Vacuum Furnaces Market Report

Published Date: 22 January 2026 | Report Code: vacuum-furnaces

Vacuum Furnaces Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Vacuum Furnaces market from 2023 to 2033, offering insights into market dynamics, trends, regional performance, and future forecasts, essential for stakeholders aiming to navigate this evolving industry.

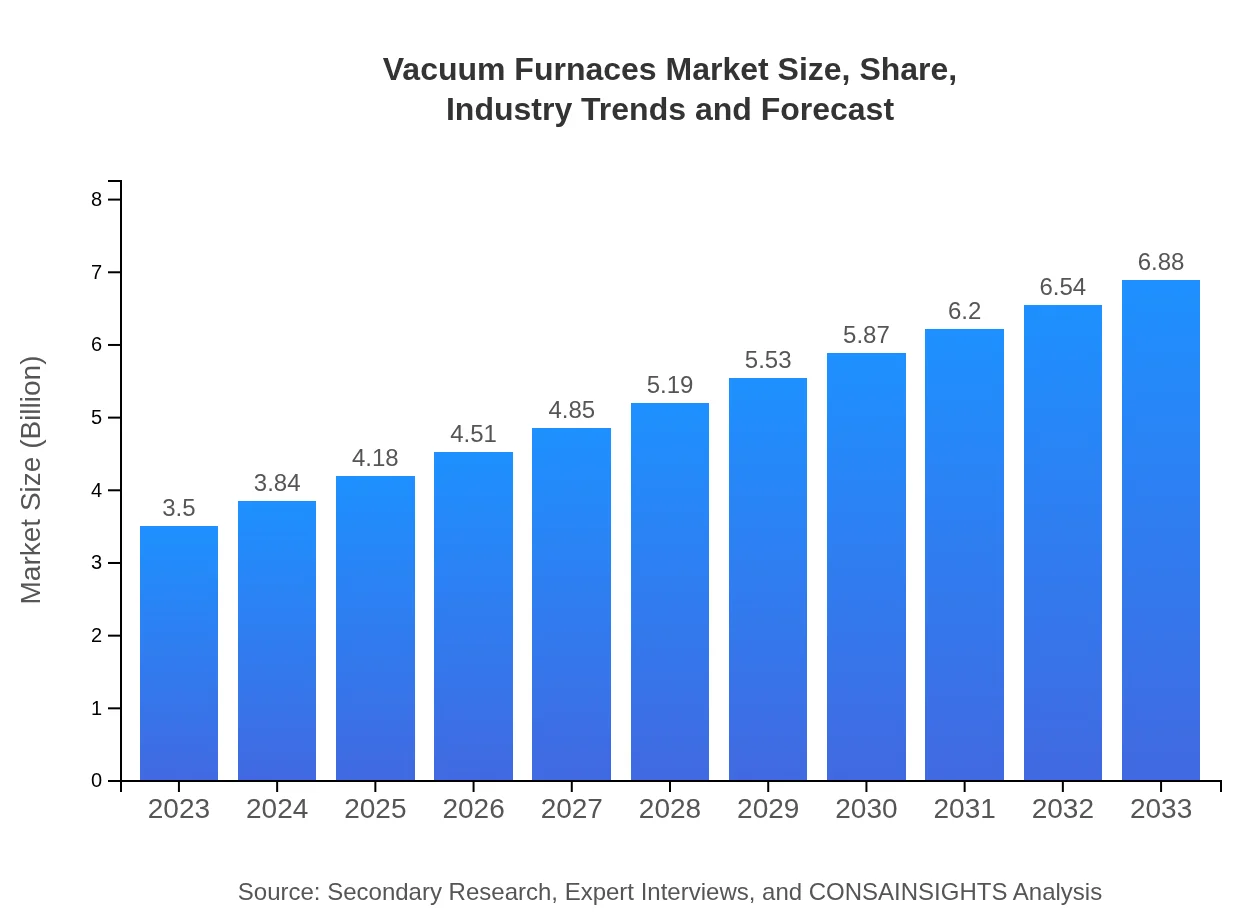

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Aubert & Duval, PVA TePla AG, Seco/Warwick |

| Last Modified Date | 22 January 2026 |

Vacuum Furnaces Market Overview

Customize Vacuum Furnaces Market Report market research report

- ✔ Get in-depth analysis of Vacuum Furnaces market size, growth, and forecasts.

- ✔ Understand Vacuum Furnaces's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Vacuum Furnaces

What is the Market Size & CAGR of Vacuum Furnaces market in 2023?

Vacuum Furnaces Industry Analysis

Vacuum Furnaces Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Vacuum Furnaces Market Analysis Report by Region

Europe Vacuum Furnaces Market Report:

In Europe, the Vacuum Furnaces market stands at $1.16 billion in 2023, with projections to achieve $2.27 billion by 2033. The presence of major automotive manufacturers and advancements in aerospace technology play a crucial role in this growth.Asia Pacific Vacuum Furnaces Market Report:

In the Asia Pacific region, the market for Vacuum Furnaces was valued at $0.59 billion in 2023, projected to reach $1.15 billion by 2033. This growth is driven by the rapid industrialization in countries like China and India, coupled with an increase in the manufacturing of aerospace and automotive components requiring high-performance materials.North America Vacuum Furnaces Market Report:

North America is a significant market for Vacuum Furnaces, with a valuation of $1.25 billion in 2023, expected to rise to $2.46 billion by 2033. The rapidly growing aerospace and defense sectors, known for high precision and quality standards, are key growth contributors.South America Vacuum Furnaces Market Report:

The South American market for Vacuum Furnaces is relatively smaller, valued at $0.20 billion in 2023, with expectations to grow to $0.39 billion by 2033. Growth in Brazil and Argentina is aided by their growing manufacturing sectors, particularly in automotive and energy applications.Middle East & Africa Vacuum Furnaces Market Report:

The Middle East and Africa market for Vacuum Furnaces is valued at approximately $0.30 billion in 2023, anticipated to reach $0.60 billion by 2033. The energy sector and growing investments in industrial manufacturing are primary drivers of this market.Tell us your focus area and get a customized research report.

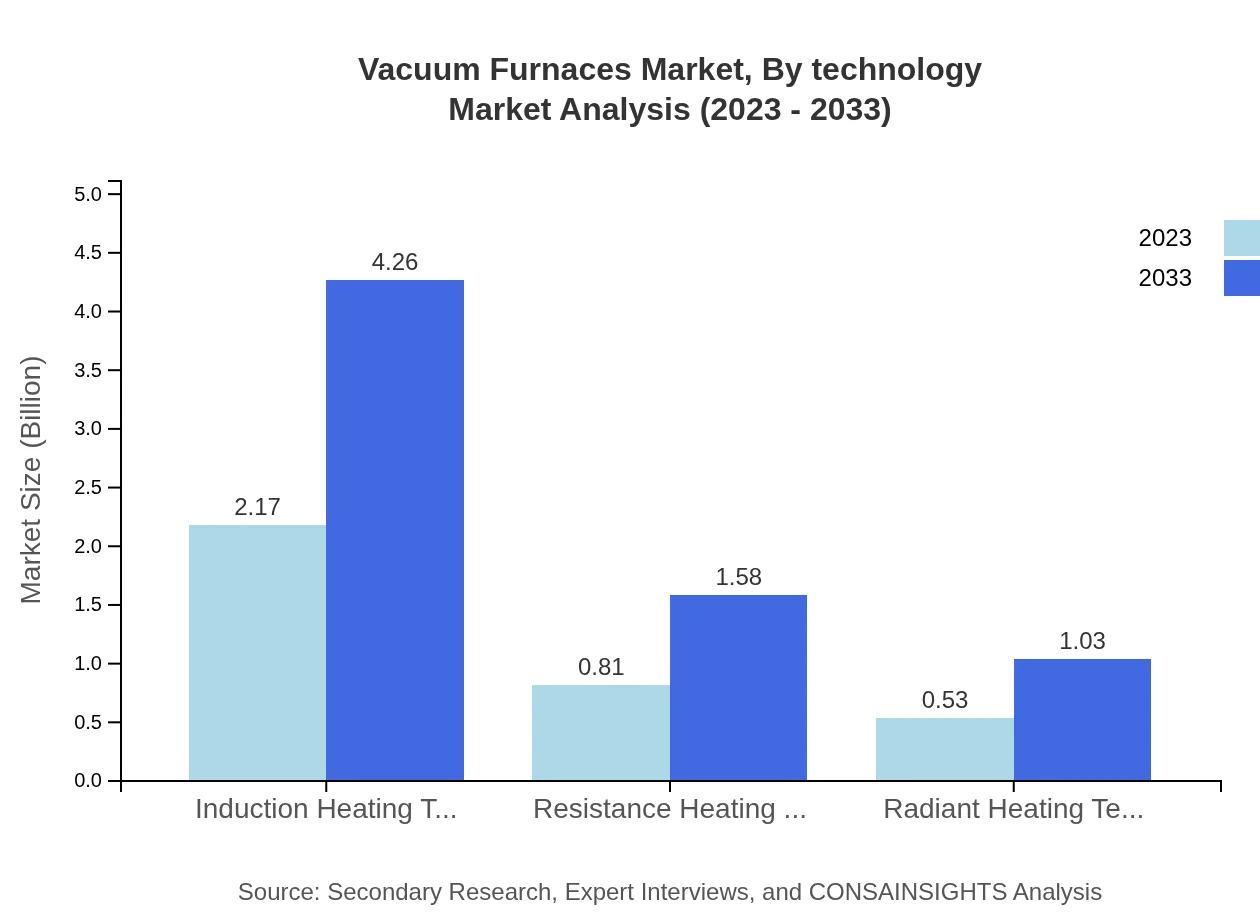

Vacuum Furnaces Market Analysis By Technology

Technologically, the Vacuum Furnaces market is dominated by Induction Heating technology, accounting for 61.98% of the market share in 2023, with a growth projection to 61.98% by 2033, underscoring its efficiency and effectiveness in thermal processing. Resistance Heating holds a 23.02% share, while Radiant Heating accounts for about 15%.

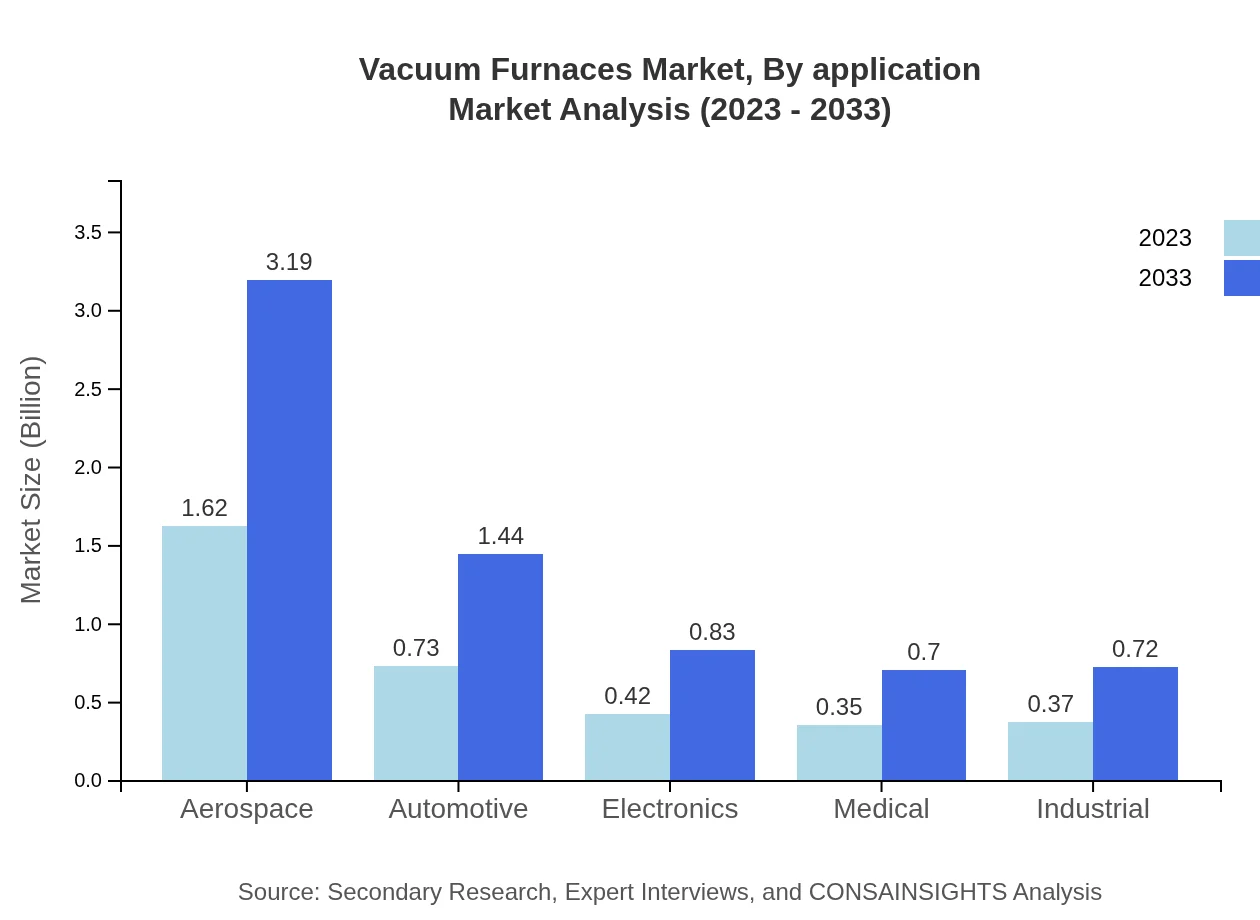

Vacuum Furnaces Market Analysis By Application

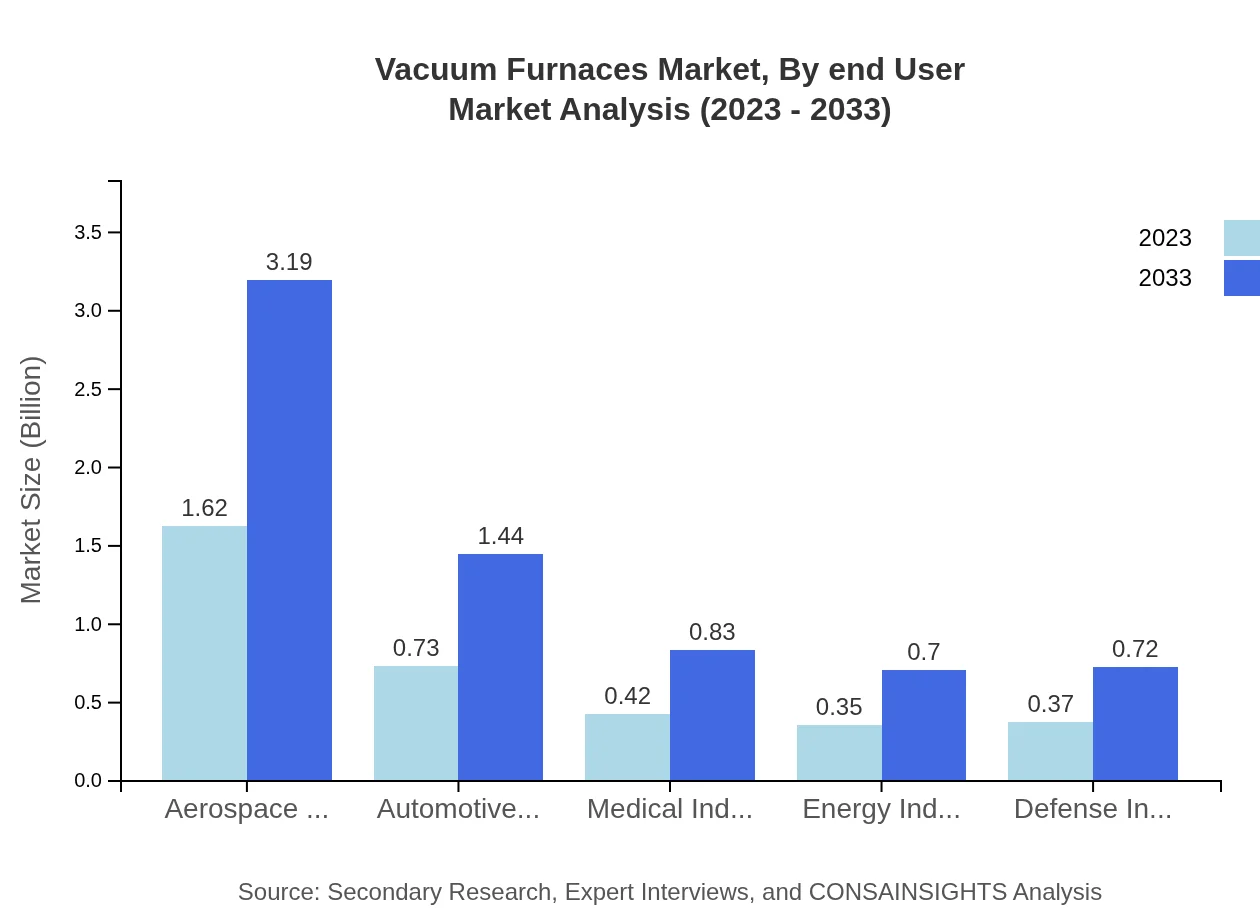

The significant applications of Vacuum Furnaces are aligned closely with industry demands. The Aerospace industry is projected to lead with a size of $1.62 billion in 2023, growing to $3.19 billion by 2033, maintaining a share of 46.35%. The Automotive and Medical industries also show promising growth, reflecting the overall trend of high-precision manufacturing.

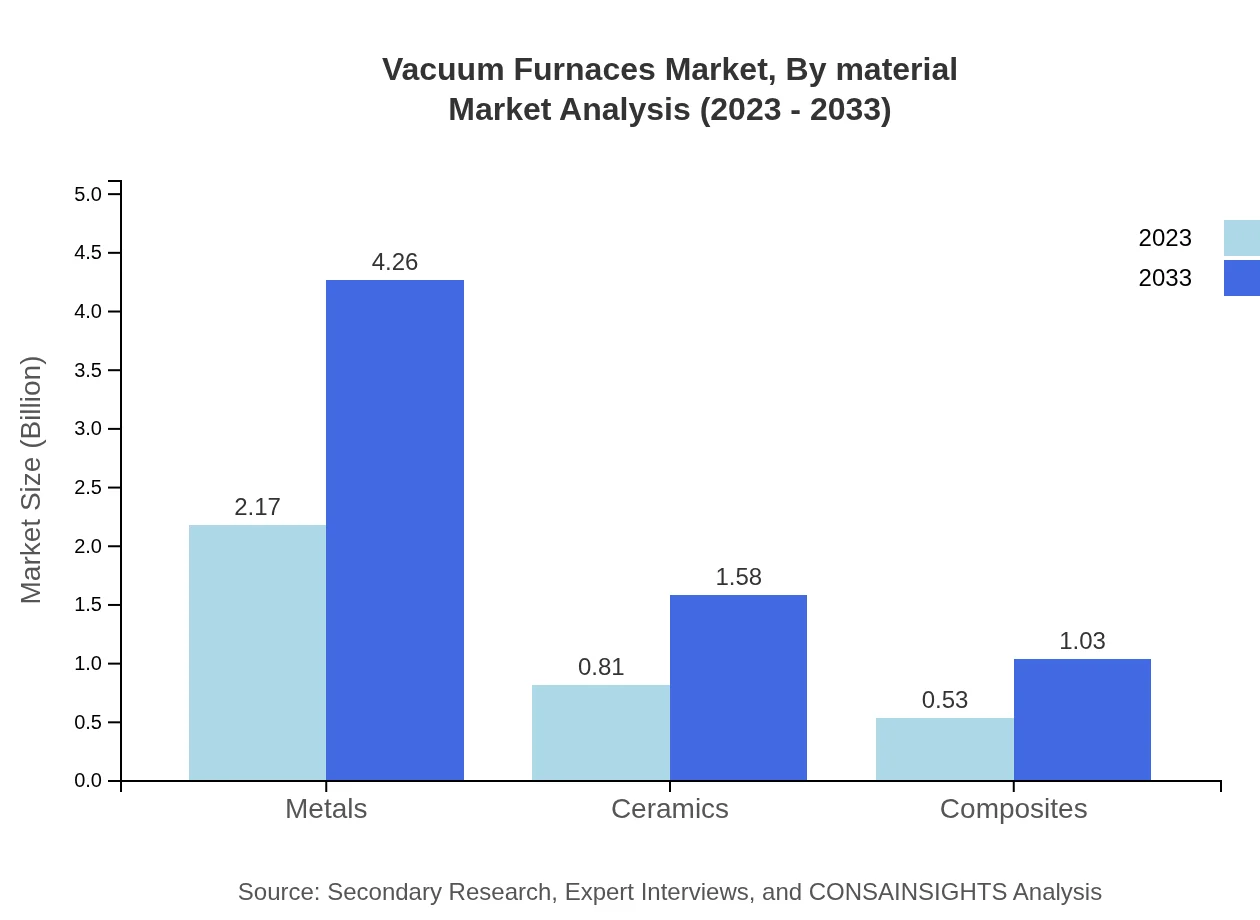

Vacuum Furnaces Market Analysis By Material

In terms of materials processed, the Metal segment leads, projected to achieve $2.17 billion in 2023, doubling to $4.26 billion by 2033, reflecting its 61.98% market share. Ceramics and Composites display significant growth as well, indicating a diversified approach to material processing in vacuum conditions.

Vacuum Furnaces Market Analysis By End User

Key industries utilizing Vacuum Furnaces include Aerospace, Automotive, Defense, and Medical sectors. Each of these industries demands specialized production methods that ensure material integrity and performance, which vacuum technology inherently supports, reflecting in their respective market shares and growth expectations.

Vacuum Furnaces Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Vacuum Furnaces Industry

Aubert & Duval:

Aubert & Duval specializes in high-performance materials and vacuum furnace solutions used primarily in aerospace and medical sectors, ensuring precision and quality.PVA TePla AG:

PVA TePla AG is a leading manufacturer of vacuum furnaces offering innovative technology solutions for various sectors, emphasizing advanced thermal processing.Seco/Warwick:

Seco/Warwick provides comprehensive vacuum furnace solution packages tailored to meet customer needs in aerospace, automotive, and defense industries.We're grateful to work with incredible clients.

FAQs

What is the market size of vacuum Furnaces?

The global vacuum furnaces market is currently valued at approximately $3.5 billion, with an expected compound annual growth rate (CAGR) of 6.8%, indicating robust growth through to 2033.

What are the key market players or companies in this vacuum Furnaces industry?

Key players in the vacuum furnaces market include leading manufacturers and technology providers focused on delivering advanced heating solutions for metal processing, aerospace, automotive, and more.

What are the primary factors driving the growth in the vacuum furnaces industry?

Factors driving growth include increased demand for high-quality manufacturing processes, advancements in materials technology, and a growing emphasis on energy efficiency and sustainability across various industries.

Which region is the fastest Growing in the vacuum furnaces market?

The fastest-growing region in the vacuum furnaces market is expected to be Europe, with market projections increasing from $1.16 billion in 2023 to $2.27 billion by 2033.

Does ConsaInsights provide customized market report data for the vacuum Furnaces industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the vacuum furnaces industry, allowing for comprehensive analysis and insights.

What deliverables can I expect from this vacuum Furnaces market research project?

Deliverables include comprehensive market analysis, trend forecasting, competitive landscape overviews, and segmented data across regions and industries relevant to vacuum furnaces.

What are the market trends of vacuum Furnaces?

Current market trends include technological advancements in heating methods, rising demand in aerospace and automotive sectors, and increasing adoption of vacuum technology for material processing.