X Ray Inspection System Market Report

Published Date: 22 January 2026 | Report Code: x-ray-inspection-system

X Ray Inspection System Market Size, Share, Industry Trends and Forecast to 2033

This report presents a comprehensive analysis of the X Ray Inspection System market from 2023 to 2033, focusing on market size, trends, and forecasts, while also providing valuable insights on key players and regional performances.

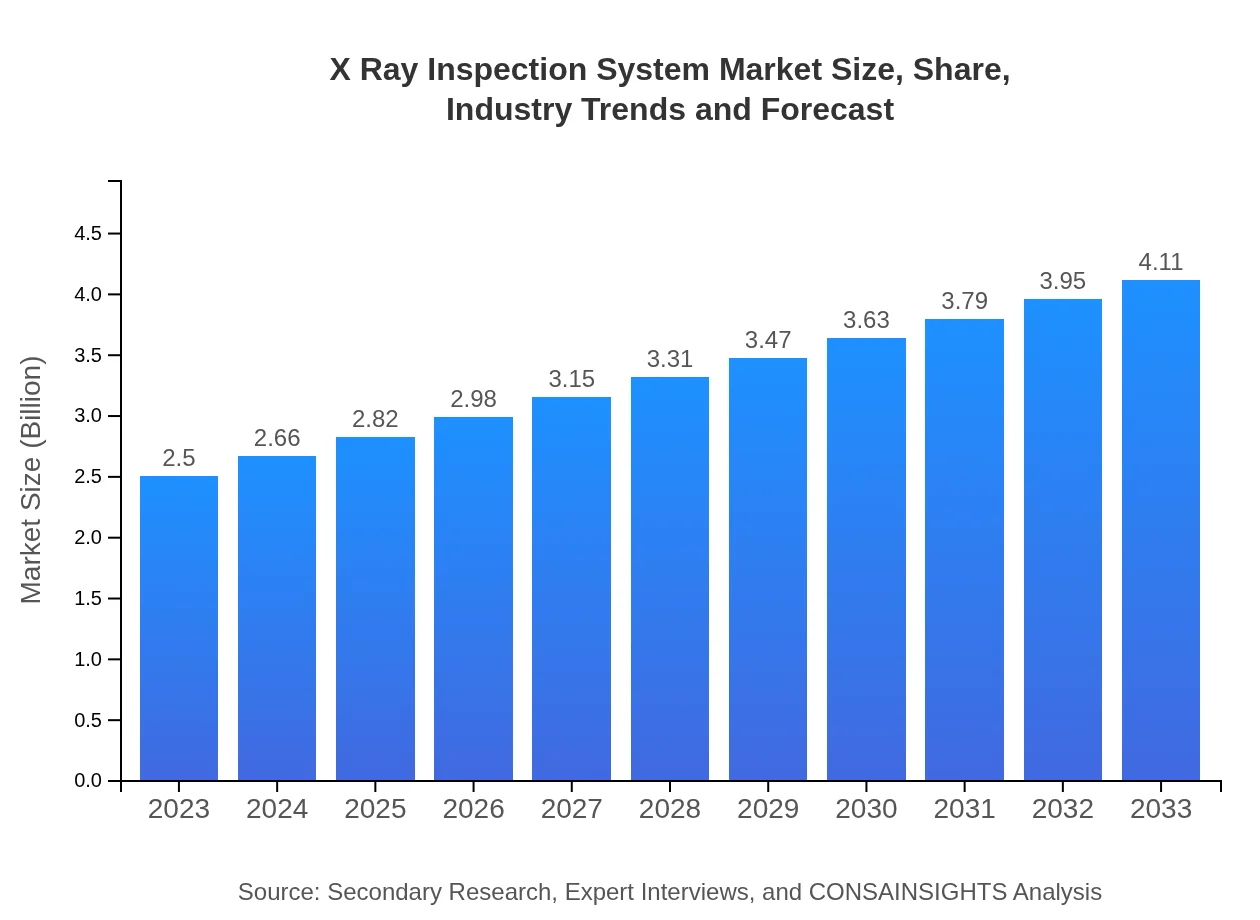

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $4.11 Billion |

| Top Companies | General Electric, Smiths Detection, Zeiss |

| Last Modified Date | 22 January 2026 |

X Ray Inspection System Market Overview

Customize X Ray Inspection System Market Report market research report

- ✔ Get in-depth analysis of X Ray Inspection System market size, growth, and forecasts.

- ✔ Understand X Ray Inspection System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in X Ray Inspection System

What is the Market Size & CAGR of X Ray Inspection System market in 2023?

X Ray Inspection System Industry Analysis

X Ray Inspection System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

X Ray Inspection System Market Analysis Report by Region

Europe X Ray Inspection System Market Report:

Europe is another critical market, where the X Ray Inspection System is expected to grow from a value of $0.75 billion in 2023 to approximately $1.23 billion by 2033. The region's focus on quality assurance and safety, alongside increasing technological adoption in industries, bolsters the market in this area.Asia Pacific X Ray Inspection System Market Report:

The Asia Pacific region is poised for substantial growth, driven by escalating industrialization and increasing safety regulations. In 2023, the market is valued at approximately $0.47 billion, with a projected growth to $0.77 billion by 2033, showcasing its expanding manufacturing and healthcare sectors that rely on advanced inspection systems.North America X Ray Inspection System Market Report:

North America holds a prominent position in the X Ray Inspection System market, with a market value of $0.91 billion in 2023, growing to $1.50 billion by 2033. This is attributed to robust end-user sectors including aerospace, manufacturing, and healthcare, coupled with rigorous regulatory standards encouraging advanced inspection methods.South America X Ray Inspection System Market Report:

In South America, the X Ray Inspection System market is steadily growing, valued at $0.21 billion in 2023 and expected to reach $0.35 billion by 2033. The rise in infrastructure projects and the need for enhanced security measures contribute significantly to this growth, alongside increasing adoption in healthcare applications.Middle East & Africa X Ray Inspection System Market Report:

The Middle East and Africa region, though smaller in terms of market size at $0.16 billion in 2023, is expected to grow to $0.27 billion by 2033. Factors such as increasing security concerns and industrial development drive this market, particularly in security-related applications.Tell us your focus area and get a customized research report.

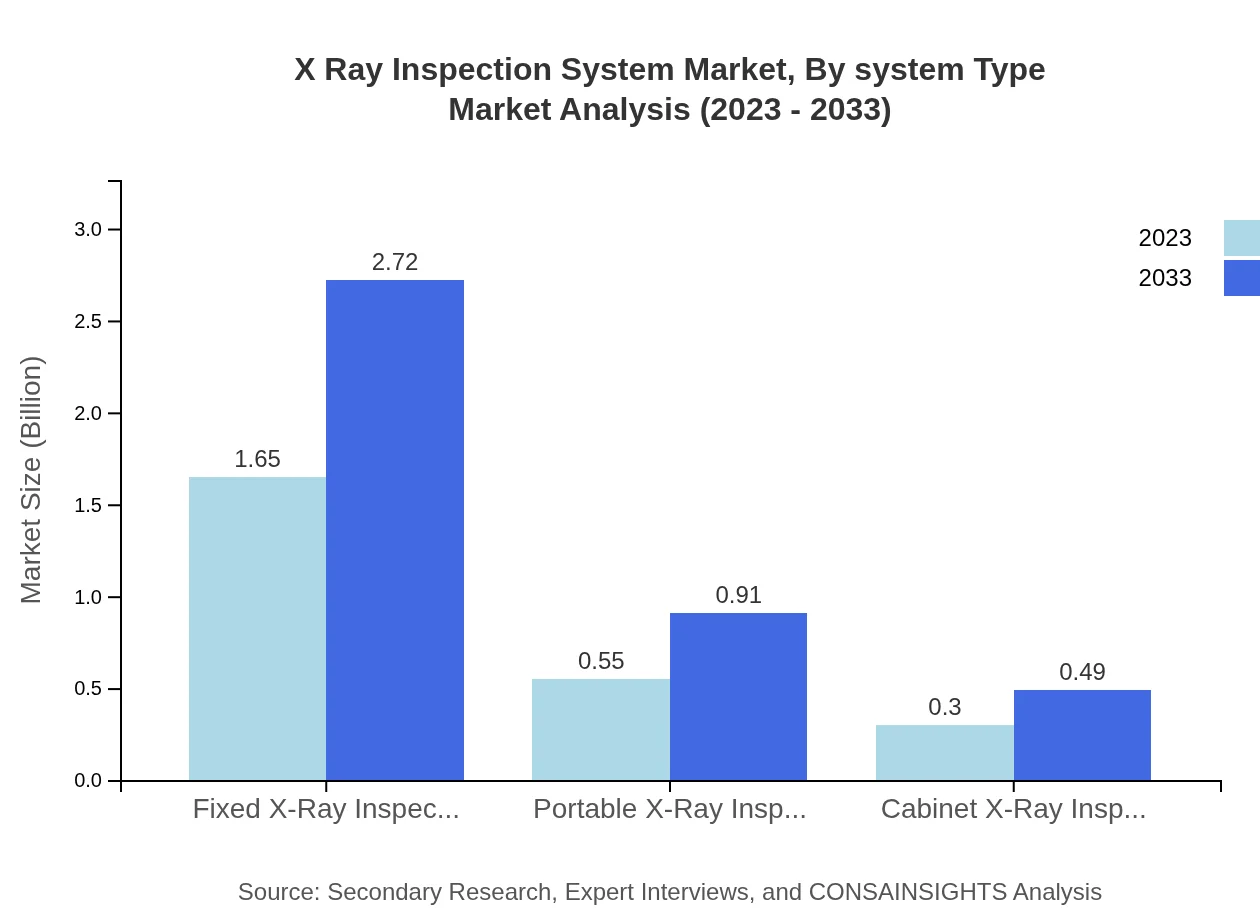

X Ray Inspection System Market Analysis By System Type

The X Ray Inspection System market, segmented by system type, has significant representation from Fixed X-Ray Inspection Systems, which dominate the market with a value of $1.65 billion in 2023 and are projected to grow to $2.72 billion by 2033, holding approximately 66.13% market share. Portable systems and Cabinet Systems also contribute notably to the market, with respective growth driven by specific application requirements, estimated at $0.55 billion and $0.30 billion in 2023, growing to $0.91 billion and $0.49 billion by 2033.

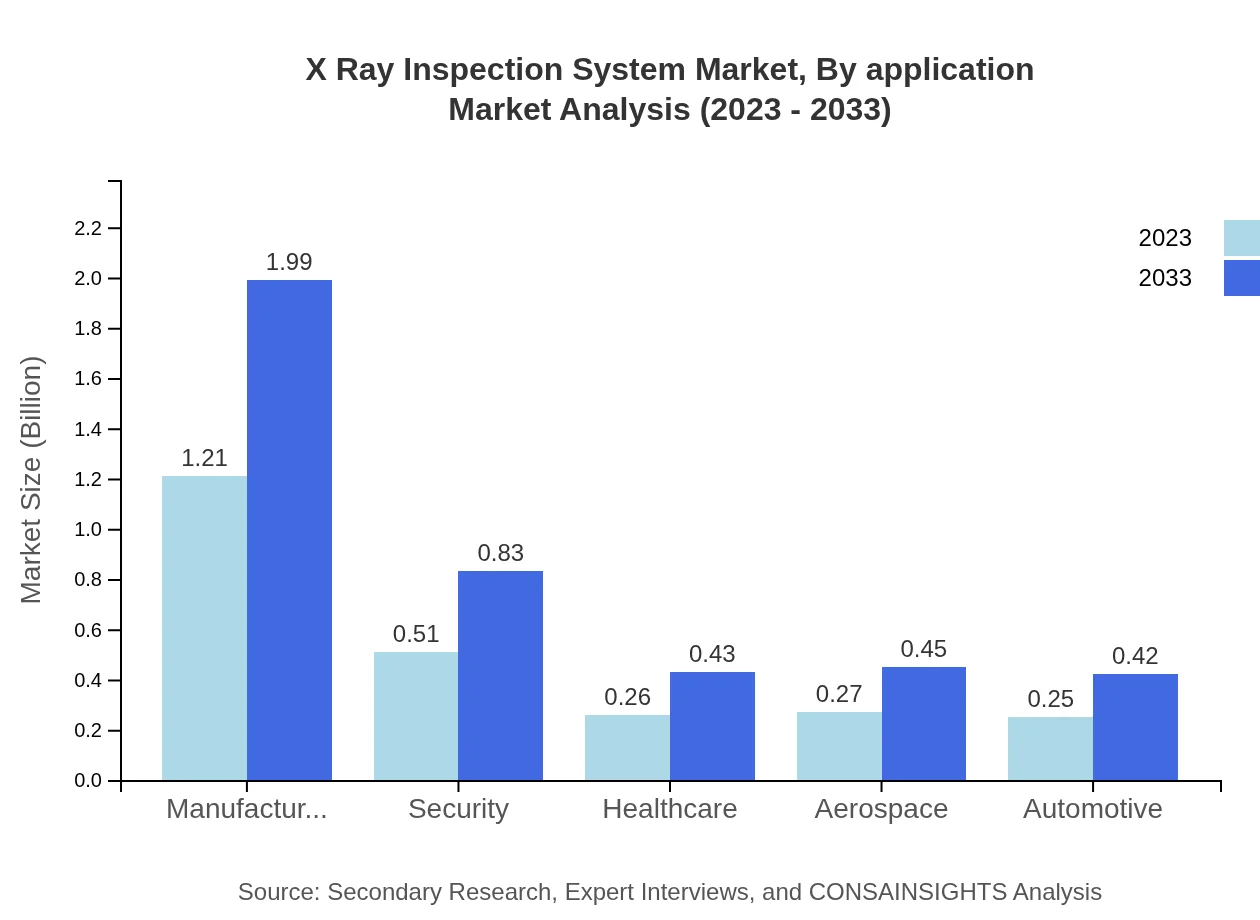

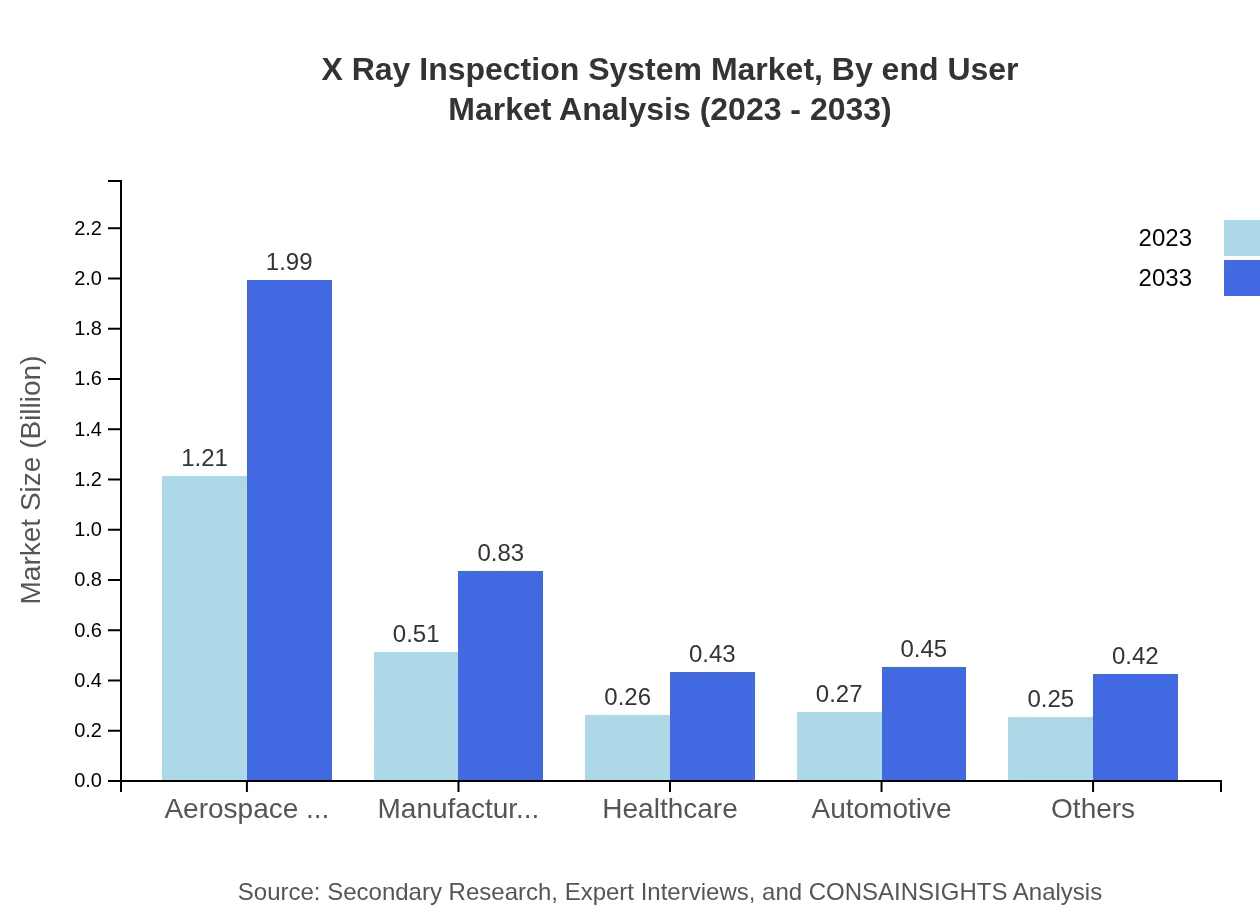

X Ray Inspection System Market Analysis By Application

By application, the Aerospace and Defense segment leads the market with a valuation of $1.21 billion in 2023 and a projected growth to $1.99 billion by 2033, reflecting its critical role in quality inspections and safety compliance. The Manufacturing sector also demonstrates strong performance, starting at $0.51 billion and expanding to $0.83 billion by 2033, while Healthcare accounts for $0.26 billion, increasing to $0.43 billion. The Automotive and Security segments present similar trends, showcasing the expanding utilization of X-Ray Inspection technology for inspection and quality control.

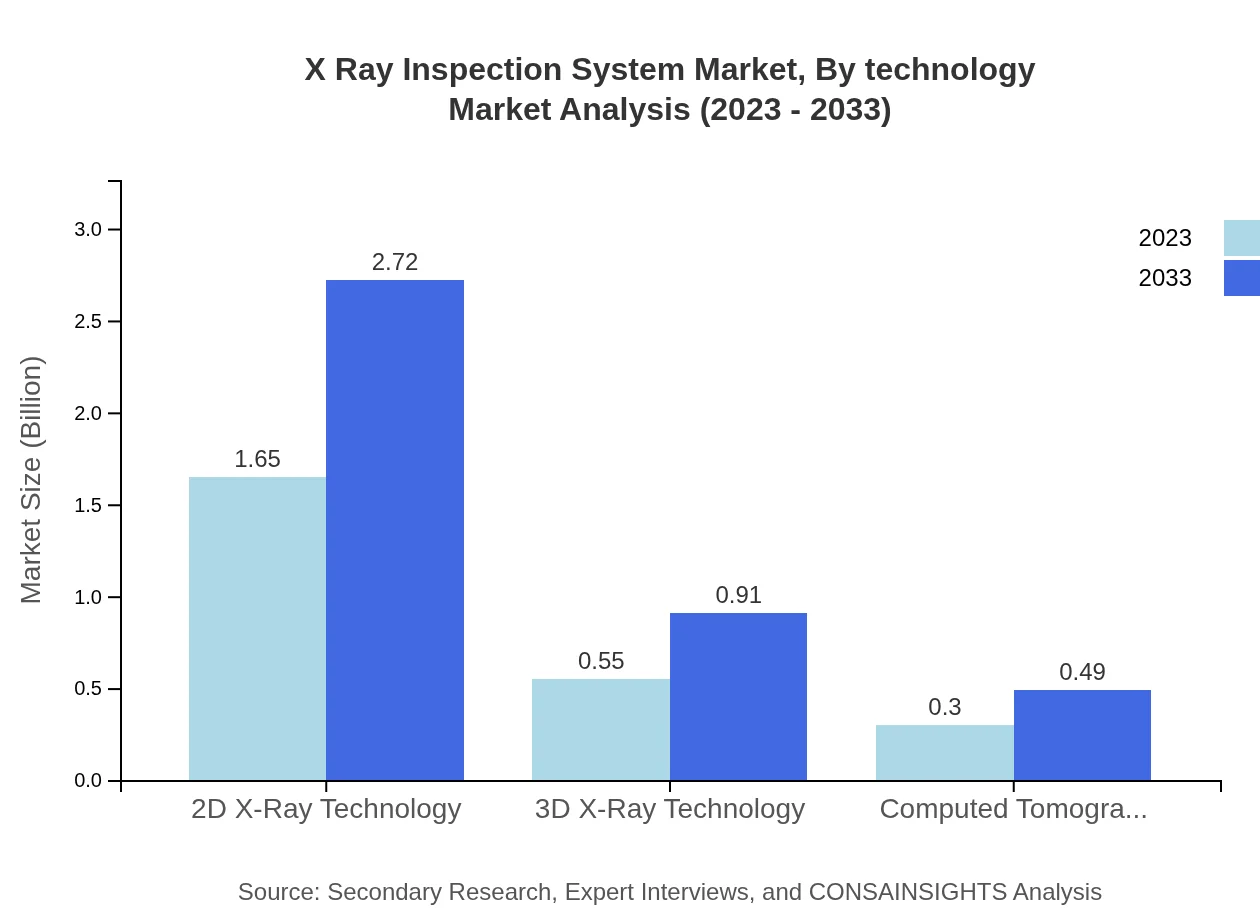

X Ray Inspection System Market Analysis By Technology

The technology segment reveals that 2D X-Ray Technology maintains a substantial market share of 66.13%, valued at $1.65 billion in 2023 and expected to rise to $2.72 billion by 2033. 3D X-Ray Technology follows, representing significant innovation, with market values of $0.55 billion in 2023, likely reaching $0.91 billion by 2033. Computed Tomography has a smaller share, valued at $0.30 billion in 2023 and anticipated to rise to $0.49 billion, but it remains an important part of advanced inspection processes.

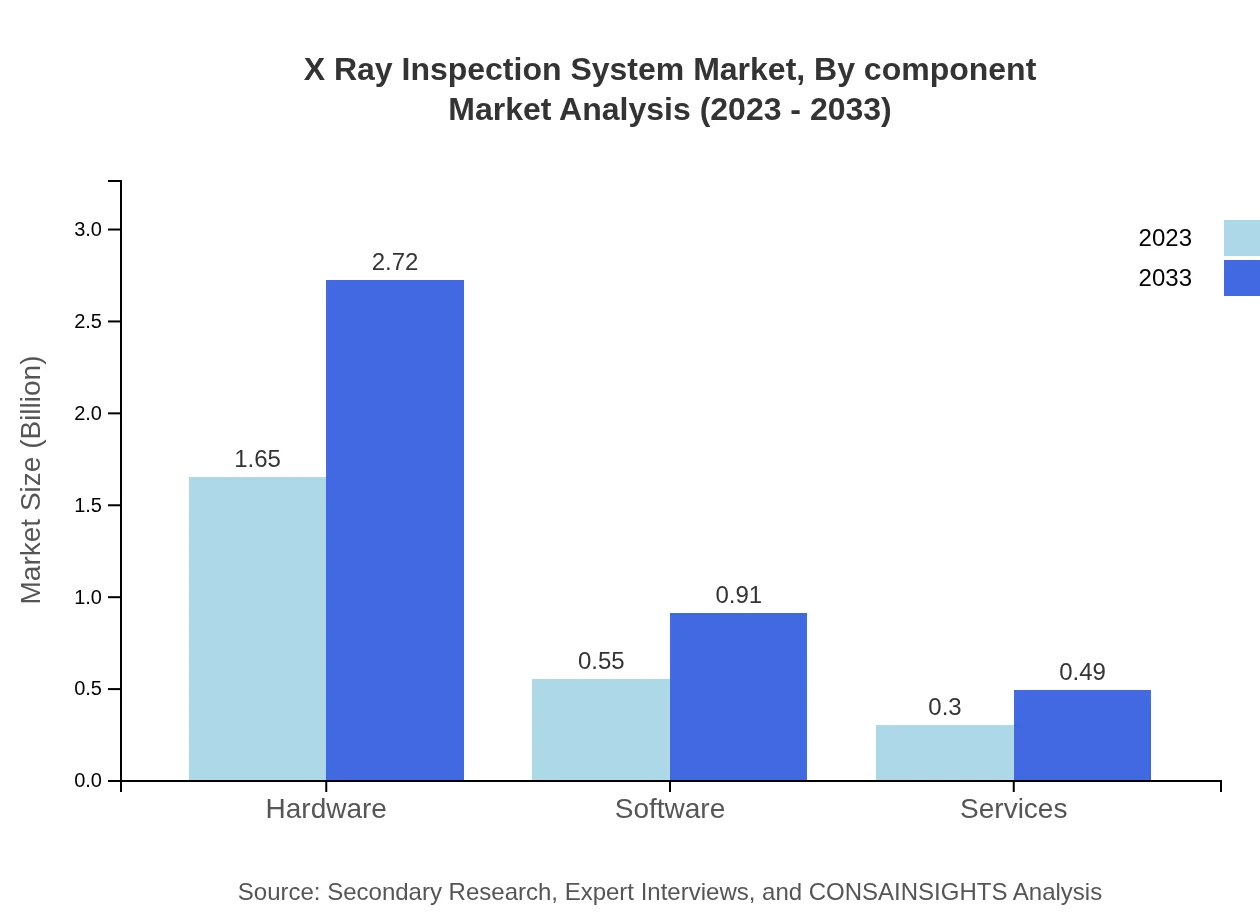

X Ray Inspection System Market Analysis By Component

In terms of components, the Hardware segment dominates the market with a size of $1.65 billion in 2023 and is projected to reach $2.72 billion by 2033, representing a significant share of 66.13%. Software and services are also crucial contributors to the ecosystem, with respective market sizes of $0.55 billion and $0.30 billion in 2023, anticipated to grow to $0.91 billion and $0.49 billion through 2033. This indicates a trend toward integrated solutions combining hardware and software for efficient inspections.

X Ray Inspection System Market Analysis By End User

The end-user analysis shows that industries such as Manufacturing and Aerospace consume the lion's share of X-Ray Inspection Systems. Manufacturing accounts for around 48.28% of the market, growing from $1.21 billion to $1.99 billion between 2023 and 2033. The Aerospace segment also holds substantial market share at approximately 10.95% from $0.27 billion in 2023 to $0.45 billion by 2033, illustrating the necessity of quality checks in critical sectors.

X Ray Inspection System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in X Ray Inspection System Industry

General Electric:

General Electric is a leading global provider of X-Ray inspection technologies, focusing on innovations that enhance inspection capabilities across industries, especially healthcare and manufacturing.Smiths Detection:

Smiths Detection specializes in providing advanced security screening technology, including X-Ray inspection systems used extensively in airports and border control.Zeiss:

Zeiss integrates advanced imaging technology into its X-Ray inspection systems, catering to sectors such as aerospace and automotive, focusing on precise measurement and control.We're grateful to work with incredible clients.