Waterjet Cutting Machine Market Report

Published Date: 22 January 2026 | Report Code: waterjet-cutting-machine

Waterjet Cutting Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Waterjet Cutting Machine market from 2023 to 2033, highlighting current trends, market size, forecasts, and key players within the industry.

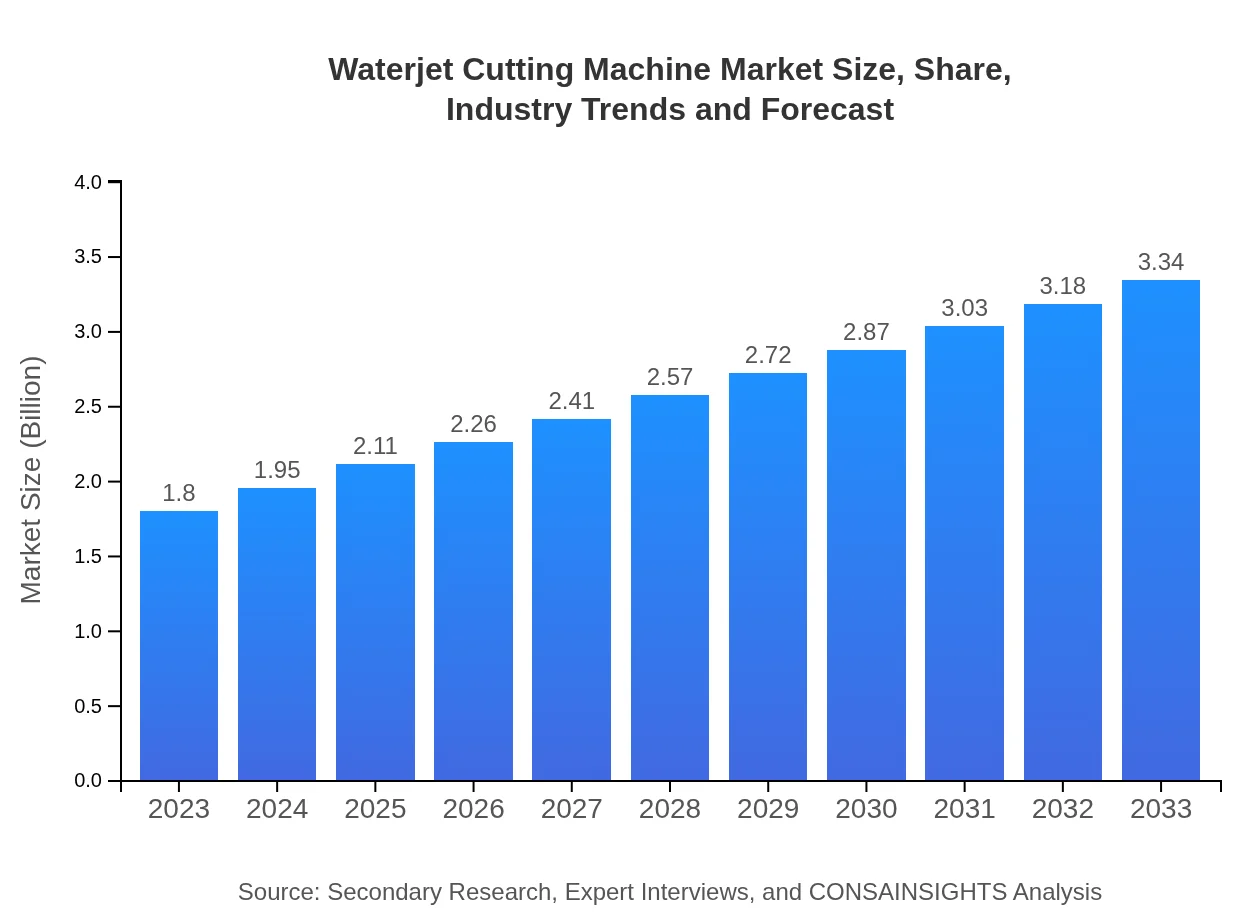

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $3.34 Billion |

| Top Companies | KMT Waterjet Systems, Jet Edge Inc., Omax Corporation, Flow International Corporation |

| Last Modified Date | 22 January 2026 |

Waterjet Cutting Machine Market Overview

Customize Waterjet Cutting Machine Market Report market research report

- ✔ Get in-depth analysis of Waterjet Cutting Machine market size, growth, and forecasts.

- ✔ Understand Waterjet Cutting Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Waterjet Cutting Machine

What is the Market Size & CAGR of Waterjet Cutting Machine market in 2023?

Waterjet Cutting Machine Industry Analysis

Waterjet Cutting Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Waterjet Cutting Machine Market Analysis Report by Region

Europe Waterjet Cutting Machine Market Report:

Europe's market is anticipated to expand from $0.56 billion in 2023 to $1.04 billion by 2033, with countries like Germany and the UK showing significant investments in advanced manufacturing technologies and sustainability efforts.Asia Pacific Waterjet Cutting Machine Market Report:

In the Asia Pacific region, the Waterjet Cutting Machine market is projected to grow from $0.31 billion in 2023 to $0.57 billion by 2033. The growth is driven by rising manufacturing activities in countries like China and India, coupled with an increasing adoption of automation technologies.North America Waterjet Cutting Machine Market Report:

North America is poised for substantial growth, with market size rising from $0.69 billion in 2023 to $1.29 billion in 2033. The United States is leading this growth through strong demand in aerospace and automotive sectors, propelled by technological advancements and investments.South America Waterjet Cutting Machine Market Report:

The South American market is expected to see growth from $0.17 billion in 2023 to $0.31 billion in 2033. Brazil and Argentina are likely to be significant contributors, driven by increasing construction and mining activities that require precise cutting solutions.Middle East & Africa Waterjet Cutting Machine Market Report:

The Middle East and Africa region is projected to grow from $0.07 billion in 2023 to $0.13 billion in 2033. The growth is primarily fueled by increasing infrastructural developments and a rising need for precise industrial operations.Tell us your focus area and get a customized research report.

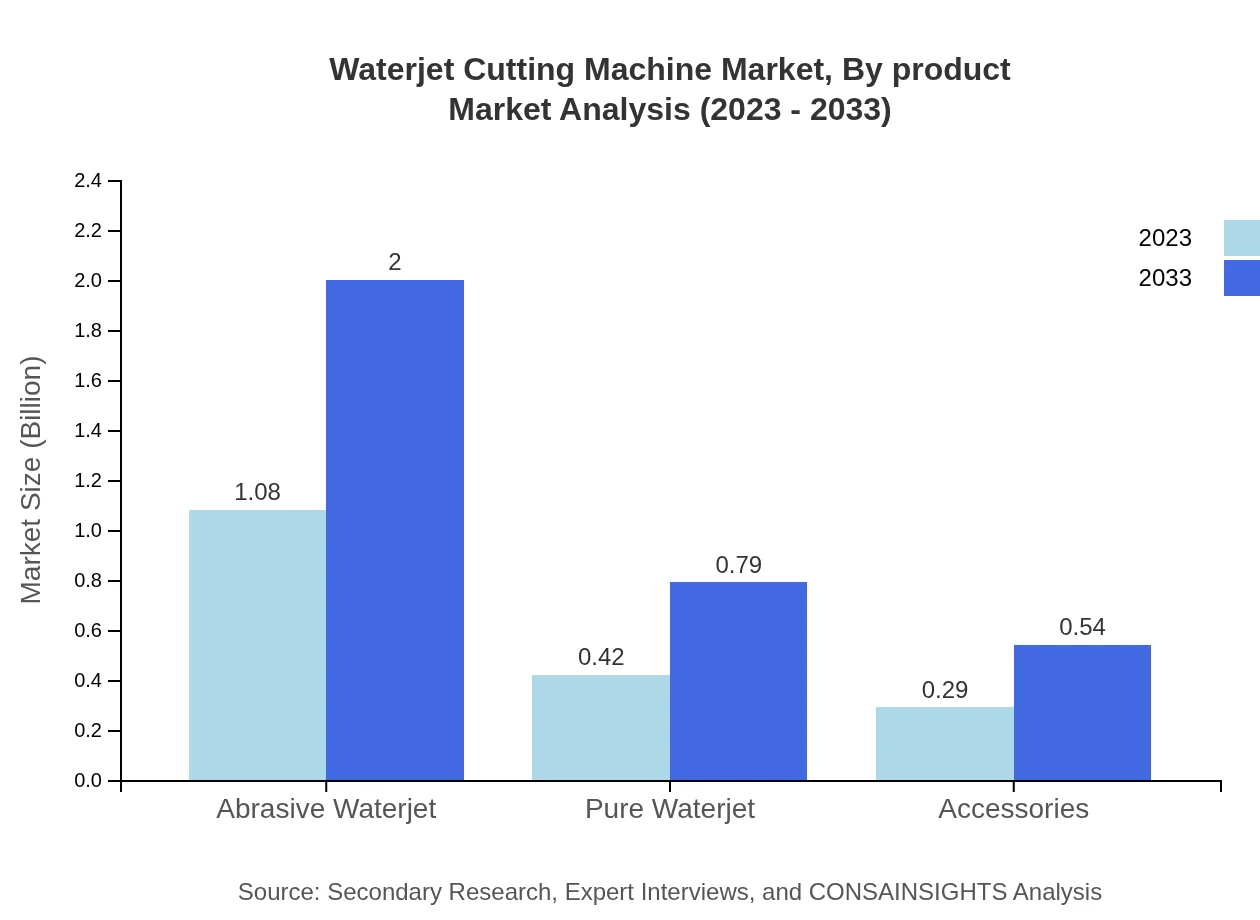

Waterjet Cutting Machine Market Analysis By Product

The product segmentation includes Abrasive Waterjet and Pure Waterjet systems, which are highly regarded for their usability across several applications. In 2023, the market for Abrasive Waterjet is valued at $1.08 billion, expected to double to $2.00 billion by 2033, maintaining a 60.11% market share. The Pure Waterjet segment, valued at $0.42 billion in 2023, is projected to grow to $0.79 billion by 2033, constituting 23.6% of the market.

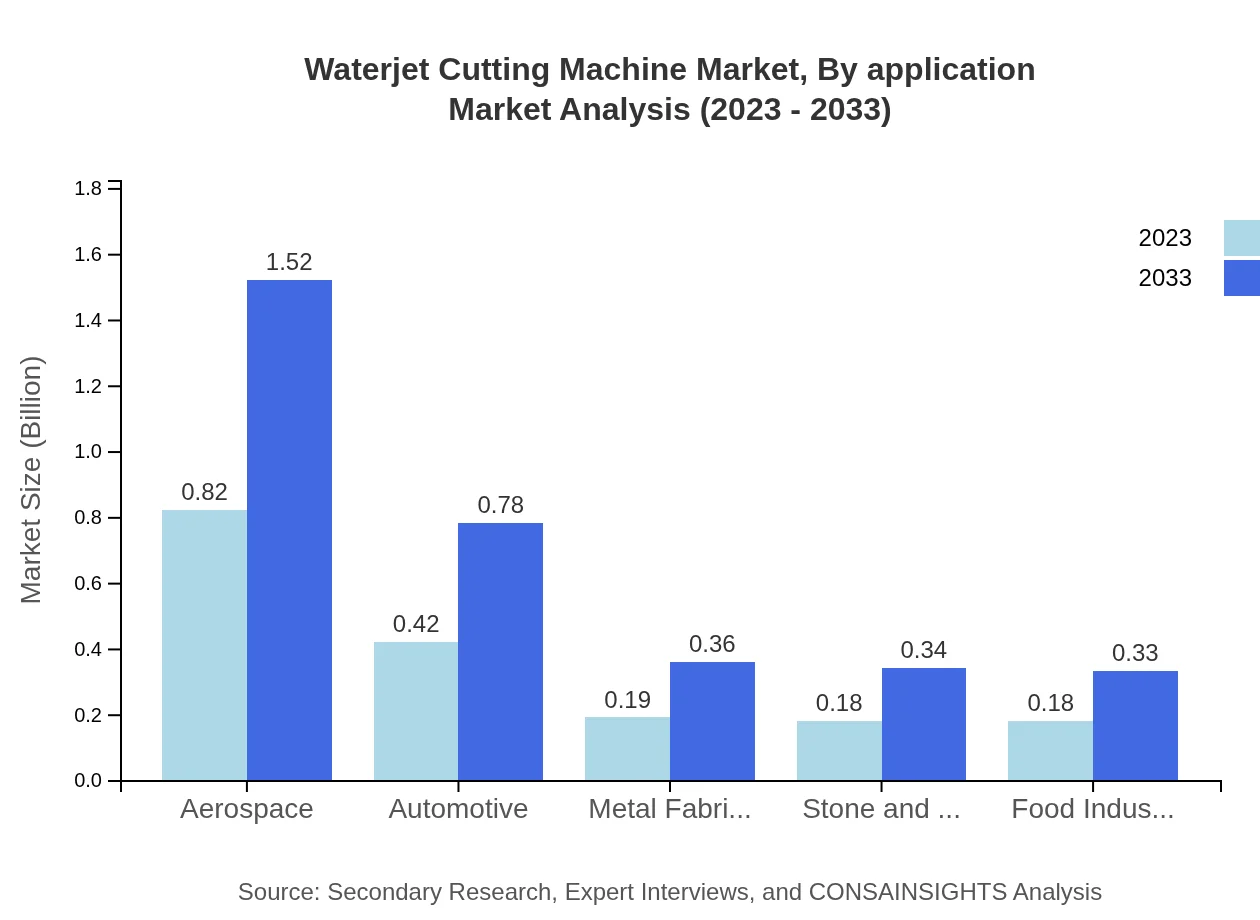

Waterjet Cutting Machine Market Analysis By Application

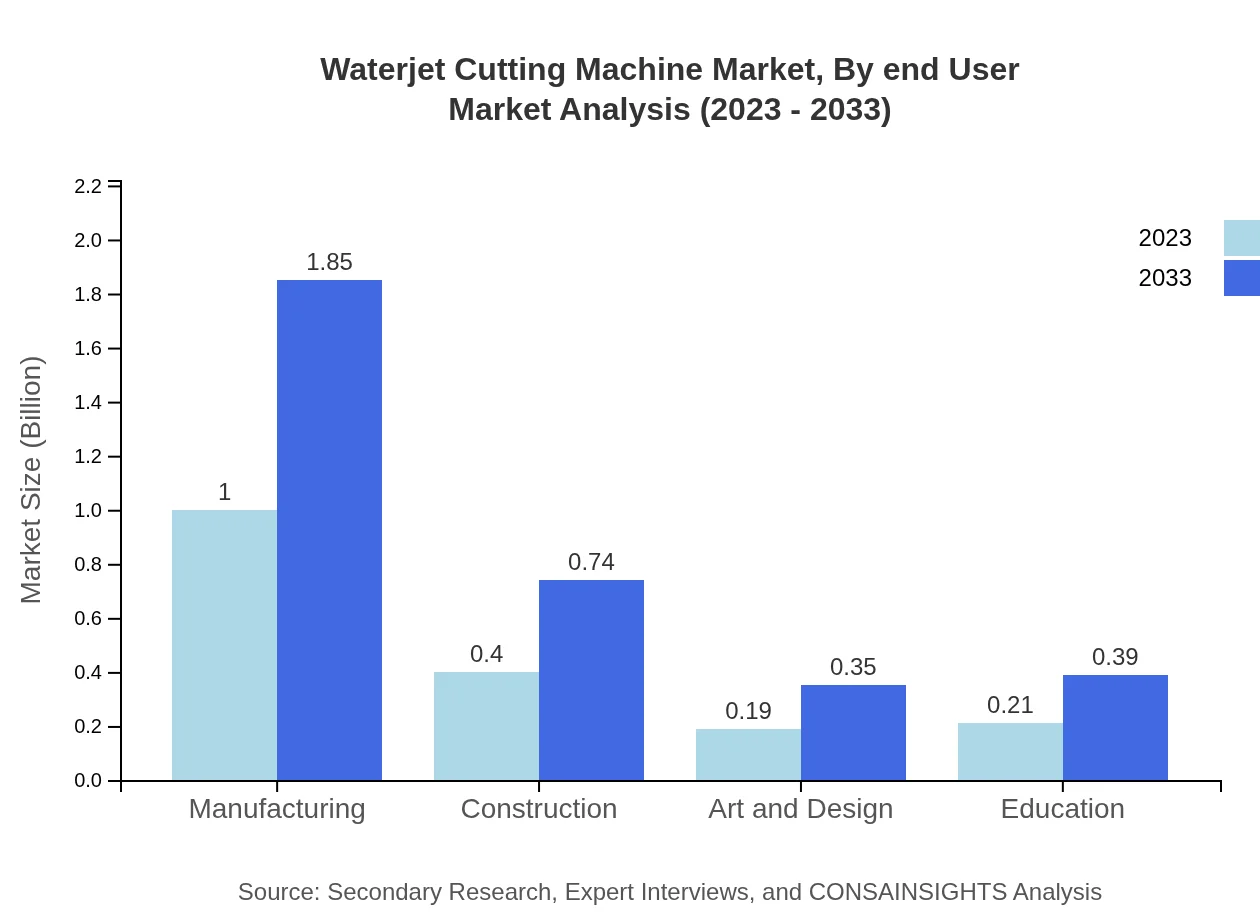

Applications of waterjet cutting span various industries. In manufacturing, the segment holds the largest market share at 55.6%, with projected growth from $1.00 billion in 2023 to $1.85 billion by 2033. The construction segment, holding a 22.18% share, is expected to grow significantly as construction activities surge globally.

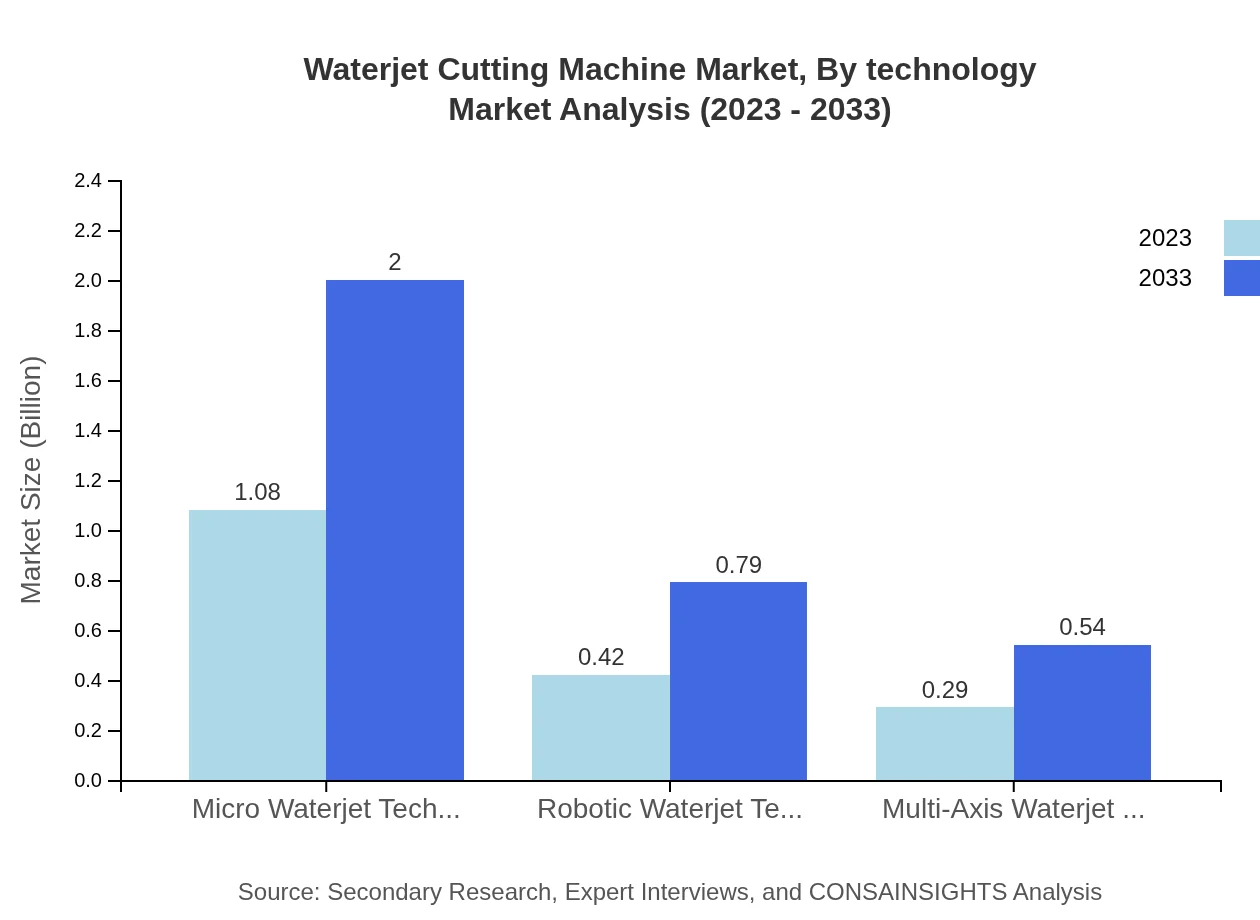

Waterjet Cutting Machine Market Analysis By Technology

Emerging technologies, such as Micro Waterjet and Robotic Waterjet Technology, are gaining traction. Micro Waterjet is expected to maintain dominance with a valuation soaring from $1.08 billion in 2023 to $2.00 billion by 2033, commanding a market share of 60.11%. Robotic Waterjet is also expected to see good growth, increasing from $0.42 billion to $0.79 billion in the same period, maintaining a 23.6% share.

Waterjet Cutting Machine Market Analysis By End User

End-user industries include Aerospace, Automotive, and Metal Fabrication among others. The aerospace sector leads with a 45.71% share, growing from $0.82 billion in 2023 to $1.52 billion by 2033, driven by the continuous quest for advanced materials in the aircraft manufacturing process.

Waterjet Cutting Machine Market Analysis By Distribution Channel

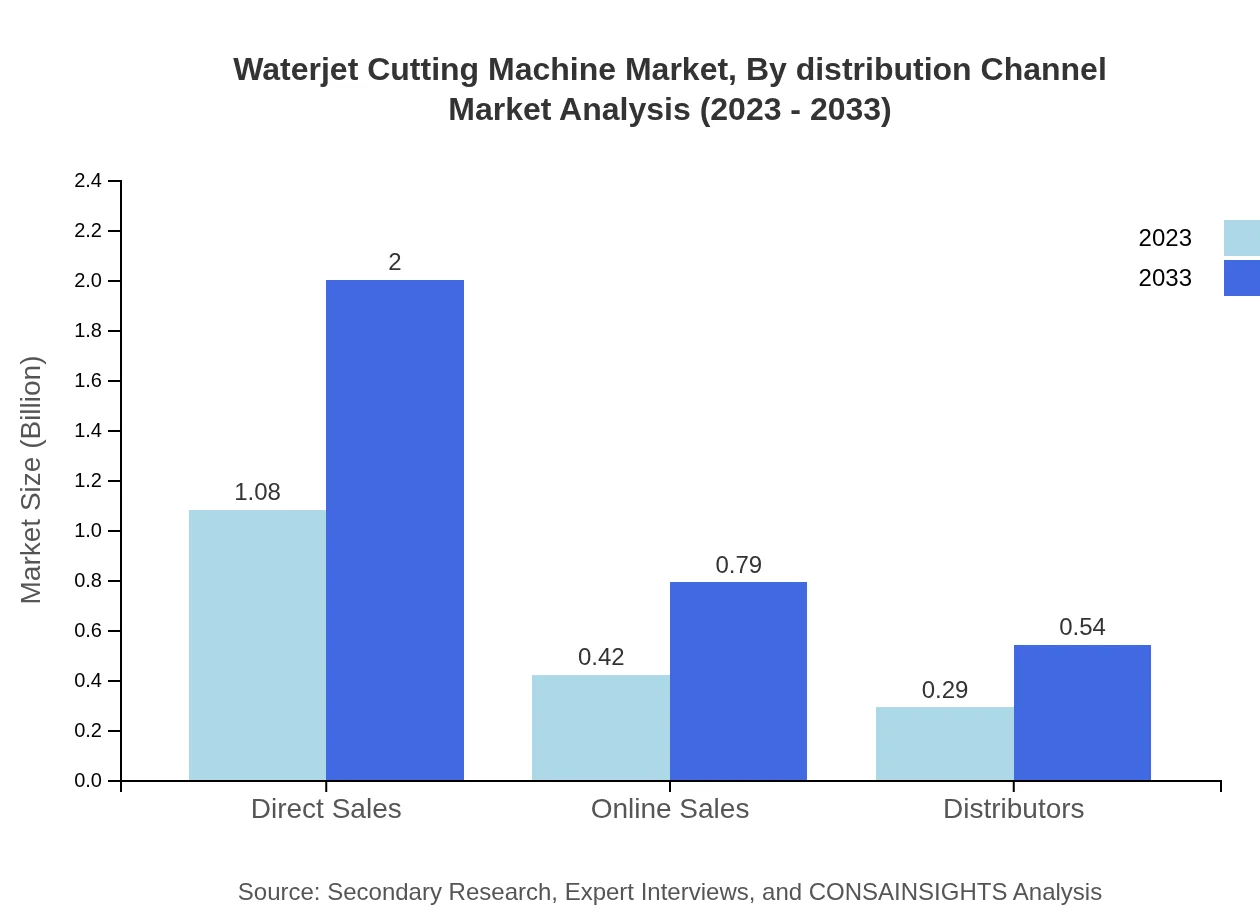

Distribution channels consist of Direct Sales, Online Sales, and Distributors. Direct Sales is the dominant channel, with a market size anticipating growth from $1.08 billion in 2023 to $2.00 billion in 2033, while Online Sales will also show considerable growth, expanding from $0.42 billion to $0.79 billion.

Waterjet Cutting Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Waterjet Cutting Machine Industry

KMT Waterjet Systems:

A leading provider of waterjet systems and components, known for innovation and high-quality machinery.Jet Edge Inc.:

Specializes in precision waterjet cutting systems and is recognized for advanced technology and customer-centric solutions.Omax Corporation:

Pioneers in waterjet technology, offering versatile solutions and robust systems suited for various industries.Flow International Corporation:

A key player in delivering cutting-edge waterjet technology, focusing on improving efficiency and performance.We're grateful to work with incredible clients.

FAQs

What is the market size of waterjet Cutting Machine?

The Waterjet Cutting Machine market is valued at $1.8 billion in 2023 and is projected to reach significant growth with a CAGR of 6.2%. By 2033, the market will expand, reflecting increasing demand in various industries.

What are the key market players or companies in this waterjet Cutting Machine industry?

Leading companies in the waterjet cutting machine market include KMT Waterjet Systems, Omax Corporation, and Flow International Corporation. These players are pivotal in driving innovation and maintaining competitive advantage in the industry.

What are the primary factors driving the growth in the waterjet Cutting Machine industry?

Key growth drivers include increased demand for precise cutting techniques in manufacturing, advancements in technology, and the growing need for automation across various sectors such as aerospace, automotive, and construction.

Which region is the fastest Growing in the waterjet Cutting Machine market?

North America is currently the fastest-growing region, expected to grow from $0.69 billion in 2023 to $1.29 billion by 2033. This expansion is fueled by technological advancements and rising industrial activities.

Does ConsaInsights provide customized market report data for the waterjet Cutting Machine industry?

Yes, ConsaInsights offers tailored market reports that cater to specific needs in the waterjet cutting machine industry, ensuring clients receive precise data and insights relevant to their business requirements.

What deliverables can I expect from this waterjet Cutting Machine market research project?

Clients can expect comprehensive reports detailing market size, segments, trends, and competitive analysis. Additional insights on regional growth and forecasts will also be included to guide strategic decisions.

What are the market trends of the waterjet Cutting Machine industry?

Current market trends are characterized by an increase in automation, the integration of advanced technologies, and a rising preference for environmentally sustainable manufacturing processes across multiple industries.