Surface Roughness Measurement Market Report

Published Date: 22 January 2026 | Report Code: surface-roughness-measurement

Surface Roughness Measurement Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Surface Roughness Measurement market, encompassing market size, growth forecasts, technology trends, and competitive landscape insights for the period 2023 to 2033.

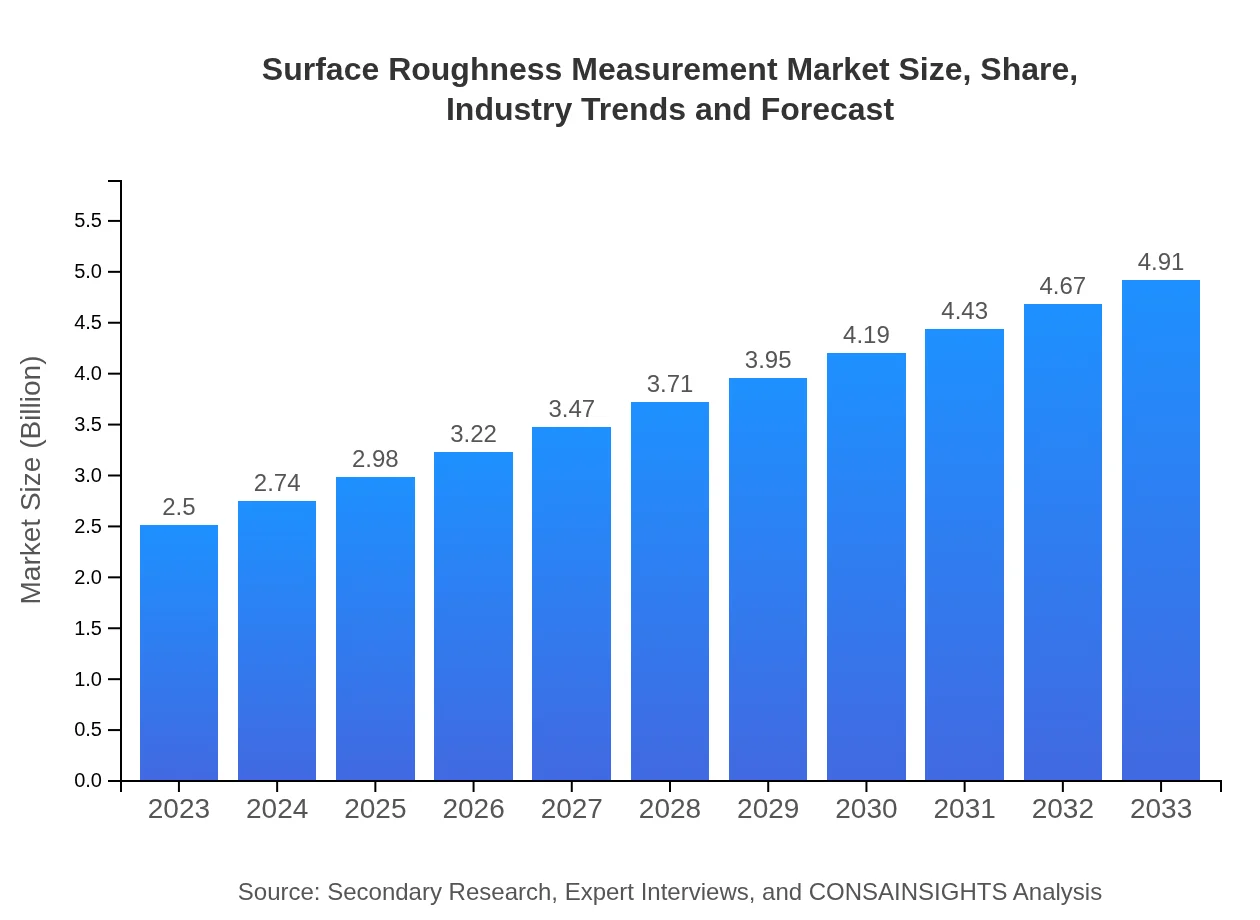

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | AMETEK, Inc., Mitutoyo Corporation, Hexagon AB, Zeiss Group |

| Last Modified Date | 22 January 2026 |

Surface Roughness Measurement Market Overview

Customize Surface Roughness Measurement Market Report market research report

- ✔ Get in-depth analysis of Surface Roughness Measurement market size, growth, and forecasts.

- ✔ Understand Surface Roughness Measurement's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Surface Roughness Measurement

What is the Market Size & CAGR of Surface Roughness Measurement market in 2023?

Surface Roughness Measurement Industry Analysis

Surface Roughness Measurement Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Surface Roughness Measurement Market Analysis Report by Region

Europe Surface Roughness Measurement Market Report:

Europe is another critical player in the Surface Roughness Measurement market, with an estimated value of $0.67 billion in 2023, expected to expand to $1.33 billion by 2033. This growth is supported by robust manufacturing practices and investments in advanced measurement technology driven by leading economies such as Germany and the UK.Asia Pacific Surface Roughness Measurement Market Report:

The Asia-Pacific region exhibits significant growth in the Surface Roughness Measurement market, with a market size of $0.48 billion in 2023, projected to grow to $0.94 billion by 2033, fueled by rapid industrialization and technological advancements across major economies like China and India. The demand for precise measurement tools in manufacturing and automotive sectors is driving this growth significantly.North America Surface Roughness Measurement Market Report:

North America holds a key share of the Surface Roughness Measurement market, valued at $0.81 billion in 2023, and projected to reach $1.59 billion by 2033. The growth is driven by a well-established aerospace and automotive industry, coupled with stringent quality and regulatory requirements that fuel demand for accurate measurement tools.South America Surface Roughness Measurement Market Report:

In South America, the market size for Surface Roughness Measurement is expected to increase from $0.20 billion in 2023 to $0.40 billion by 2033. The growth is largely attributed to the rising investments in manufacturing and a gradual shift towards modernization in production processes in countries like Brazil and Argentina.Middle East & Africa Surface Roughness Measurement Market Report:

In the Middle East and Africa, the market size for Surface Roughness Measurement is approximately $0.34 billion in 2023, anticipated to reach $0.66 billion by 2033. The growth is spurred by increasing industrial activities and growing awareness regarding quality standards, primarily in the oil and gas sectors.Tell us your focus area and get a customized research report.

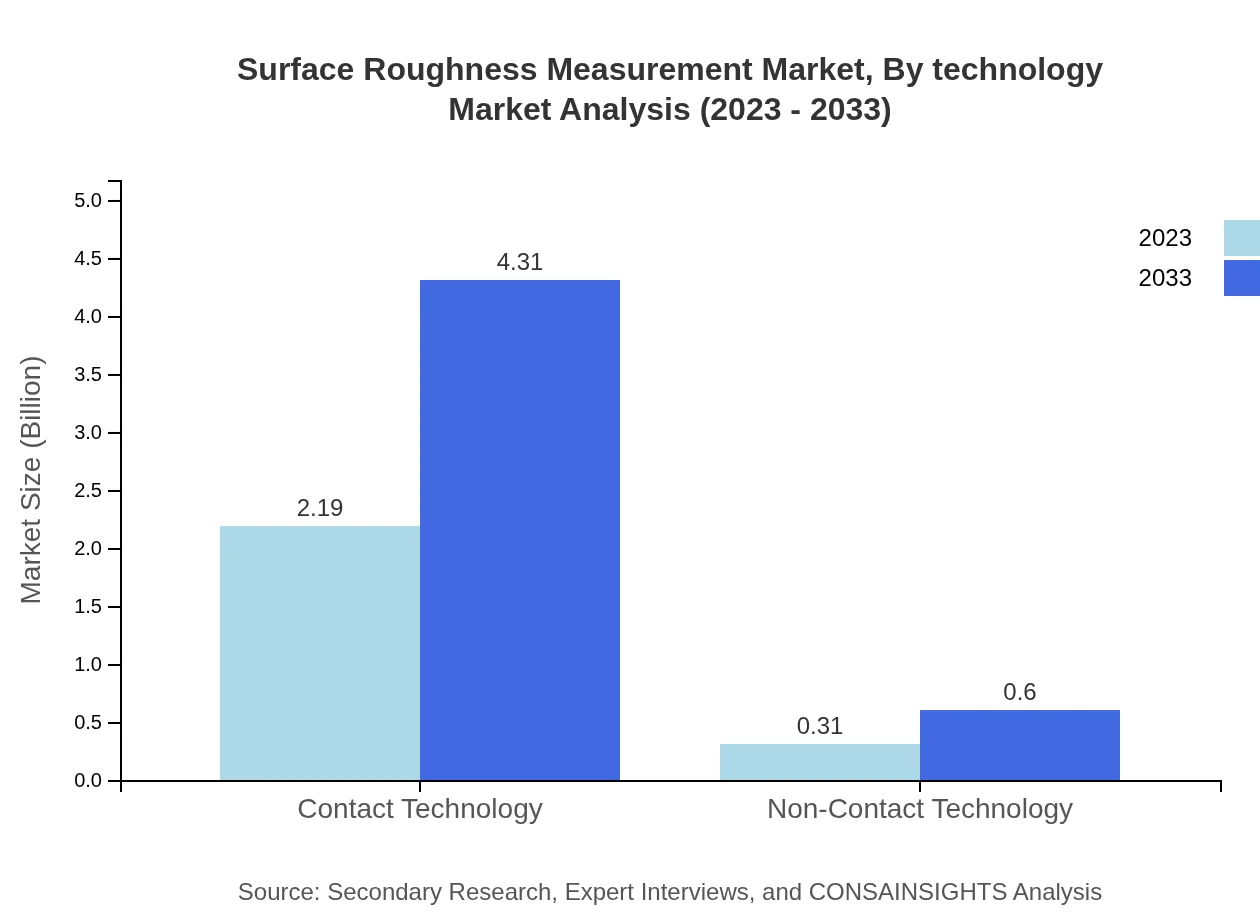

Surface Roughness Measurement Market Analysis By Technology

The market is predominantly divided between contact and non-contact measurement technologies. The contact technology segment, with a market size of $2.19 billion in 2023 and projected to reach $4.31 billion by 2033, holds a significant share due to its established accuracy and reliability. Non-contact technology, although smaller at $0.31 billion in 2023 and growing to $0.60 billion by 2033, is gaining traction due to its speed and avoidance of surface damage.

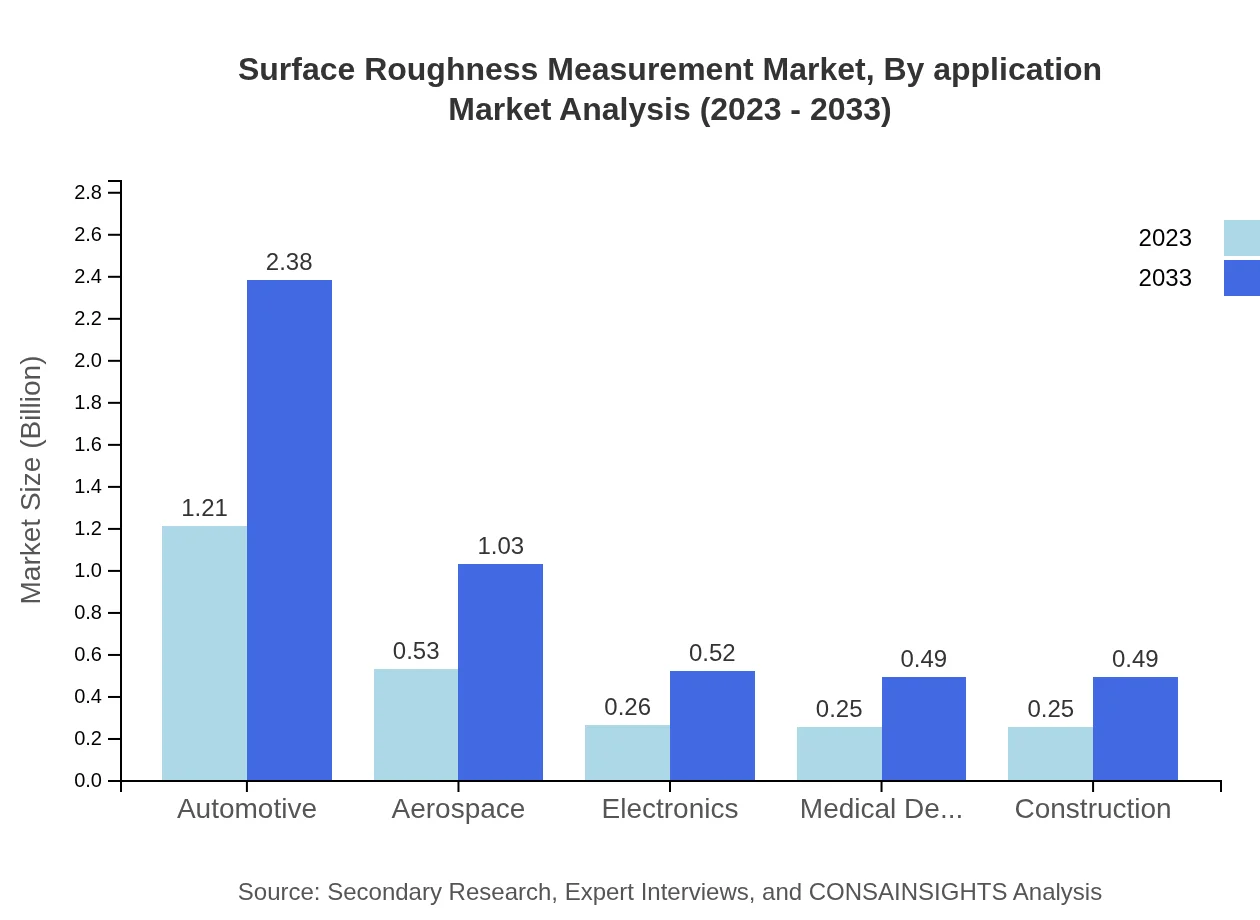

Surface Roughness Measurement Market Analysis By Application

Applications in industries such as automotive and aerospace dominate the Surface Roughness Measurement market, signifying their critical role in quality assurance. For instance, the automotive segment is projected to grow from $1.21 billion in 2023 to $2.38 billion by 2033. Other significant applications include electronics and medical devices, showcasing the technology's versatility across sectors.

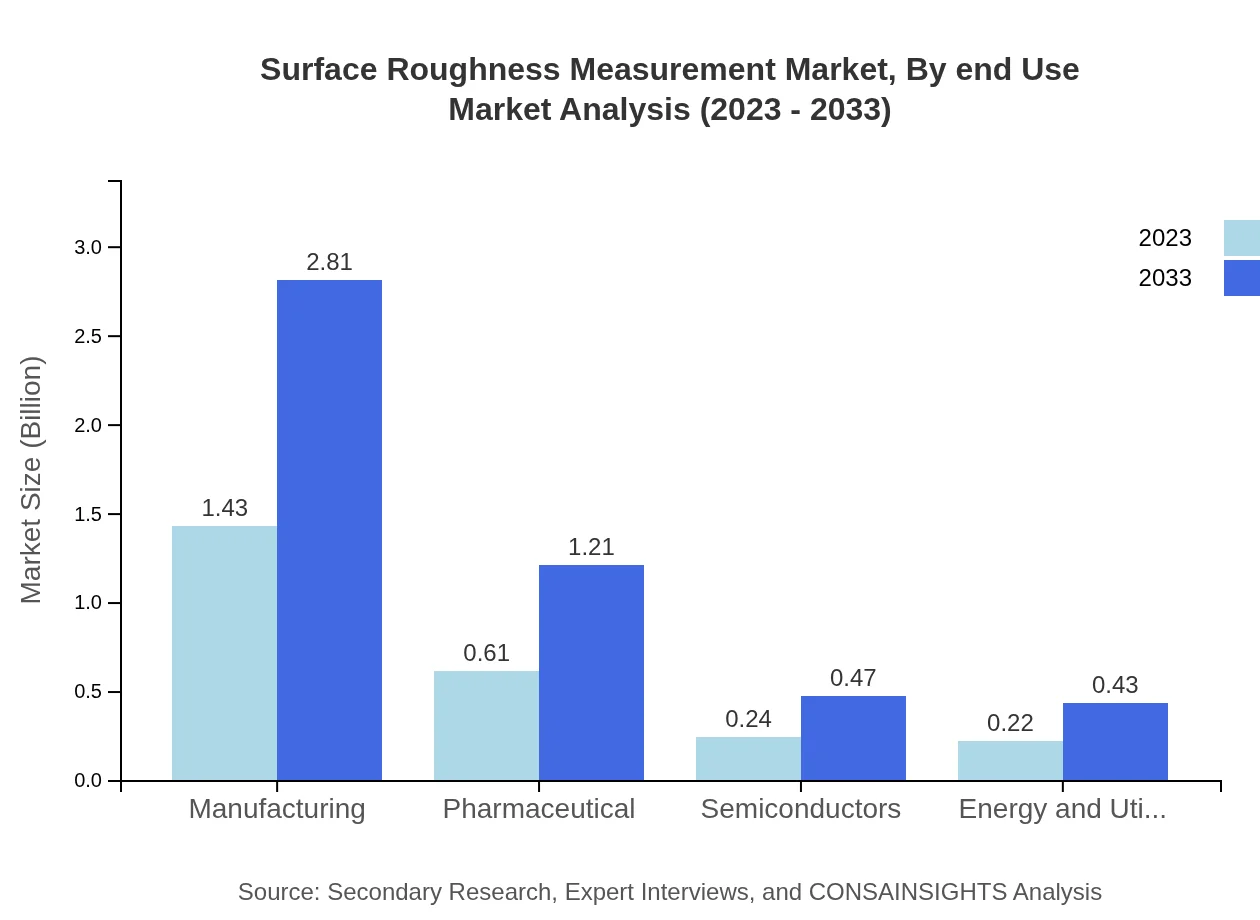

Surface Roughness Measurement Market Analysis By End Use

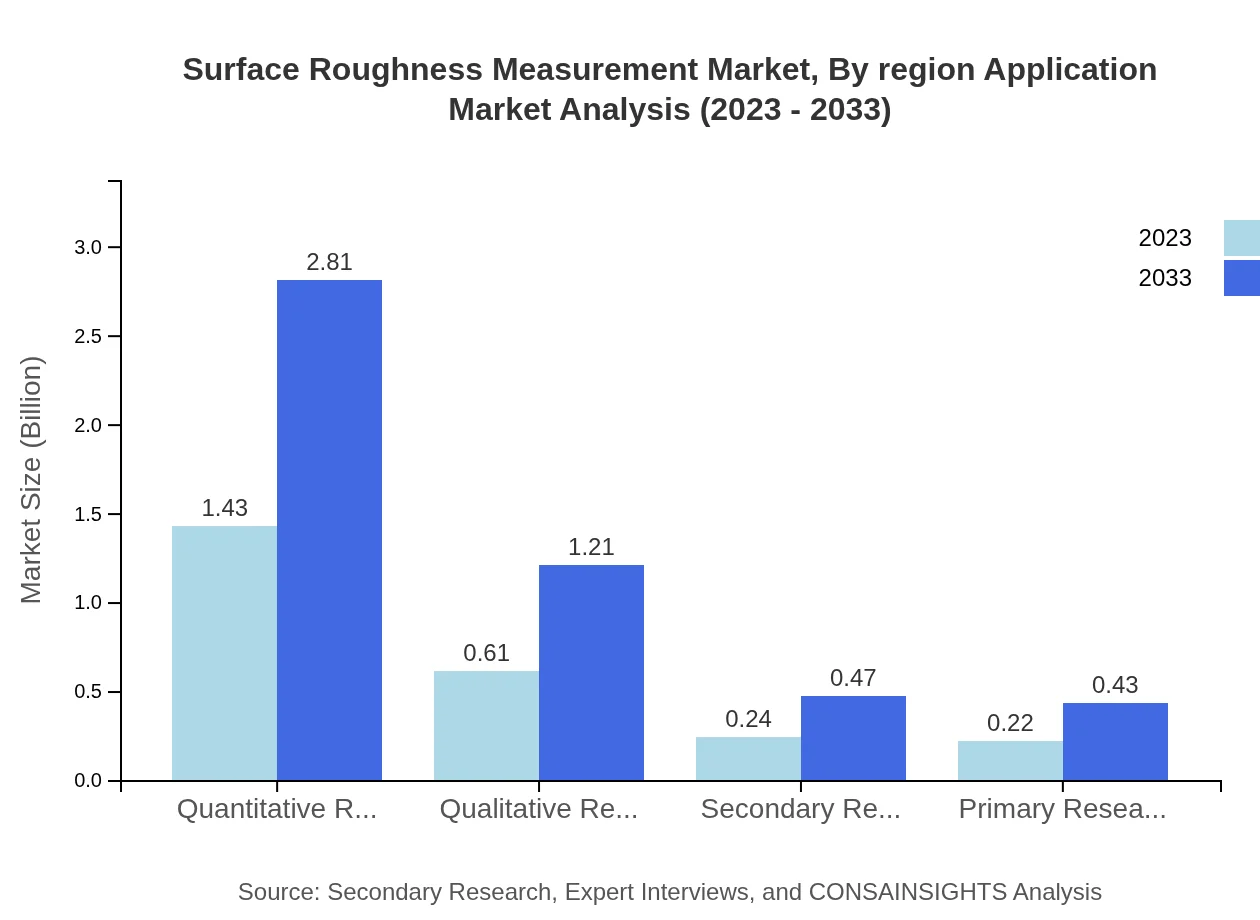

The end-use segment highlights diverse industries, with manufacturing leading and projected to grow from $1.43 billion in 2023 to $2.81 billion by 2033. The pharmaceutical and aerospace sectors also show robust growth trends, indicating heightened emphasis on precision in those industries.

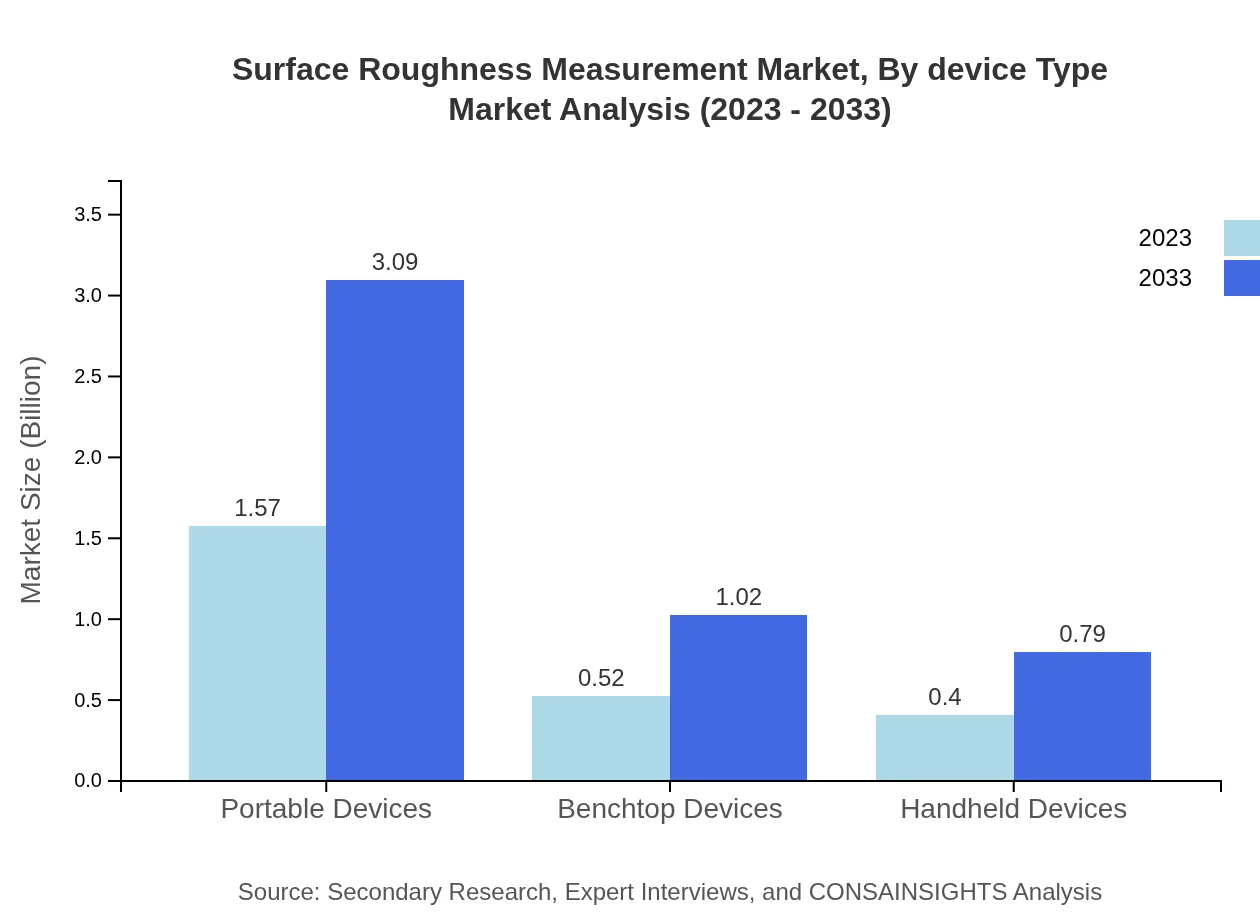

Surface Roughness Measurement Market Analysis By Device Type

Device types are categorized into portable, benchtop, and handheld devices. Portable devices lead the market with a share of 62.97% in 2023, growing from $1.57 billion to $3.09 billion by 2033, reflecting the need for flexibility in measurements. Benchtop and handheld devices show steady growth as well, catering to specific user preferences.

Surface Roughness Measurement Market Analysis By Region Application

Research methodologies encompass quantitative and qualitative research approaches. Quantitative research remains dominant in the Surface Roughness Measurement market, sized at $1.43 billion in 2023 and expected to reach $2.81 billion by 2033. Qualitative research also holds significant relevance, particularly in understanding user requirements and application trends.

Surface Roughness Measurement Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Surface Roughness Measurement Industry

AMETEK, Inc.:

Ametek provides advanced measurement systems that serve industrial and electronic applications. Their products are known for precision and reliability, making them leaders in the surface roughness measurement market.Mitutoyo Corporation:

Mitutoyo is a renowned manufacturer of precision measuring instruments, offering a diverse range of surface roughness measurement tools known for their technological innovation.Hexagon AB:

Hexagon specializes in precision measuring technologies, delivering solutions that enhance manufacturing productivity through accurate surface measurement.Zeiss Group:

Zeiss produces high-quality optical systems and measurement technologies, focusing on innovation in the surface characterization market.We're grateful to work with incredible clients.

FAQs

What is the market size of surface Roughness Measurement?

The surface roughness measurement market is currently valued at approximately $2.5 billion, with a projected compound annual growth rate (CAGR) of 6.8% between 2023 and 2033.

What are the key market players or companies in the surface Roughness Measurement industry?

Key players in the surface roughness measurement industry include leading manufacturers and suppliers specializing in advanced metrology equipment, surface analysis technologies, and precision measurement solutions, fostering competition and innovation.

What are the primary factors driving the growth in the surface Roughness Measurement industry?

Factors driving growth in the surface roughness measurement sector include technological advancements, increasing applications across industries such as automotive and aerospace, and growing demand for high-precision measurement for quality control.

Which region is the fastest Growing in the surface Roughness Measurement?

The North American region, with a significant market size of $0.81 billion in 2023 expected to grow to $1.59 billion by 2033, is the fastest-growing region for surface roughness measurement technologies.

Does ConsaInsights provide customized market report data for the surface Roughness Measurement industry?

Yes, ConsaInsights offers customized market reports tailored to the unique needs of clients, providing in-depth analysis and insights specific to the surface roughness measurement industry.

What deliverables can I expect from this surface Roughness Measurement market research project?

Deliverables include detailed market analysis, segmentation data, growth forecasts, competitive landscape assessments, and region-specific insights, ensuring comprehensive coverage of the surface roughness measurement market.

What are the market trends of surface roughness measurement?

Current market trends indicate a shift towards automation, increased adoption of portable measurement devices, advancements in non-contact measurement technology, and growing regulatory standards for quality assurance.