Thick Film Resistor Market Report

Published Date: 31 January 2026 | Report Code: thick-film-resistor

Thick Film Resistor Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive overview of the Thick Film Resistor market, including insights into market size, growth forecasts from 2023 to 2033, key industry trends, segmentation analysis, and competitive landscape details.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

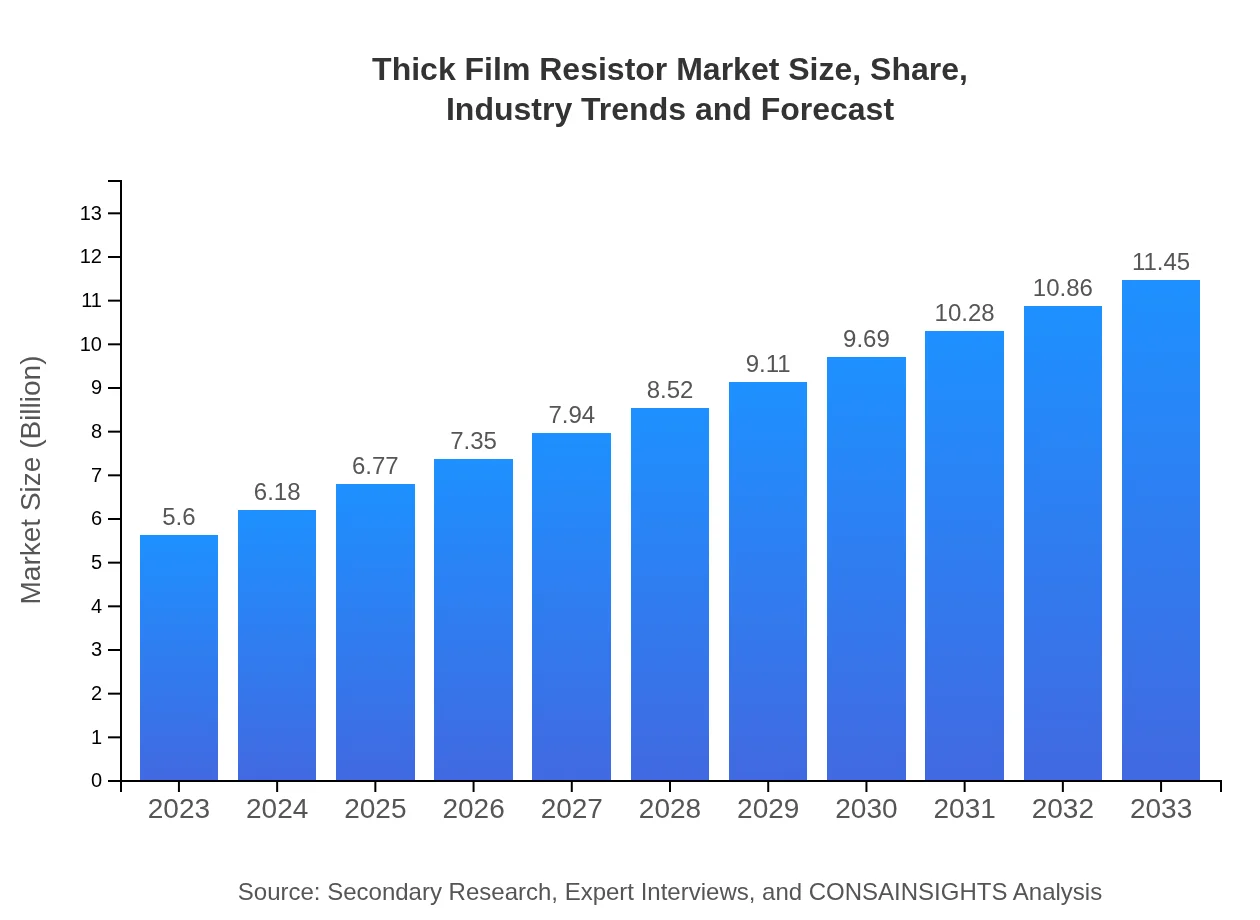

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $11.45 Billion |

| Top Companies | Vishay Intertechnology, Panasonic Corporation, TE Connectivity, KOA Speer Electronics |

| Last Modified Date | 31 January 2026 |

Thick Film Resistor Market Overview

Customize Thick Film Resistor Market Report market research report

- ✔ Get in-depth analysis of Thick Film Resistor market size, growth, and forecasts.

- ✔ Understand Thick Film Resistor's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Thick Film Resistor

What is the Market Size & CAGR of Thick Film Resistor market in 2023?

Thick Film Resistor Industry Analysis

Thick Film Resistor Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Thick Film Resistor Market Analysis Report by Region

Europe Thick Film Resistor Market Report:

Europe presents a strong market for Thick Film Resistors, valued at $1.83 billion in 2023 with projections of reaching $3.74 billion by 2033. The established automotive sector paired with stringent energy efficiency regulations is key to driving growth in this market.Asia Pacific Thick Film Resistor Market Report:

In 2023, the Asia Pacific region holds a market value of $1.05 billion and is projected to reach $2.15 billion by 2033, driven by high demand from the electronics and automotive sectors. The region's growth is fueled by emerging economies such as China and India, where industrial output and electronic consumption are escalating.North America Thick Film Resistor Market Report:

With a market size of $1.96 billion in 2023, North America is anticipated to surge to $4.01 billion by 2033. This growth is largely inspired by advancements in automotive electronics and consumer devices, leading to a sustained demand for sophisticated resistors with enhanced performance.South America Thick Film Resistor Market Report:

The South American Thick Film Resistor market was valued at $0.43 billion in 2023 and is expected to grow to $0.88 billion by 2033. A resurgence in industrial activities and increases in local electronics manufacturing will bolster demand for thick film resistors in this region.Middle East & Africa Thick Film Resistor Market Report:

The Middle East and Africa market is smaller, with a value of $0.32 billion in 2023, likely increasing to $0.66 billion by 2033. Growth in telecommunications and the oil and gas industry is expected to set the pace for the demand of Thick Film Resistors.Tell us your focus area and get a customized research report.

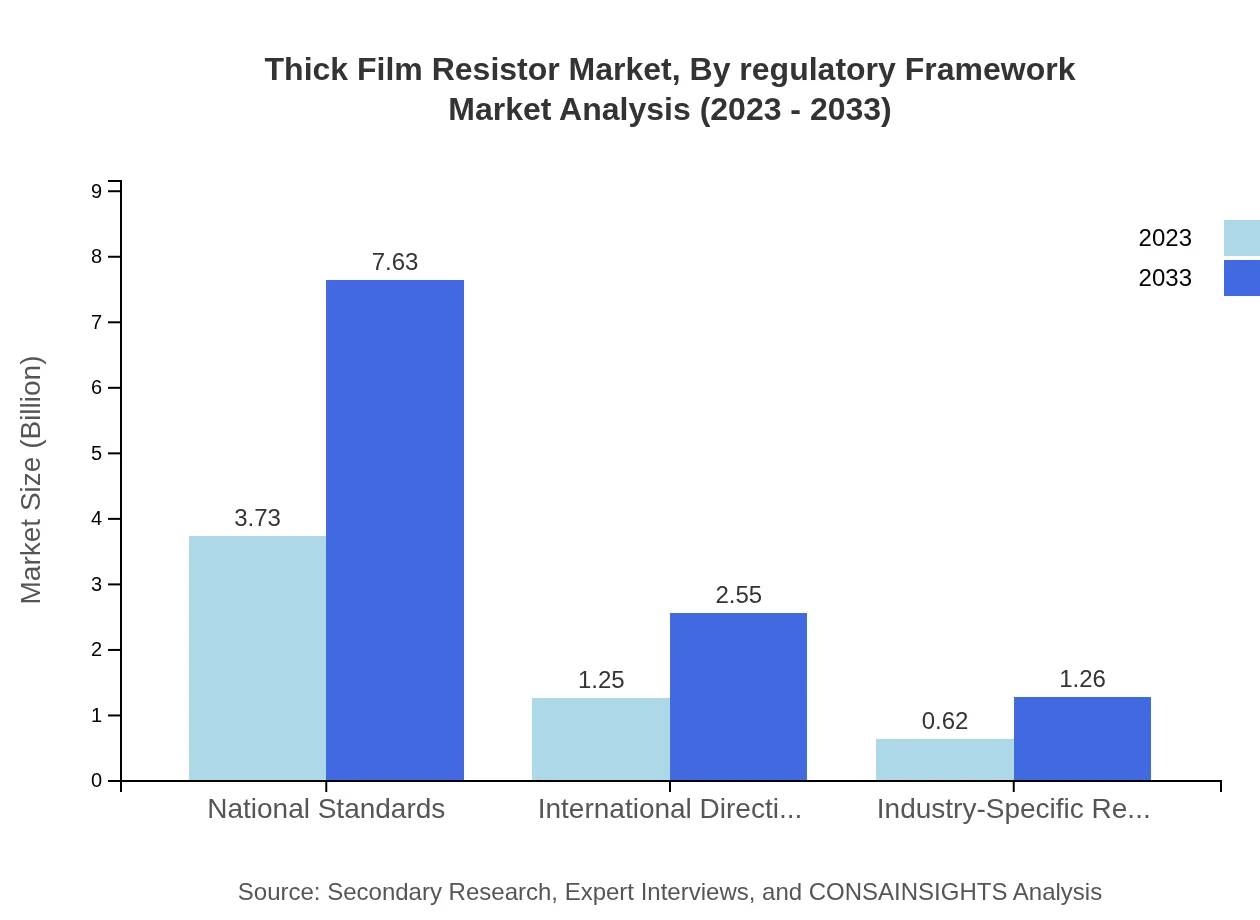

Thick Film Resistor Market Analysis By Product

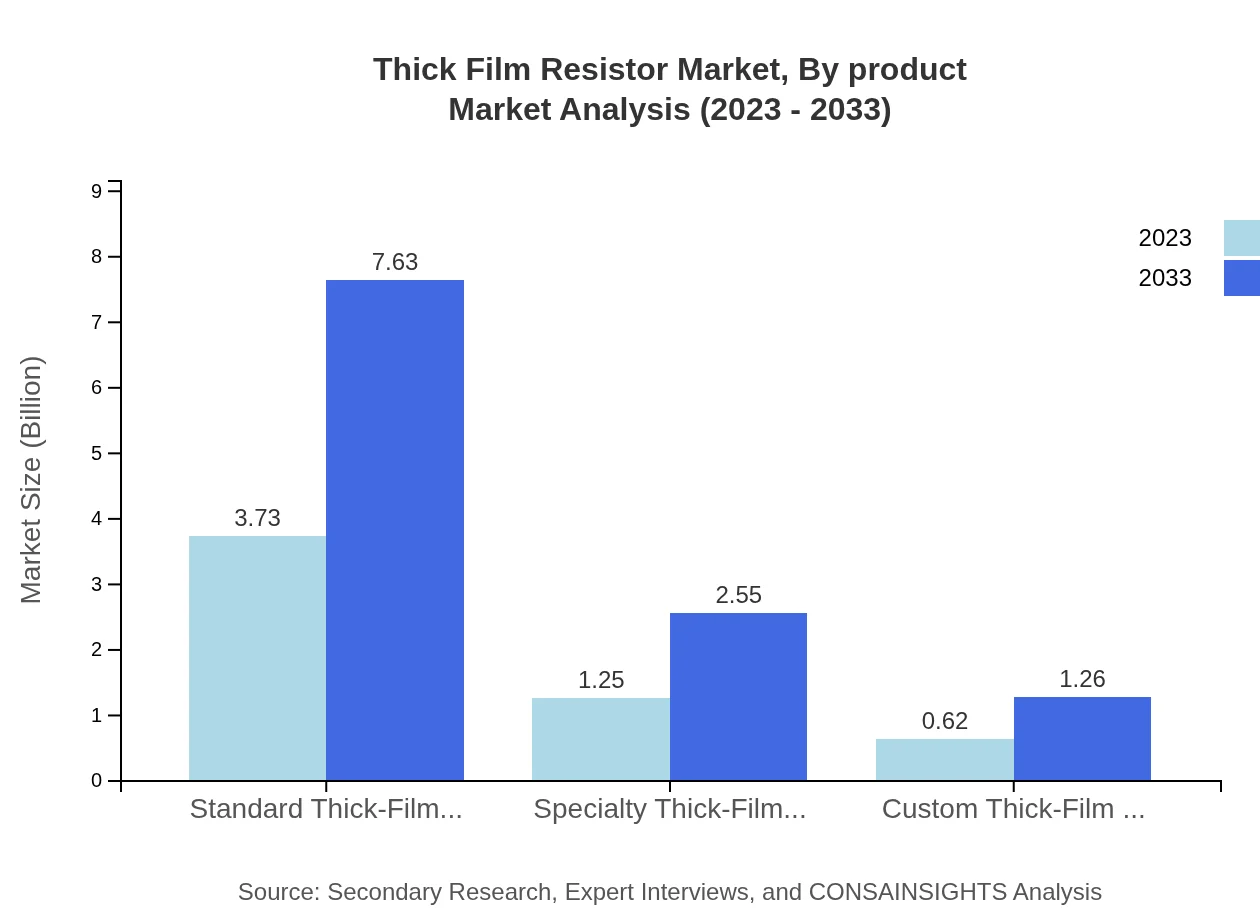

The market's product segmentation highlights a leading share of standard thick-film resistors, accounting for a market size of $3.73 billion in 2023, projected to increase to $7.63 billion by 2033. Specialty thick-film resistors follow, with market sizes of $1.25 billion in 2023 and expected growth to $2.55 billion by 2033. Custom thick-film resistors maintain significance with approximately $0.62 billion in 2023 and growth to $1.26 billion by 2033.

Thick Film Resistor Market Analysis By Application

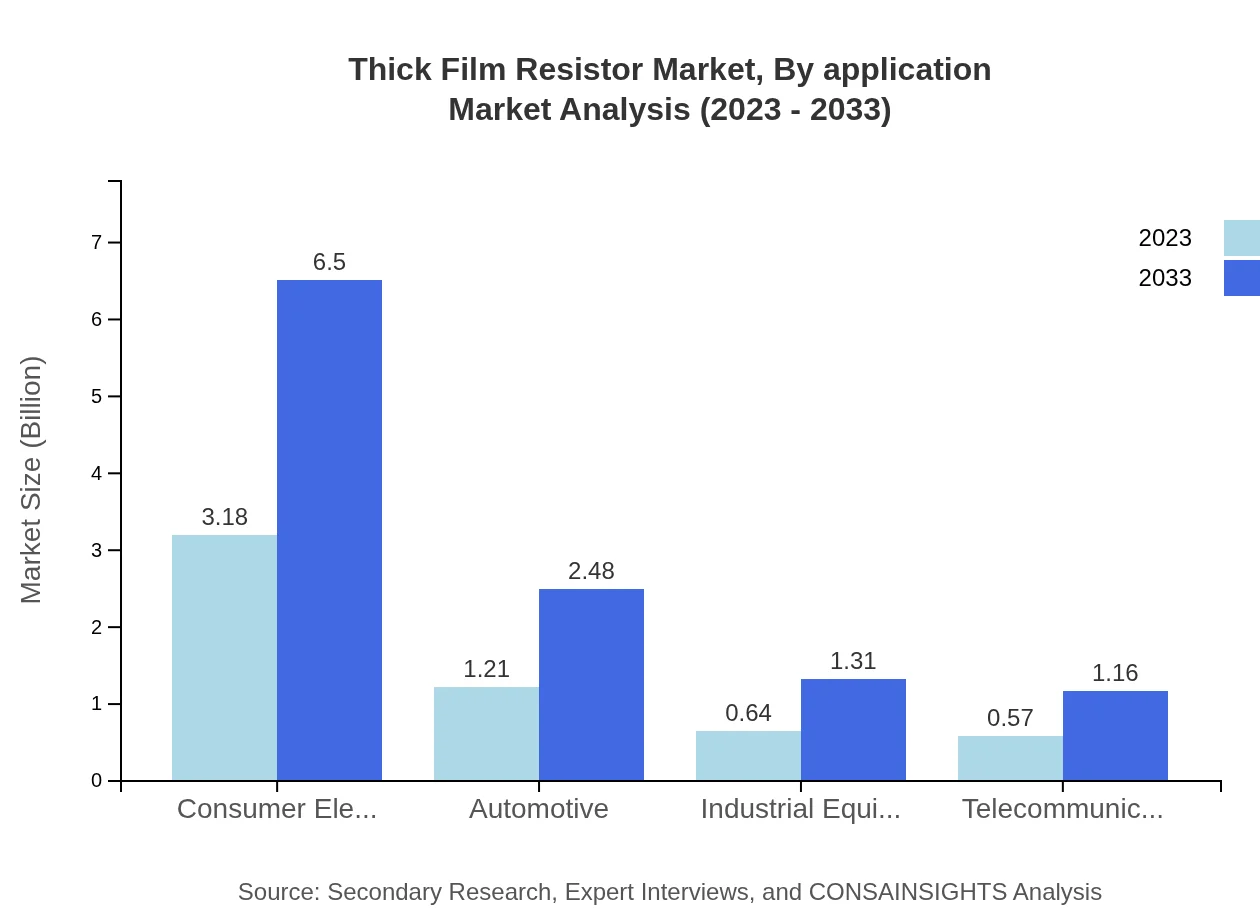

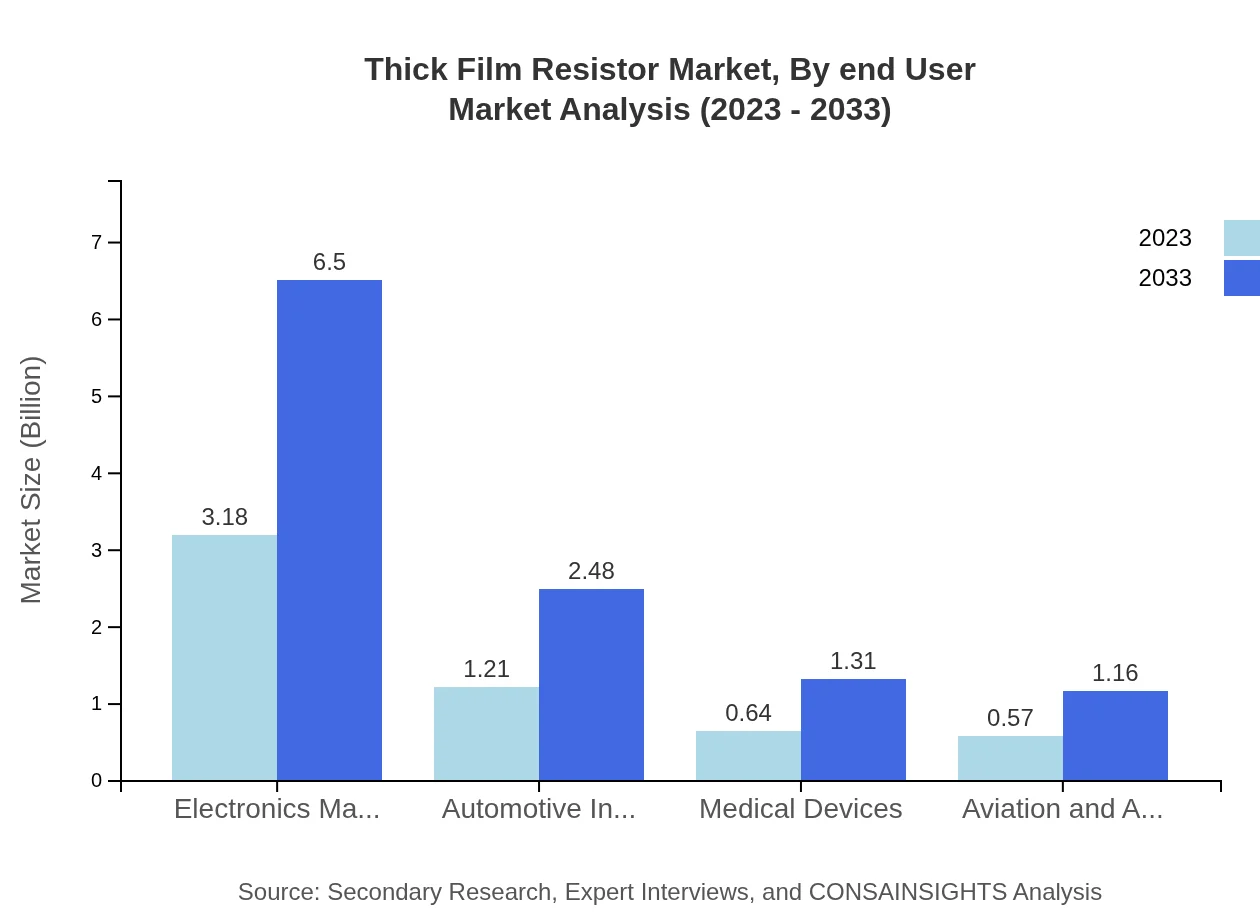

Applications of thick-film resistors are prevalent in various industries, especially in electronics manufacturing, which represents a significant share of 56.76% with market values scaling from $3.18 billion in 2023 to $6.50 billion by 2033. The automotive sector, holding a 21.67% share, will increase from $1.21 billion in 2023 to $2.48 billion by 2033, reflecting the growing integration of electronics in vehicles.

Thick Film Resistor Market Analysis By Technology

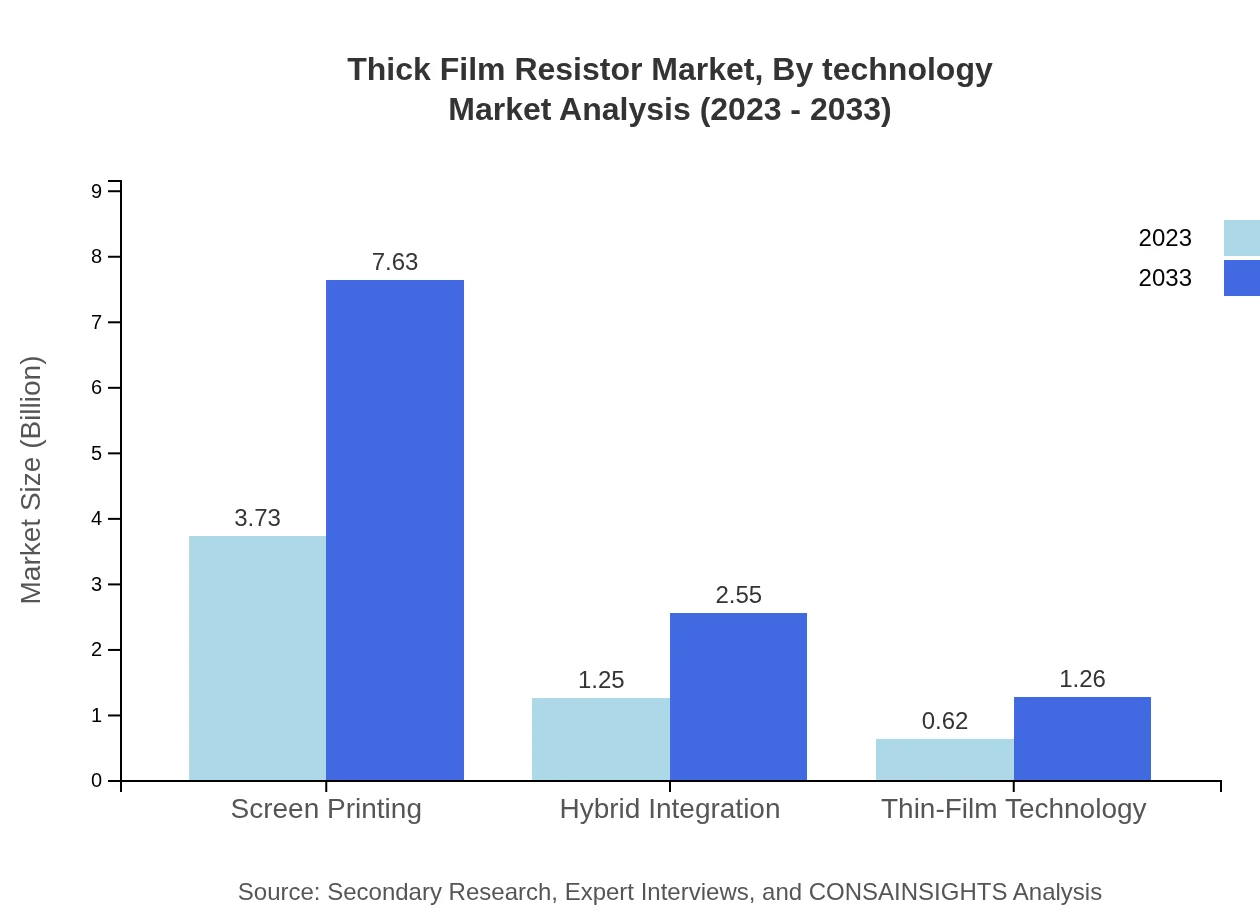

Thick-film resistors utilize innovative technologies, further improving accuracy and application across multiple sectors. A leading trend includes the adaptation of screen printing technology, which dominates the market with a 66.64% share, growing from $3.73 billion in 2023 to $7.63 billion by 2033. Hybrid integration technology is gaining traction, accounting for 22.32% of the market.

Thick Film Resistor Market Analysis By End User

The Electronics Manufacturing industry remains the predominant end-user of thick-film resistors, contributing to a $3.18 billion market size in 2023 with projections of $6.50 billion by 2033. The automotive industry closely follows, reflecting the rising demand for electronic controls and sensors, with market growth mirroring technological enhancements.

Thick Film Resistor Market Analysis By Regulatory Framework

Regulatory frameworks play a crucial role in the Thick Film Resistor market, particularly concerning environmental regulations. Compliance with national standards is crucial, holding a substantial market share of 66.64%, set to grow from $3.73 billion in 2023 to $7.63 billion by 2033. International directives and specific industry regulations are also pivotal for ensuring safety and quality across applications.

Thick Film Resistor Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Thick Film Resistor Industry

Vishay Intertechnology:

A leading manufacturer of discrete semiconductors, Vishay offers a wide range of thick film resistors known for their performance in various applications, including automotive and industrial electronics.Panasonic Corporation:

Panasonic is a renowned global electronics company producing high-quality thick film resistors tailored for consumer electronics, automotive, and telecommunications sectors.TE Connectivity:

TE Connectivity engages in providing connectivity and sensor solutions, producing reliable thick film resistors that meet stringent industry standards.KOA Speer Electronics:

Specializing in passive electronic components, KOA offers a variety of thick film resistors designed for high-performance applications, catering to the needs of diverse industries.We're grateful to work with incredible clients.

FAQs

What is the market size of thick Film Resistor?

The thick-film resistor market is projected to grow from $5.6 billion in 2023 to an estimated $11.1 billion by 2033, reflecting a CAGR of 7.2%. This growth indicates a strong demand and expanding applications across various sectors.

What are the key market players or companies in the thick Film Resistor industry?

Key players in the thick-film resistor market include Vishay Intertechnology, Yageo Corporation, and KOA Speer Electronics. These companies are recognized for their technological advancements and comprehensive product offers, significantly influencing the market landscape.

What are the primary factors driving the growth in the thick Film resistor industry?

The growth in the thick-film resistor industry is driven by the increasing demand from the electronics sector, advancements in automotive technologies, and the rising trend of miniaturization in device manufacturing. Additionally, regulatory requirements for component reliability bolster demand.

Which region is the fastest Growing in the thick Film resistor?

Asia-Pacific is currently the fastest-growing region in the thick-film resistor market, with growth anticipated from $1.05 billion in 2023 to $2.15 billion by 2033. This growth is fueled by the increasing electronics manufacturing in emerging markets.

Does ConsaInsights provide customized market report data for the thick Film resistor industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the thick-film resistor industry. Clients can request insights based on geographical, segmental, and product line variations to better inform their strategic decisions.

What deliverables can I expect from this thick Film resistor market research project?

Deliverables from this market research include detailed market analysis, forecasts, segmentation data, competitive analysis, and insights into consumer behavior. Additionally, comprehensive reports will provide actionable recommendations based on industry trends.

What are the market trends of thick Film resistor?

Current market trends in thick-film resistors include a shift towards eco-friendly manufacturing processes, increased use in automation and AI technologies, and a strong focus on semiconductor applications. This reflects broader trends toward sustainability and efficiency in manufacturing.