Tension Control Market Report

Published Date: 22 January 2026 | Report Code: tension-control

Tension Control Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Tension Control market, offering insights into market size, segmentation, regional analysis, and trends from 2023 to 2033.

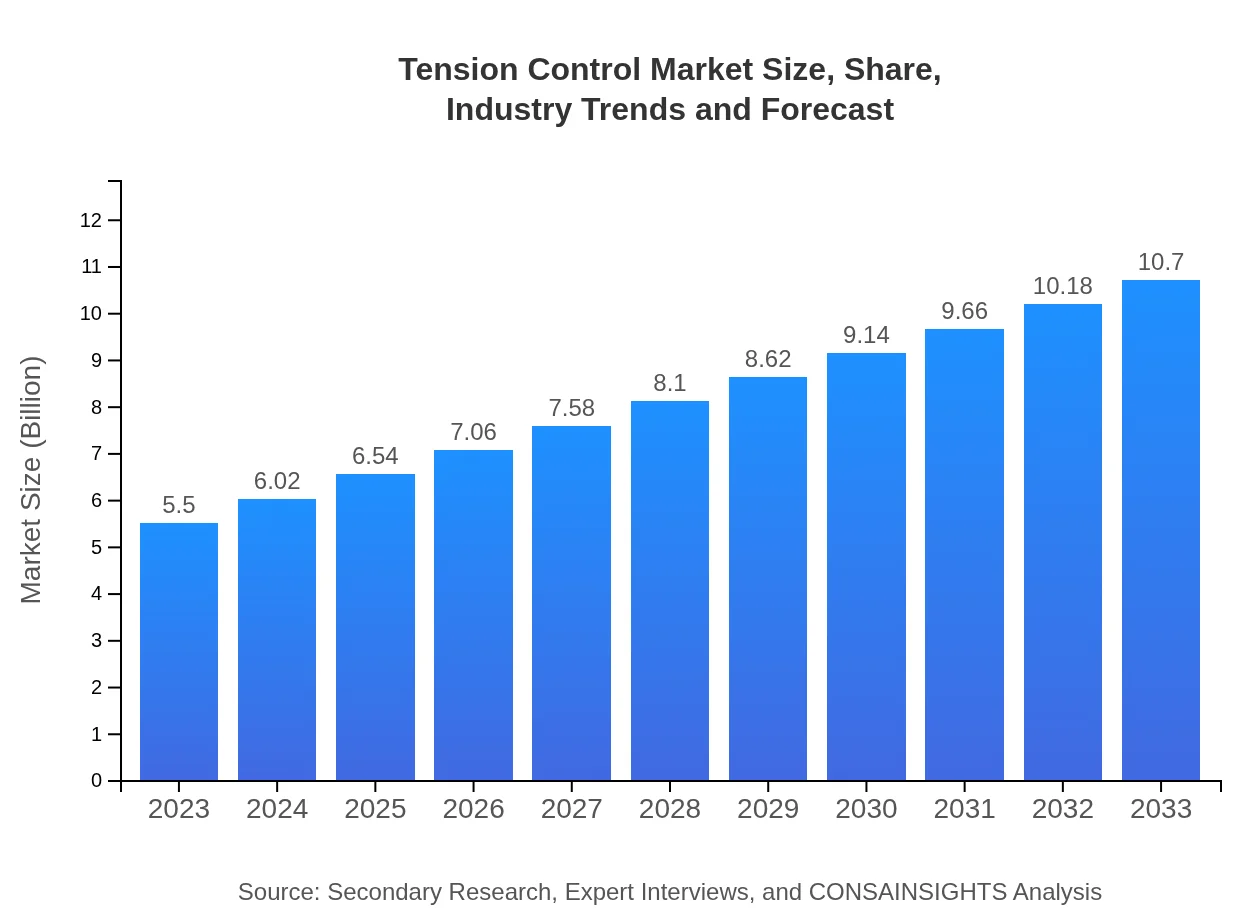

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.50 Billion |

| CAGR (2023-2033) | 6.7% |

| 2033 Market Size | $10.70 Billion |

| Top Companies | Applied Materials, Rockwell Automation, Siemens AG, ABB Ltd. |

| Last Modified Date | 22 January 2026 |

Tension Control Market Overview

Customize Tension Control Market Report market research report

- ✔ Get in-depth analysis of Tension Control market size, growth, and forecasts.

- ✔ Understand Tension Control's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Tension Control

What is the Market Size & CAGR of Tension Control market in 2023?

Tension Control Industry Analysis

Tension Control Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Tension Control Market Analysis Report by Region

Europe Tension Control Market Report:

Europe's Tension Control market will see growth from about $1.38 billion in 2023 to approximately $2.68 billion by 2033, supported by stringent regulations promoting automation and operational efficiency.Asia Pacific Tension Control Market Report:

In 2023, the Asia Pacific region is valued at approximately $1.18 billion, projected to grow to $2.30 billion by 2033, reflecting a growing manufacturing base and increasing investment in automation technologies.North America Tension Control Market Report:

The North America Tension Control market, valued at about $1.84 billion in 2023, is expected to more than double to approximately $3.57 billion by 2033, indicating strong demand in automotive and manufacturing sectors.South America Tension Control Market Report:

South America shows market growth from approximately $0.48 billion in 2023 to around $0.94 billion by 2033, driven largely by expansion in the packaging and textile industries.Middle East & Africa Tension Control Market Report:

The Middle East and Africa market, estimated at $0.62 billion in 2023, is anticipated to reach $1.21 billion by 2033, with growing adoption of advanced manufacturing practices across various sectors.Tell us your focus area and get a customized research report.

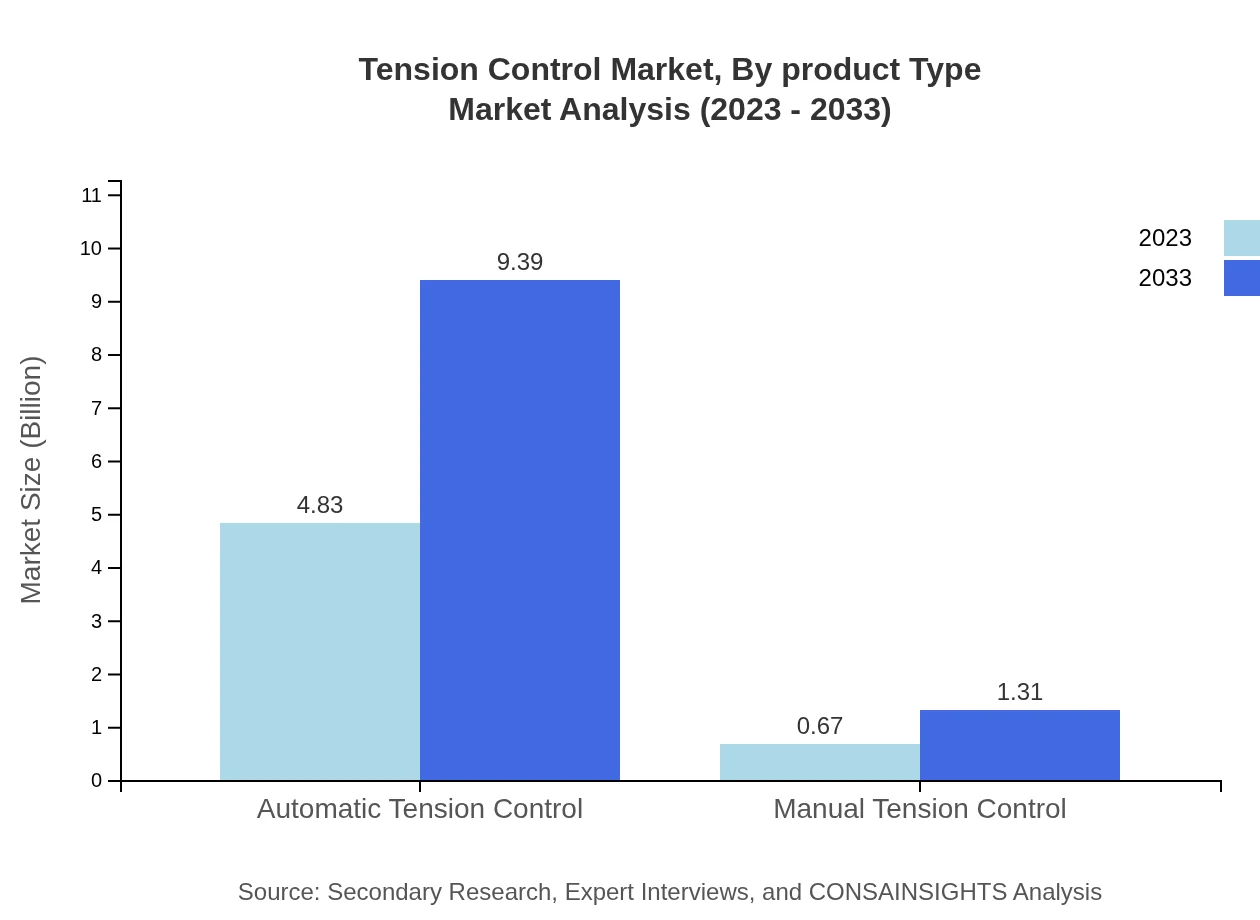

Tension Control Market Analysis By Product Type

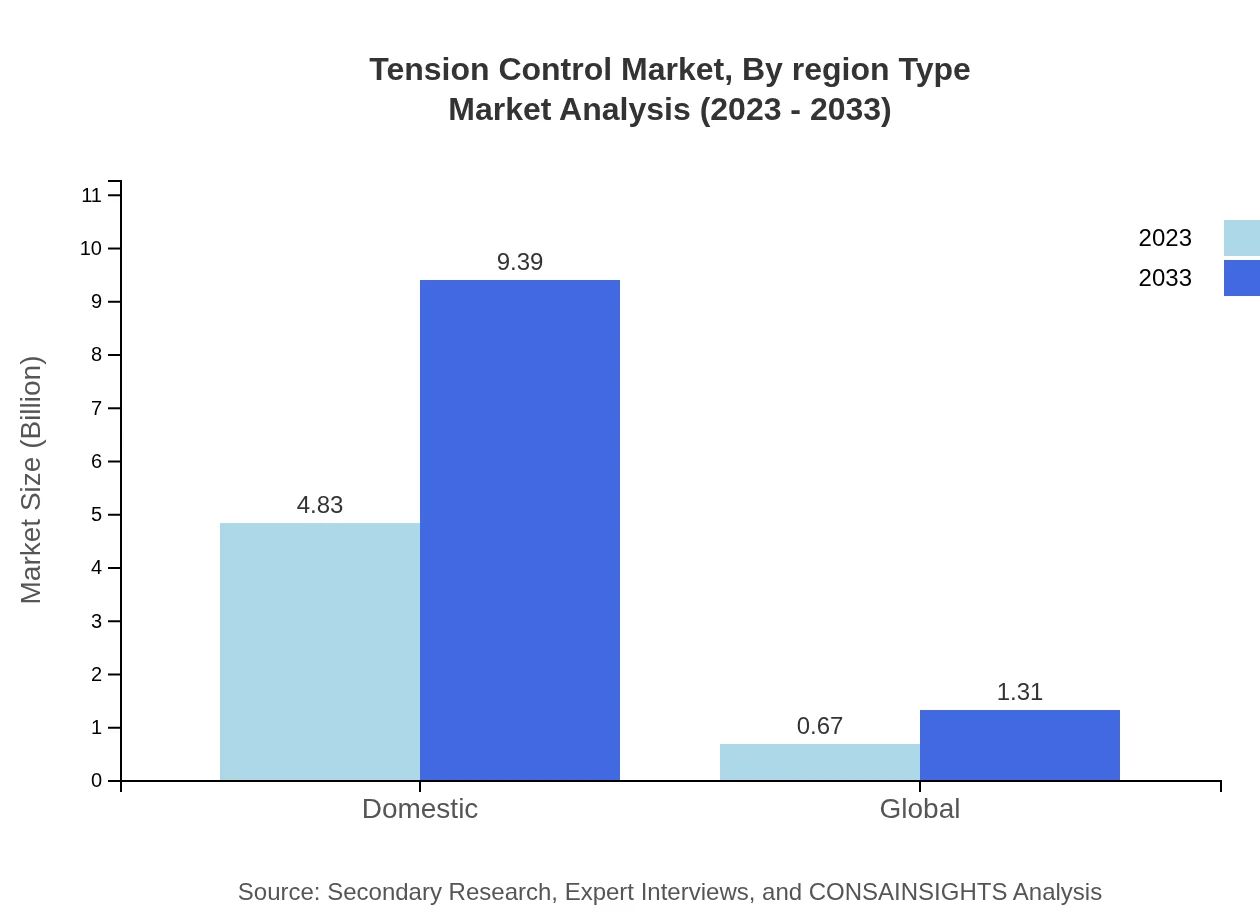

The Tension Control market shows significant performance across various product types. Automatic tension control is projected to grow from $4.83 billion in 2023 to $9.39 billion by 2033, dominating the market share due to increased automation. In contrast, manual tension control, while still relevant, is expected to see slower growth, moving from $0.67 billion in 2023 to $1.31 billion by 2033.

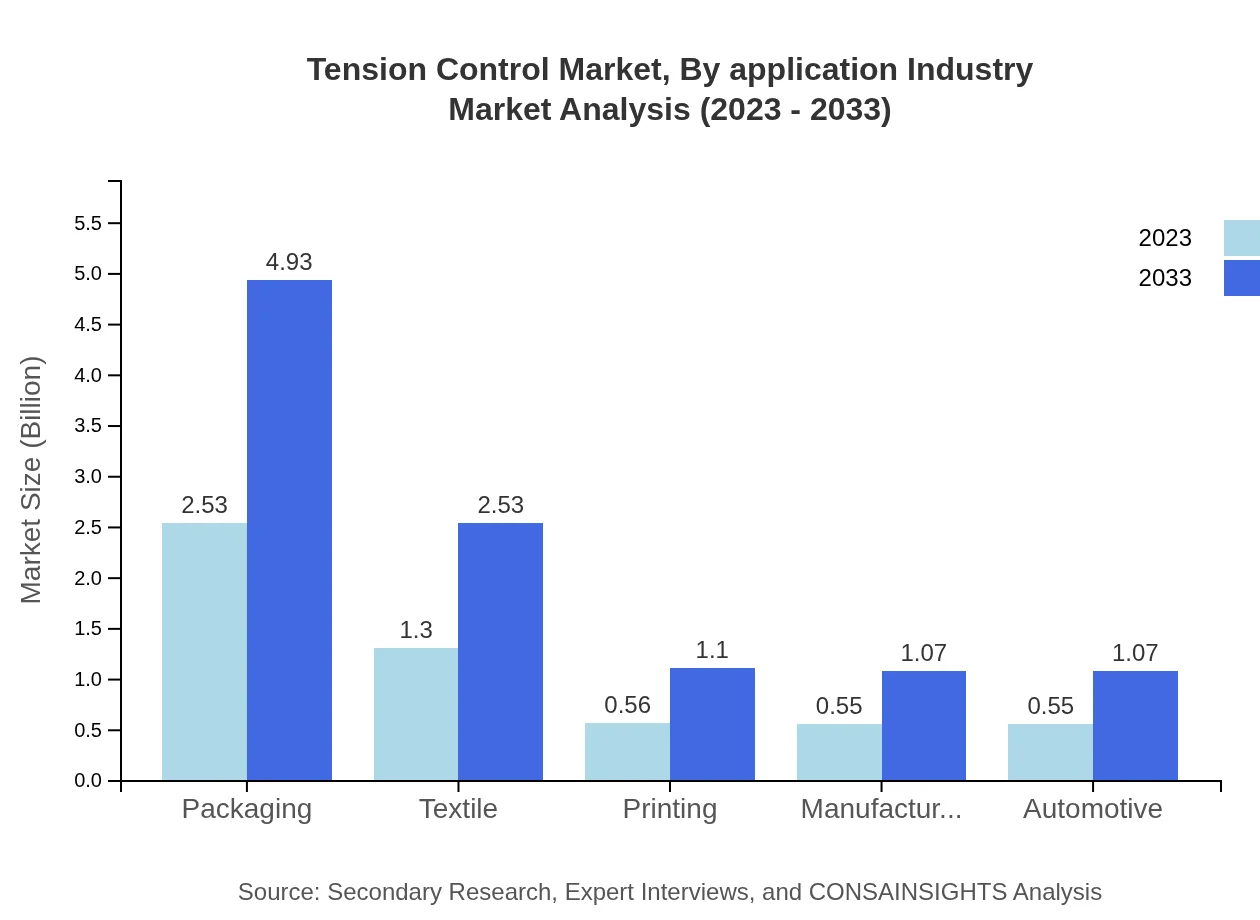

Tension Control Market Analysis By Application Industry

Packaging is projected to maintain a leading market share within the Tension Control segment, growing from $2.53 billion in 2023 to $4.93 billion by 2033. Other important industries include textiles, with growth from $1.30 billion to $2.53 billion, and automotive and manufacturing holding steady shares of about $0.55 billion each by 2033.

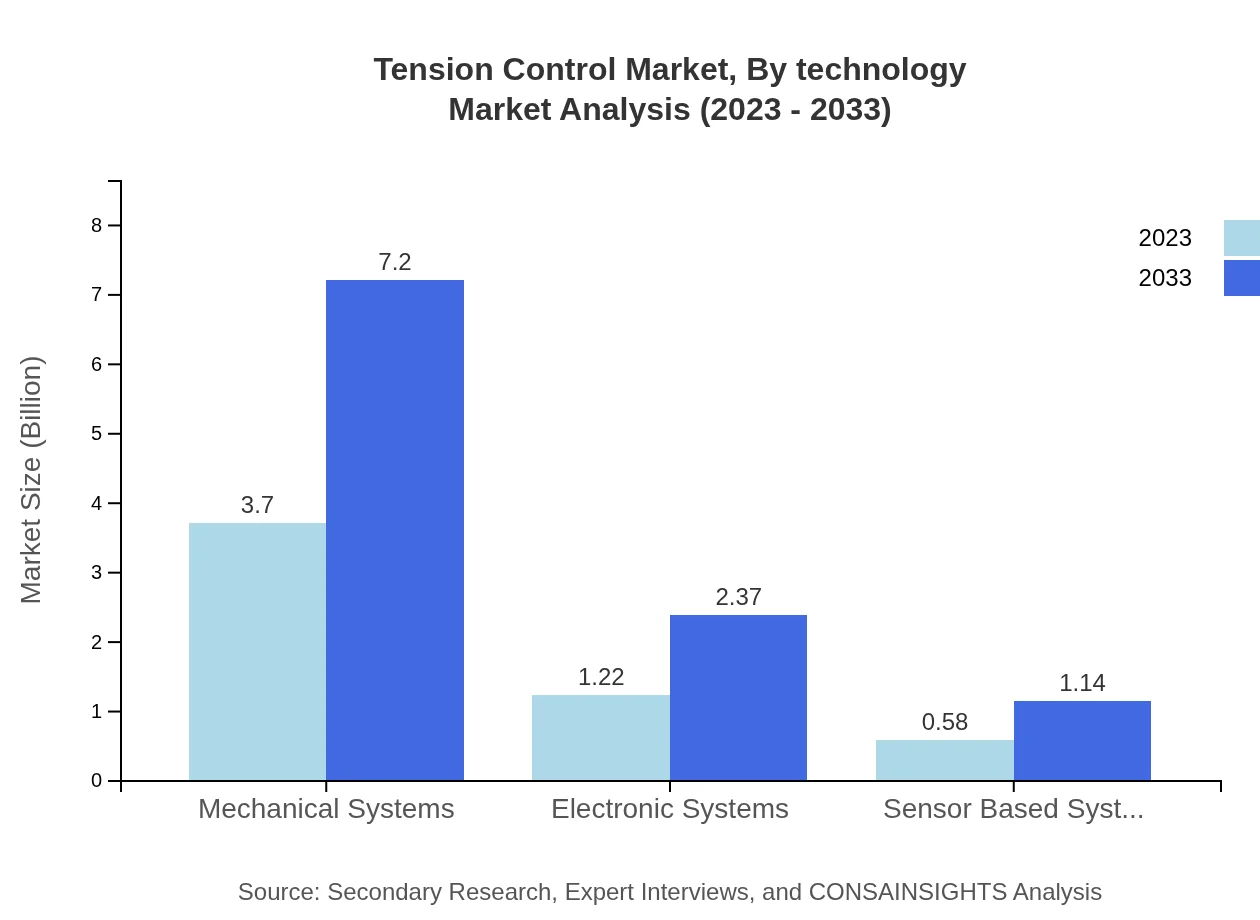

Tension Control Market Analysis By Technology

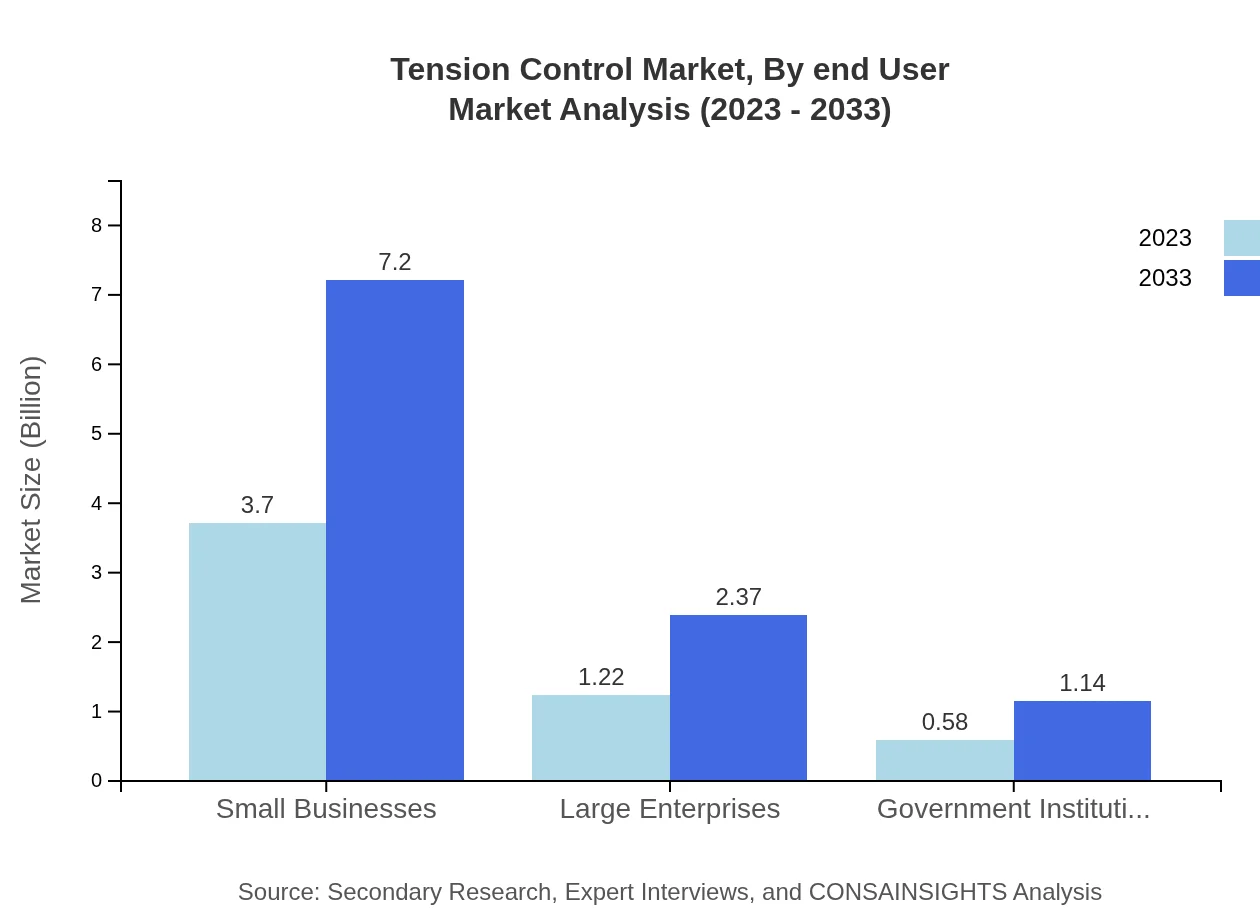

The Tension Control technology landscape reveals a strong inclination towards electronic systems, projected to grow from $1.22 billion to $2.37 billion, while sensor-based systems will observe a similar growth trajectory from $0.58 billion to $1.14 billion by 2033.

Tension Control Market Analysis By End User

Segmenting by end-user reveals that small businesses will significantly dominate the market, expected to grow from $3.70 billion in 2023 to $7.20 billion by 2033, thereby reflecting an increasing reliance on effective tension control solutions to enhance production quality and reduce waste.

Tension Control Market Analysis By Region Type

Each region exhibits unique characteristics, influencing the Tension Control market. North America leads in advanced technology adoption, Europe focuses on compliance with efficiency standards, and the Asia Pacific region is ramping up manufacturing efforts featuring increased tension control solution demands.

Tension Control Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Tension Control Industry

Applied Materials:

A leading global provider of materials engineering solutions for the semiconductor, flat panel display, and solar photovoltaic industries.Rockwell Automation:

An enterprise enabling companies to create a more productive and connected world through innovative automation solutions.Siemens AG:

Siemens is a worldwide leader in automation and digitalization in the manufacturing and processing industries.ABB Ltd.:

A pioneering technology leader in industrial automation and power grids that drive efficiency in manufacturing.We're grateful to work with incredible clients.

FAQs

What is the market size of tension Control?

The market size of the tension-control industry is estimated at $5.5 billion in 2023, with a projected CAGR of 6.7% from 2023 to 2033. This growth signals increasing demand for tension control solutions across various sectors.

What are the key market players or companies in this tension Control industry?

Key players in the tension-control market include major technology firms and specialized equipment manufacturers, providing innovative solutions tailored to industries such as automotive, manufacturing, textile, and packaging.

What are the primary factors driving the growth in the tension Control industry?

Growth in the tension-control industry is driven by advancements in automation technology, increased demand from manufacturing sectors, and the growing need for efficient production processes to minimize waste and enhance productivity.

Which region is the fastest Growing in the tension Control market?

The fastest-growing region in the tension-control market is North America, projected to grow from $1.84 billion in 2023 to $3.57 billion in 2033, driven by significant industrial activity and technology adoption.

Does ConsaInsights provide customized market report data for the tension Control industry?

Yes, ConsaInsights offers customized market report data, allowing clients to obtain specific insights tailored to their needs within the tension-control industry, including market trends and competitive analysis.

What deliverables can I expect from this tension Control market research project?

From this tension-control market research project, you can expect detailed reports, data analysis, market forecasts, regional insights, and segment-specific information, assisting in strategic decision-making.

What are the market trends of tension Control?

Trends in the tension-control market include the increasing use of automation, a shift towards smart technology integration, and a growing focus on sustainable practices within manufacturing processes.