Technical Insulation Market Report

Published Date: 22 January 2026 | Report Code: technical-insulation

Technical Insulation Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report provides insights into the Technical Insulation market, covering market dynamics, trends, and forecasts for the period 2023 to 2033. It highlights key segments, regional analyses, and industry leaders, offering a strategic view of market opportunities.

| Metric | Value |

|---|---|

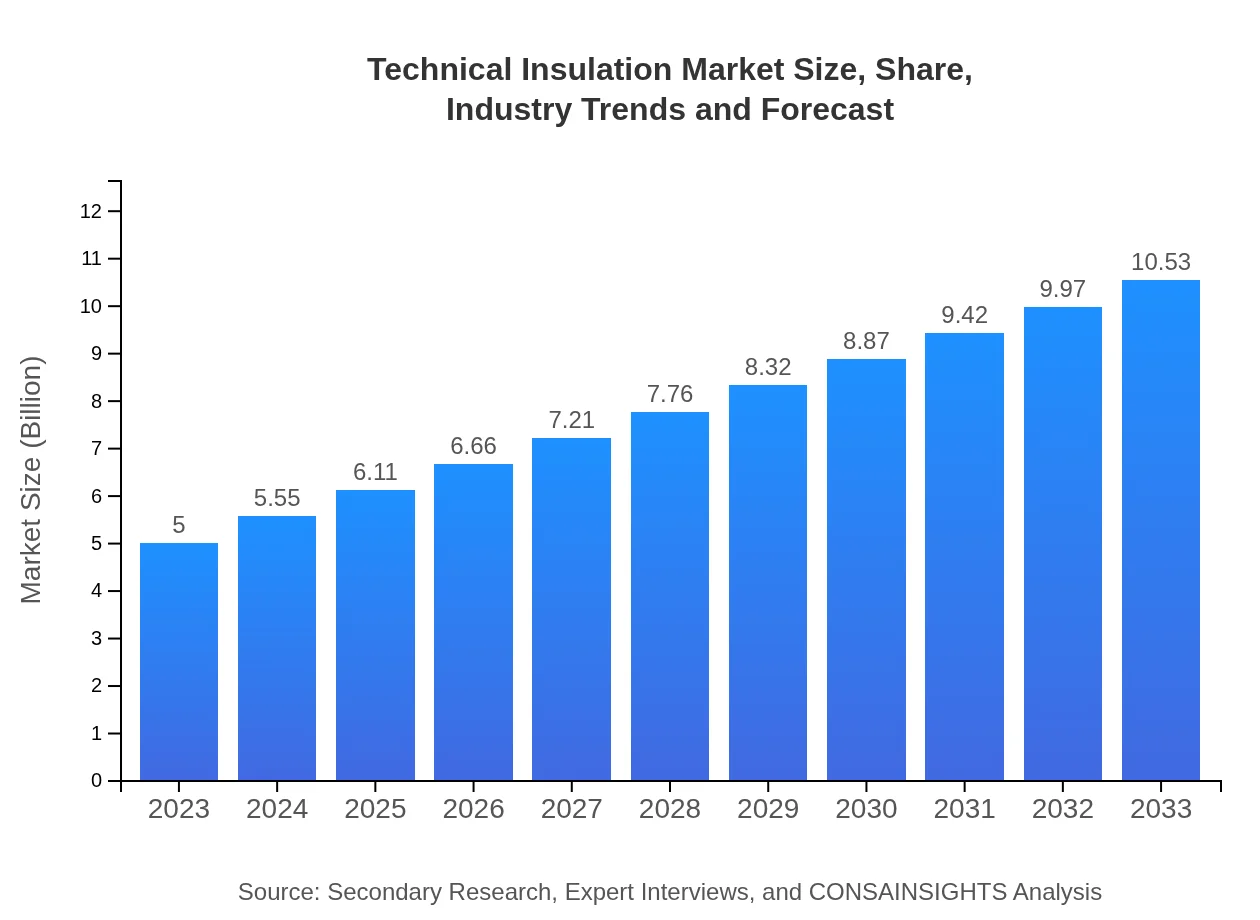

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Saint-Gobain, Owens Corning, Rockwool International, Knauf Insulation |

| Last Modified Date | 22 January 2026 |

Technical Insulation Market Overview

Customize Technical Insulation Market Report market research report

- ✔ Get in-depth analysis of Technical Insulation market size, growth, and forecasts.

- ✔ Understand Technical Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Technical Insulation

What is the Market Size & CAGR of Technical Insulation market in 2023?

Technical Insulation Industry Analysis

Technical Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Technical Insulation Market Analysis Report by Region

Europe Technical Insulation Market Report:

Europe's Technical Insulation market is anticipated to grow vigorously, increasing from $1.87 billion in 2023 to $3.94 billion by 2033. The European Union's strong commitment to reducing carbon emissions and promoting sustainable energy solutions enhances the demand for advanced insulation products.Asia Pacific Technical Insulation Market Report:

The Asia-Pacific region represents a significant market for Technical Insulation, with a projected growth from $0.83 billion in 2023 to $1.74 billion by 2033. This growth is driven by rapid industrialization, urbanization, and increased infrastructural development across countries such as China and India, where energy efficiency is a growing priority.North America Technical Insulation Market Report:

North America is one of the largest markets for Technical Insulation, projected to grow from $1.61 billion in 2023 to $3.39 billion by 2033. This growth is propelled by stringent building codes and an increasing focus on energy-efficient buildings, particularly in the United States and Canada.South America Technical Insulation Market Report:

In South America, the Technical Insulation market is expected to increase from $0.24 billion in 2023 to approximately $0.51 billion by 2033. Key growth factors include the expansion of the construction and automotive industries, coupled with heightened awareness regarding thermal efficiency.Middle East & Africa Technical Insulation Market Report:

The Middle East and Africa market is expected to expand from $0.45 billion in 2023 to $0.95 billion by 2033. Factors driving this growth include ongoing construction projects, growth in power generation, and an increasing emphasis on energy conservation within industrial sectors.Tell us your focus area and get a customized research report.

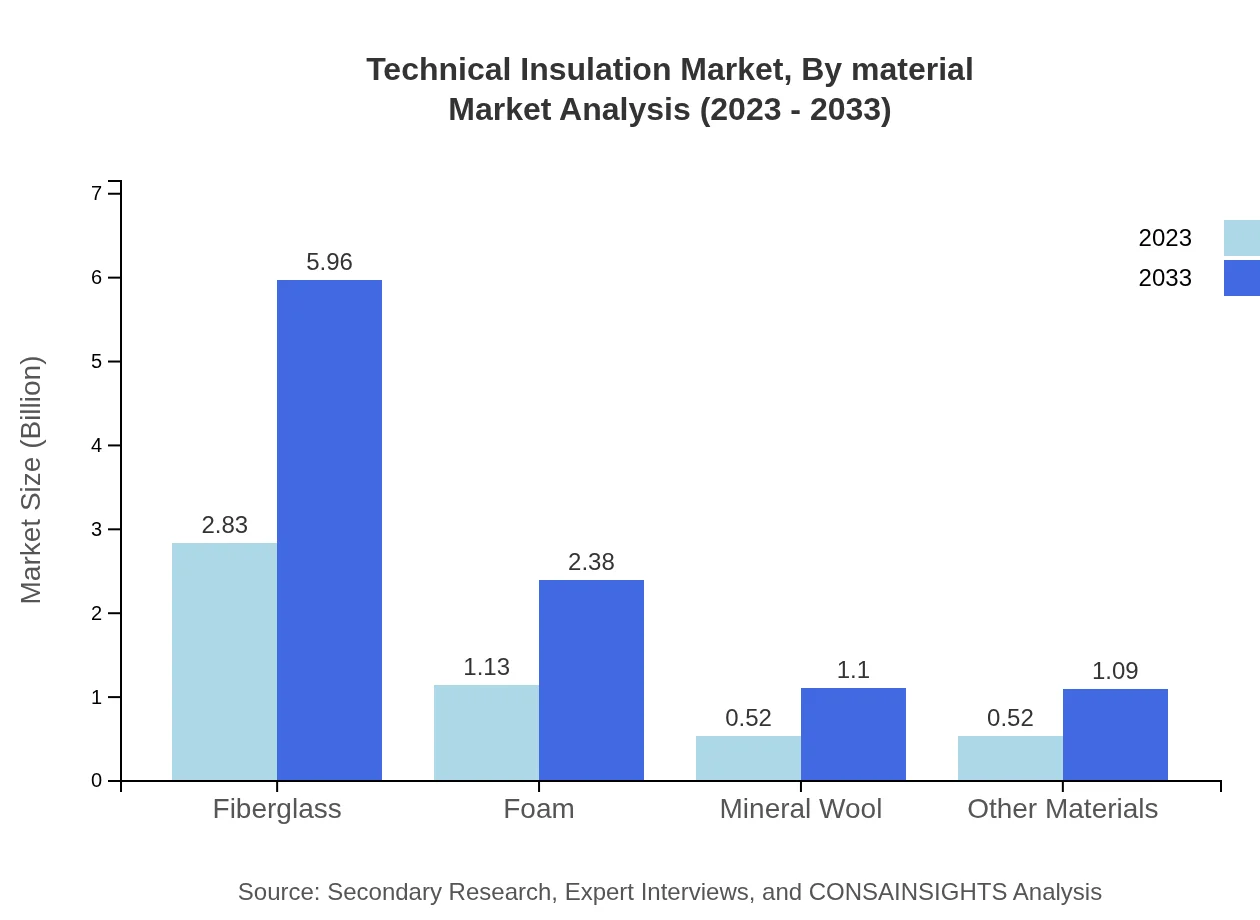

Technical Insulation Market Analysis By Material

The Technical Insulation market is primarily dominated by fiberglass, which accounts for a significant share of the market. In 2023, fiberglass is valued at $2.83 billion and is forecasted to reach $5.96 billion by 2033. Foam has a notable share, currently at $1.13 billion and projected at $2.38 billion by 2033, indicating its importance in thermal insulation applications. Mineral wool and other materials also present significant opportunities, growing in response to specific industrial requirements.

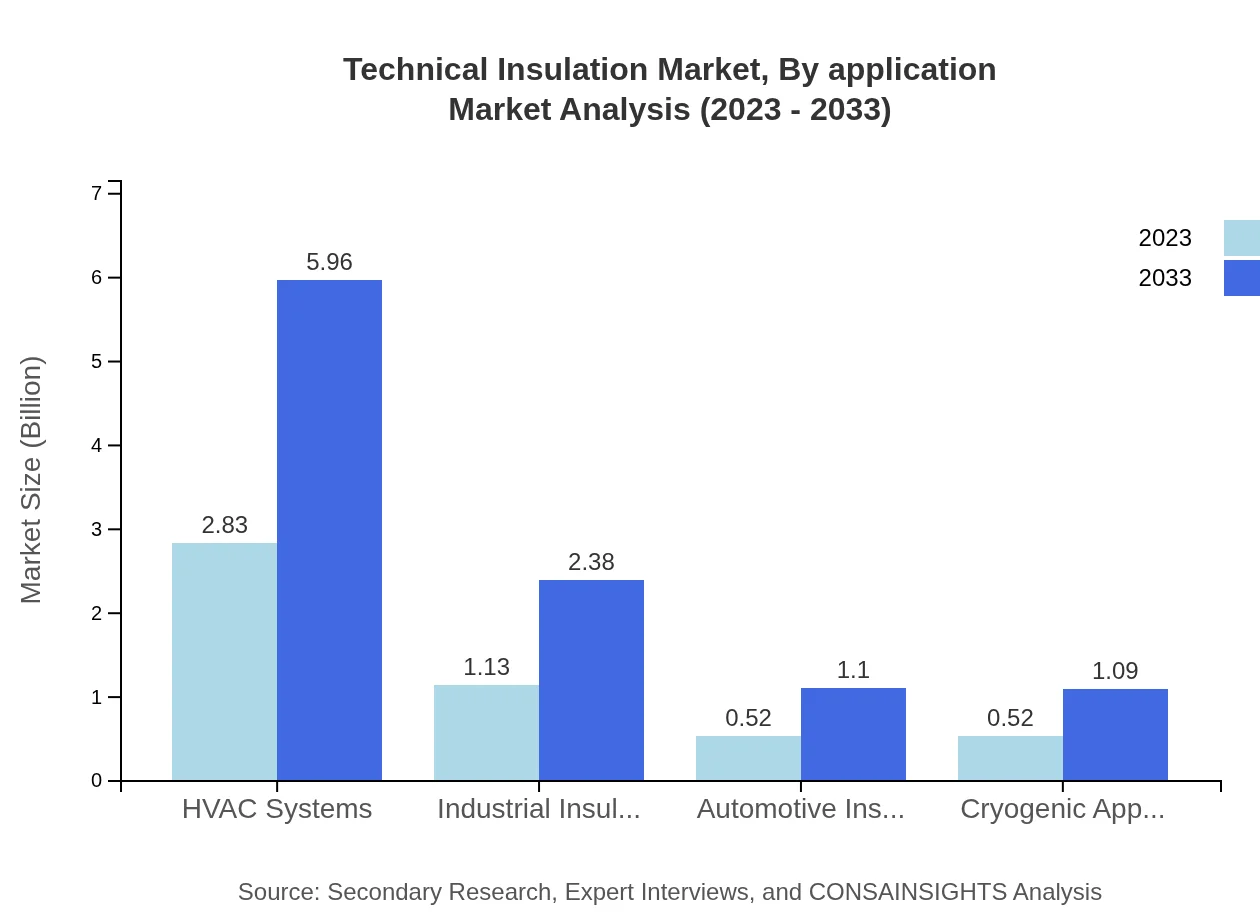

Technical Insulation Market Analysis By Application

Applications of Technical Insulation include construction, oil and gas, power generation, and HVAC systems. The construction segment leads the market, valued at $2.83 billion in 2023 and expected to reach $5.96 billion by 2033. The oil and gas industry's demand reflects an increase from $1.13 billion to $2.38 billion over the forecast period, underlining the sector's reliance on robust insulation solutions for operational efficiency.

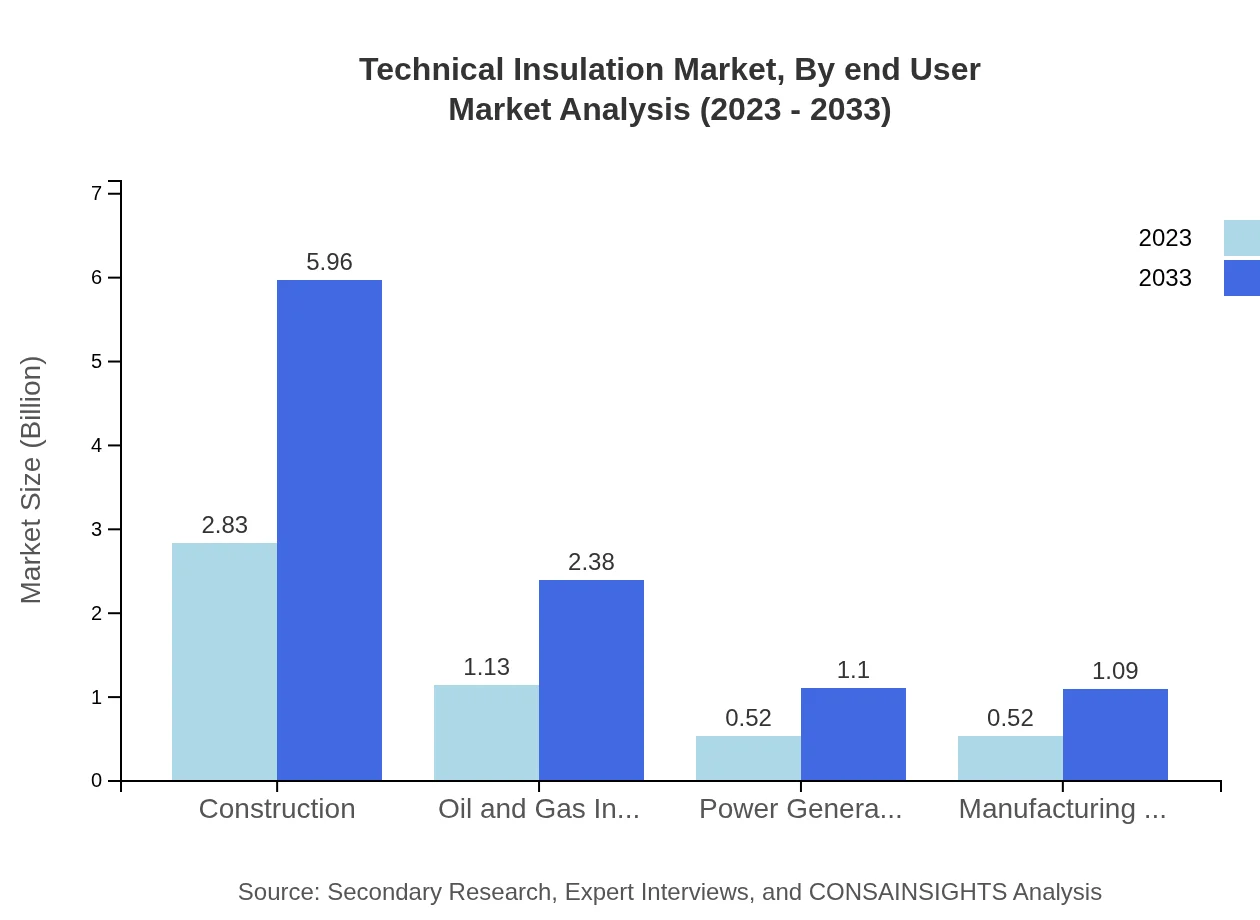

Technical Insulation Market Analysis By End User

Various end-user industries including construction, automotive, and manufacturing leverage Technical Insulation. The construction sector accounts for a significant market share, emphasizing thermal efficiency in buildings. Automotive insulation is also gaining traction, projected to grow from $0.52 billion in 2023 to $1.10 billion by 2033 as mandates for reducing vehicle emissions rise.

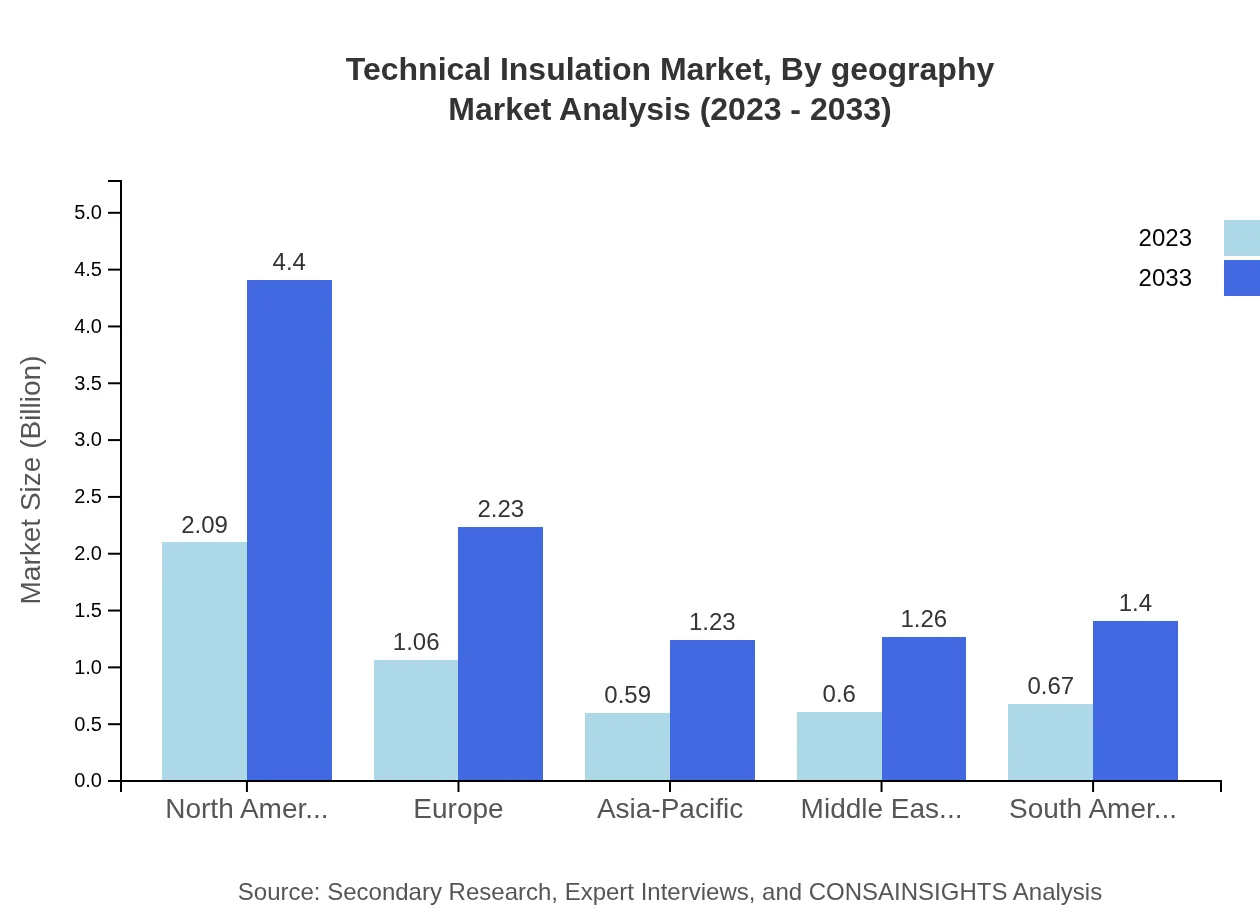

Technical Insulation Market Analysis By Geography

Geographically, North America leads the Technical Insulation market, comprising over 40% of the market share in 2023. Europe follows with substantial investments in sustainable infrastructure. The growth in Asia-Pacific is bolstered by industrialization, whereas regions like South America and the Middle East are emerging markets with growth potential influenced by increasing infrastructure investments.

Technical Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Technical Insulation Industry

Saint-Gobain:

A leading construction and insulation materials manufacturer known for its innovative solutions in thermal insulation, contributing significantly to energy-saving initiatives worldwide.Owens Corning:

A major player in the fiberglass insulation market, providing high-performance building materials and advanced thermal insulation solutions across various industries.Rockwool International:

Specializing in mineral wool insulation, Rockwool is recognized for its sustainable insulation products catering to energy efficiency in construction and industry.Knauf Insulation:

A global leader in insulation solutions, offering a wide range of products for building and industrial applications, known for innovation and sustainability.We're grateful to work with incredible clients.

FAQs

What is the market size of technical Insulation?

The global technical insulation market is valued at approximately $5 billion in 2023 and is projected to grow to $11 billion by 2033, with a compound annual growth rate (CAGR) of 7.5%. This growth is fueled by increasing demand across various sectors.

What are the key market players or companies in this technical Insulation industry?

Key players in the technical insulation market include major companies like Owens Corning, Rockwool International, and Johns Manville. These firms are recognized for their innovative insulating materials and solutions designed for construction, oil and gas, and power generation sectors.

What are the primary factors driving the growth in the technical Insulation industry?

The growth in the technical insulation industry is primarily driven by rising construction activities, growing energy efficiency mandates, and increased awareness of thermal insulation benefits. Technologies in HVAC systems and stringent building regulations further enhance demand for quality insulation materials.

Which region is the fastest Growing in the technical Insulation?

The Asia-Pacific region is identified as the fastest-growing market for technical insulation, growing from $0.83 billion in 2023 to $1.74 billion by 2033. This growth is attributed to rapid industrialization and infrastructure development in countries like China and India.

Does ConsaInsights provide customized market report data for the technical Insulation industry?

Yes, ConsaInsights offers customized market report data tailored to the technical insulation industry. Clients can request specific insights and analyses based on unique business needs, ensuring they receive relevant and actionable market intelligence.

What deliverables can I expect from this technical Insulation market research project?

From the technical-insulation market research project, clients can expect comprehensive reports featuring market size data, CAGR analysis, regional breakdowns, segmentation insights, and competitive landscape assessments to guide strategic business decisions.

What are the market trends of technical Insulation?

Current trends in the technical insulation market include a shift towards sustainable materials, increasing application in renewable energy sectors, and the adoption of advanced insulation technologies. The ongoing push for energy-efficient designs continues to influence market dynamics.