Tank Insulation Market Report

Published Date: 22 January 2026 | Report Code: tank-insulation

Tank Insulation Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Tank Insulation market, focusing on its current dynamics, growth prospects, and forecasts from 2023 to 2033. It encompasses market size, segmentation, regional insights, and the impact of trends and technologies in the industry.

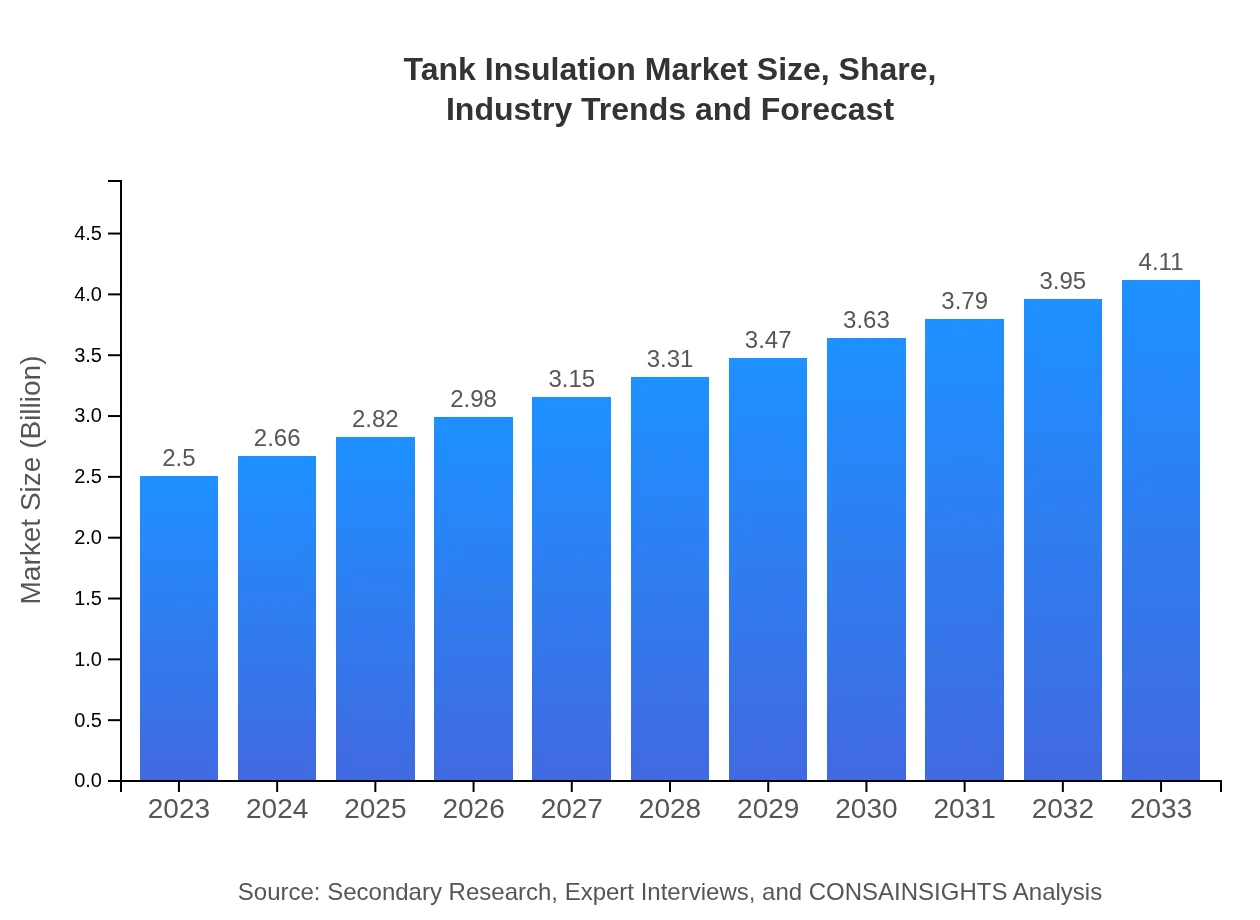

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $4.11 Billion |

| Top Companies | Rockwool International A/S, BASF SE, Kingspan Group, Owens Corning |

| Last Modified Date | 22 January 2026 |

Tank Insulation Market Overview

Customize Tank Insulation Market Report market research report

- ✔ Get in-depth analysis of Tank Insulation market size, growth, and forecasts.

- ✔ Understand Tank Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Tank Insulation

What is the Market Size & CAGR of Tank Insulation market in 2023?

Tank Insulation Industry Analysis

Tank Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Tank Insulation Market Analysis Report by Region

Europe Tank Insulation Market Report:

Europe’s tank insulation market is projected to grow from $0.61 billion in 2023 to $1.01 billion by 2033. Environmental regulations and increasing energy efficiency standards in the EU are pushing industries to adopt advanced insulation solutions. The focus on renewable energy sources and their storage further accentuates the market demand.Asia Pacific Tank Insulation Market Report:

The Asia Pacific region showcases strong growth potential for the tank insulation market, driven by rapid industrialization and expanding infrastructure projects. In 2023, the market size is estimated at $0.51 billion, expected to grow to $0.83 billion by 2033, emphasizing a CAGR of approximately 5.0%. Countries like China and India are leading this growth with substantial investments in oil, gas, and chemical sectors.North America Tank Insulation Market Report:

North America remains a crucial market for tank insulation, valued at $0.81 billion in 2023 and forecasted to reach $1.33 billion by 2033. The extensive presence of leading oil and gas companies and a rising focus on retrofitting insulation solutions in aging facilities are driving demand. The region is also at the forefront of innovations in insulation technologies.South America Tank Insulation Market Report:

The South American tank insulation market, valued at $0.25 billion in 2023, is projected to reach $0.40 billion by 2033. The growth of oil and gas exploration activities and increasing industrialization are key factors. Additionally, regulatory initiatives towards environmental sustainability will contribute to this market's expansion.Middle East & Africa Tank Insulation Market Report:

The Middle East and Africa market is expected to see growth from $0.32 billion in 2023 to $0.53 billion by 2033 due to economic diversification efforts in the region, particularly in oil-producing countries. Investment in renewable energy is also expected to play a significant role in market growth.Tell us your focus area and get a customized research report.

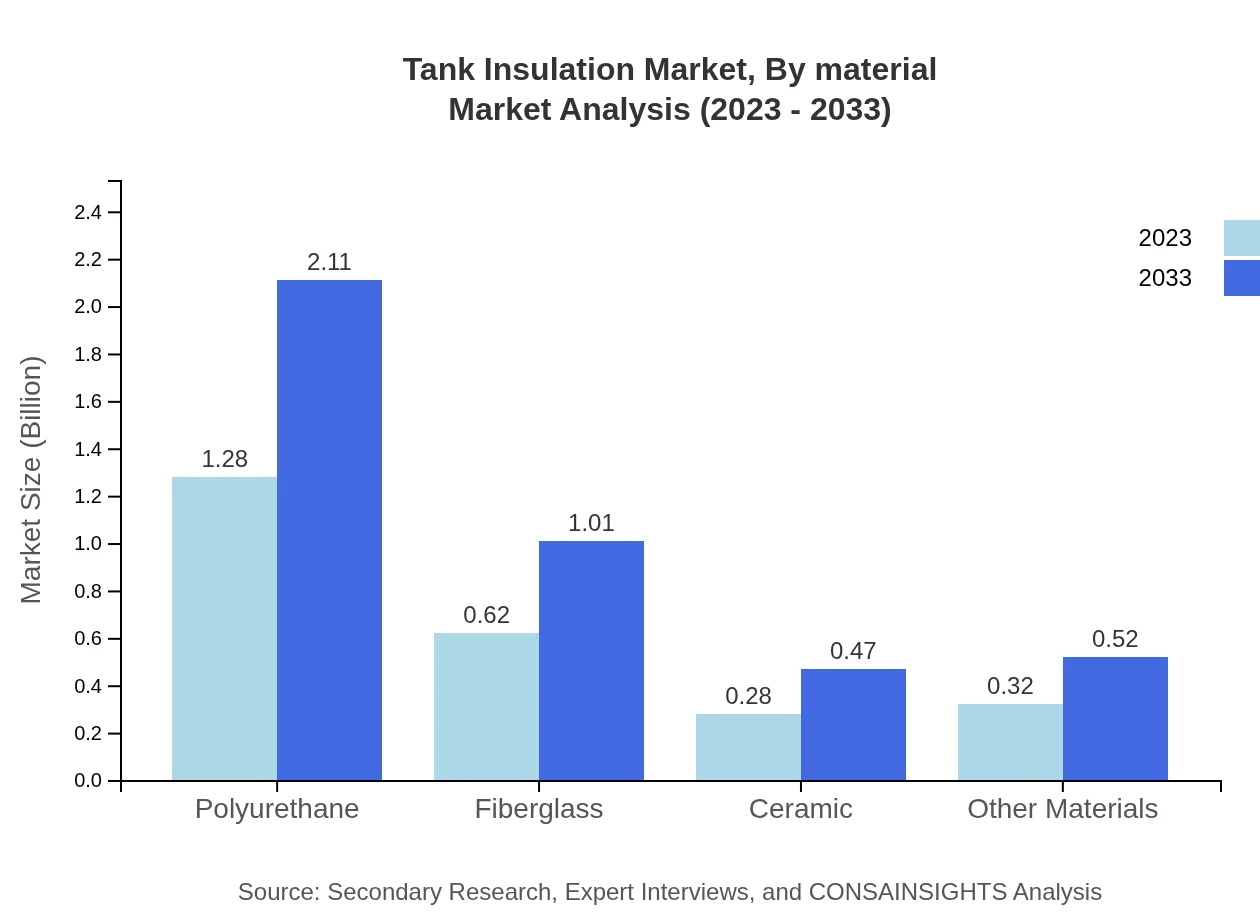

Tank Insulation Market Analysis By Material

The Tank Insulation market segmentation by material reveals varying performances: Polyurethane holds a significant share at $1.28 billion in 2023, expected to reach $2.11 billion by 2033. Fiberglass is also notable, growing from $0.62 billion to $1.01 billion. Ceramic and other materials will equally serve niche applications, keeping the market diversified.

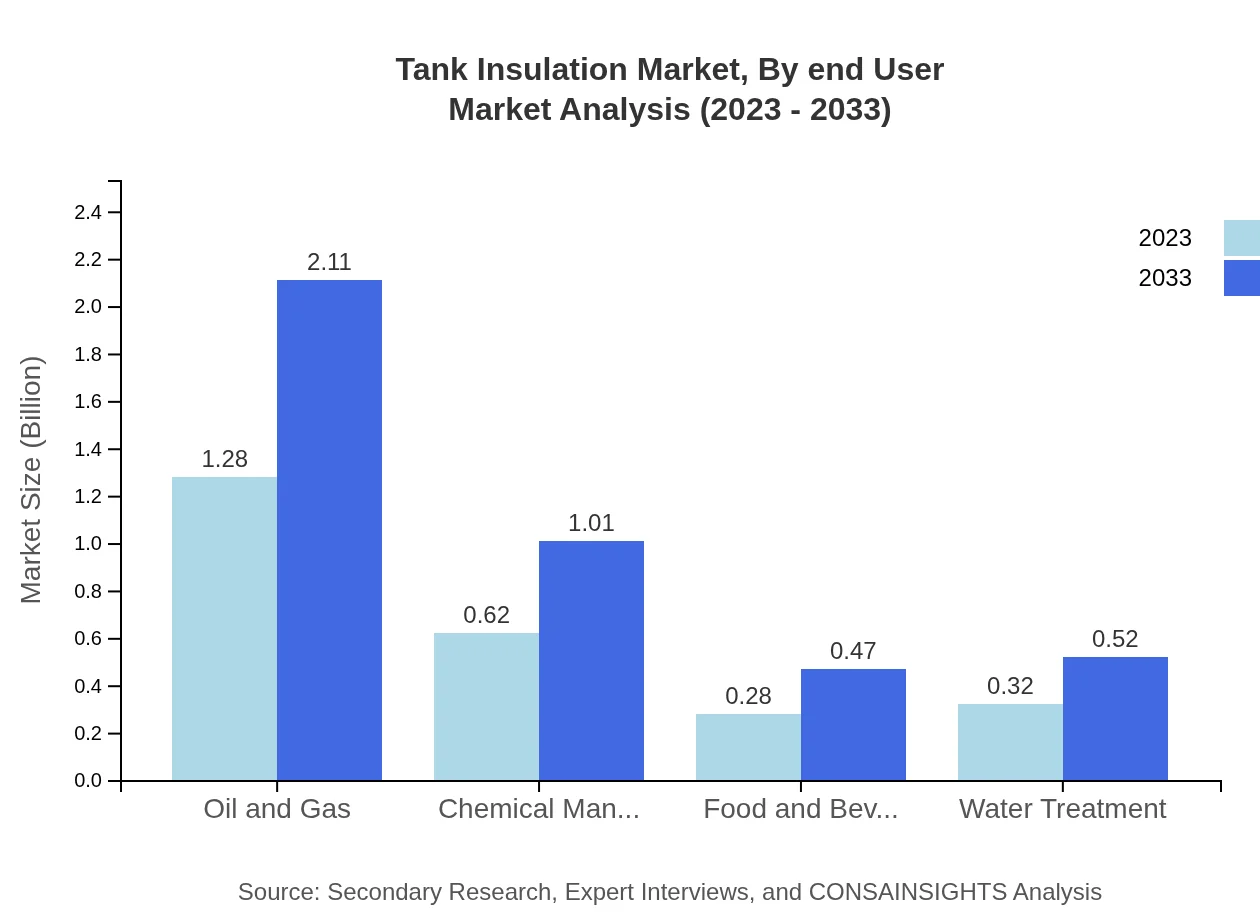

Tank Insulation Market Analysis By Application

In terms of applications, the market for oil and gas insulation is leading, valued at $1.28 billion in 2023, and is projected to reach $2.11 billion by 2033. This segment illustrates the criticality of insulation in high-energy sectors, with chemical manufacturing, food, and beverage segments following closely in growth potential.

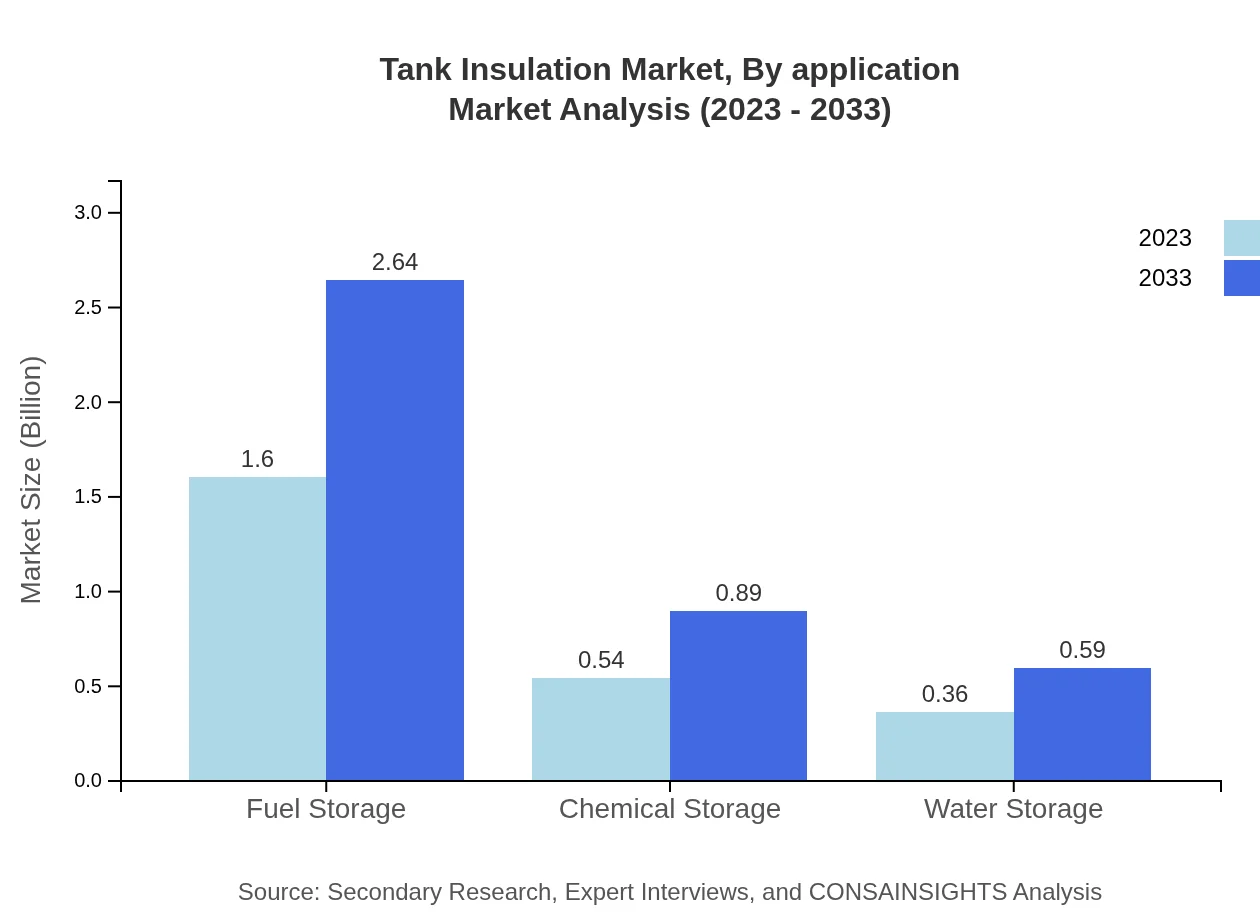

Tank Insulation Market Analysis By End User

The end-user analysis reflects the importance of tank insulation across various industries. Notably, fuel storage dominates with a market share of 64.12% ($1.60 billion in 2023) growing to $2.64 billion by 2033. Other sectors include water storage and chemical storage, each making significant contributions to total market dynamics based on their specific needs.

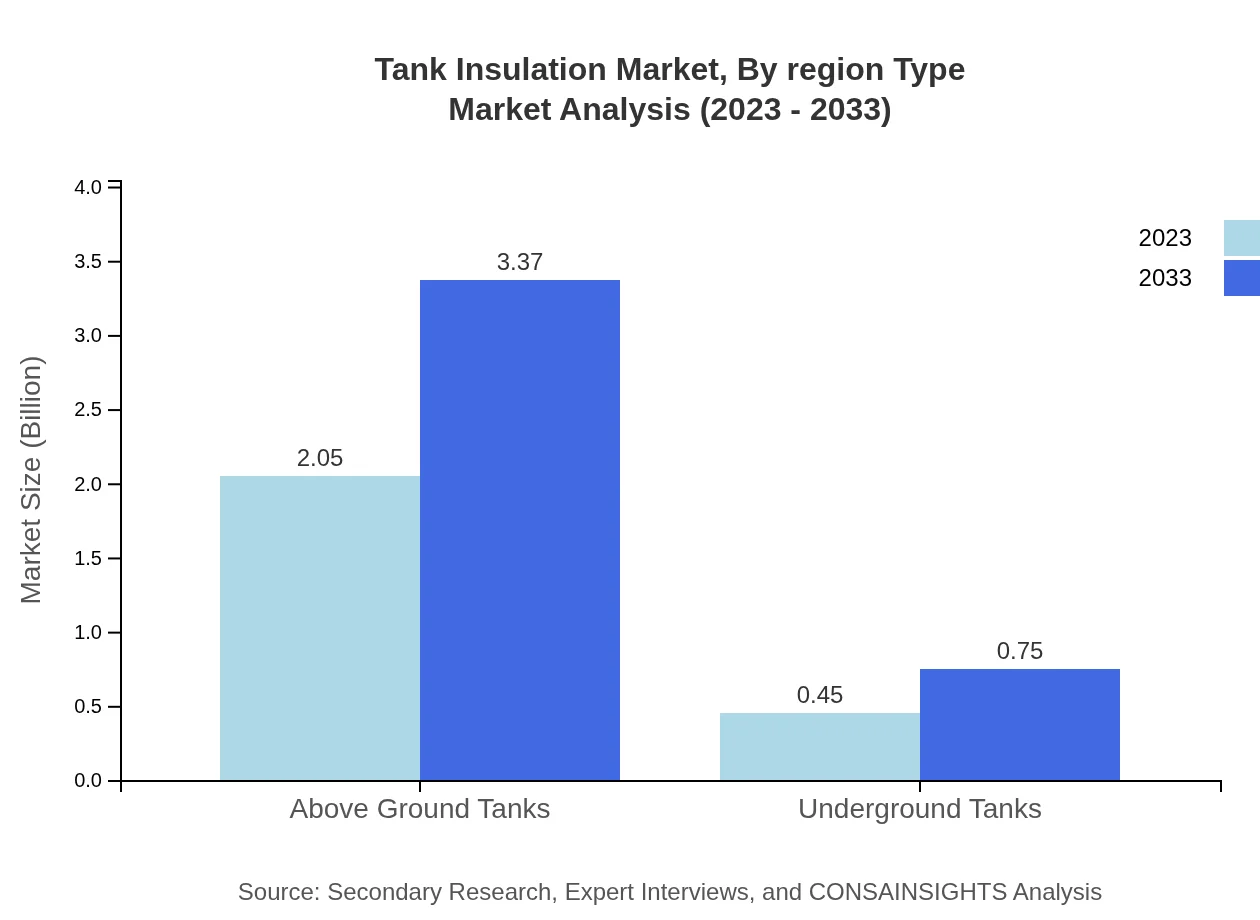

Tank Insulation Market Analysis By Region Type

Regional analysis emphasizes how different geographical areas are adapting to tank insulation needs. North America and Europe lead in technological advancements, whereas Asia Pacific shows rapid market growth due to infrastructural developments. The Middle East and Africa are gradually increasing investment in insulation as part of broader industrial growth strategies.

Tank Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Tank Insulation Industry

Rockwool International A/S:

A leader in insulation solutions, Rockwool specializes in stone wool insulation and has a wide portfolio catering to various industrial segments, ensuring thermal efficiency and sustainability.BASF SE:

BASF is a global chemical producer and a leading supplier of polyurethane insulation products, known for developing innovative solutions that enhance energy efficiency in industrial applications.Kingspan Group:

Kingspan champions a comprehensive range of insulation solutions across the construction and industrial sectors, focusing heavily on energy performance in line with global standards.Owens Corning:

Owens Corning specializes in insulation and roofing materials and is recognized for their fiberglass insulation solutions, promoting energy efficiency in diverse applications.We're grateful to work with incredible clients.

FAQs

What is the market size of tank insulation?

The tank insulation market is currently valued at approximately $2.5 billion, with a projected CAGR of 5%, reflecting robust demand and growth potential over the next decade.

What are the key market players or companies in this tank insulation industry?

Key market players in the tank insulation industry include companies such as Rockwool International, Owens Corning, and Kingspan Group, all of whom lead in innovation and product development.

What are the primary factors driving the growth in the tank insulation industry?

The growth in the tank insulation industry is primarily driven by increasing energy efficiency regulations, heightened demand from the oil and gas sector, and advancements in insulation materials enhancing performance.

Which region is the fastest Growing in the tank insulation?

The fastest-growing region in the tank insulation market is North America, projected to grow from $0.81 billion in 2023 to $1.33 billion by 2033, reflecting a significant annual growth.

Does ConsaInsights provide customized market report data for the tank insulation industry?

Yes, ConsaInsights offers customized market report data for the tank insulation industry to meet specific research needs and business strategies.

What deliverables can I expect from this tank insulation market research project?

Expect comprehensive deliverables, including detailed market analysis, forecasts, competitor insights, segmentation data, and actionable recommendations tailored to your strategic needs.

What are the market trends of tank insulation?

Current market trends in tank insulation include a shift towards sustainable materials, increasing adoption of advanced insulation technologies, and a growing emphasis on regulatory compliance in energy-efficient installations.