Tire Mold Market Report

Published Date: 22 January 2026 | Report Code: tire-mold

Tire Mold Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Tire Mold market from 2023 to 2033, including market size, growth insights, trends, and regional breakdowns, along with crucial segments and contributions from key players.

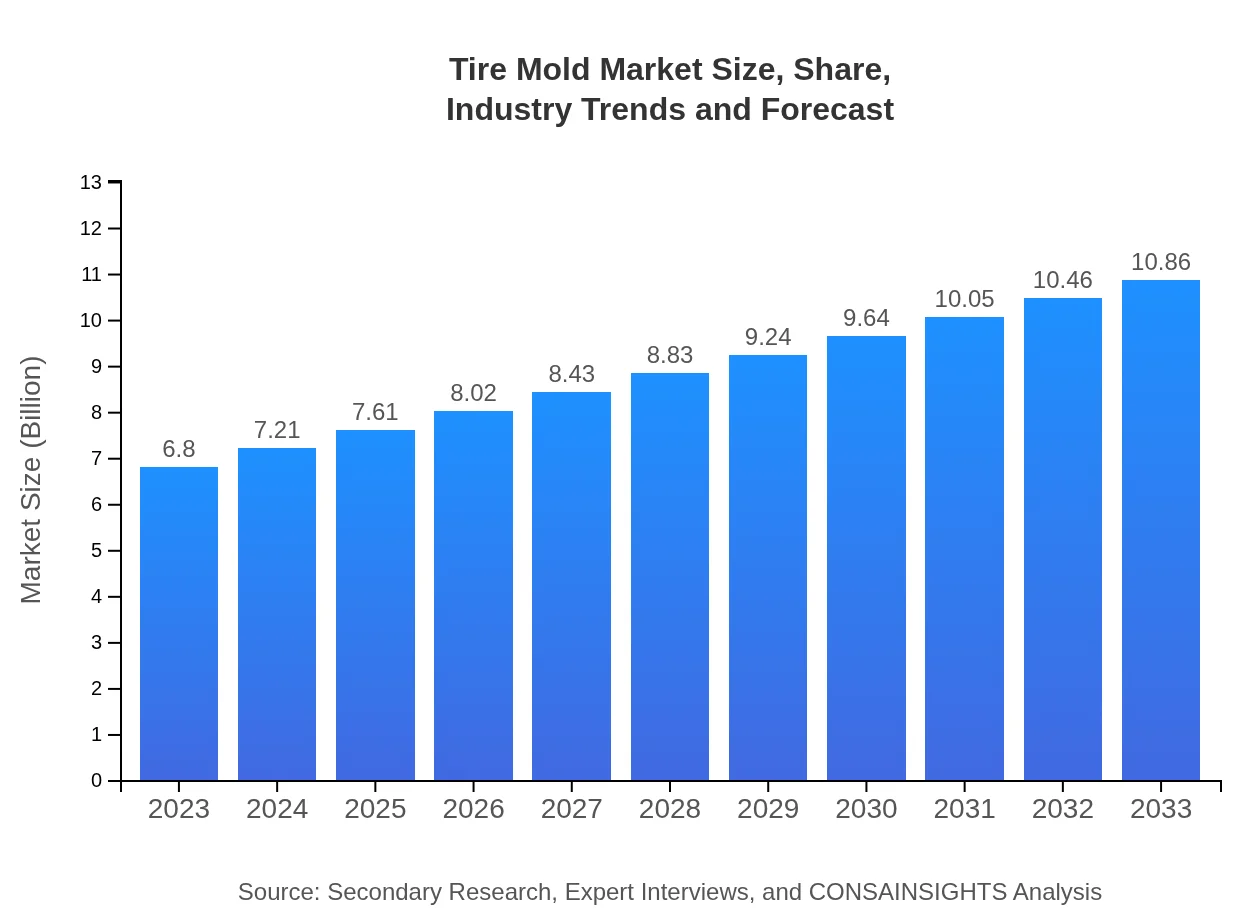

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.80 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $10.86 Billion |

| Top Companies | Haas Automation, Inc., Tech Molded Plastics Inc., Continental AG, Mold-Masters Limited |

| Last Modified Date | 22 January 2026 |

Tire Mold Market Overview

Customize Tire Mold Market Report market research report

- ✔ Get in-depth analysis of Tire Mold market size, growth, and forecasts.

- ✔ Understand Tire Mold's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Tire Mold

What is the Market Size & CAGR of Tire Mold market in 2023?

Tire Mold Industry Analysis

Tire Mold Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Tire Mold Market Analysis Report by Region

Europe Tire Mold Market Report:

In Europe, the Tire Mold market is forecasted to grow from $2.16 billion in 2023 to $3.45 billion in 2033. The region is focusing on sustainability, leading to increased demand for molds that support eco-friendly tire manufacturing.Asia Pacific Tire Mold Market Report:

The Asia Pacific region is anticipated to lead the Tire Mold market, projected to grow from $1.37 billion in 2023 to $2.19 billion in 2033. The growth is driven by increasing automotive production, particularly in countries like China and India, supported by government initiatives to enhance infrastructure and transportation.North America Tire Mold Market Report:

North America, with a market size of $2.19 billion in 2023, is projected to reach $3.50 billion by 2033. The U.S. and Canada are experiencing growth due to the rise in electric vehicle production and the need for advanced tire technologies.South America Tire Mold Market Report:

The South American market, valued at $0.50 billion in 2023, is expected to grow to $0.79 billion by 2033. While the growth is slower compared to other regions, demand for tire molds is increasing due to a recovering automotive sector and investments in manufacturing.Middle East & Africa Tire Mold Market Report:

The Middle East and Africa market is expected to expand from $0.58 billion in 2023 to $0.93 billion by 2033, driven by growing automotive industries in emerging markets and increasing tire demand.Tell us your focus area and get a customized research report.

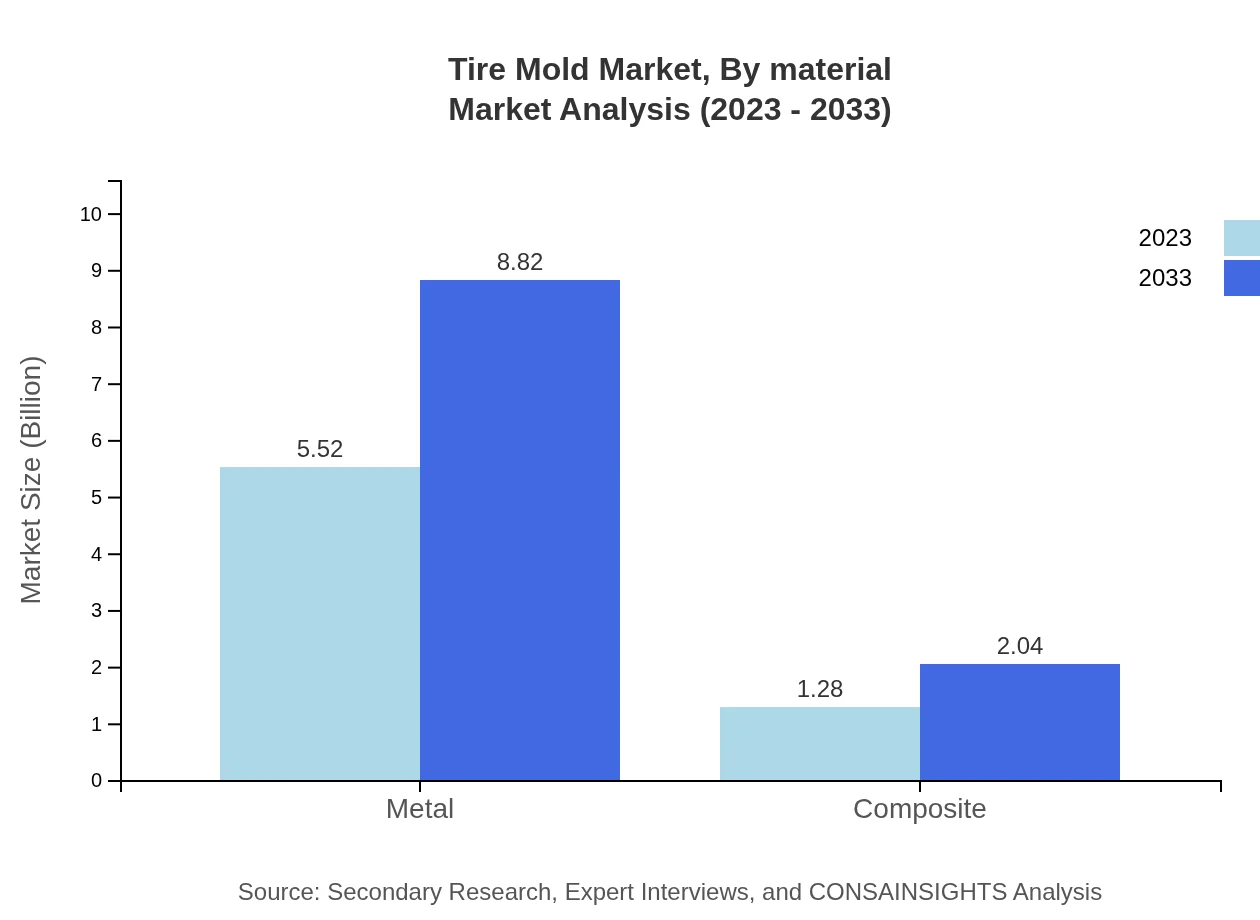

Tire Mold Market Analysis By Material

The material segment is crucial, with metal molds representing the majority share (81.21% in 2023) valued at $5.52 billion, projected to reach $8.82 billion by 2033. Composite molds, while smaller in market share (18.79%), are also gaining traction due to lightweight and performance advantages.

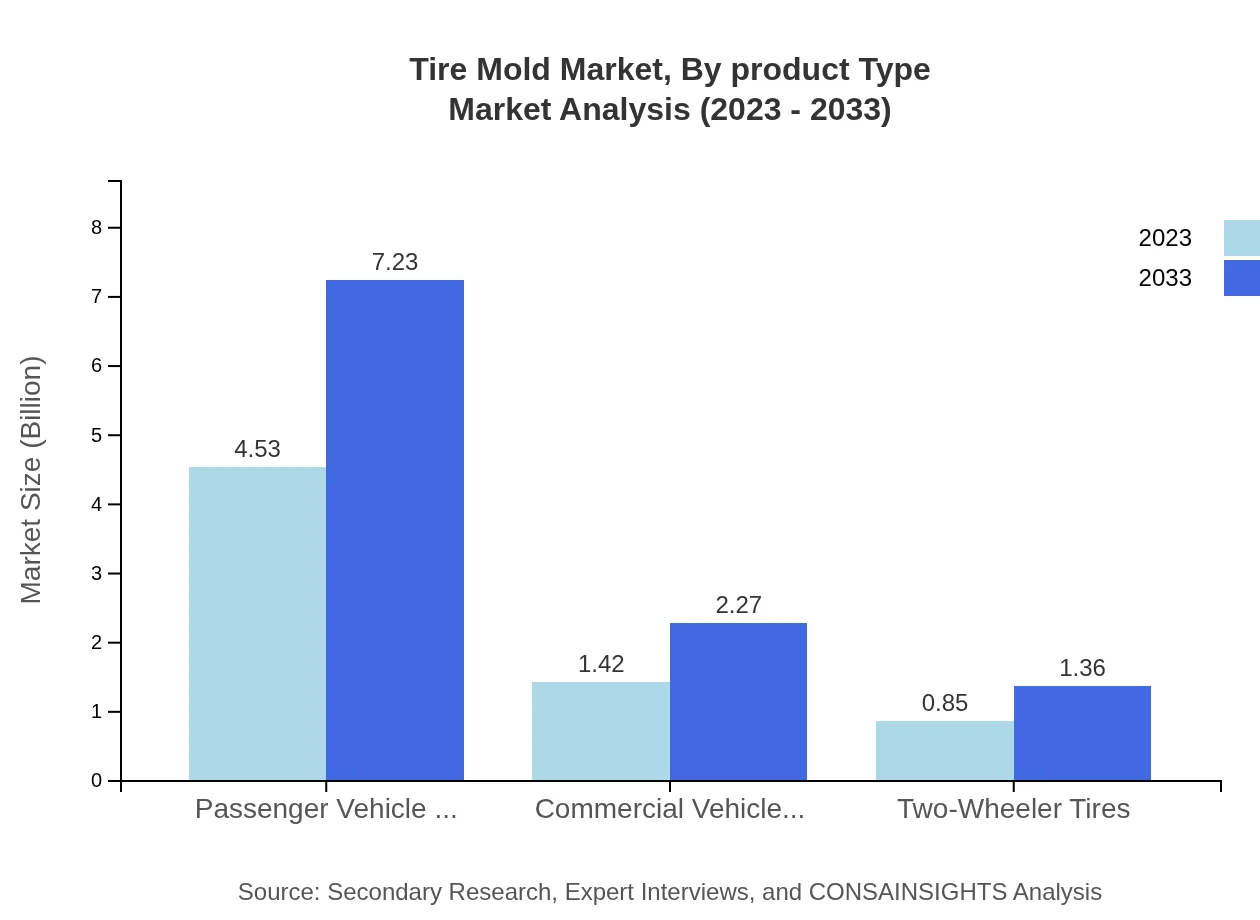

Tire Mold Market Analysis By Product Type

Passenger vehicle tires dominate the product type segment (66.59% share) valued at $4.53 billion in 2023 and expected to grow to $7.23 billion by 2033. Commercial and two-wheeler tires contribute significantly, reflecting diverse consumer demands across vehicle types.

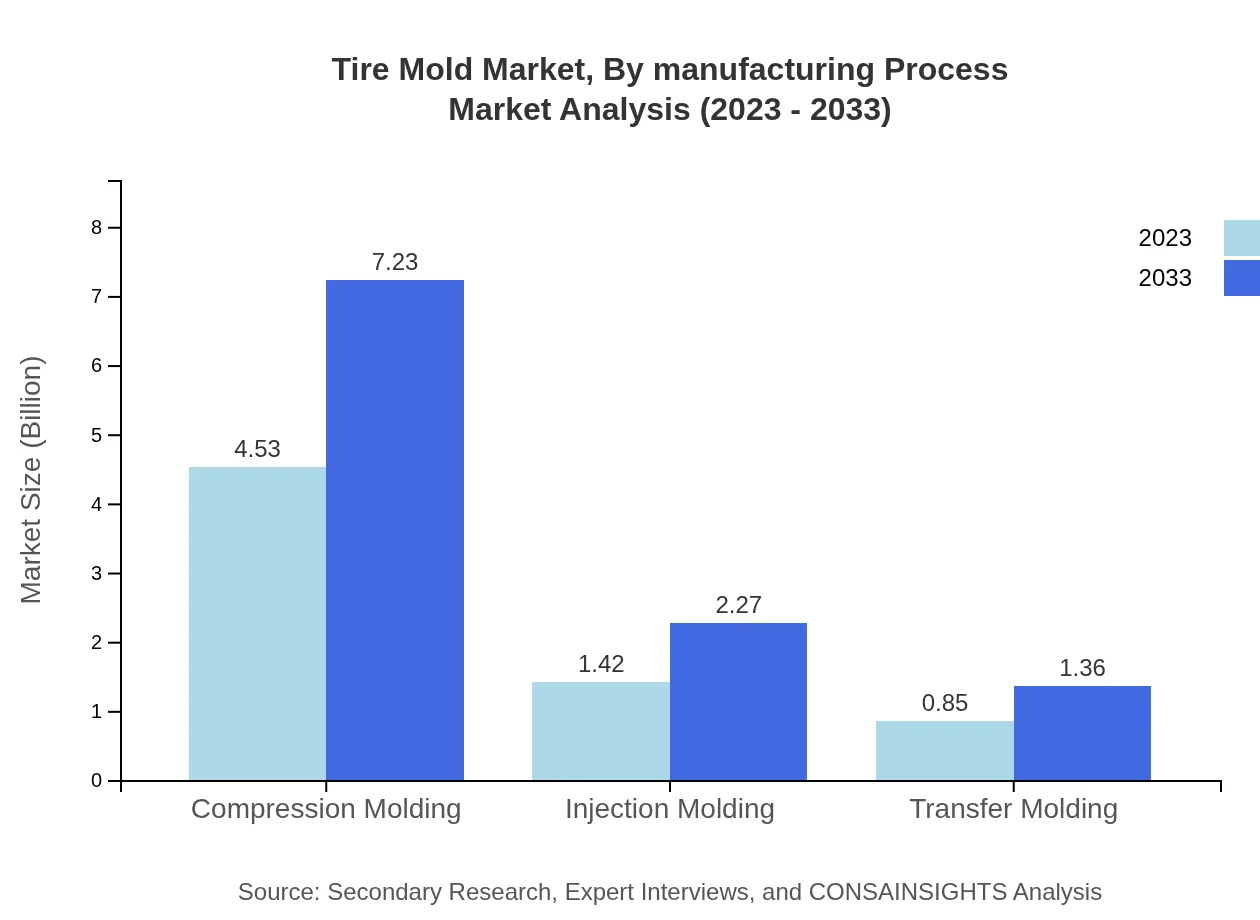

Tire Mold Market Analysis By Manufacturing Process

Compression molding holds the largest share (66.59%), valued at $4.53 billion in 2023 and forecasted to reach $7.23 billion by 2033. Injection and transfer molding processes are also important, catering to specific production requirements in tire manufacturing.

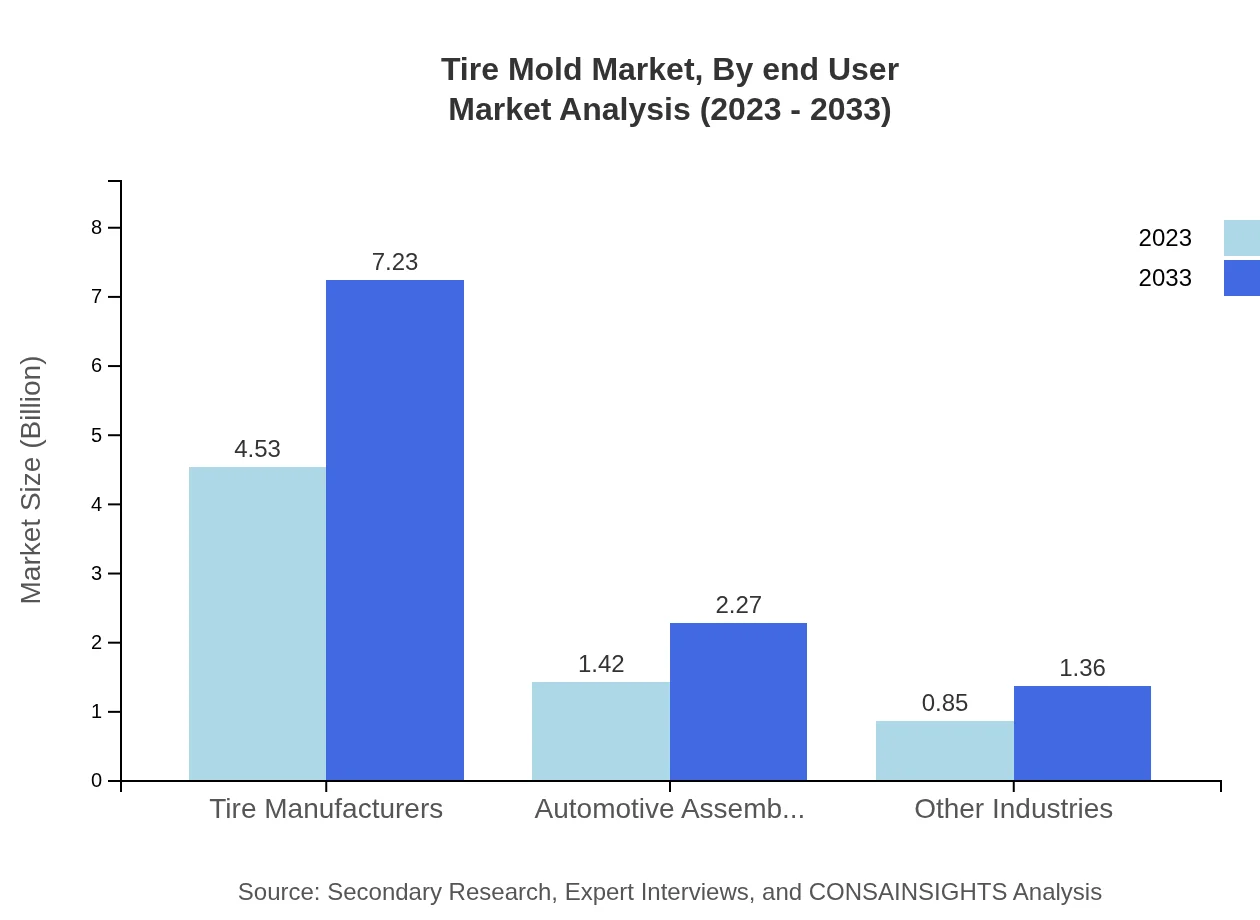

Tire Mold Market Analysis By End User

Tire manufacturers represent the primary end-user segment (66.59%) valued at $4.53 billion in 2023, poised to grow to $7.23 billion by 2033. Automotive assemblers and other industries contribute to market diversity, indicating growth potential across various sectors.

Tire Mold Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Tire Mold Industry

Haas Automation, Inc.:

A leader in manufacturing CNC machines, Haas Automation produces high-quality tire molds that meet the industry's stringent performance standards.Tech Molded Plastics Inc.:

Specializing in advanced manufacturing, Tech Molded Plastics offers innovative tire mold solutions aimed at optimizing production efficiency.Continental AG:

A significant player in the tire industry, Continental AG invests in tire mold technology to enhance its portfolio of high-performance tires.Mold-Masters Limited:

Known for their cutting-edge mold technologies, Mold-Masters supports diverse applications within the Tire Mold market, enhancing quality and production speed.We're grateful to work with incredible clients.

FAQs

What is the market size of tire Mold?

The global tire mold market is projected to reach $6.8 billion by 2033, growing at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2033. This reflects a robust growth trajectory boosted by increasing tire demand.

What are the key market players or companies in this tire Mold industry?

Key players in the tire-mold market include major tire manufacturers and molding technology companies specializing in innovative designs and efficient production processes, which are critical to meet the growing demand in the automotive sector.

What are the primary factors driving the growth in the tire Mold industry?

The tire-mold industry is driven by rising automotive production, advancements in tire technology, increasing demand for electric vehicles, and the push towards sustainable and high-performance tires that require innovative molds.

Which region is the fastest Growing in the tire Mold?

The Asia Pacific region is the fastest growing for tire molds, with market projections increasing from $1.37 billion in 2023 to $2.19 billion in 2033. This growth is fueled by expanding automotive manufacturing hubs.

Does ConsaInsights provide customized market report data for the tire Mold industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs within the tire-mold industry, ensuring clients receive relevant and actionable insights based on their unique business requirements.

What deliverables can I expect from this tire Mold market research project?

Expect comprehensive market analysis, detailed segmentation data, regional insights, competitive landscape information, and actionable recommendations tailored to inform strategic decision-making in the tire-mold market.

What are the market trends of tire Mold?

Key trends in the tire-mold market include the shift towards advanced materials, increasing automation in manufacturing processes, and the integration of digital technologies, which enhance efficiency and reduce production costs.