Ultrasonic Non Destructive Testing Ndt Equipment Market Report

Published Date: 31 January 2026 | Report Code: ultrasonic-non-destructive-testing-ndt-equipment

Ultrasonic Non Destructive Testing Ndt Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Ultrasonic Non Destructive Testing (NDT) Equipment market from 2023 to 2033. It includes insights on market trends, size, growth forecasts, and key players in the industry.

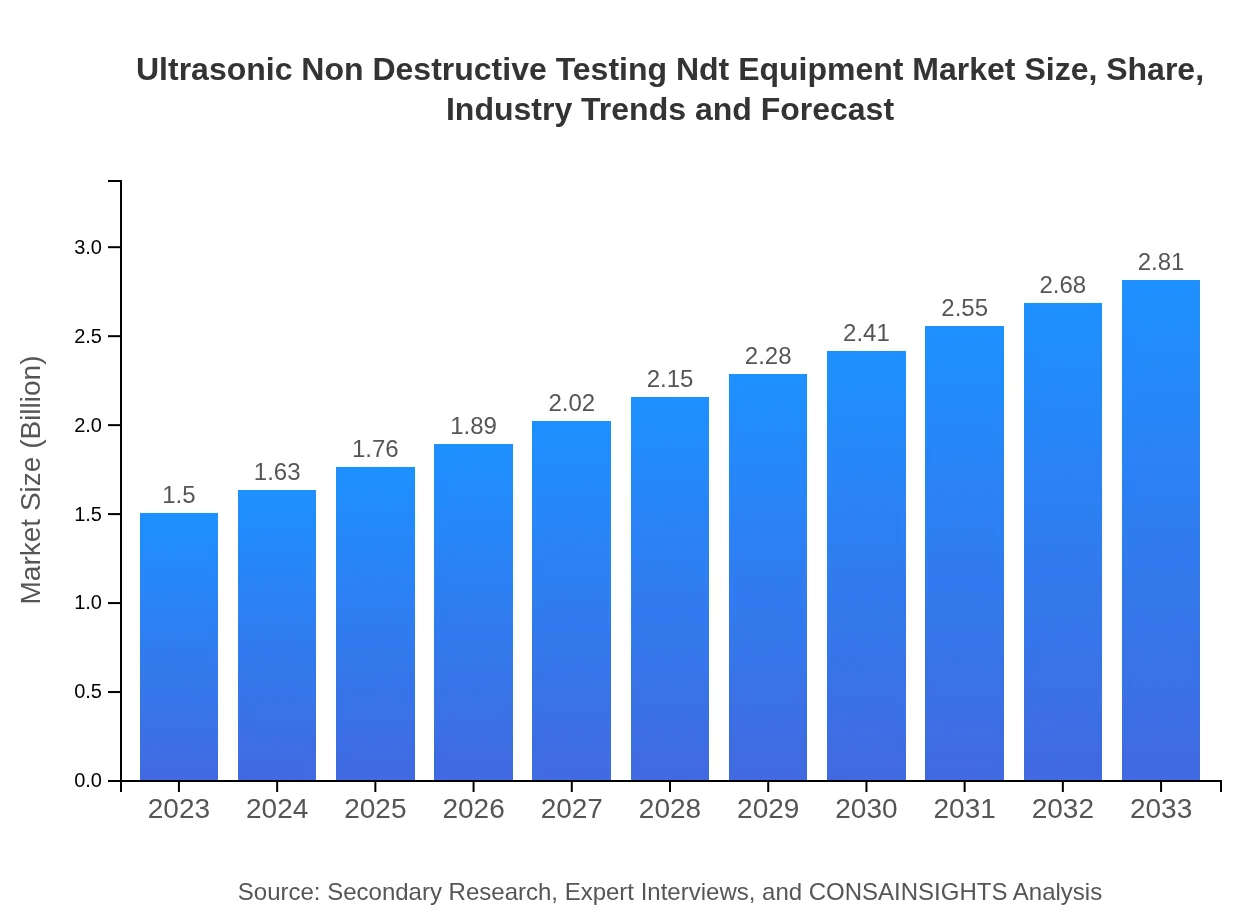

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $2.81 Billion |

| Top Companies | Olympus Corporation, GE Inspection Technologies, Nordson Corporation, Ashtead Technology |

| Last Modified Date | 31 January 2026 |

Ultrasonic Non Destructive Testing Ndt Equipment Market Overview

Customize Ultrasonic Non Destructive Testing Ndt Equipment Market Report market research report

- ✔ Get in-depth analysis of Ultrasonic Non Destructive Testing Ndt Equipment market size, growth, and forecasts.

- ✔ Understand Ultrasonic Non Destructive Testing Ndt Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Ultrasonic Non Destructive Testing Ndt Equipment

What is the Market Size & CAGR of Ultrasonic Non Destructive Testing Ndt Equipment market in 2023?

Ultrasonic Non Destructive Testing Ndt Equipment Industry Analysis

Ultrasonic Non Destructive Testing Ndt Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis Report by Region

Europe Ultrasonic Non Destructive Testing Ndt Equipment Market Report:

Europe's market is expected to grow from USD 0.47 billion in 2023 to USD 0.88 billion by 2033, driven by stringent safety and quality regulations as well as a focus on maintenance in critical industries.Asia Pacific Ultrasonic Non Destructive Testing Ndt Equipment Market Report:

In the Asia Pacific region, the Ultrasonic NDT Equipment market is valued at USD 0.30 billion in 2023, with projections to reach USD 0.55 billion by 2033. A growing industrial base and increasing investments in infrastructure are driving demand in countries like China and India.North America Ultrasonic Non Destructive Testing Ndt Equipment Market Report:

North America represents a significant market, with a value of USD 0.51 billion in 2023, anticipated to grow to USD 0.95 billion by 2033. The demand is propelled by advanced technological implementations and high regulatory standards across industries.South America Ultrasonic Non Destructive Testing Ndt Equipment Market Report:

The South American market is currently valued at USD 0.08 billion in 2023, with a forecast of reaching USD 0.15 billion by 2033. Growth in this region is mainly supported by the oil and gas sector, where rigorous testing and compliance regulations are becoming more prevalent.Middle East & Africa Ultrasonic Non Destructive Testing Ndt Equipment Market Report:

The Middle East and Africa market, valued at USD 0.15 billion in 2023, is expected to reach USD 0.28 billion by 2033, with growth largely influenced by the oil and gas industry and ongoing infrastructure development initiatives.Tell us your focus area and get a customized research report.

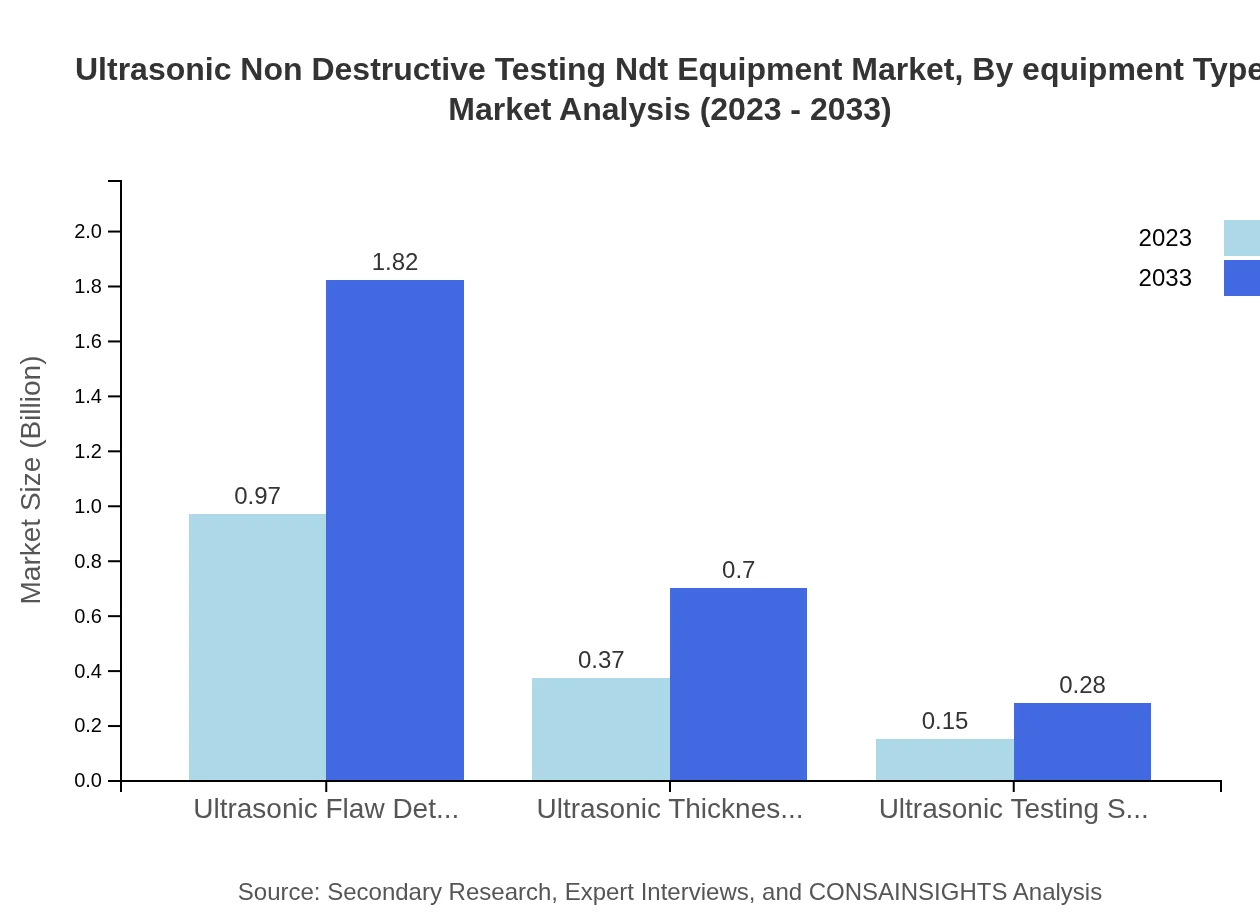

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis By Equipment Type

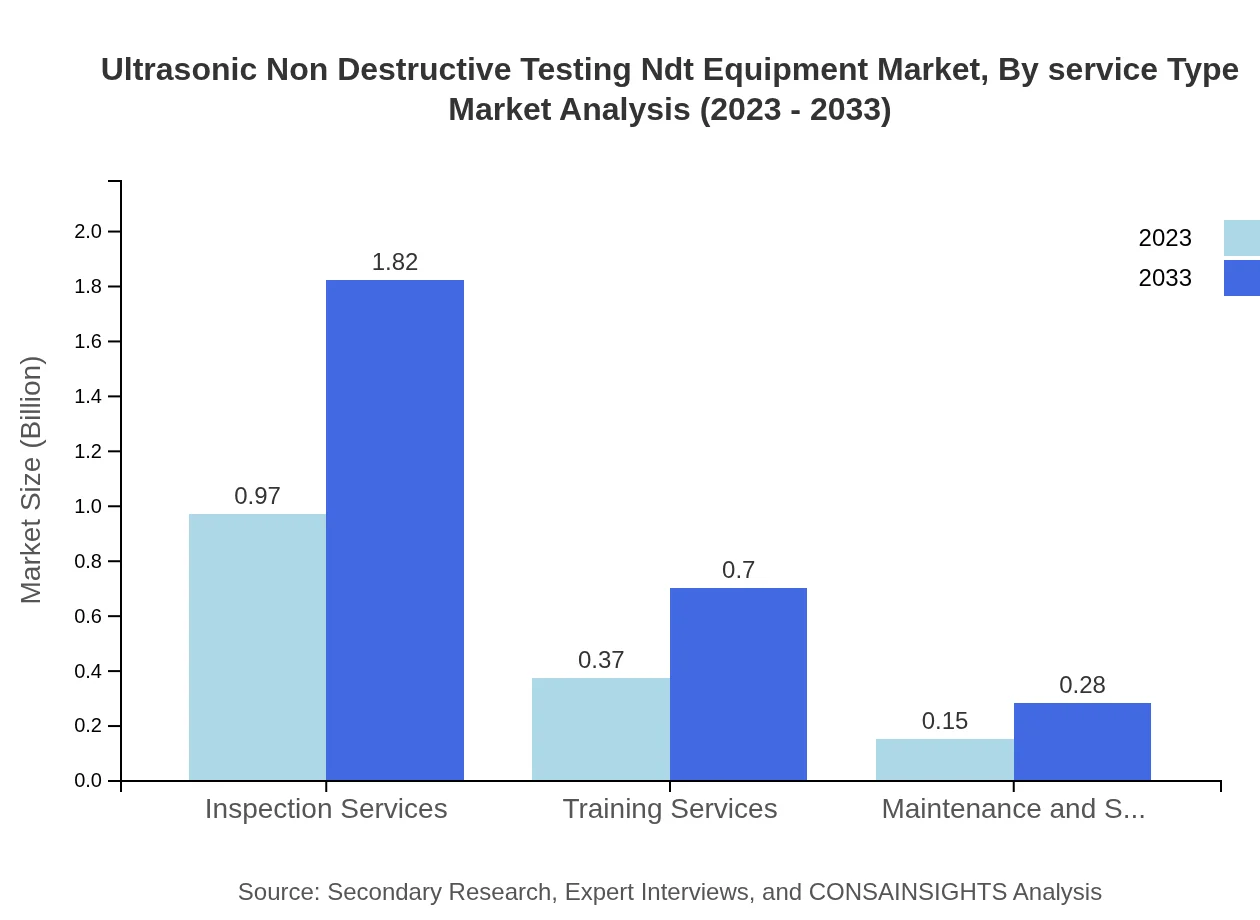

The conventional ultrasonic testing equipment holds the largest market share, capturing approximately 64.99% in 2023, worth USD 0.97 billion, and is projected to grow to USD 1.82 billion by 2033. Other segments such as phased array ultrasonic testing and time of flight diffraction testing contribute meaningfully to the market, with shares of 24.97% and 10.04% respectively.

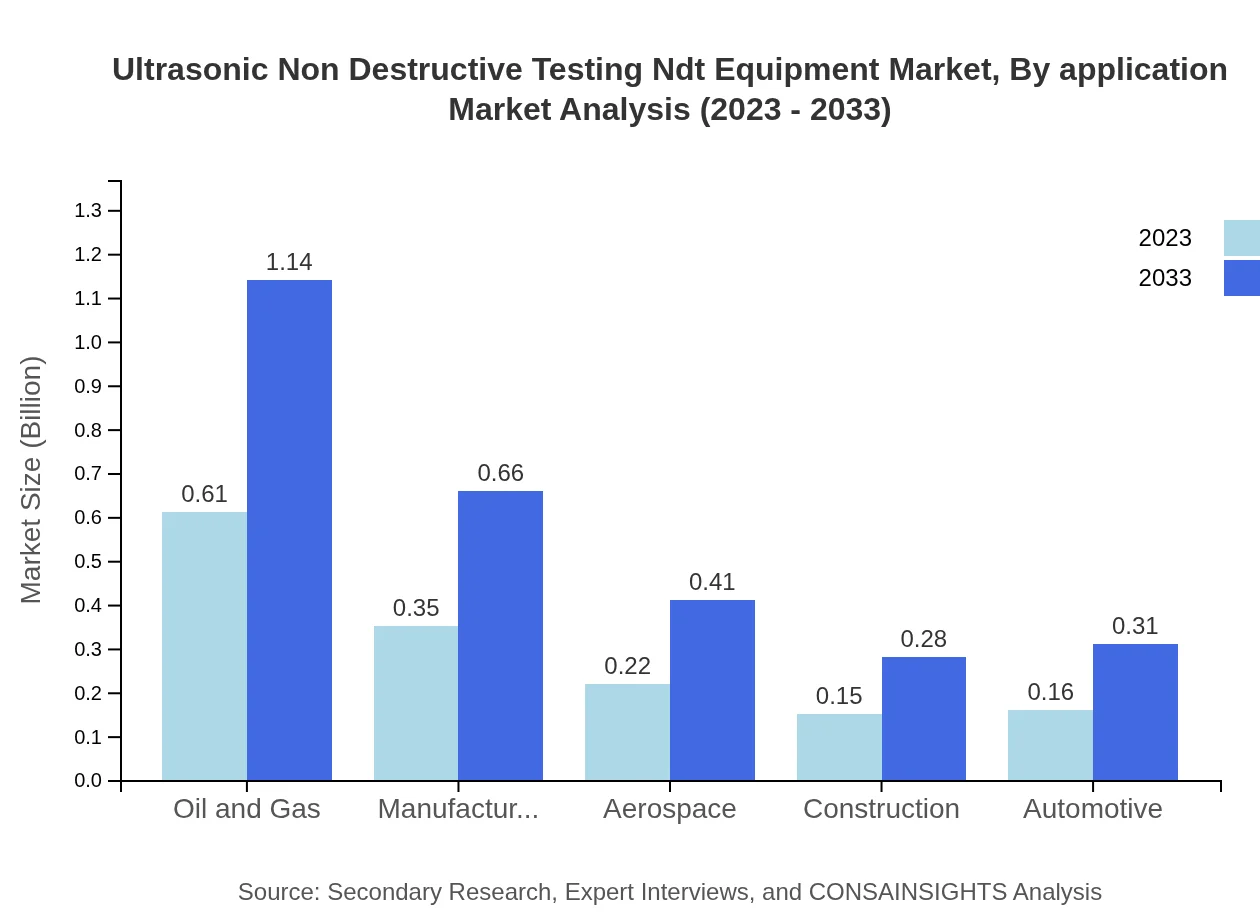

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis By Application

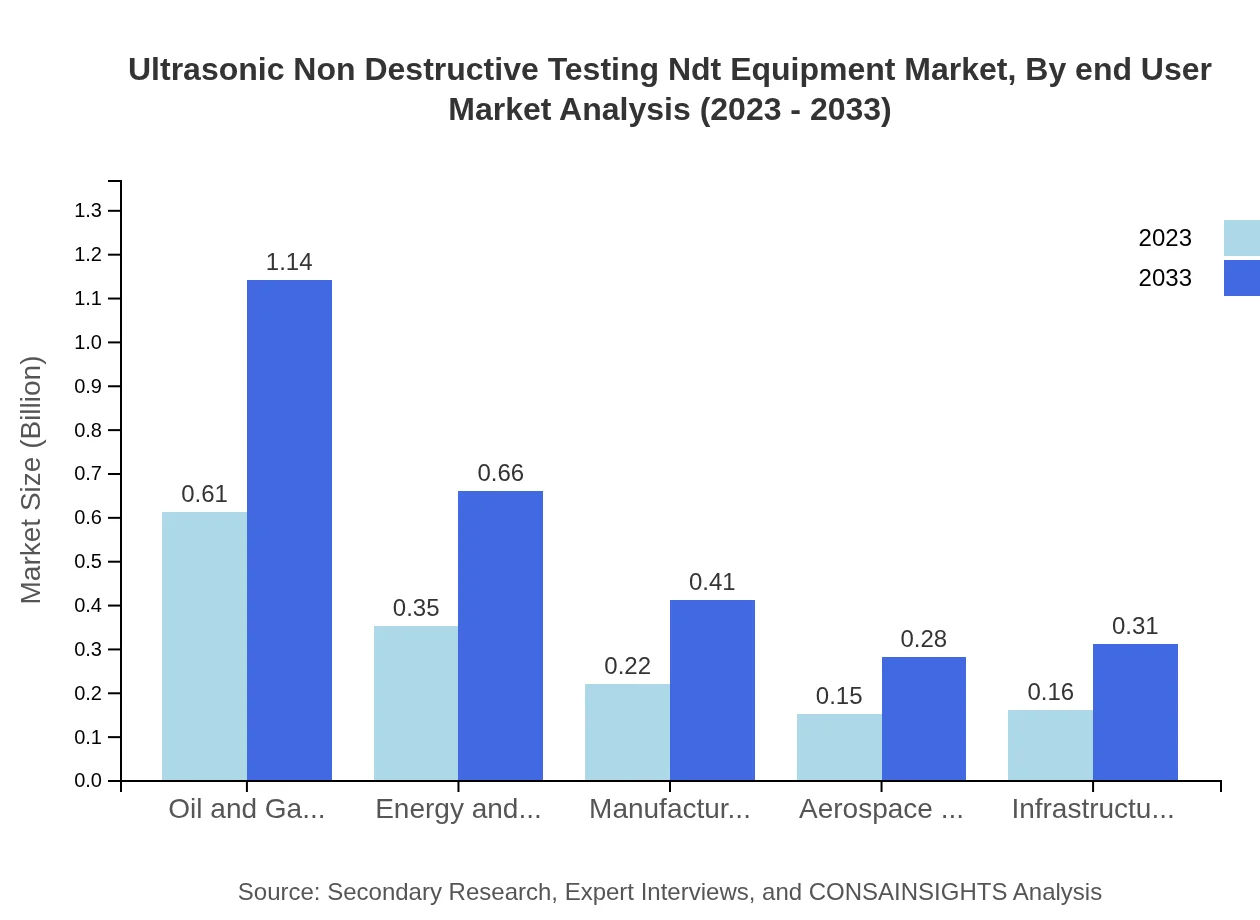

The oil and gas industry is the largest segment, accounting for 40.78% of the market in 2023, valued at USD 0.61 billion, and expected to rise to USD 1.14 billion by 2033. Manufacturing, aerospace, and construction also represent key sectors where ultrasonic NDT solutions are critical.

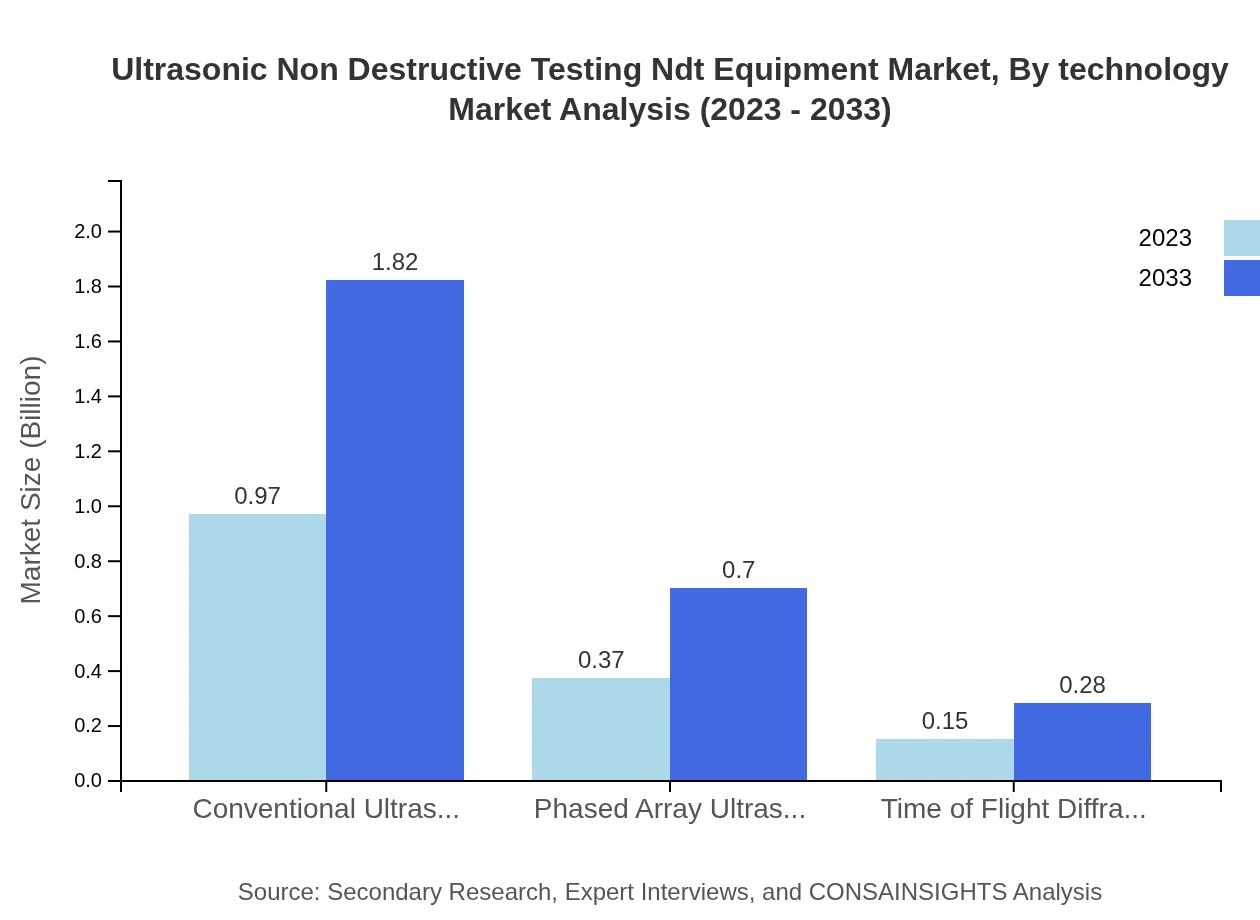

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis By Technology

With the evolution of technology, advanced ultrasonic testing methodologies have gained traction. Phased array and conventional ultrasonic testing technologies dominate the market, accounting for a combined share that emphasizes the continuation of traditional methods while integrating modern innovations.

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis By End User

Key end-user industries include oil and gas, manufacturing, aerospace, and infrastructure. The oil and gas sector remains the largest end-user, emphasizing the need for regular inspections in hazardous environments, while manufacturing follows closely behind due to high production standards.

Ultrasonic Non Destructive Testing Ndt Equipment Market Analysis By Service Type

Inspections services constitute the largest share of the service market, valued at USD 0.97 billion in 2023, growing to USD 1.82 billion by 2033. Training services also hold a significant portion, offering essential skill development to personnel involved in NDT.

Ultrasonic Non Destructive Testing Ndt Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Ultrasonic Non Destructive Testing Ndt Equipment Industry

Olympus Corporation:

A leading provider of ultrasonic testing equipment, known for its innovative solutions and strong market presence across various industries.GE Inspection Technologies:

Key player specializing in advanced inspection technologies, offering a wide range of ultrasonic NDT solutions highly regarded for quality and reliability.Nordson Corporation:

Provides Ultrasonic NDT equipment with a focus on high precision and reliability, serving multiple industries including aerospace and automotive.Ashtead Technology:

Recognized for its extensive range of rental inspection equipment, specializing in advanced ultrasonic testing solutions.We're grateful to work with incredible clients.

FAQs

What is the market size of ultrasonic non Destructive testing (NDT) equipment?

The ultrasonic non-destructive testing (NDT) equipment market is currently valued at $1.5 billion, with a projected CAGR of 6.3% over the next decade. By 2033, the market is expected to expand significantly, reflecting growing adoption across various industries.

What are the key market players or companies in the ultrasonic non Destructive testing (NDT) equipment industry?

Key players in the ultrasonic NDT equipment industry include renowned companies such as GE Inspection Technologies, Olympus Corporation, and Siemens. Their continuous innovation and advanced technology offerings contribute significantly to market competitiveness and growth.

What are the primary factors driving the growth in the ultrasonic NDT equipment industry?

Primary growth factors for the ultrasonic NDT equipment market include increasing safety regulations, the need for quality assurance in manufacturing, and the adoption of NDT in aerospace and automotive sectors to prevent structural failures and ensure operational efficiency.

Which region is the fastest Growing in the ultrasonic NDT equipment market?

The North America region is the fastest-growing market for ultrasonic NDT equipment, with an estimated market size of $0.95 billion by 2033. This is driven by high demand across energy, power, and manufacturing sectors, fostering extensive technological advancements.

Does ConsaInsights provide customized market report data for the ultrasonic NDT equipment industry?

Yes, ConsaInsights provides customized market report data tailored to specific needs within the ultrasonic NDT equipment industry. This service enables clients to obtain insights aligned with their unique business goals and market position.

What deliverables can I expect from this ultrasonic NDT equipment market research project?

Deliverables from this market research project include comprehensive market analysis reports, segmentation data, competitor landscape insights, growth forecasts, and actionable recommendations to support strategic planning and market entry strategies.

What are the market trends of ultrasonic NDT equipment?

Current market trends in the ultrasonic NDT equipment industry include the rise of robotic automation in inspection processes, increased use of advanced NDT techniques like phased array testing, and a stronger focus on digital transformation for efficiency and accuracy.