Thermal Interface Materials Market Report

Published Date: 31 January 2026 | Report Code: thermal-interface-materials

Thermal Interface Materials Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Thermal Interface Materials market, including market size, trends, and forecasts for the period 2023-2033, as well as regional insights and competitive landscape assessments.

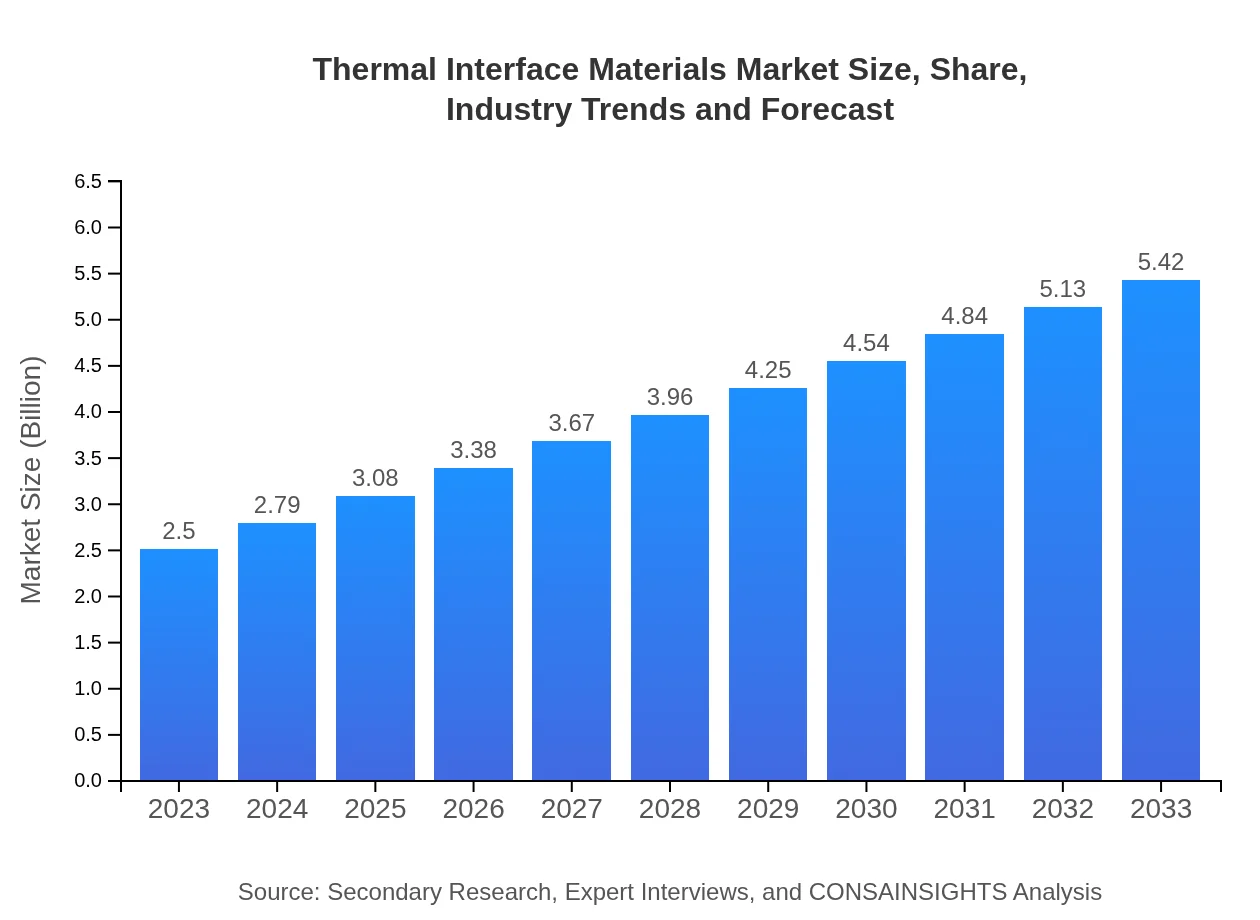

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $5.42 Billion |

| Top Companies | Henkel AG & Co. KGaA, Momentive Performance Materials Inc., 3M Company, Dow Inc. |

| Last Modified Date | 31 January 2026 |

Thermal Interface Materials Market Overview

Customize Thermal Interface Materials Market Report market research report

- ✔ Get in-depth analysis of Thermal Interface Materials market size, growth, and forecasts.

- ✔ Understand Thermal Interface Materials's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Thermal Interface Materials

What is the Market Size & CAGR of Thermal Interface Materials market in 2023?

Thermal Interface Materials Industry Analysis

Thermal Interface Materials Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Thermal Interface Materials Market Analysis Report by Region

Europe Thermal Interface Materials Market Report:

The European market is predicted to grow from USD 0.68 billion in 2023 to USD 1.48 billion by 2033, driven by stringent regulations on energy efficiency and sustainability, prompting manufacturers to adopt advanced thermal management solutions.Asia Pacific Thermal Interface Materials Market Report:

In the Asia Pacific region, the Thermal Interface Materials market is expected to grow from USD 0.51 billion in 2023 to USD 1.11 billion by 2033. This growth is driven primarily by the rapid expansion of electronics manufacturing in countries like China, Japan, and South Korea.North America Thermal Interface Materials Market Report:

North America is expected to exhibit significant growth, with the market size rising from USD 0.89 billion in 2023 to USD 1.93 billion by 2033. The region's strong focus on technological research and development, coupled with the presence of key market players, fuels this demand.South America Thermal Interface Materials Market Report:

The South American market for Thermal Interface Materials is projected to increase from USD 0.18 billion in 2023 to USD 0.39 billion by 2033. Government initiatives to promote technological advancement in the region will help accelerate market growth.Middle East & Africa Thermal Interface Materials Market Report:

In the Middle East and Africa, the market is set to rise from USD 0.23 billion in 2023 to USD 0.50 billion by 2033. Ongoing infrastructure developments and a surge in technology adoption in the region are paving the way for growth in the TIMs sector.Tell us your focus area and get a customized research report.

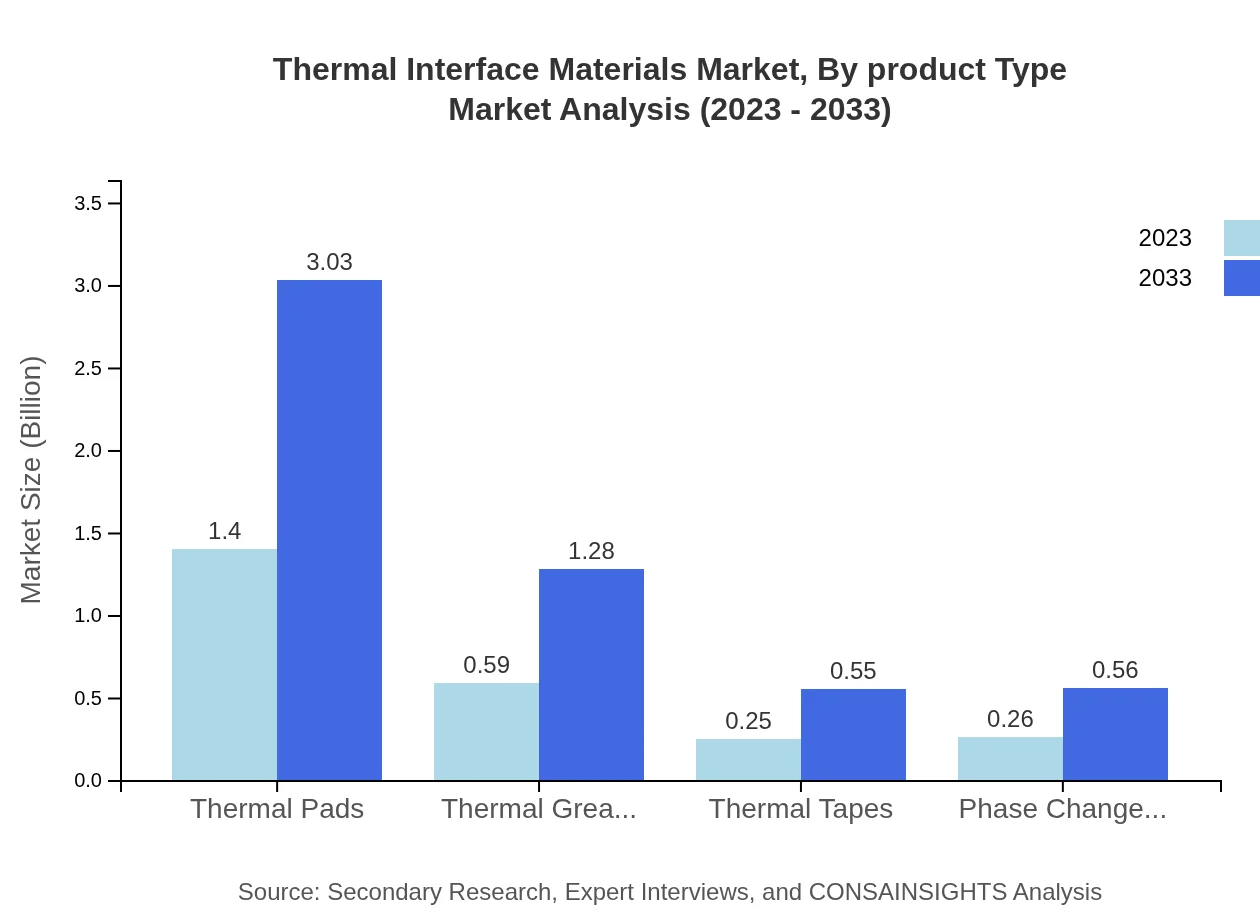

Thermal Interface Materials Market Analysis By Product Type

The product type segment of the Thermal Interface Materials market includes thermal pads, thermal greases, thermal tapes, and phase change materials. In 2023, thermal pads dominate the market with a size of USD 1.40 billion, expected to grow to USD 3.03 billion by 2033. Thermal greases are also significant, projected to rise from USD 0.59 billion to USD 1.28 billion in the same period. These products are critical for efficient thermal management in various applications.

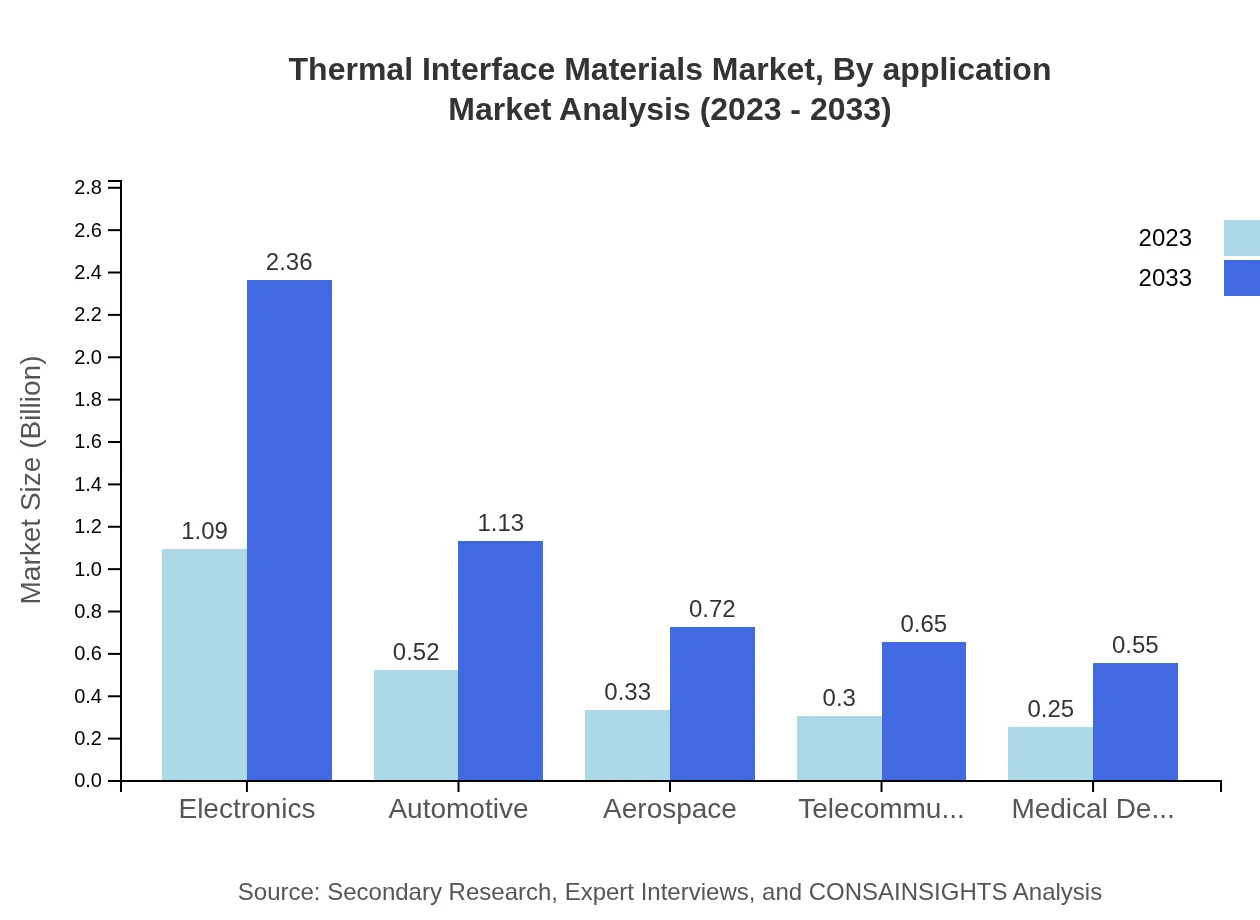

Thermal Interface Materials Market Analysis By Application

The key application segments include consumer electronics, industrial, automotive, aerospace, telecommunications, and medical devices. The consumer electronics segment leads with a market size of USD 1.40 billion in 2023, growing to USD 3.03 billion by 2033, accounting for a 55.99% market share. This is followed by the automotive sector, expected to grow from USD 0.52 billion to USD 1.13 billion, representing a growing need for thermal management in electric and hybrid vehicles.

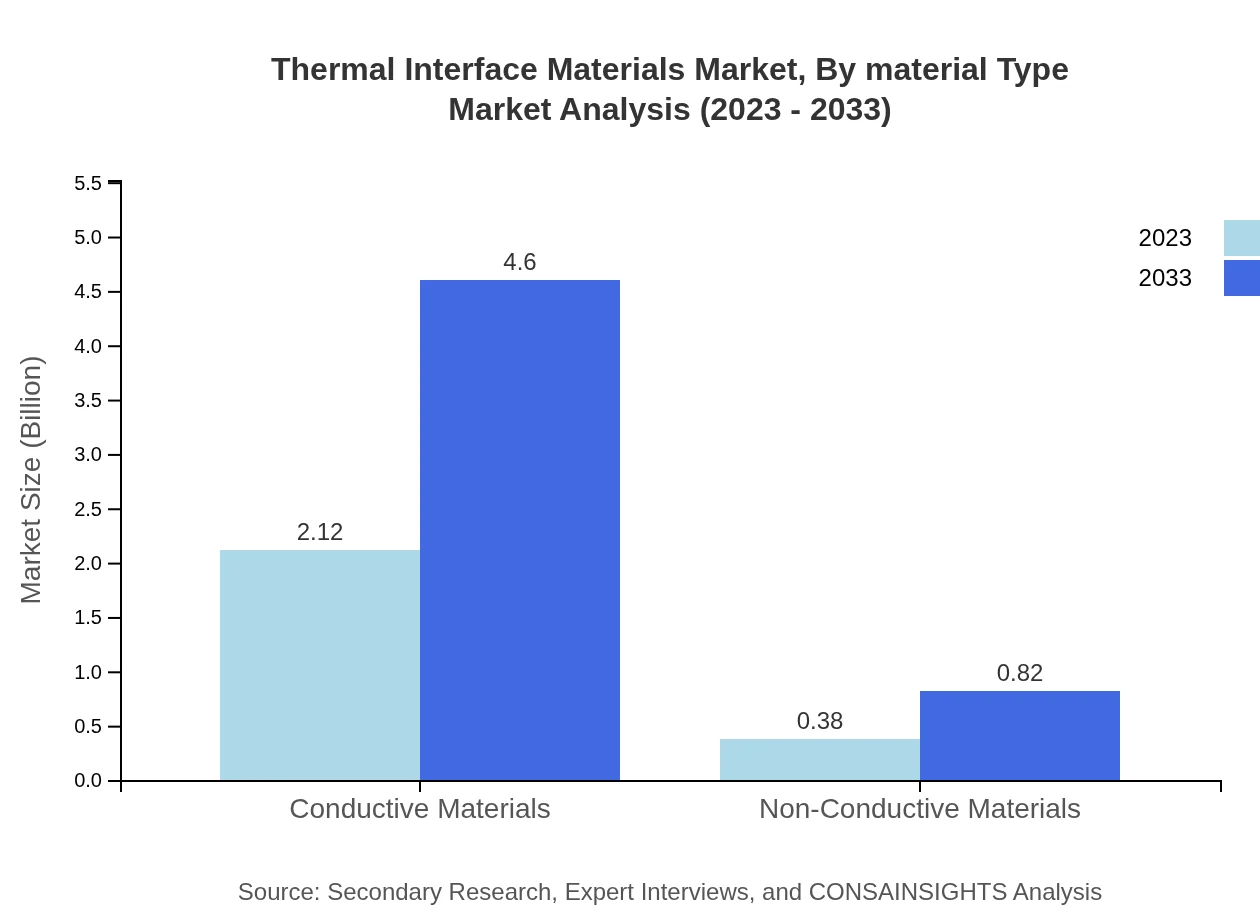

Thermal Interface Materials Market Analysis By Material Type

From a material type perspective, the market is divided into conductive and non-conductive materials, with conductive materials constituting the larger market share at 84.93%. The market size for conductive materials is set to grow from USD 2.12 billion in 2023 to USD 4.60 billion by 2033. Non-conductive materials are expected to expand as well, increasing from USD 0.38 billion to USD 0.82 billion.

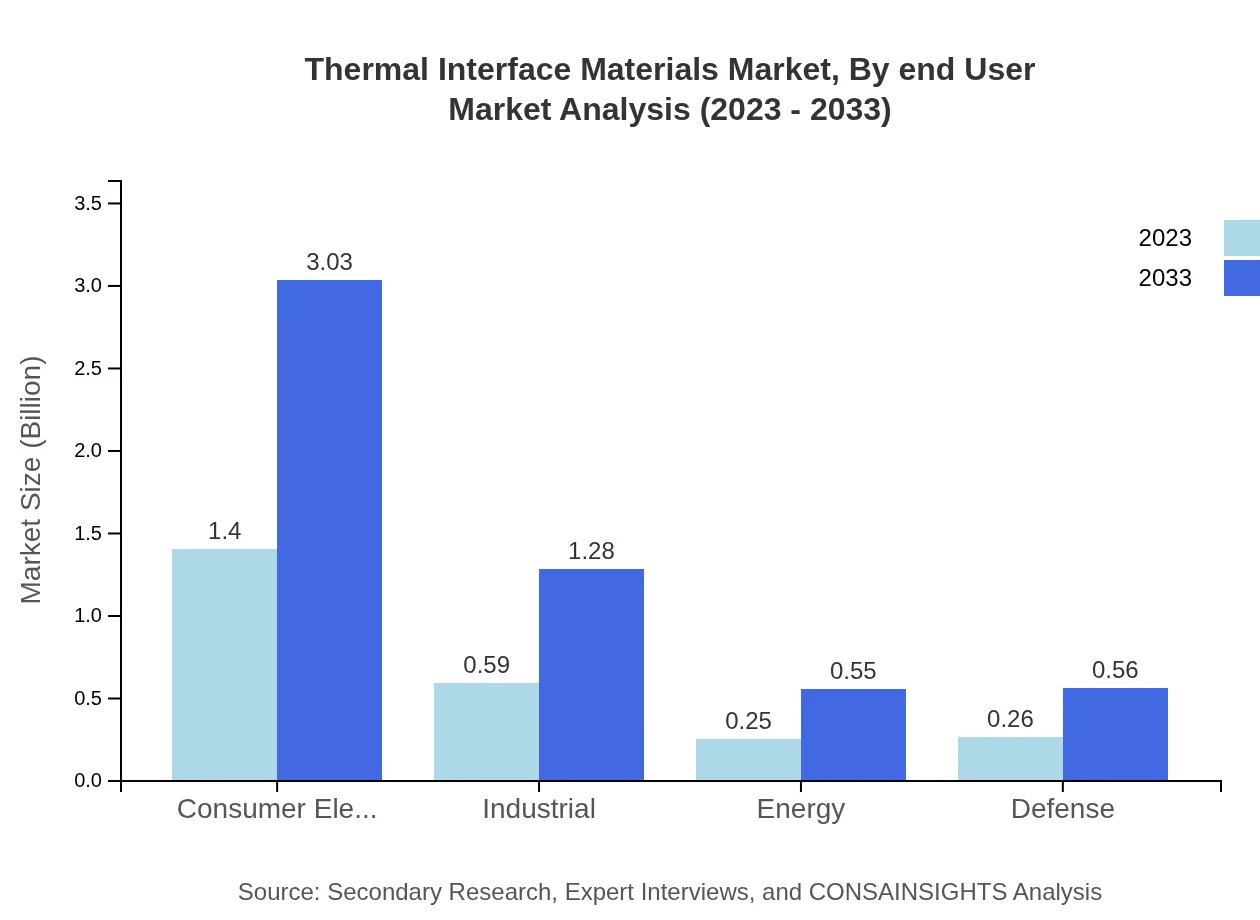

Thermal Interface Materials Market Analysis By End User

The end-user segment comprises consumer electronics, automotive, aerospace, telecommunications, and medical devices. Each sector is experiencing distinct levels of growth, driven by technological advancements and increasing thermal management needs. The aerospace sector, for example, is expected to grow from USD 0.33 billion to USD 0.72 billion, reflecting a rising demand for efficient thermal solutions in aviation technologies.

Thermal Interface Materials Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Thermal Interface Materials Industry

Henkel AG & Co. KGaA:

Henkel is a leading global provider of adhesives, sealants, and surface treatments including thermal interface materials that enhance electronics performance.Momentive Performance Materials Inc.:

Momentive is known for its innovative materials and solutions, providing high-quality thermal greases and pads that are critical for thermal management.3M Company:

3M is a diversified technology company with a wide array of thermal interface materials designed for electronics, automotive, and industrial applications.Dow Inc.:

Dow offers a range of thermal interface materials, focusing on performance and sustainability in high-demand applications.We're grateful to work with incredible clients.

FAQs

What is the market size of thermal Interface Materials?

As of 2023, the global thermal-interface-materials market is valued at approximately $2.5 billion, with a projected compound annual growth rate (CAGR) of 7.8% from 2023 to 2033, indicating strong future growth potential.

What are the key market players or companies in the thermal Interface Materials industry?

The thermal-interface-materials industry is characterized by several key players who dominate the market, including leaders in manufacturing and technology specializing in thermal management solutions. These companies consistently innovate to improve product performance and meet emerging customer needs.

What are the primary factors driving the growth in the thermal Interface Materials industry?

The growth of the thermal-interface-materials market is driven by increasing demand for efficient thermal management in electronics, the rising trend of miniaturization in consumer electronics, and advancements in automotive and industrial applications requiring effective heat dissipation solutions.

Which region is the fastest Growing in the thermal Interface Materials market?

The Asia-Pacific region stands out as the fastest-growing market for thermal-interface materials, projected to grow from $0.51 billion in 2023 to $1.11 billion in 2033, driven by increasing electronics manufacturing and automotive innovations.

Does ConsaInsights provide customized market report data for the thermal Interface Materials industry?

Yes, ConsaInsights offers tailored market report data specifically for the thermal-interface-materials sector. We understand that unique business requirements necessitate customized insights to guide strategic decisions effectively.

What deliverables can I expect from this thermal Interface Materials market research project?

Expect comprehensive deliverables from this project, including detailed market analysis reports, segmented data covering various applications like consumer electronics, automotive, and industrial sectors, along with forecasts, trends, and competitive landscape identifications.

What are the market trends of thermal Interface Materials?

Key market trends indicate a growing use of advanced materials like thermal pads and greases, increased adoption in energy-efficient technologies, and a shift toward developing sustainable, high-performance thermal management solutions in various sectors.