Xray Detector For Nondestructive Testing Market Report

Published Date: 31 January 2026 | Report Code: xray-detector-for-nondestructive-testing

Xray Detector For Nondestructive Testing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Xray Detector for Nondestructive Testing market from 2023 to 2033, including insights into market size, growth projections, segmentation, regional analysis, industry trends, key players, and future forecasts.

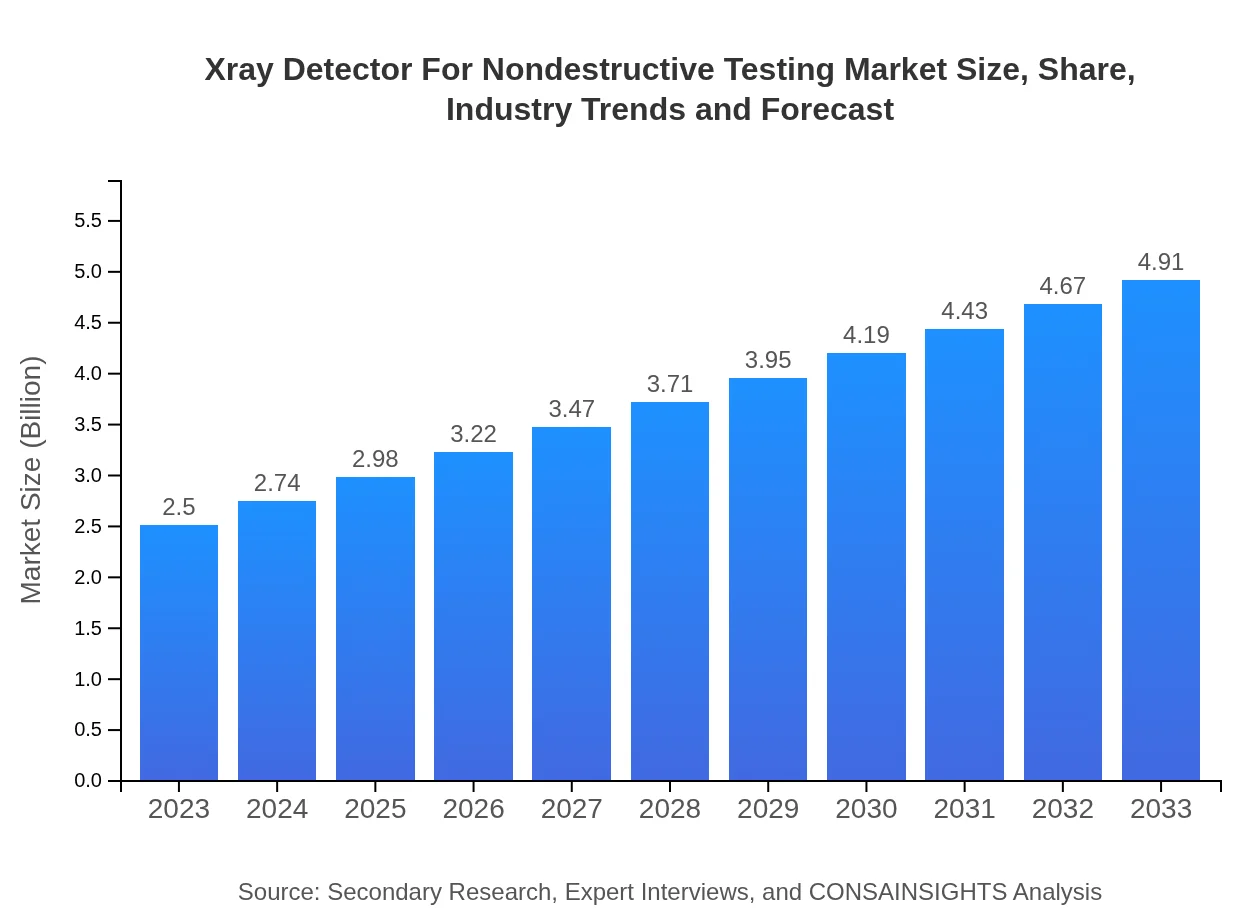

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | GE Inspection Technologies, Olympus Corporation, Mistras Group, Inc., Nikon Metrology |

| Last Modified Date | 31 January 2026 |

Xray Detector For Nondestructive Testing Market Overview

Customize Xray Detector For Nondestructive Testing Market Report market research report

- ✔ Get in-depth analysis of Xray Detector For Nondestructive Testing market size, growth, and forecasts.

- ✔ Understand Xray Detector For Nondestructive Testing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Xray Detector For Nondestructive Testing

What is the Market Size & CAGR of Xray Detector For Nondestructive Testing market in 2023?

Xray Detector For Nondestructive Testing Industry Analysis

Xray Detector For Nondestructive Testing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Xray Detector For Nondestructive Testing Market Analysis Report by Region

Europe Xray Detector For Nondestructive Testing Market Report:

Europe's market size is anticipated to increase from $0.76 billion in 2023 to $1.49 billion in 2033, fueled by investments in new technologies and a strong focus on safety standards across industries.Asia Pacific Xray Detector For Nondestructive Testing Market Report:

In the Asia-Pacific region, the market is expected to grow from $0.47 billion in 2023 to $0.92 billion by 2033. Key drivers include industrial expansion, infrastructure development, and increasing investments in quality control measures.North America Xray Detector For Nondestructive Testing Market Report:

North America holds a substantial share of the market, with a projected growth from $0.95 billion in 2023 to $1.87 billion by 2033. The presence of major industrial sectors and stringent regulatory frameworks are driving the adoption of advanced X-ray inspection technologies.South America Xray Detector For Nondestructive Testing Market Report:

For South America, the market size is projected to rise from $0.17 billion in 2023 to $0.33 billion by 2033. Economic growth in the region is boosting demand for nondestructive testing technologies in various industries.Middle East & Africa Xray Detector For Nondestructive Testing Market Report:

The Middle East and Africa market is expected to grow from $0.15 billion in 2023 to $0.30 billion in 2033, driven by advancements in the oil and gas sector and an increasing focus on industrial safety measures.Tell us your focus area and get a customized research report.

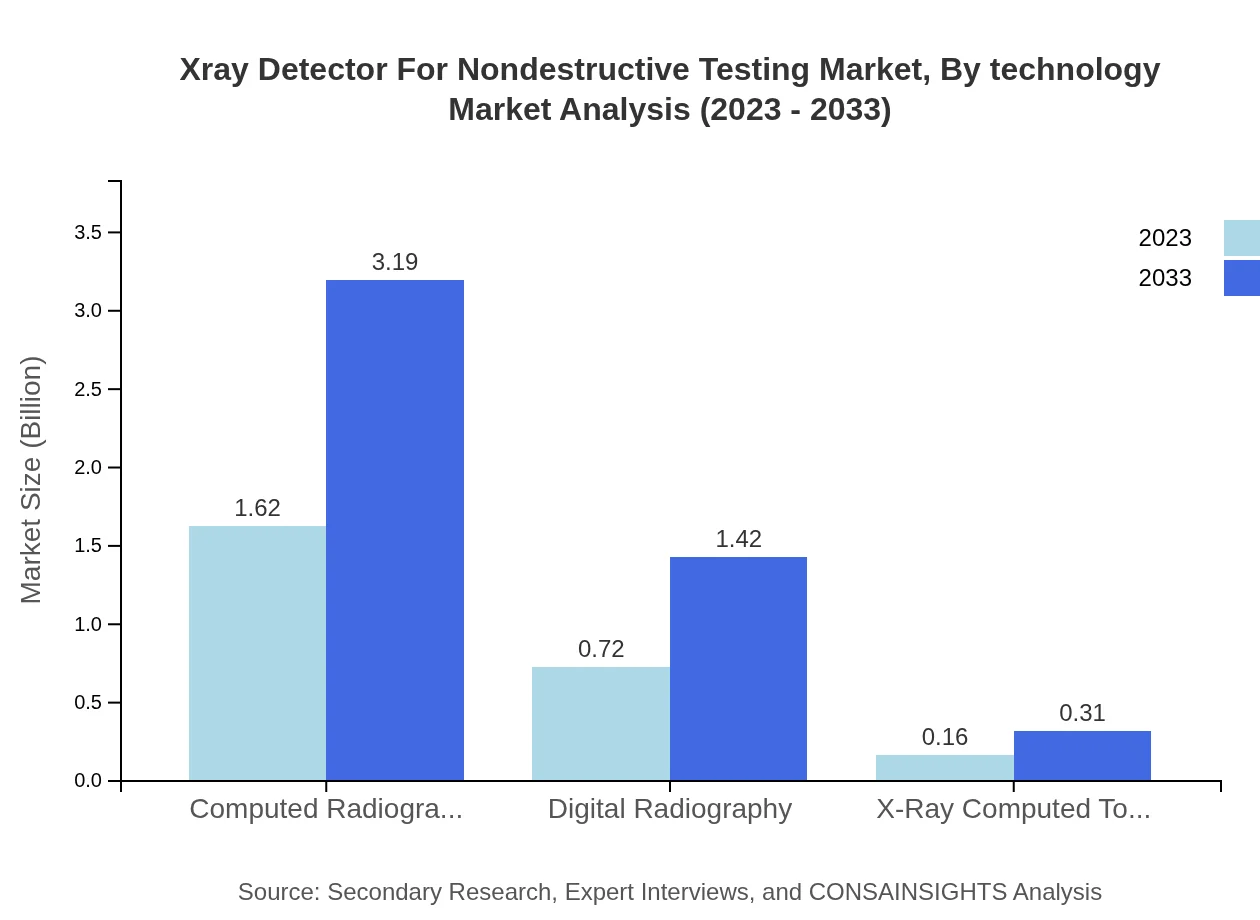

Xray Detector For Nondestructive Testing Market Analysis By Technology

Among the various technologies, Computed Radiography dominates with a market size of $1.62 billion in 2023, expected to reach $3.19 billion by 2033, holding a 64.95% share. Digital Radiography and X-Ray Computed Tomography also contribute significantly, with market sizes of $0.72 billion and $0.16 billion in 2023, respectively.

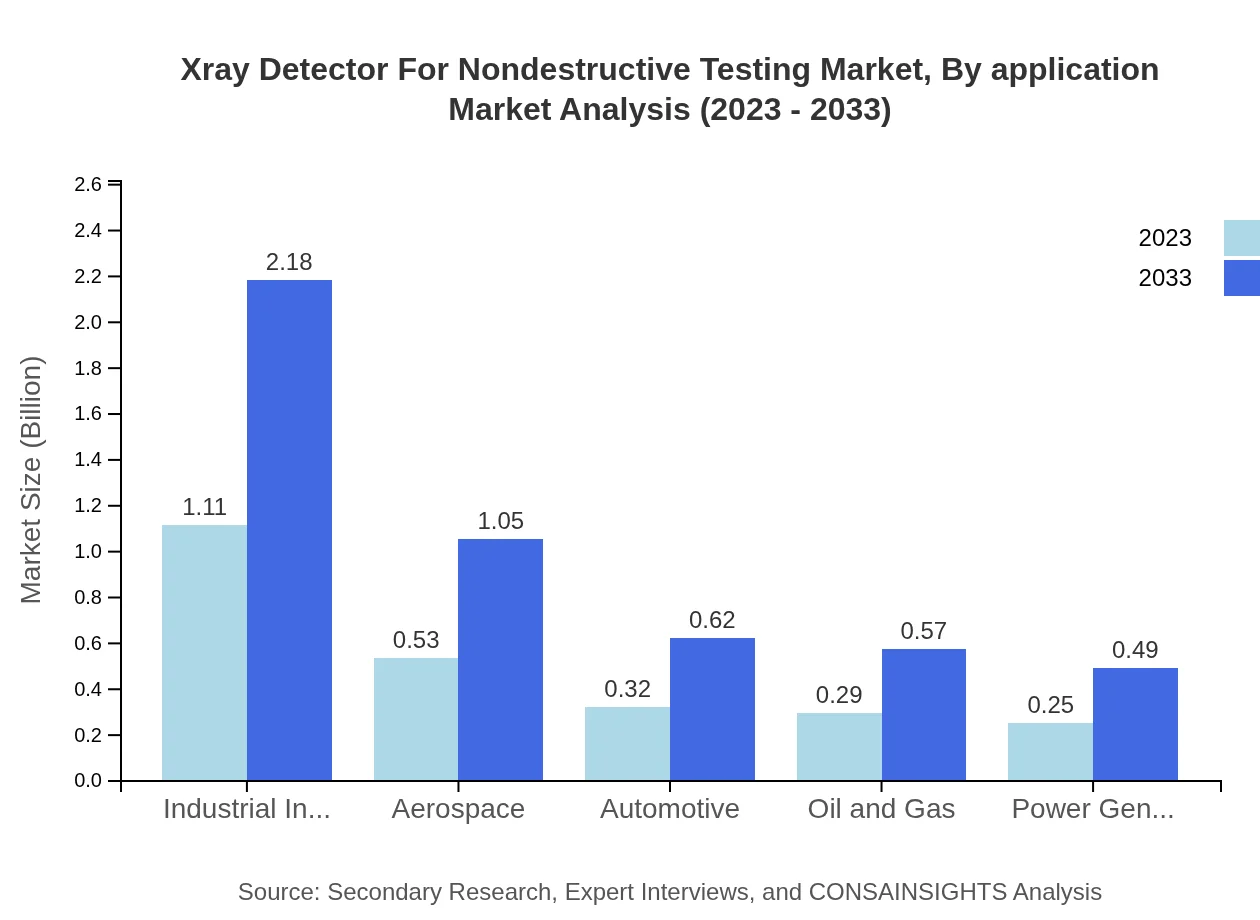

Xray Detector For Nondestructive Testing Market Analysis By Application

Industrial Inspection is the leading application, accounting for $1.11 billion in 2023 and projected to grow to $2.18 billion by 2033, with a significant share of 44.41%. Other applications such as aerospace and automotive testing are also seeing increased adoption.

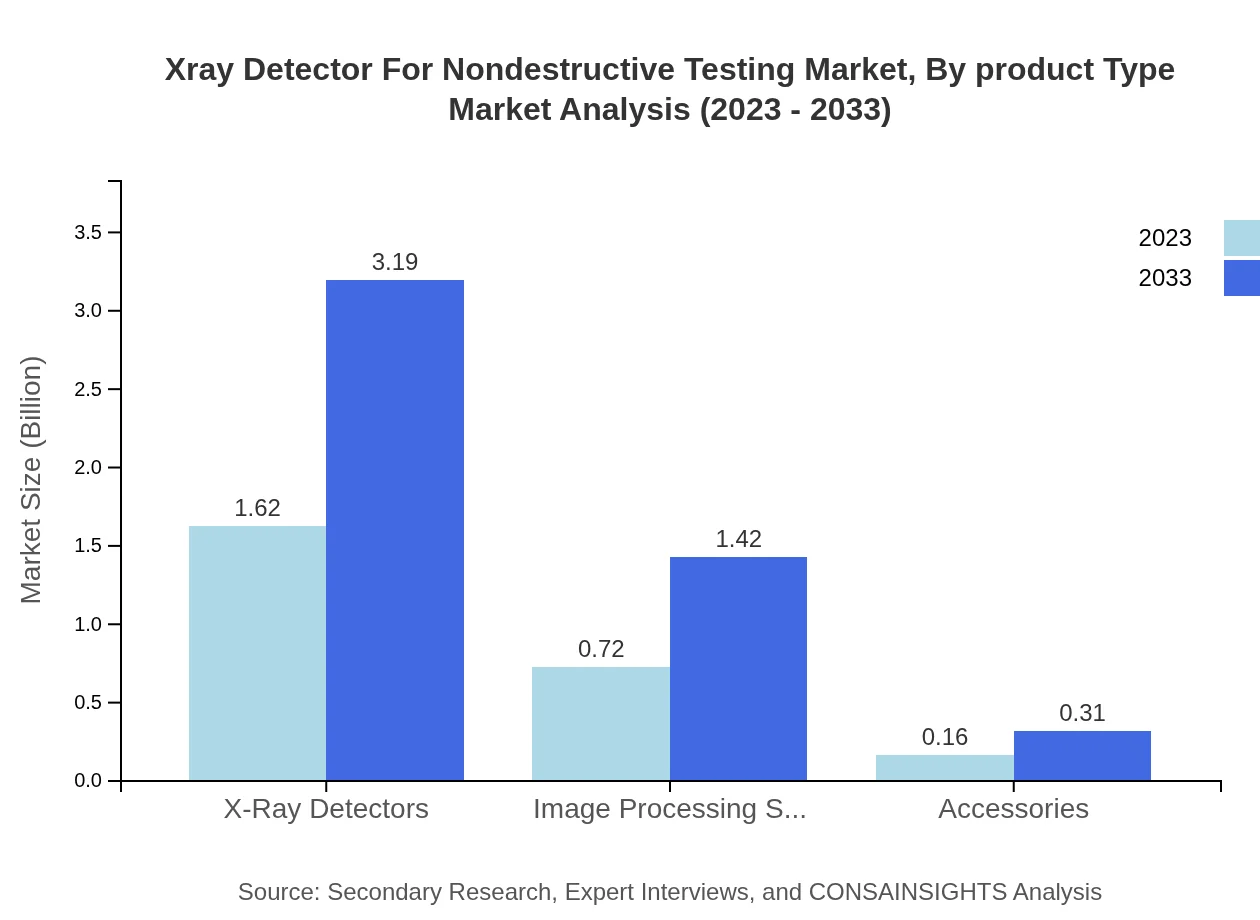

Xray Detector For Nondestructive Testing Market Analysis By Product Type

X-Ray Detectors represent the largest product type segment, with sales of $1.62 billion in 2023, increasing to $3.19 billion by 2033. Accessories and Image Processing Software are also vital, contributing to overall market dynamics.

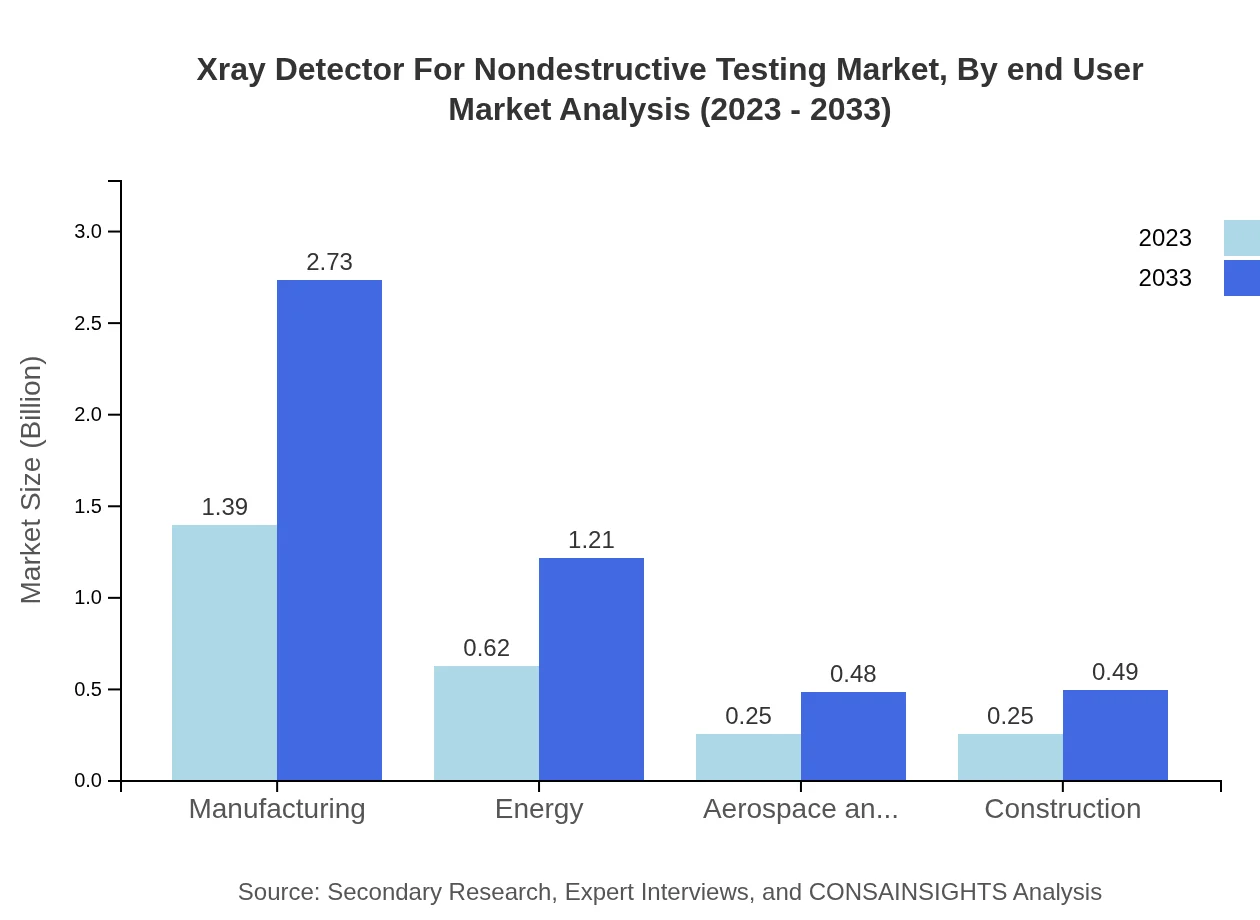

Xray Detector For Nondestructive Testing Market Analysis By End User

Manufacturing leads the market with a valuation of $1.39 billion in 2023, expected to grow to $2.73 billion. The energy sector follows closely, indicating a high demand for reliable testing solutions.

Xray Detector For Nondestructive Testing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Xray Detector For Nondestructive Testing Industry

GE Inspection Technologies:

Part of General Electric, this company provides advanced NDT solutions and is a leader in the development of X-ray inspection technologies.Olympus Corporation:

Specializes in precision technology and provides a range of X-ray detectors for industrial applications, focusing on high-quality imaging systems.Mistras Group, Inc.:

Provides asset protection solutions and innovative technology in nondestructive testing, including X-ray imaging.Nikon Metrology:

Offers advanced imaging technology for NDT applications, known for high-resolution inspection systems.We're grateful to work with incredible clients.

FAQs

What is the market size of x Ray detector for nondestructive testing?

The global x-ray detector market for nondestructive testing is valued at approximately $2.5 billion in 2023, with a projected CAGR of 6.8% through 2033. This growth reflects increased demand across various industrial sectors.

What are the key market players or companies in the x Ray detector for nondestructive testing industry?

The key players in the x-ray detector market include major manufacturers and technology companies specializing in nondestructive testing solutions. These can include firms that develop imaging technology and those focused on materials inspection.

What are the primary factors driving the growth in the x Ray detector for nondestructive testing industry?

Growth in the x-ray detector market is propelled by factors like increasing demand for safety regulations, advances in technology, and the rising need for efficient, non-invasive inspection methods across industries such as aerospace and manufacturing.

Which region is the fastest Growing in the x Ray detector for nondestructive testing?

The fastest-growing region in the x-ray detector market is projected to be North America, with market size expected to grow from $0.95 billion in 2023 to $1.87 billion by 2033. This growth is supported by technological advancements and regulatory standards.

Does ConsaInsights provide customized market report data for the x Ray detector for nondestructive testing industry?

Yes, ConsaInsights offers customized market report data for the x-ray detector industry, allowing clients to tailor research findings to specific needs, regions, or market segments, ensuring relevant insights for strategic decision-making.

What deliverables can I expect from this x Ray detector for nondestructive testing market research project?

Expect to receive comprehensive reports detailing market size, forecasts, competitive analysis, trends, and segment data. Deliverables may include visual data representations and insights into regulatory impacts and technological advancements.

What are the market trends of x Ray detector for nondestructive testing?

Key trends in the x-ray detector market involve a shift towards digital radiography, integration of advanced image processing software, and increasing adoption of x-ray systems in various sectors, reflecting ongoing technological evolution.

What segment is dominating the x Ray detector for nondestructive testing market?

The manufacturing sector dominates the x-ray detector market, holding a substantial share of 55.58% in 2023, with expected growth from $1.39 billion to $2.73 billion by 2033, highlighting the sector's reliance on advanced inspection techniques.