Super Abrasives Market Report

Published Date: 02 February 2026 | Report Code: super-abrasives

Super Abrasives Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Super Abrasives market from 2023 to 2033, providing insights on market size, trends, industry analysis, growth forecasts, and regional breakdowns. It aims to assist stakeholders in understanding market dynamics and opportunities in the evolving landscape.

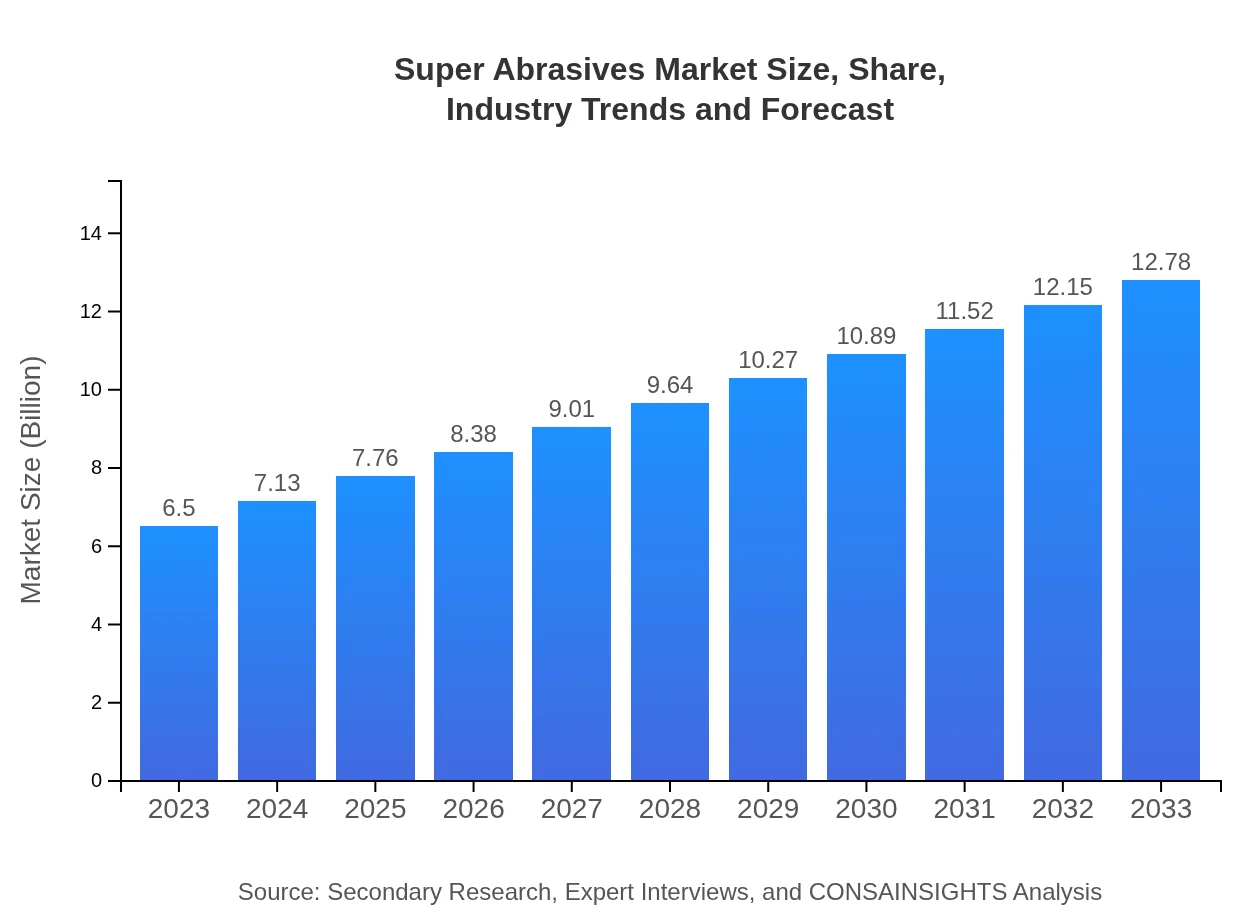

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $12.78 Billion |

| Top Companies | Element Six, Saint-Gobain, 3M, Norton |

| Last Modified Date | 02 February 2026 |

Super Abrasives Market Overview

Customize Super Abrasives Market Report market research report

- ✔ Get in-depth analysis of Super Abrasives market size, growth, and forecasts.

- ✔ Understand Super Abrasives's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Super Abrasives

What is the Market Size & CAGR of Super Abrasives market in 2023?

Super Abrasives Industry Analysis

Super Abrasives Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Super Abrasives Market Analysis Report by Region

Europe Super Abrasives Market Report:

Europe's Super Abrasives market is projected to grow from USD 2.05 billion in 2023 to USD 4.02 billion by 2033. The region has a robust manufacturing base, and an increasing focus on sustainability and efficiency is likely to drive the adoption of super abrasives.Asia Pacific Super Abrasives Market Report:

The Asia Pacific region held a market size of USD 1.35 billion in 2023, projected to grow to USD 2.66 billion by 2033. This growth is fueled by industrial expansion in countries like China and India, alongside increasing demand from the automotive and electronics sectors. The rapid urbanization and infrastructure development in these nations further supports the market for super abrasives.North America Super Abrasives Market Report:

North America, with a market value of USD 2.12 billion in 2023, is expected to reach USD 4.17 billion by 2033. The region's advanced manufacturing capabilities, along with significant investments in R&D, especially in the aerospace and healthcare sectors, are key drivers of growth in this market.South America Super Abrasives Market Report:

South America currently offers a modest market presence, with a valuation of USD 0.11 billion in 2023, expected to increase to USD 0.21 billion by 2033. Economic growth in Brazil and Argentina, alongside improved manufacturing practices, is likely to boost the demand for super abrasives in the region.Middle East & Africa Super Abrasives Market Report:

The Middle East and Africa are expected to see growth from USD 0.87 billion in 2023 to USD 1.71 billion by 2033. The expanding construction industry and rising investments in infrastructure projects contribute to this growth, alongside increased manufacturing activities.Tell us your focus area and get a customized research report.

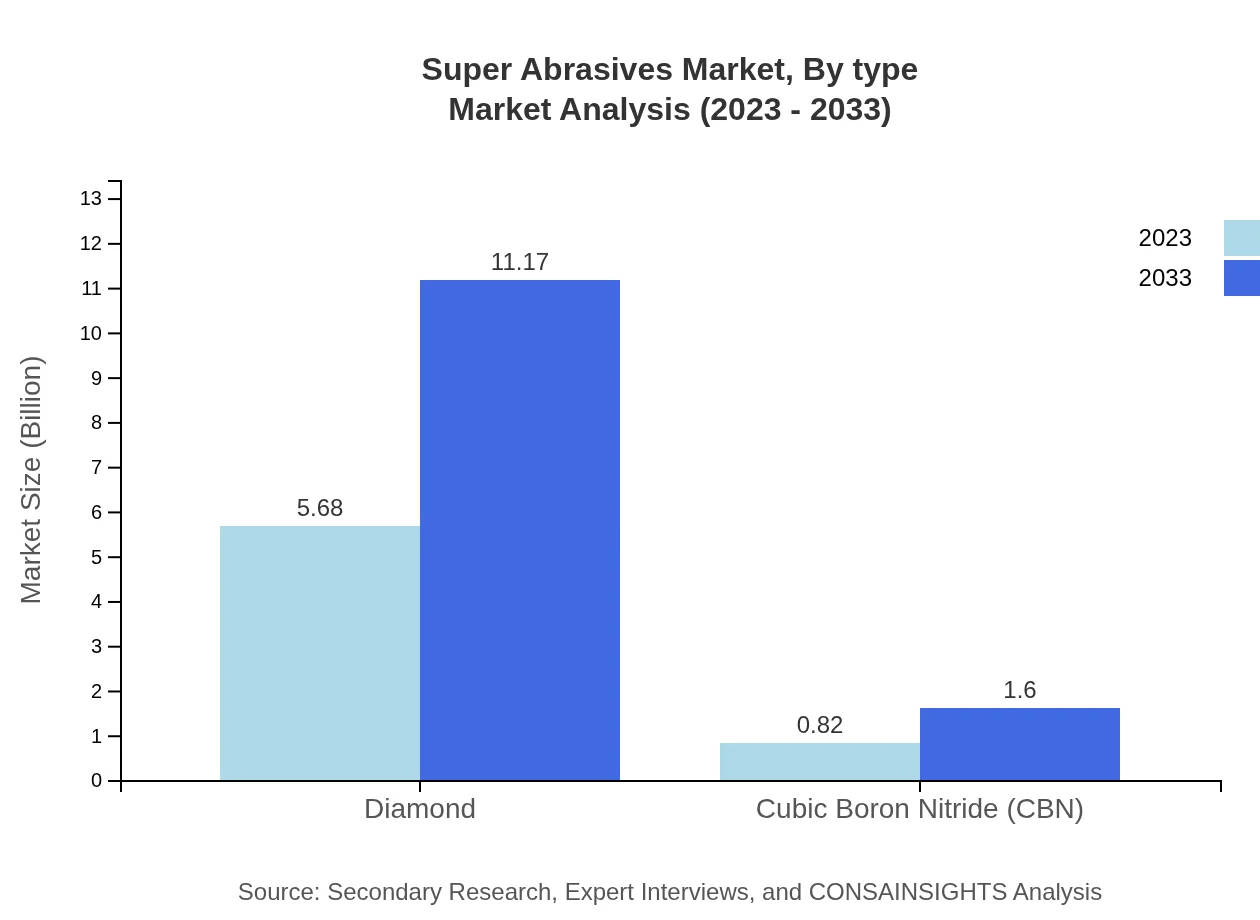

Super Abrasives Market Analysis By Type

In 2023, the diamond segment leads the Super Abrasives market, valued at USD 5.68 billion, with a consistent share of 87.46%. CBN abrasives, while smaller at USD 0.82 billion, showcase significant growth potential, driven by advancements in grinding technologies.

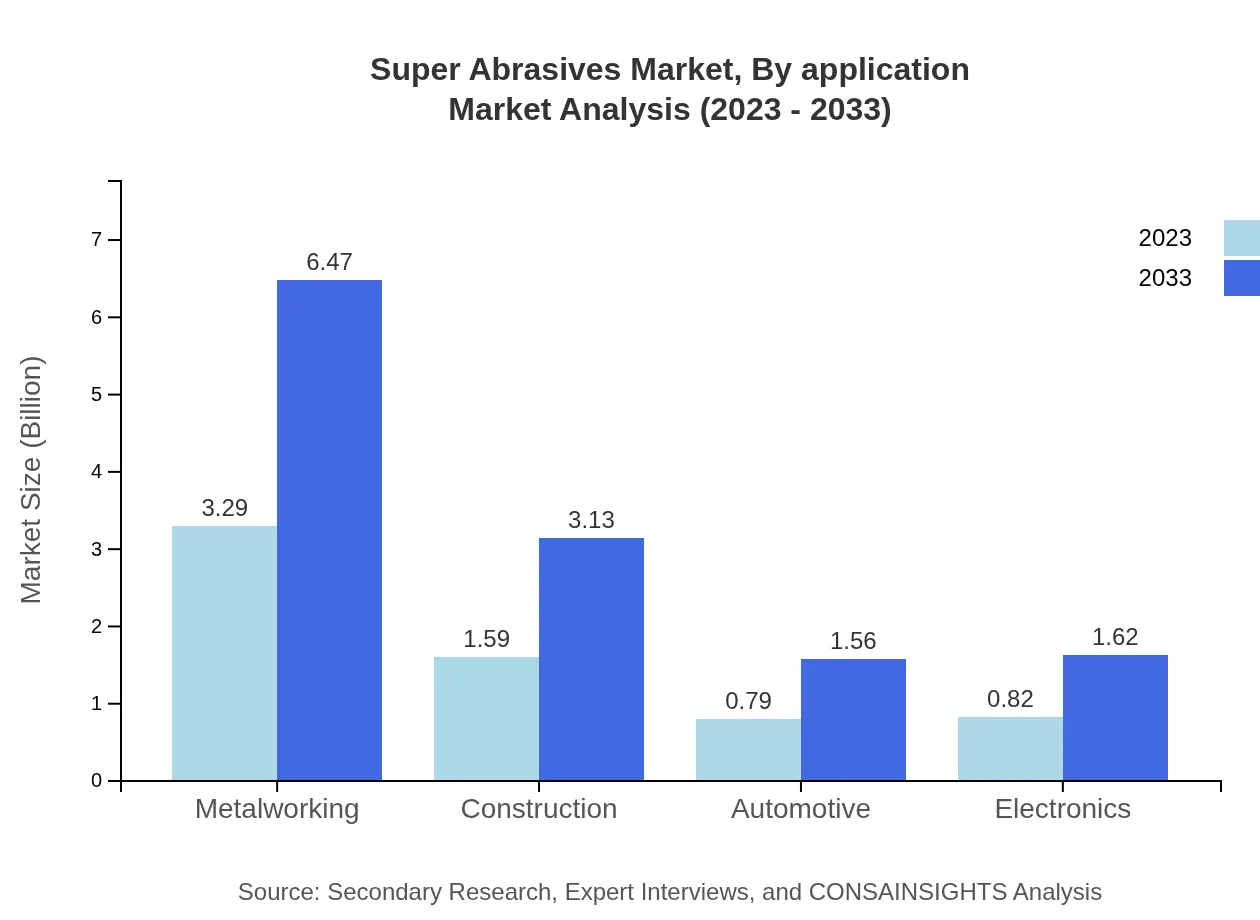

Super Abrasives Market Analysis By Application

The manufacturing segment commands a substantial market share of 50.66%, valued at USD 3.29 billion in 2023, highlighting the crucial role super abrasives play in ensuring precision and efficiency in industrial processes.

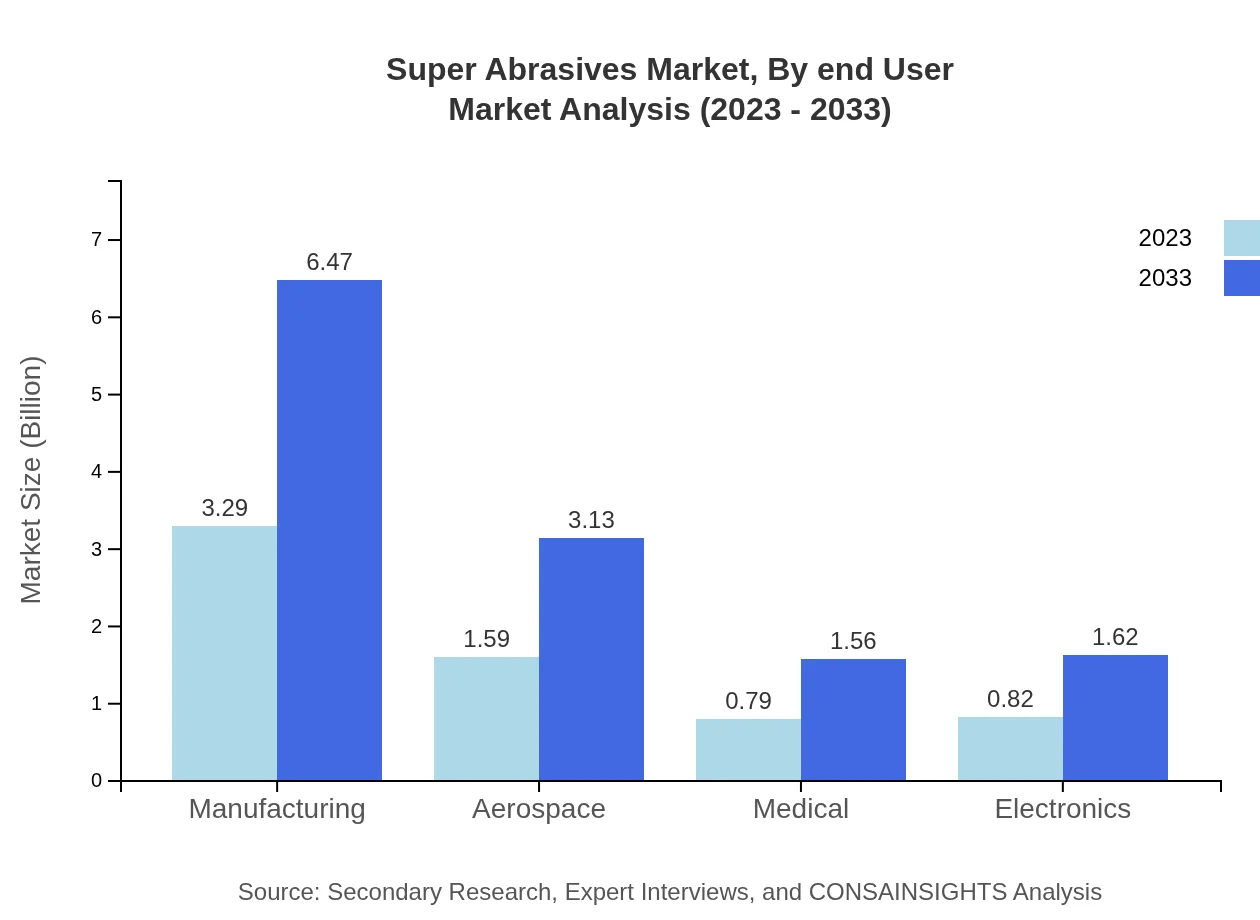

Super Abrasives Market Analysis By End User

Key end-user industries such as aerospace (USD 1.59 billion) and automotive (USD 0.79 billion) dominate the market, reflecting the growing application of super abrasives in critical manufacturing sectors requiring high precision.

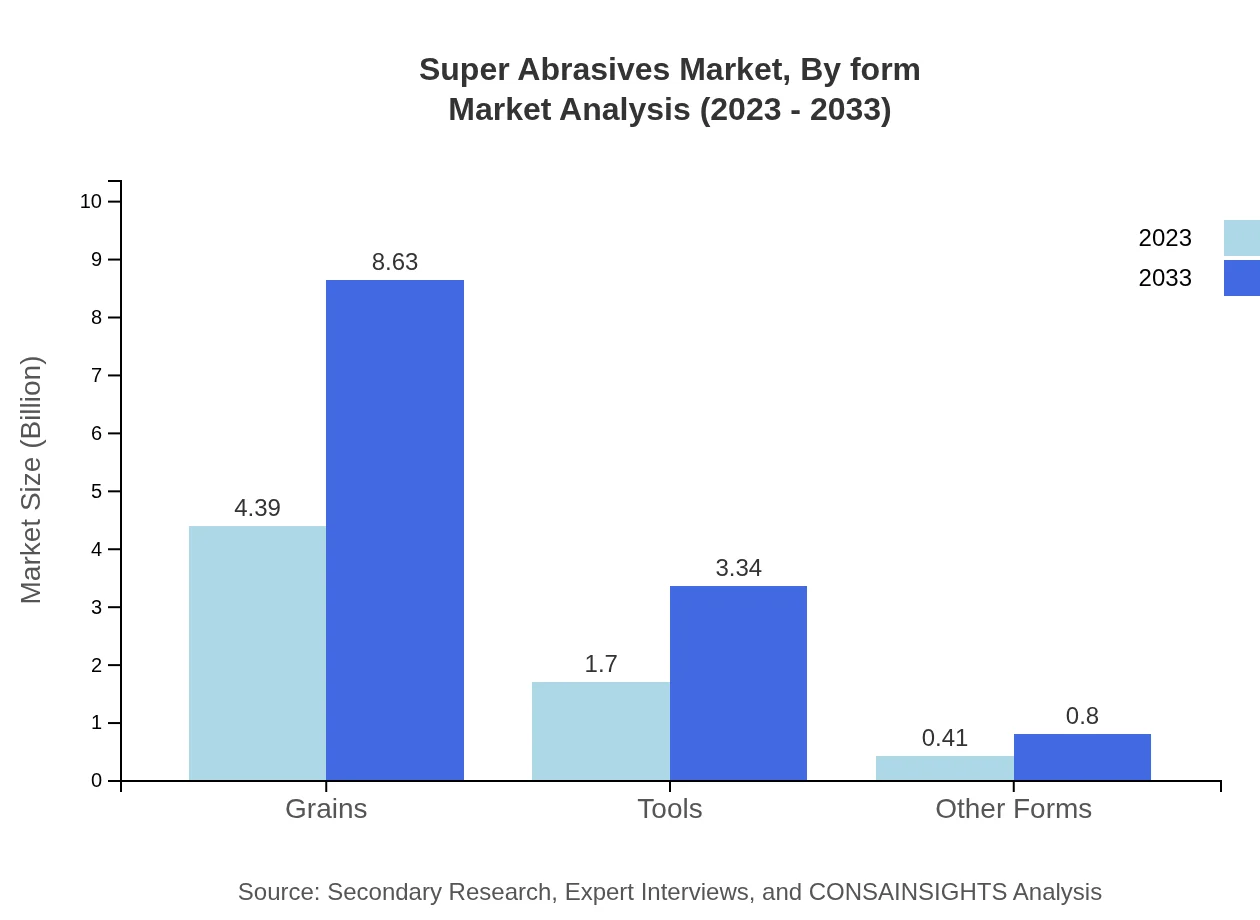

Super Abrasives Market Analysis By Form

The Super Abrasives market includes various forms such as grains, tools, and other forms, with grains dominating the market valuation at USD 4.39 billion in 2023, contributing to 67.59% market share.

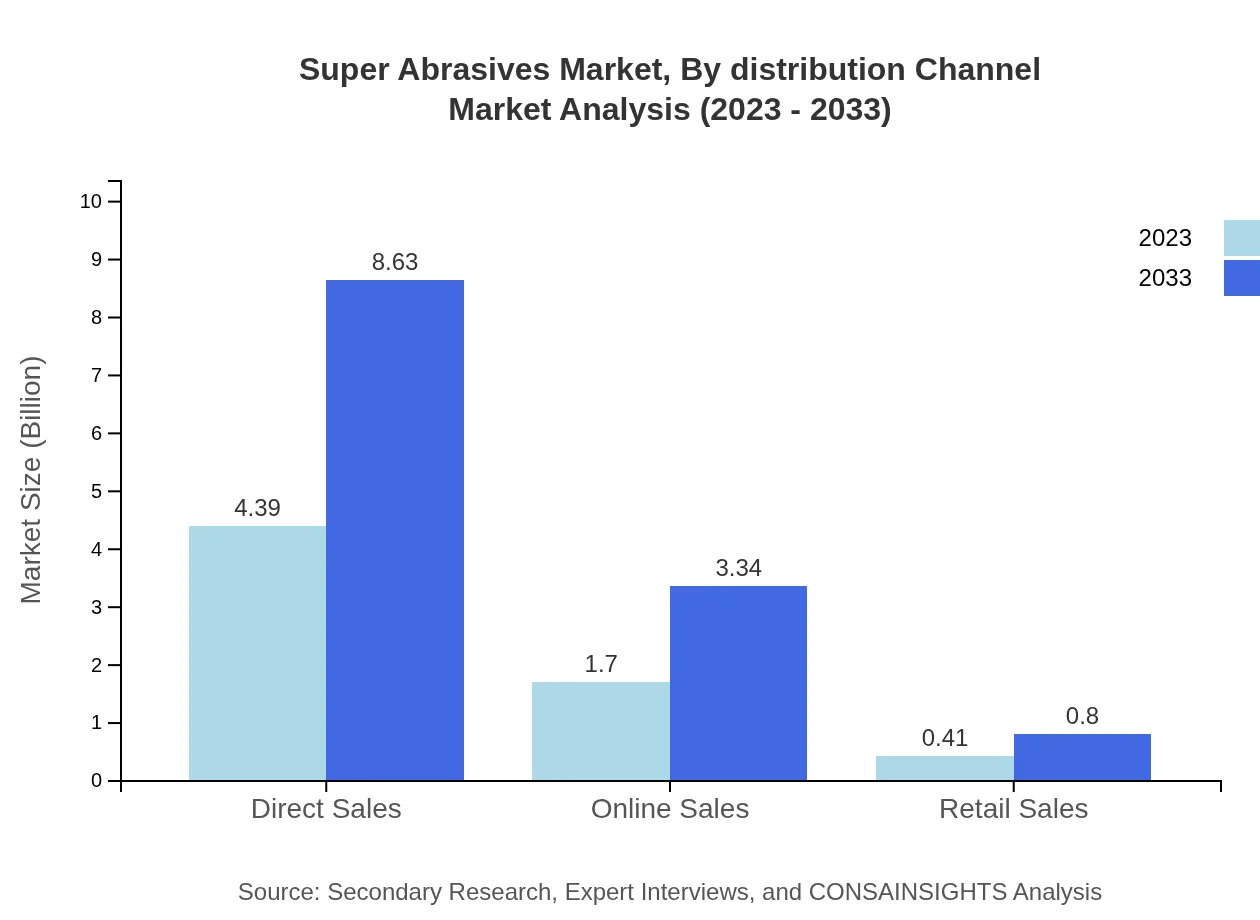

Super Abrasives Market Analysis By Distribution Channel

Direct sales are the most significant distribution channel, capturing a 67.59% market share in 2023, valued at USD 4.39 billion, indicating a preference for direct engagement between manufacturers and users for tailored solutions.

Super Abrasives Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Super Abrasives Industry

Element Six:

A leading manufacturer of synthetic diamonds and super abrasives, Element Six is known for its cutting-edge technology and extensive industry applications ranging from automotive to electronics.Saint-Gobain:

Saint-Gobain manufactures a wide range of high-performance abrasive materials, including super abrasives, leveraging innovative solutions to meet customer needs across various industries.3M:

An established leader in industrial products, 3M offers a comprehensive range of super abrasives and solutions that enhance productivity and efficiency across many sectors.Norton:

Part of Saint-Gobain, Norton specializes in abrasive solutions, including super abrasives, catering to diverse markets including metalworking, automotive, aerospace, and more.We're grateful to work with incredible clients.

FAQs

What is the market size of super Abrasives?

The global super-abrasives market is projected to reach $6.5 billion by 2033, growing at a CAGR of 6.8% from 2023. This growth is driven by increasing demand in various industries such as manufacturing, aerospace, and automotive.

What are the key market players or companies in the super Abrasives industry?

Key players in the super-abrasives market include major manufacturers such as 3M, Saint-Gobain, and Element Six. These companies dominate through innovation, diversification in product offerings, and strategic partnerships.

What are the primary factors driving the growth in the super Abrasives industry?

The growth in the super-abrasives market is primarily driven by advancements in manufacturing technologies, the increasing application in various industries, and a rise in demand for high-precision tools and components.

Which region is the fastest Growing in the super Abrasives market?

The Asia Pacific region is the fastest-growing market for super-abrasives, projected to increase from $1.35 billion in 2023 to $2.66 billion by 2033. This growth is due to rapid industrialization and increased manufacturing activities.

Does ConsaInsights provide customized market report data for the super Abrasives industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the super-abrasives industry, allowing businesses to make informed decisions based on unique market dynamics.

What deliverables can I expect from this super Abrasives market research project?

Deliverables from the super-abrasives market research project include comprehensive reports, detailed market analysis, segmented data insights, and tailored recommendations based on key growth trends and market opportunities.

What are the market trends of super Abrasives?

Market trends for super-abrasives include increasing adoption of diamond and cubic boron nitride materials, growth in online sales platforms, and enhanced usage in cutting-edge applications such as electronics and aerospace.