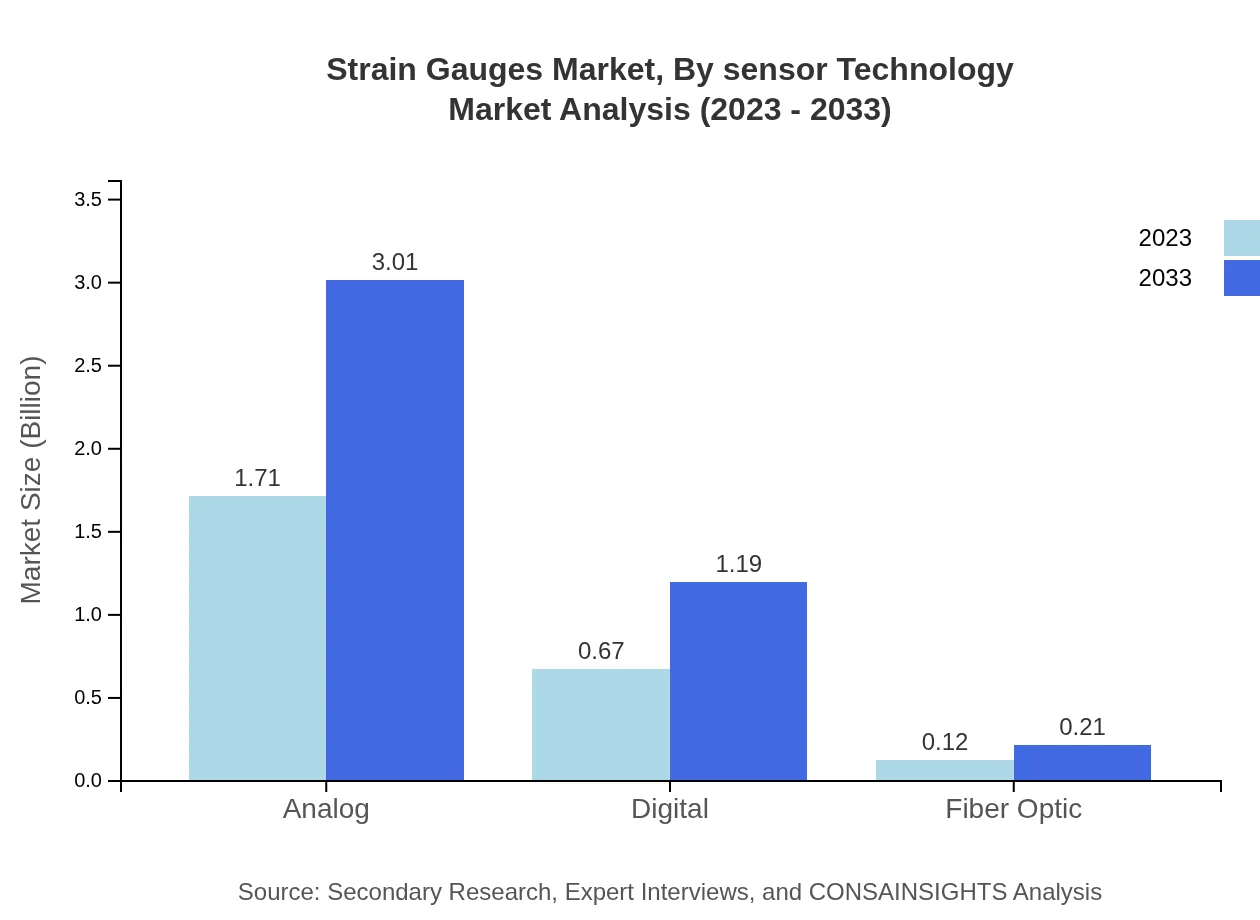

Strain Gauges Market Analysis By Sensor Technology

The Strain Gauges market is segmented by sensor technology into Analog and Digital technologies. The Analog segment holds a substantial market share of USD 1.71 billion (68.37% share) in 2023, growing to USD 3.01 billion by 2033. Digital technology, valued at USD 0.67 billion (26.92% share), is anticipated to reach USD 1.19 billion in 2033, driven by advancements in digital sensor technologies.

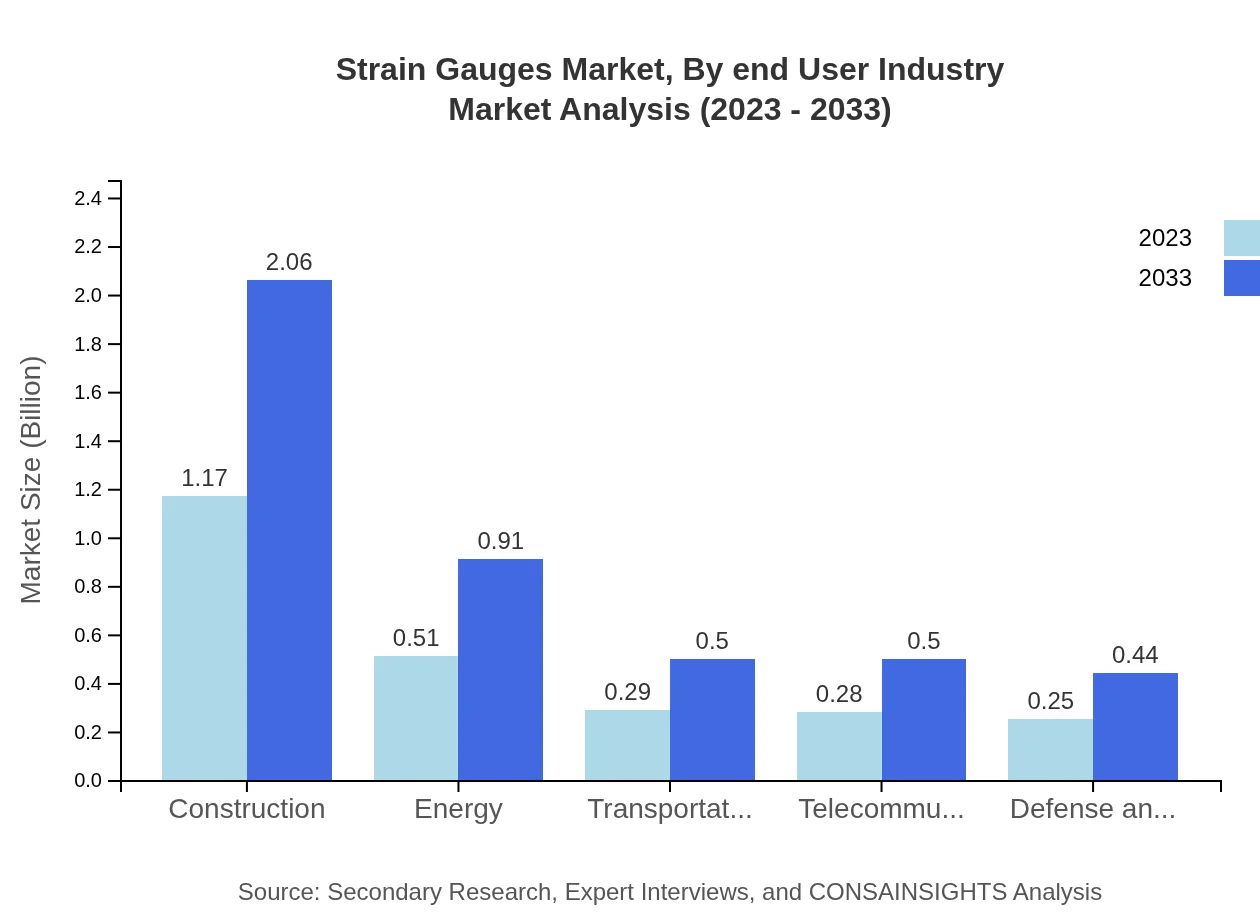

Strain Gauges Market Analysis By End User Industry

The Strain Gauges market by end-user industry encompasses sectors such as Civil Engineering, Medical Devices, Transportation, and Defense. Civil Engineering is significant with USD 0.29 billion (11.45% share) in 2023, growing to USD 0.50 billion. The Medical Devices and Telecommunications sectors follow closely, indicating a broad applicability and increased reliance on strain gauges across numerous industries.

Strain Gauges Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Strain Gauges Industry

Vishay Precision Group:

A leading manufacturer specializing in precision measurement and materials. They are known for their high-quality strain gages and extensive product line used in demanding applications globally.HBM:

HBM is renowned for its pioneering technologies in the sensing industry, particularly in strain gauges and load cells, driving innovation across numerous industrial sectors.Omega Engineering:

Known for their wide array of products for sensing and measurement, Omega Engineering remains a key player with solutions tailored for a variety of industries including healthcare, energy, and manufacturing.Micro-Epsilon:

Focusing on non-contact measurement technologies, Micro-Epsilon offers advanced strain gauge solutions utilized widely in quality assurance and automation.We're grateful to work with incredible clients.

FAQs

What is the market size of strain Gauges?

The global strain gauges market size was valued at approximately $2.5 billion in 2023 and is projected to grow at a CAGR of 5.7%, reaching about $4.01 billion by 2033, reflecting increased adoption across various industries.

What are the key market players or companies in the strain Gauges industry?

Key players in the strain gauges industry include Hitec Products, Omega Engineering, Vishay Precision Group, and FLIR Systems, among others, which contribute to innovation and advancements within the sector.

What are the primary factors driving the growth in the strain gauges industry?

The growth of the strain gauges market is driven by the booming automotive sector, increasing demand for smart technologies, advancements in sensor technology, and growing applications in civil engineering and aerospace.

Which region is the fastest Growing in the strain gauges market?

Europe is the fastest-growing region in the strain gauges market, projected to expand from $0.74 billion in 2023 to $1.31 billion by 2033, attributed to robust industrial frameworks and technological advancements.

Does ConsaInsights provide customized market report data for the strain Gauges industry?

Yes, Consainsights offers customized market report data tailored to specific needs within the strain gauges industry, delivering comprehensive insights and analytics to support strategic decision-making.

What deliverables can I expect from this strain Gauges market research project?

Expect deliverables such as detailed market analysis, growth forecasts, competitive landscape assessments, and segment-specific reports highlighting trends in various applications of strain gauges.

What are the market trends of strain gauges?

Current trends in the strain gauges market include the growing adoption of digital strain gauges, increased use in healthcare devices, and innovations in sensor materials leading to enhanced performance and accuracy.