Hazardous Area Equipment Market Report

Published Date: 22 January 2026 | Report Code: hazardous-area-equipment

Hazardous Area Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Hazardous Area Equipment market from 2023 to 2033, covering market size, CAGR, industry insights, regional analysis, segmentation, and leading players. It offers critical insights into trends shaping the future of this industry.

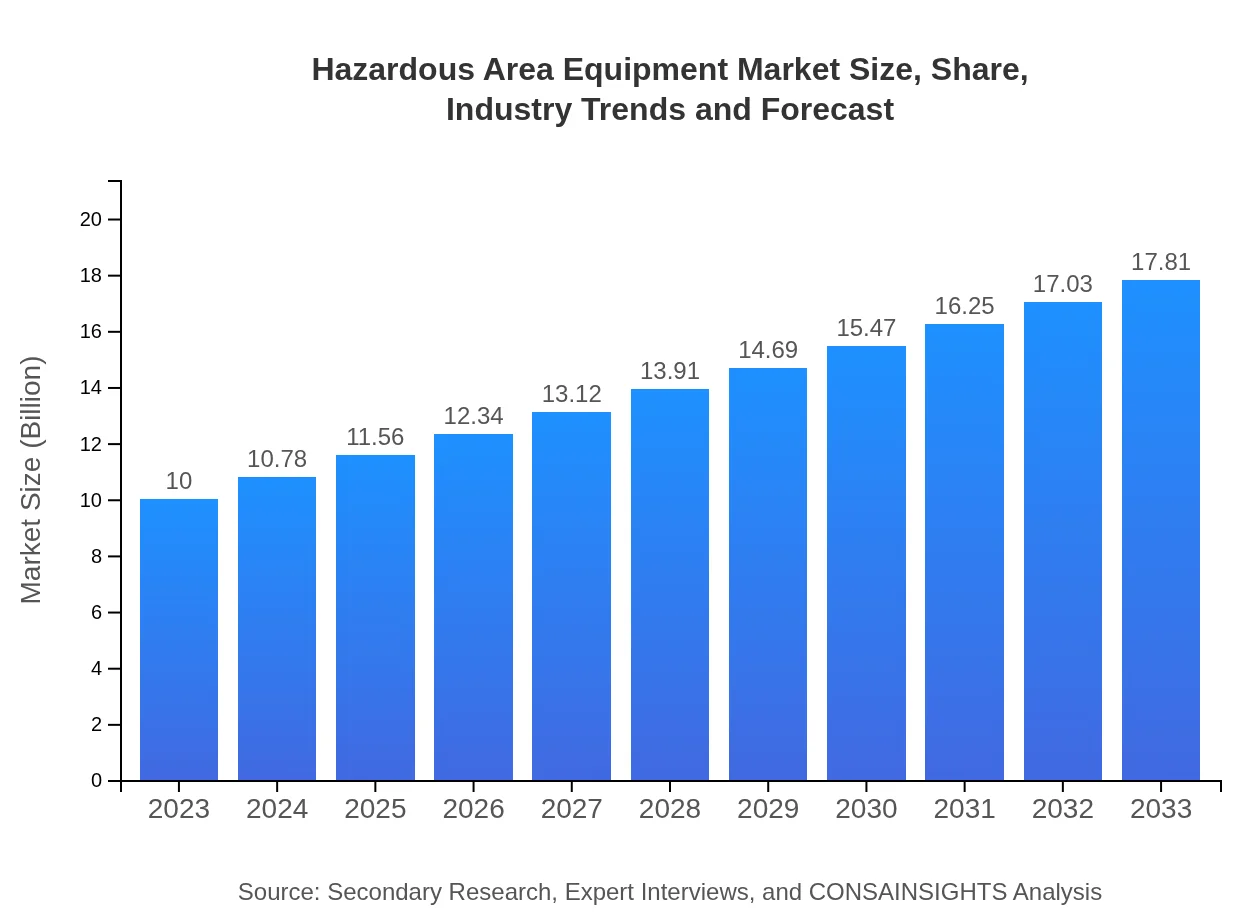

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $17.81 Billion |

| Top Companies | Siemens AG, Honeywell International Inc., Schneider Electric, Eaton Corporation PLC |

| Last Modified Date | 22 January 2026 |

Hazardous Area Equipment Market Overview

Customize Hazardous Area Equipment Market Report market research report

- ✔ Get in-depth analysis of Hazardous Area Equipment market size, growth, and forecasts.

- ✔ Understand Hazardous Area Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hazardous Area Equipment

What is the Market Size & CAGR of Hazardous Area Equipment market in 2033?

Hazardous Area Equipment Industry Analysis

Hazardous Area Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hazardous Area Equipment Market Analysis Report by Region

Europe Hazardous Area Equipment Market Report:

The European market is projected to grow from $2.68 billion in 2023 to $4.78 billion by 2033. Stringent safety regulations and a strong focus on environmental sustainability augment the demand for innovative safety solutions. Countries with mature industrial sectors are leading this growth.Asia Pacific Hazardous Area Equipment Market Report:

In 2023, the Asia Pacific market is valued at $2.15 billion, expected to grow to $3.83 billion by 2033. Rapid industrialization and infrastructural development in countries like China and India drive the demand. Additionally, increasing investments in transforming industrial facilities into factories compliant with strict safety standards fuel market growth.North America Hazardous Area Equipment Market Report:

North America, valued at $3.66 billion in 2023, is forecasted to reach $6.52 billion by 2033. The region is characterized by stringent regulations and high safety standards, particularly in the oil and gas and chemical sectors. The demand is driven by technology advancements and the integration of automation in hazardous environments.South America Hazardous Area Equipment Market Report:

The South American market is relatively smaller, with a value of $0.17 billion in 2023, projected to increase to $0.30 billion by 2033. The market is primarily influenced by the oil and gas industry and the growing emphasis on safety regulations. However, economic fluctuations present challenges to substantial growth.Middle East & Africa Hazardous Area Equipment Market Report:

The Middle East and Africa market is estimated at $1.34 billion in 2023, with expectations of reaching $2.38 billion by 2033. This growth is driven by the oil and gas sector's expansion and elevated safety standards amid increasing industrial activities in the region.Tell us your focus area and get a customized research report.

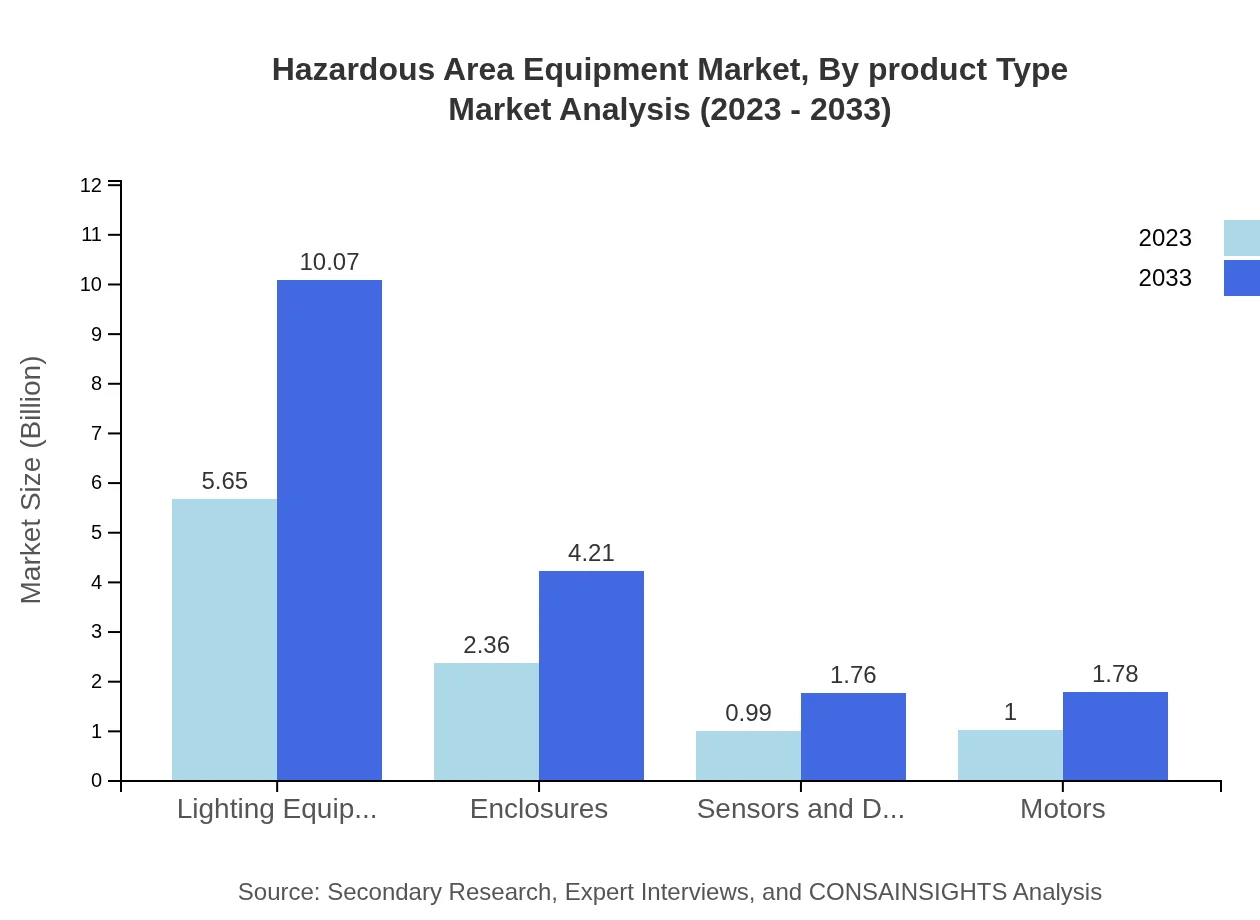

Hazardous Area Equipment Market Analysis By Product Type

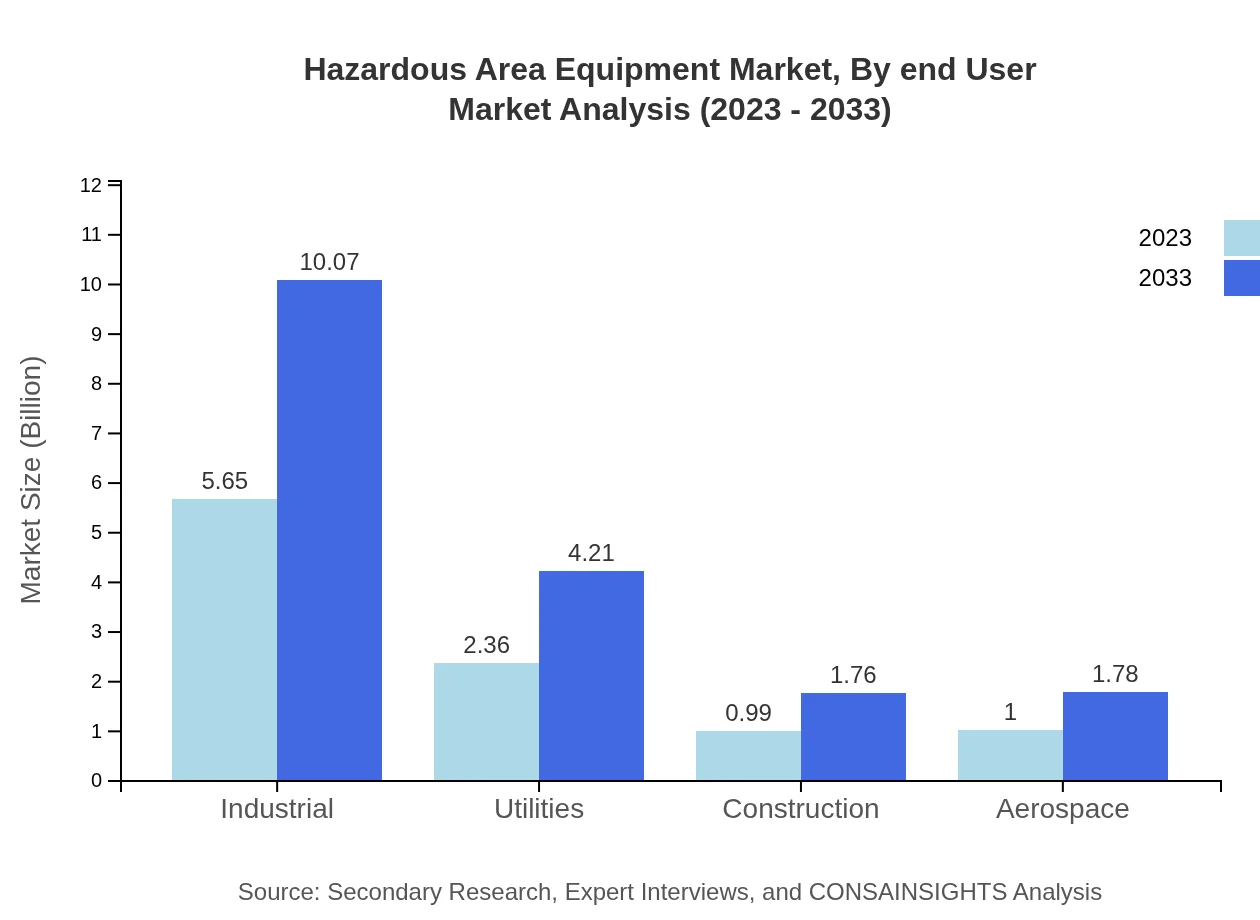

The Hazardous Area Equipment market by product type is dominated by lighting equipment, enclosures, and sensors and detectors. The lighting equipment market is valued at $5.65 billion in 2023, expected to grow to $10.07 billion by 2033, forming a substantial share of the market. Enclosures account for $2.36 billion in 2023, forecasted to increase to $4.21 billion. Additionally, sensors and detectors contribute significantly, ensuring monitoring and safety in hazardous environments.

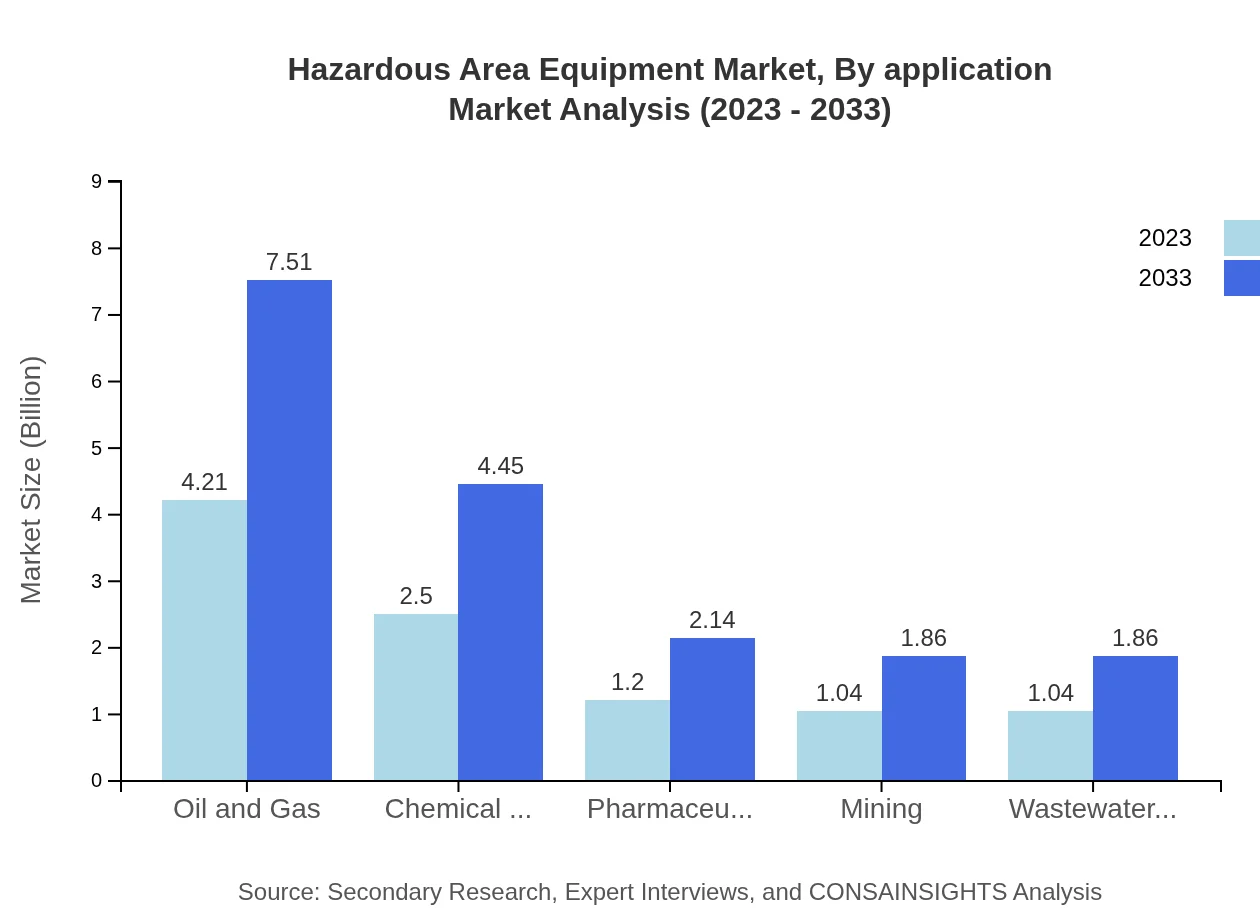

Hazardous Area Equipment Market Analysis By Application

Applications are pivotal in the Hazardous Area Equipment market, with the oil and gas sector being a major contributor, holding a 42.15% share in 2023. Other critical applications include chemical manufacturing (24.99%), pharmaceuticals (12.01%), and mining (10.43%). The increasing focus on safety across these sectors amplifies demand for hazardous area solutions.

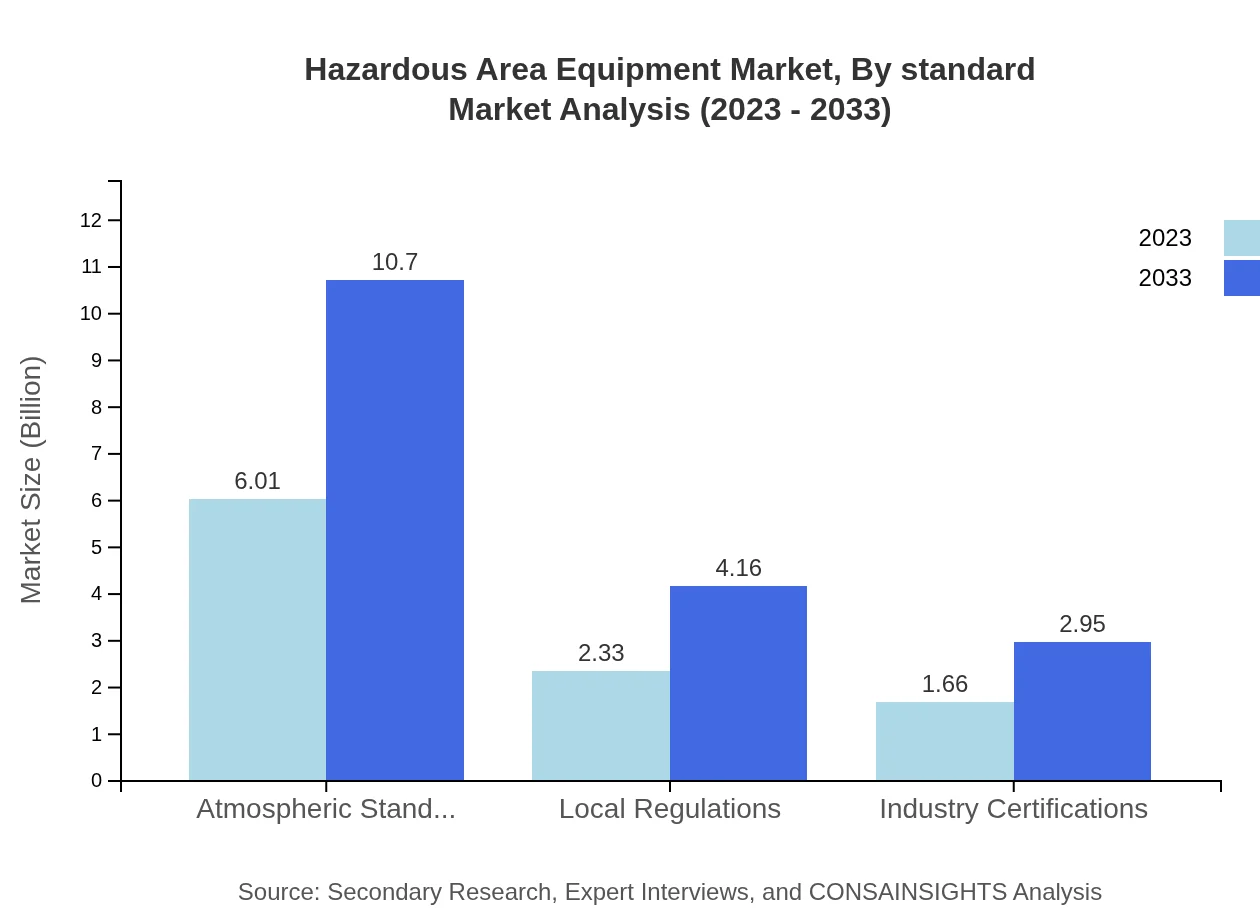

Hazardous Area Equipment Market Analysis By Standard

Standards such as Atmospheric Standards and Local Regulations significantly influence the Hazardous Area Equipment market. The Atmospheric Standards sector accounts for a size of $6.01 billion in 2023, expected to grow to $10.70 billion. Local regulations also play a crucial role, with a market size growing from $2.33 billion to $4.16 billion over the forecast period.

Hazardous Area Equipment Market Analysis By End User

The end-user analysis reveals a strong concentration of hazardous area equipment usage in the oil and gas sector, reflecting a deep-rooted demand for reliable safety solutions. Other end-users include utilities and construction, showcasing the market's diversity across various industries needing adherence to safety standards.

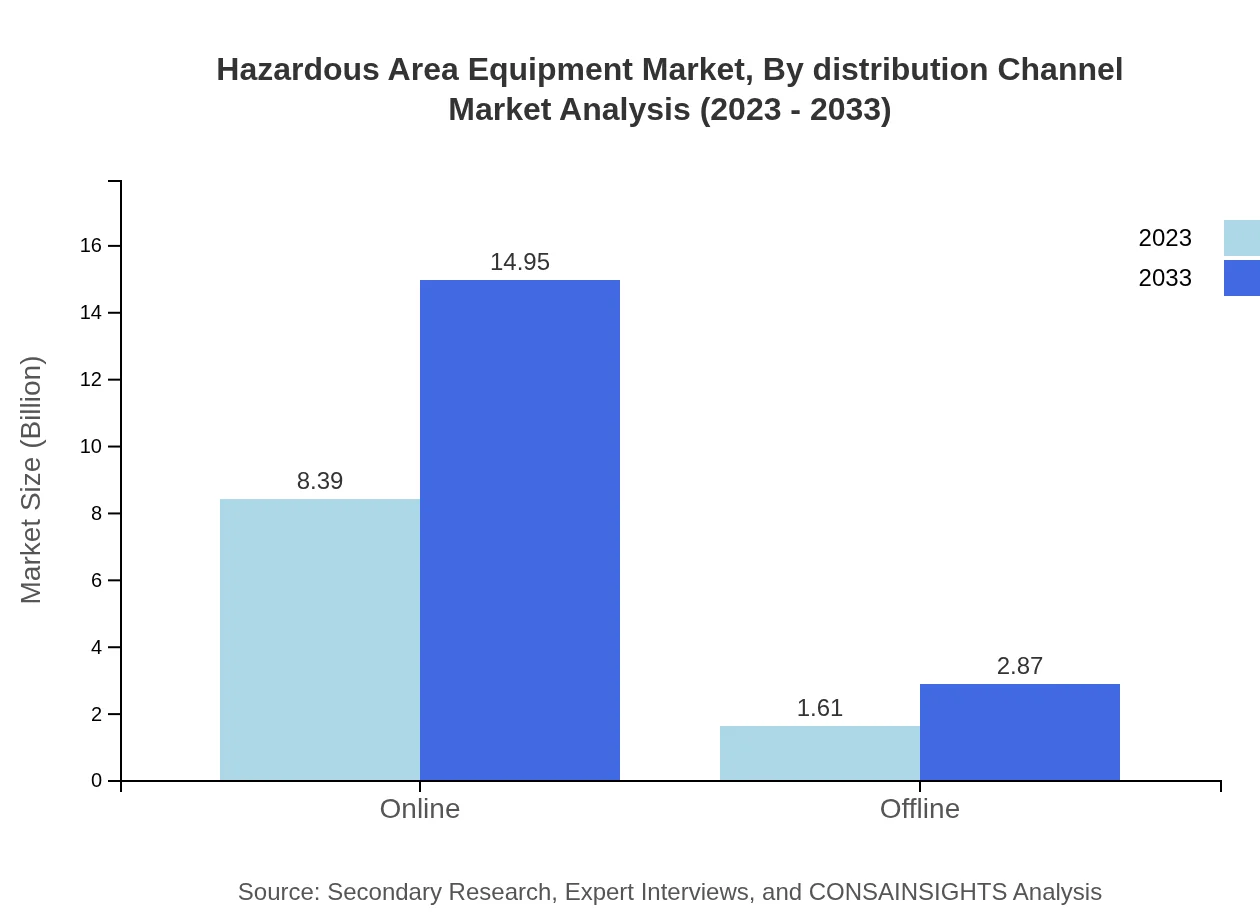

Hazardous Area Equipment Market Analysis By Distribution Channel

The distribution of hazardous area equipment is streamlined through online and offline channels. The online segment accounts for 83.91% of market share in 2023, with significant potential for growth as manufacturers adopt advanced digital strategies. Offline channels, while smaller, held a notable share of 16.09%, serving traditional retail and direct sales strategies.

Hazardous Area Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hazardous Area Equipment Industry

Siemens AG:

A global leader in automation and digitalization, Siemens offers a comprehensive range of hazardous area equipment that aligns with safety standards while enhancing operational efficiency.Honeywell International Inc.:

Honeywell provides a diverse portfolio of products and services that cater to hazardous area applications, emphasizing safety, reliability, and compliance with global standards.Schneider Electric:

Specializing in energy management and automation, Schneider Electric delivers innovative solutions for hazardous environments, focusing on energy efficiency and sustainability.Eaton Corporation PLC:

Eaton is recognized for its high-performance products designed for hazardous location applications, providing automation and controls to enhance safety and operational reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of hazardous Area Equipment?

The hazardous area equipment market is currently valued at approximately $10 billion, with a projected compound annual growth rate (CAGR) of 5.8% from 2023 to 2033. This growth indicates a steadily increasing demand for safety Equipment in hazardous environments.

What are the key market players or companies in this hazardous Area Equipment industry?

Key players in the hazardous area equipment industry include major manufacturing firms that specialize in safety and compliance products, as they play crucial roles in meeting strict industry regulations and providing innovative solutions to reduce risks in dangerous environments.

What are the primary factors driving the growth in the hazardous Area Equipment industry?

Factors driving growth include increasing regulatory requirements for workplace safety, technological advancements, and rising investments in industries such as oil and gas, which demand reliable equipment to ensure worker safety in hazardous locations.

Which region is the fastest Growing in the hazardous Area Equipment?

The North American region is the fastest-growing market for hazardous area equipment, expected to grow from $3.66 billion in 2023 to $6.52 billion by 2033, driven by robust industrial activity and stringent safety regulations.

Does ConsaInsights provide customized market report data for the hazardous Area Equipment industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the hazardous area equipment industry, providing insights that align with individual market conditions, business objectives, and strategic planning requirements.

What deliverables can I expect from this hazardous Area Equipment market research project?

From the hazardous area equipment market research project, you can expect comprehensive reports featuring in-depth market analysis, key trends, competitor insights, and detailed segment breakdowns to inform strategic decision-making.

What are the market trends of hazardous Area Equipment?

Market trends in hazardous area equipment include increased automation, advancements in safety technology, a shift towards more environmentally friendly equipment, and growing adoption in industries such as construction, mining, and chemical manufacturing.